Sliding-raising mechanism of ditcher

A ditching machine, sliding warping technology, applied in the direction of excavation/covering ditches, application, planting methods, etc., can solve the problems of flameout, diesel engine speed reduction, insufficient tightening force, etc., and achieve low soil firmness and soil moisture The effect of large and small cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

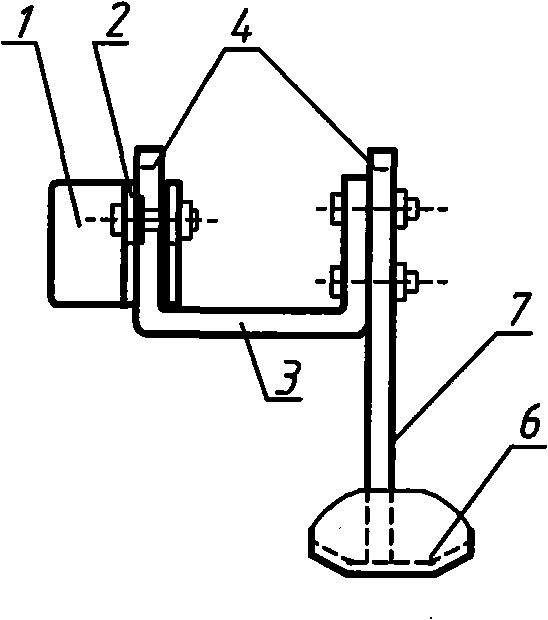

[0017] Embodiment 1. The sliding and warping mechanism of the ditching machine includes a closed casing arranged on the front end of the ditching machine frame arm 1 and a sliding and warping 6. One side of the closed casing is provided with a bolt hole and a sliding and warping post 7 is provided with a plurality of bolt holes. In addition, a U-shaped joint block 3 is provided, and the two vertical columns of the U-shaped joint block are provided with bolt holes; when a new ditch is opened in ordinary flat fields, the bolts are used to directly fix the sliding warped column on the closed casing , When it is necessary to repeat ditching to the old ditch, the U-shaped joint block is first fixed on the closed casing with bolts, and then the sliding upright column is bolted on another vertical column of the U-shaped joint block.

Embodiment 2

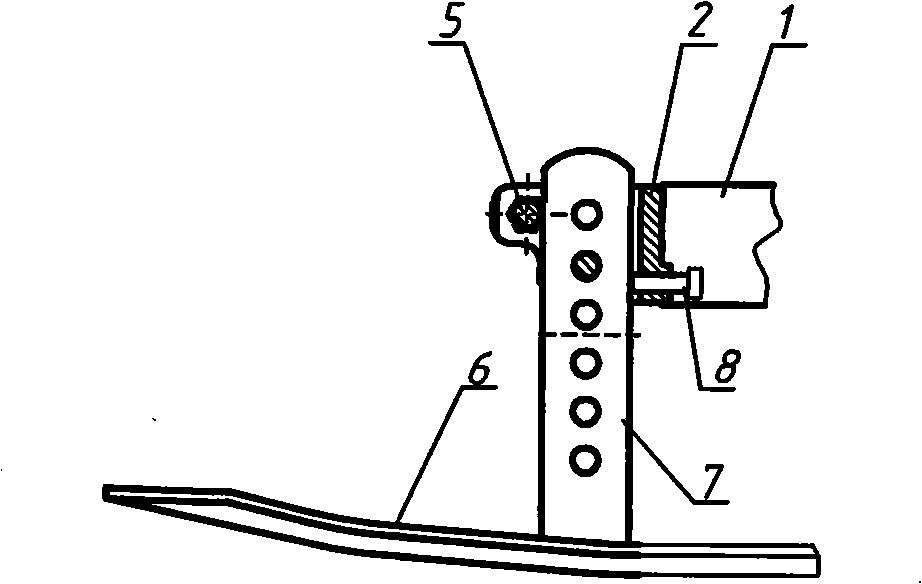

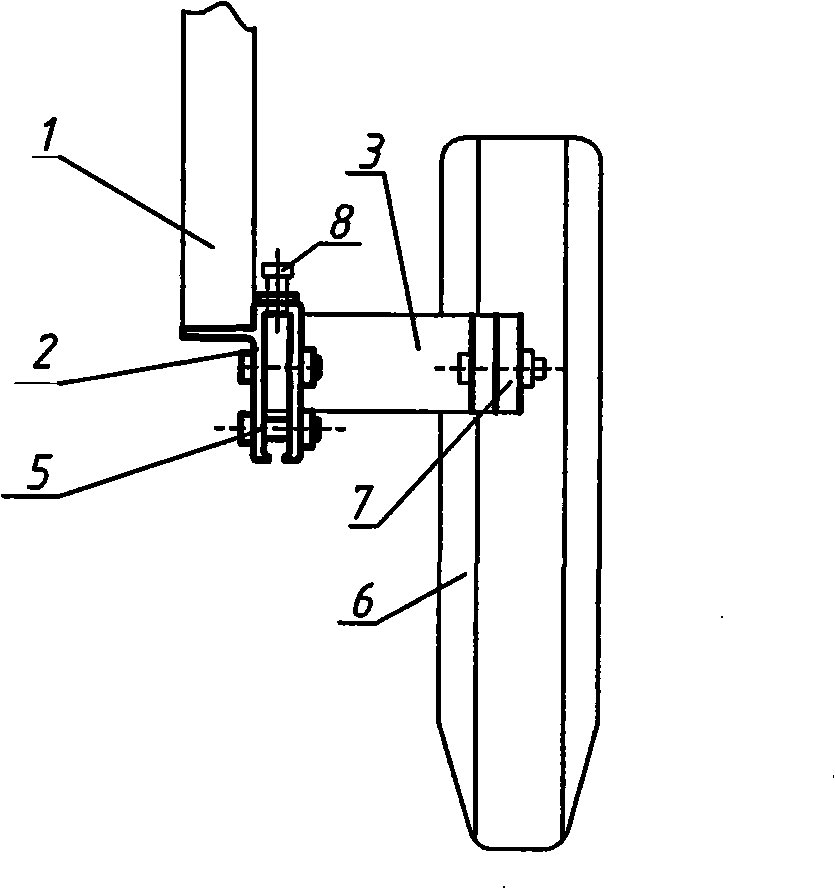

[0018] Embodiment 2, as figure 1 , 2 , 3 shown. The sliding mechanism of the ditching machine includes the sliding clip 2 and the sliding clip 6 arranged at the front end of the ditching machine frame arm 1; the front end of the sliding clip 2 is an opening, and the middle parts of both sides are symmetrically provided with bolt holes; the sliding clip Column 7 is provided with a plurality of bolt holes. Also be provided with a U-shaped connecting block 3 in addition, two vertical columns 4 of the U-shaped connecting block are provided with bolt holes; , When it is necessary to repeat the ditching of the old ditch, the U-shaped joint block is first fixed on the sliding clamp with bolts, and then the sliding vertical column is fixed on another vertical column of the U-shaped joint block with bolts. Such as Figure 4 and Figure 5 As shown, clamping bolt holes 5 are arranged symmetrically on the front of both sides of the sliding clip, and the two sides of the sliding clip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com