Sugar-producing and texture-improving bakery methods and products formed therefrom

a technology of sugar-producing and texture-enhancing bakery methods and products, which is applied in the field of bakery products preparation, can solve the problems of harmful end products such as triglycerides, uric acid, and free radicals, and achieve the effects of improving the performance preventing staling maltogenic amylases, and increasing the functionality of anti-staling maltogenic amylases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

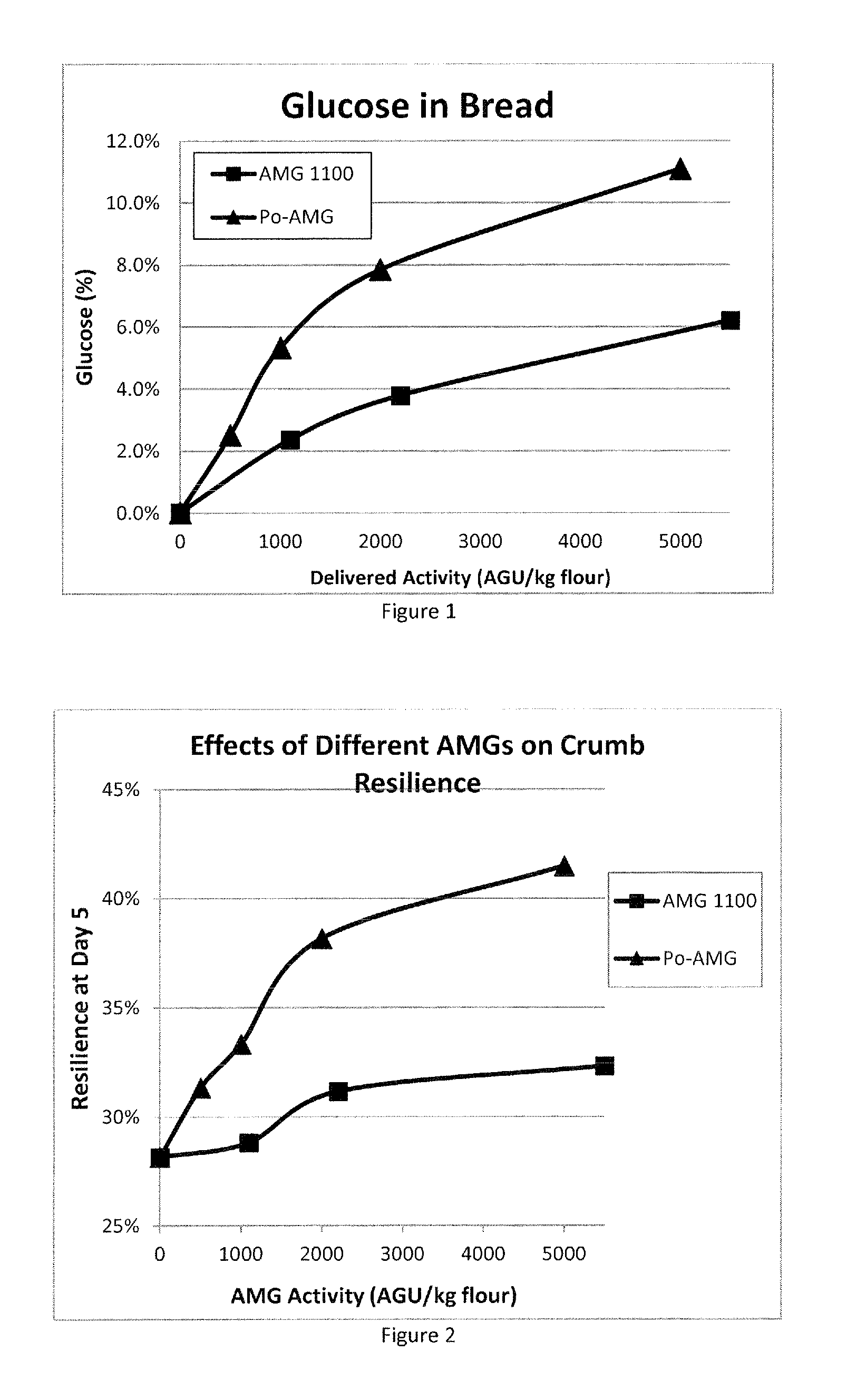

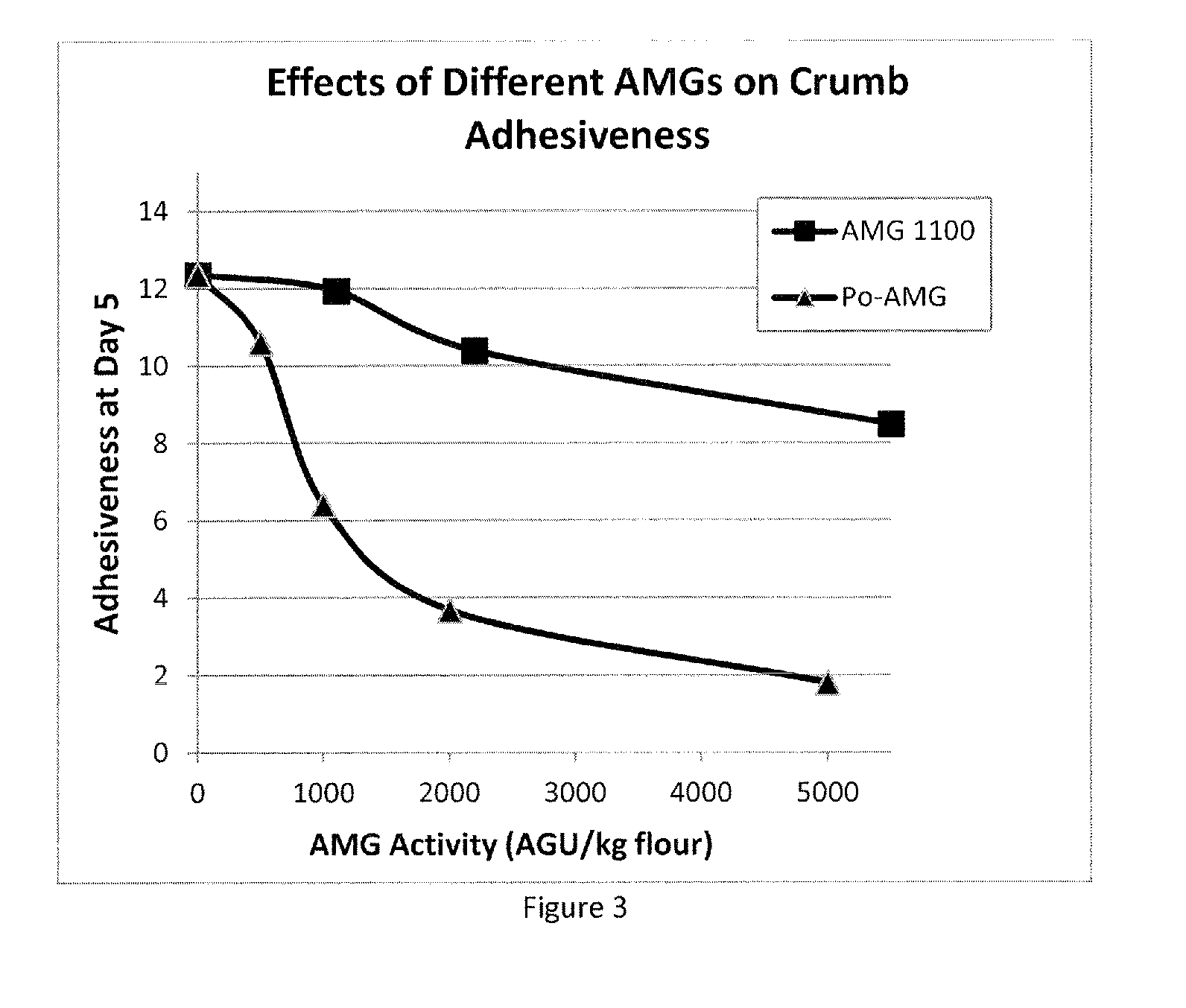

Amyloglucosidase Sugar Production and Texture Modification

[0092]A conventional raw starch degrading (“RSD”) amyloglucosidase, AMG 1100 (from Novozymes®, North Carolina), was compared to a thermally-stable amyloglucosidase, Po-AMG (from Novozymes®), in bread baking for their sugar production and crumb texture modification capabilities. A standard white pan bread formulation was prepared according to the following process.

White Straight Pan Bread

[0093]

Ingredients% of flour weightGramFlour100.0700.00DEPENDOX ® AXCA0.040.28Salt2.014.00Granulated sugar (sucrose)1.07.00Calcium Propionate0.32.10Soy Oil2.014.00Yeast - compressed7.0049.00Water64.0448.00GMS 90 SSB1.07.00Sodium Stearoyl Lactylate0.352.45(SSL)UFP 250C0.503.50Total Weight176.3AA blend of ascorbic acid, azodicarbonamide (ADA), fungal enzymes, and wheat starch (available from Corbion, Lenexa, KS).BHydrated monoglycerides (emulsifier; available from Corbion).CUltra Fresh Premium 250 (shelf-life extending enzymes; available from Cor...

