Preparation method of micro-branched micro-crosslinked polyacrylamide

A technology of polyacrylamide and acrylamide monomer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of polymer viscosity drop, polymer chain mechanical degradation, and impact on recovery, and achieve good Effect of shear resistance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

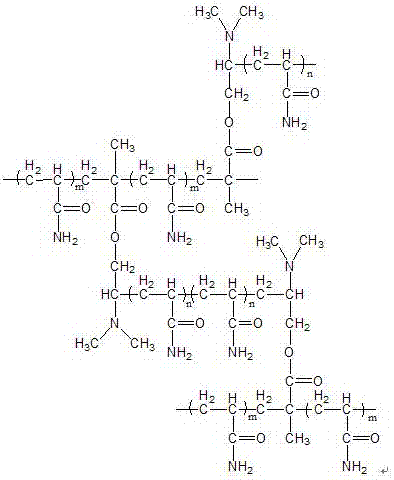

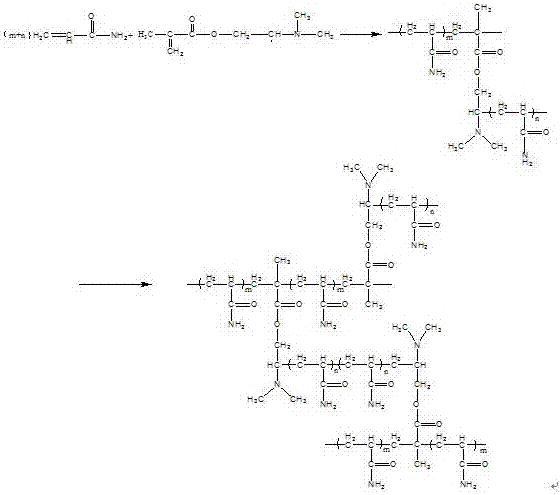

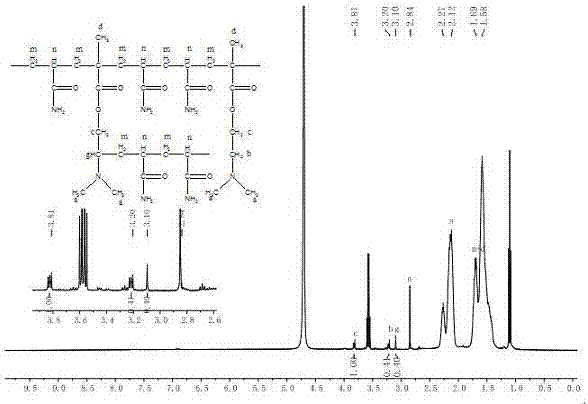

[0022] Example 1 Preparation of micro-branched micro-crosslinked polyacrylamide

[0023] The steps are as follows: add 400g of pure water to a 500ml beaker, add 100g of acrylamide monomer, stir well, put the beaker in a 40°C water bath and keep warm until the solution temperature is 40°C, then add dimethylaminoethyl methacrylate, Ammonium persulfate, sodium formate, EDTA, manganese acetylacetonate, wherein the molar ratio of dimethylaminoethyl methacrylate to ammonium persulfate is 4:1, the amount of ammonium persulfate added is 0.1% of the mass of acrylamide monomer, and the amount of sodium formate added The amount is 0.05% of the mass of acrylamide monomer, the amount of EDTA is 0.02% of the mass of acrylamide monomer, and the amount of manganese acetylacetonate is 0.04% of the mass of acrylamide monomer; Carry out under ambient conditions, take out the colloid after fully reacting for 6 hours, granulate, add hydrolyzing agent NaOH accounting for 2.5% of the total mass of t...

Embodiment 2

[0026] Example 2: According to the polymerization method and steps in Example 1, the difference is that the molar ratio of dimethylaminoethyl methacrylate to ammonium persulfate is 1:1. Other polymerization conditions remained unchanged.

Embodiment 3

[0027] Example 3: According to the polymerization method and steps in Example 1, the difference is that ammonium persulfate is changed to potassium persulfate, and the molar ratio of dimethylaminoethyl methacrylate to potassium persulfate is 3:1. Other polymerization conditions remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com