A floor-cleaning machine

A ground cleaning and cleaning machine technology, applied in cleaning machinery, road cleaning, cleaning equipment and other directions, can solve the problem of expensive ground cleaning machines, and achieve the effects of cheap cleaning machines, low firmness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

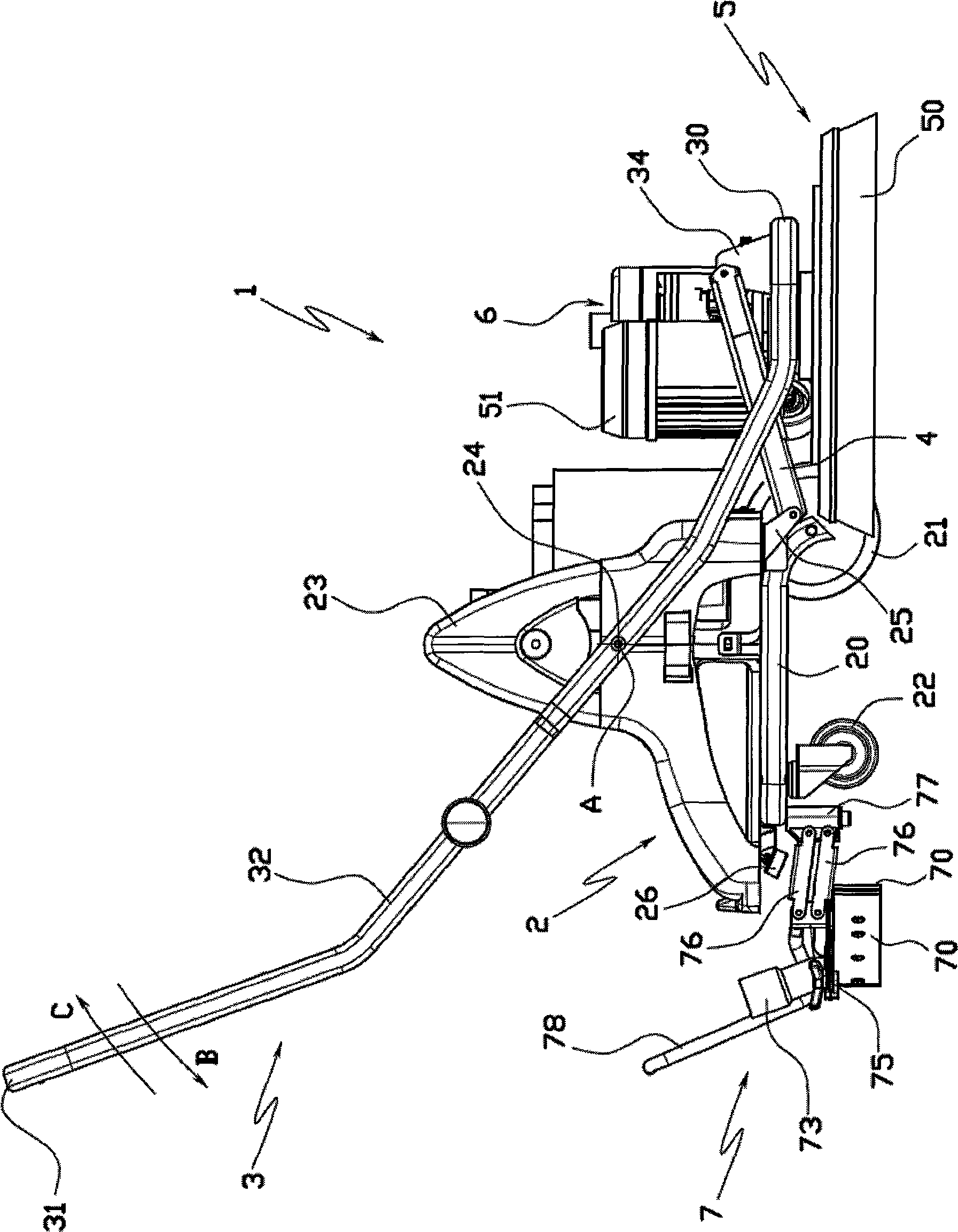

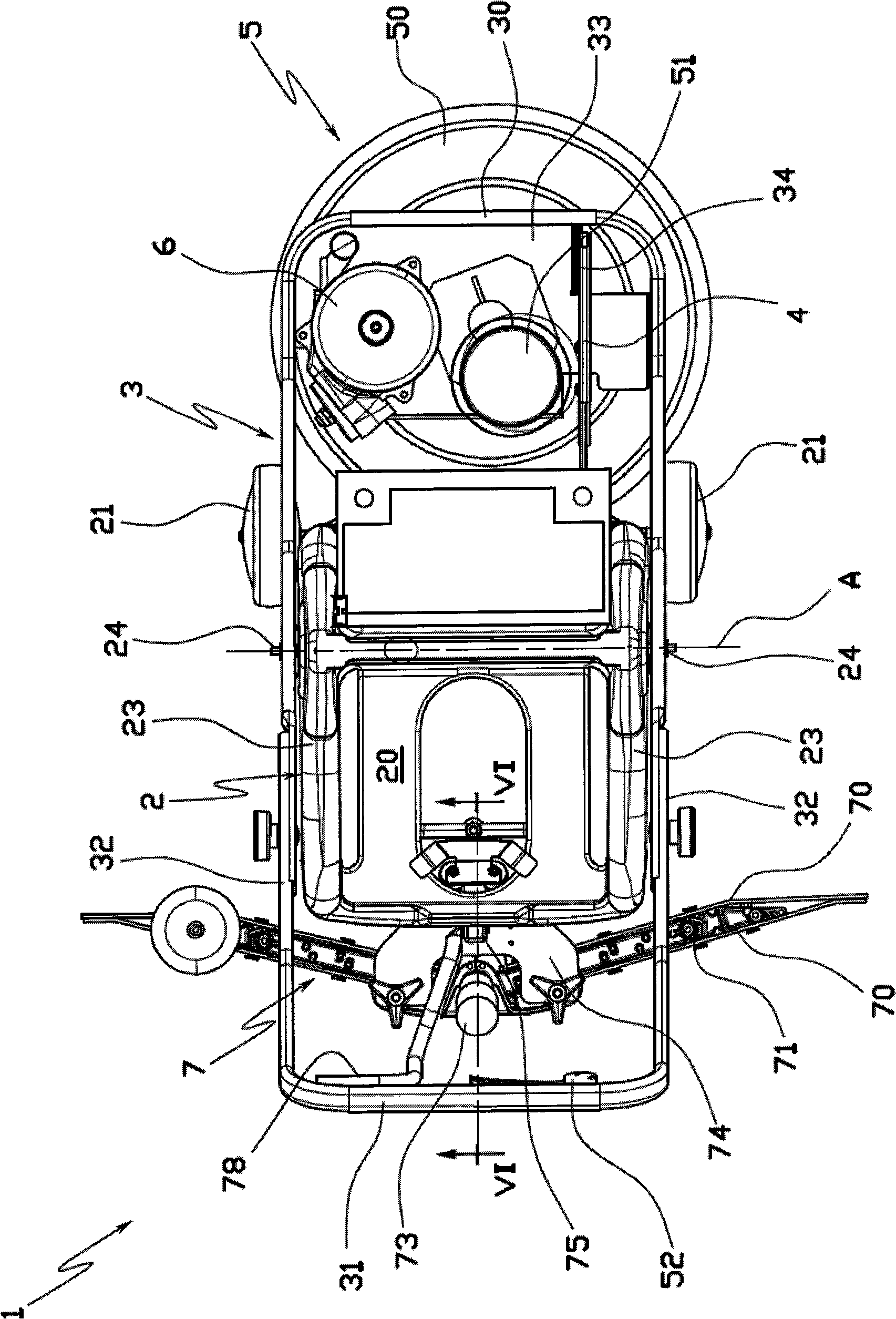

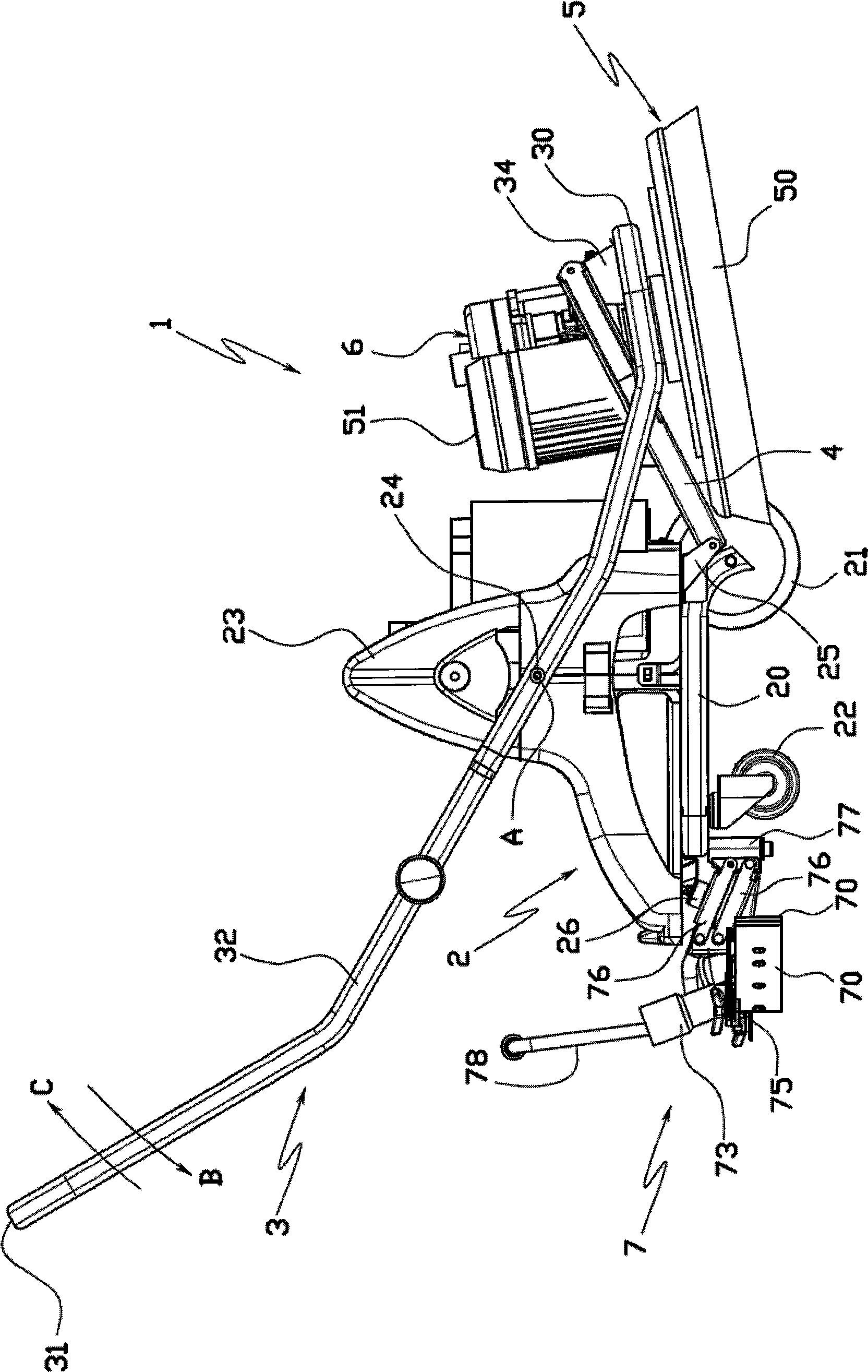

[0025] The floor cleaning machine 1 comprises a very compact, lightweight support trolley 2 having a horizontal base 20 and three support wheels including two coaxial, fixed axle front wheels 21 and a pivoting rear wheel 22 .

[0026] Two oppositely positioned, identically shaped convex side elements 23 are secured to the movable support trolley 2, laterally delimiting the loading space of said trolley 2, preferably made of plastic.

[0027] A rigid frame 3 , preferably made of sheet steel, is hinged to said side elements 23 .

[0028] Such as figure 2 As shown, the frame 3 has rounded corners and two cross-bars, namely a front cross-bar 30 and a rear cross-bar 31 , which are connected together by two opposite longitudinal bars 32 of the same shape.

[0029] The rigid frame 3 is embedded on the outer surface of the side elements 23 of the mobile support trolley 2 and is articulated to said trolley 2 by means of two hinged connections 24 connecting the respective side element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com