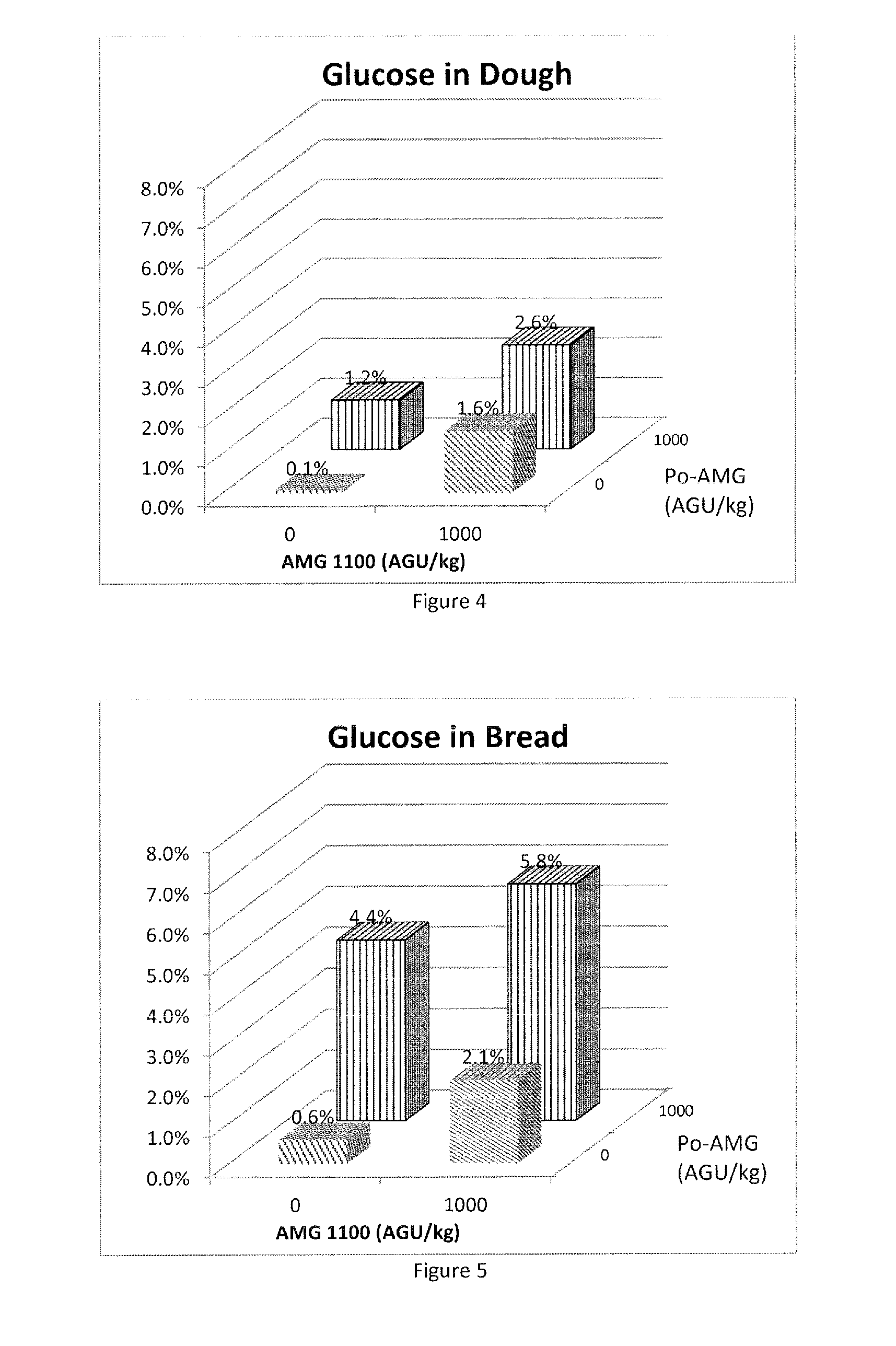

example 2

Analysis of Sugar Production Capability

[0100]A standard white pan bread formulation was prepared according to the following formulation and the same processing parameters described in Example 1. All of the bread dough was made with 1% added-sugar and specified amounts of amyloglucosidases.

White Straight Pan Bread

[0101]

Ingredients% of flour weightGramFlour100.0700.00DEPENDOX ® AXC0.040.28Salt2.014.00Granulated sugar (sucrose)1.07.00Calcium Propionate0.32.10Soy Oil2.014.00Yeast - compressed5.5038.50Water64.0448.00GMS 90 SS1.07.00SSL0.352.45NOVAMYL ® 3DA0.020.14Total Weight174.8AAn anti-staling enzyme from Novozymes ®.

Formula Variations

[0102]

Dough #1234AGU / kg flourAMG 11000010001000Po-AMG0100001000

Again, samples of proofed dough were collected and flash frozen for sugar analysis. Dough sugar was extracted as described above, except that 10 g of dough was dispersed in 90 g of water. The results are shown in FIGS. 4-6. Sugar content in the proofed dough and in the baked bread was analyze...

example 3

Sugar Content and its Effect on Anti-Staling Enzyme

[0105]A standard white pan bread formulation was prepared according to the following formulation. Five different formulations were prepared by varying the amount of sugar added to the formulation, the level of anti-staling enzyme (NOVAMYL®), and the amount of amyloglucosidase, Po-AMG, and other ingredients were varied accordingly, as shown in the Tables below.

White Straight Pan Bread

[0106]

Ingredients% of flour weightGramFlour100.0700DEPENDOX ® AXC0.060.42Salt2.014Granulated sugar (sucrose)VaryVaryCalcium Propionate0.21.4SSL (optional)0.352.45GMS-90 (optional)1.007Soy Oil2.0141% BXP 250010.100.7Yeast - dryVaryVaryWaterVaryVaryTotal WeightVaryVary

Formula Variations

[0107]

Dough #12345Po-AMG0 AGU / kg1000 AGU / kgflourflourSugar (sucrose - % of flour8%4%0%weight)Novamyl (MANU / kg flour)02000100020001000Yeast-dry (% of flour3.03.02.52.52.0weight)Water (% of flour weight)62.062.063.063.064.0

[0108]By using the inventive enzyme compositions, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com