Chemical activation and refining of southern pine kraft fibers

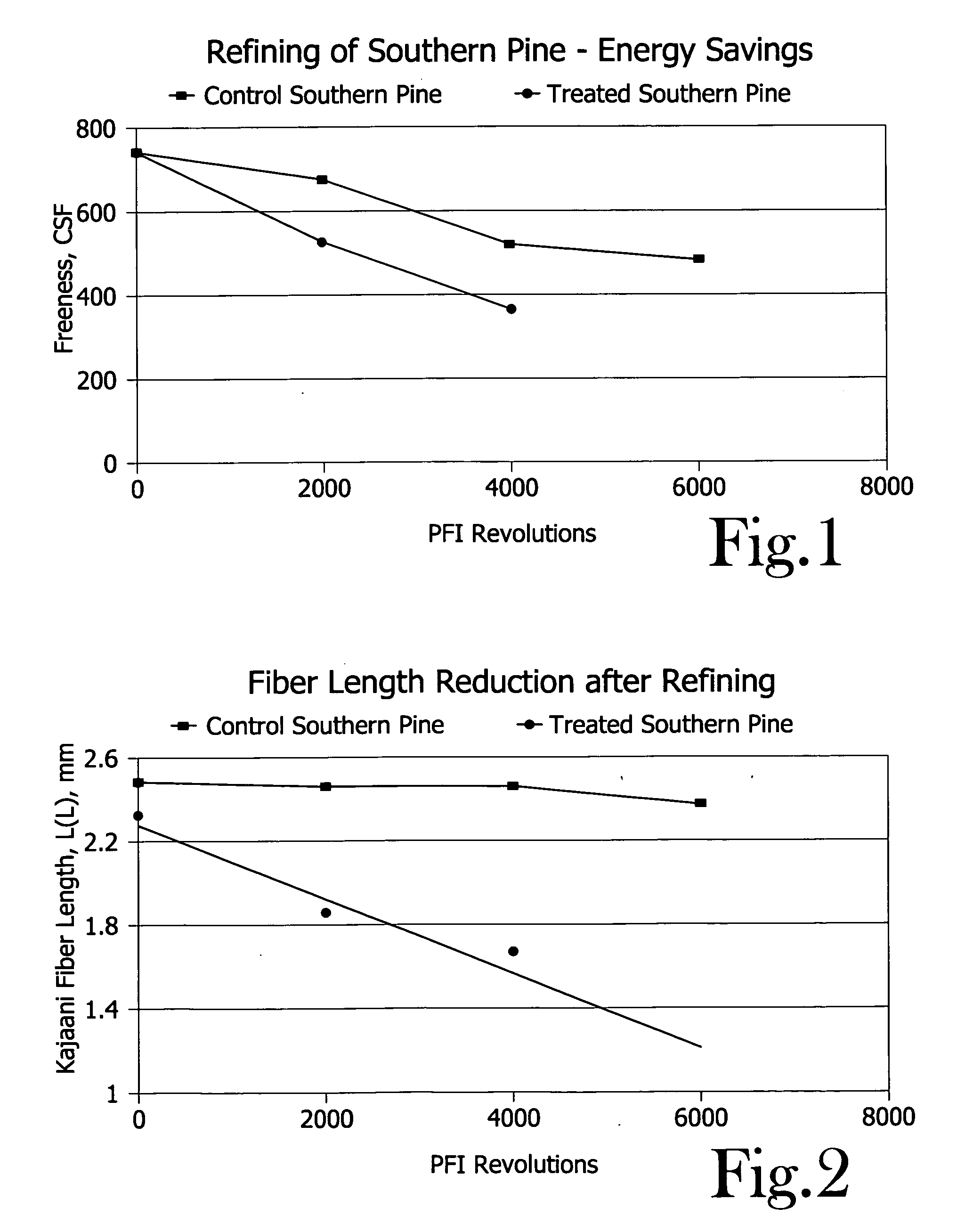

a technology of southern pine and kraft fibers, applied in the field of papermaking, can solve the problems of not being able to achieve the desired modification, dramatically less refining energy, etc., and achieve the effects of enhancing freeness, reducing material deterioration, and improving the bonding of fibers within the sh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0041] Bleached southern pine as employed in Example 1 was treated with 1% hydrogen peroxide based on pulp at pH 4, with 0.006% FE (II) as from ferrous sulfate. The treatment was carried out at the temperature of 70° C. for 1 hour. The treated pulp and control were PFI refined as in Example 1. TAPPI hand sheets were then made from these pulps.

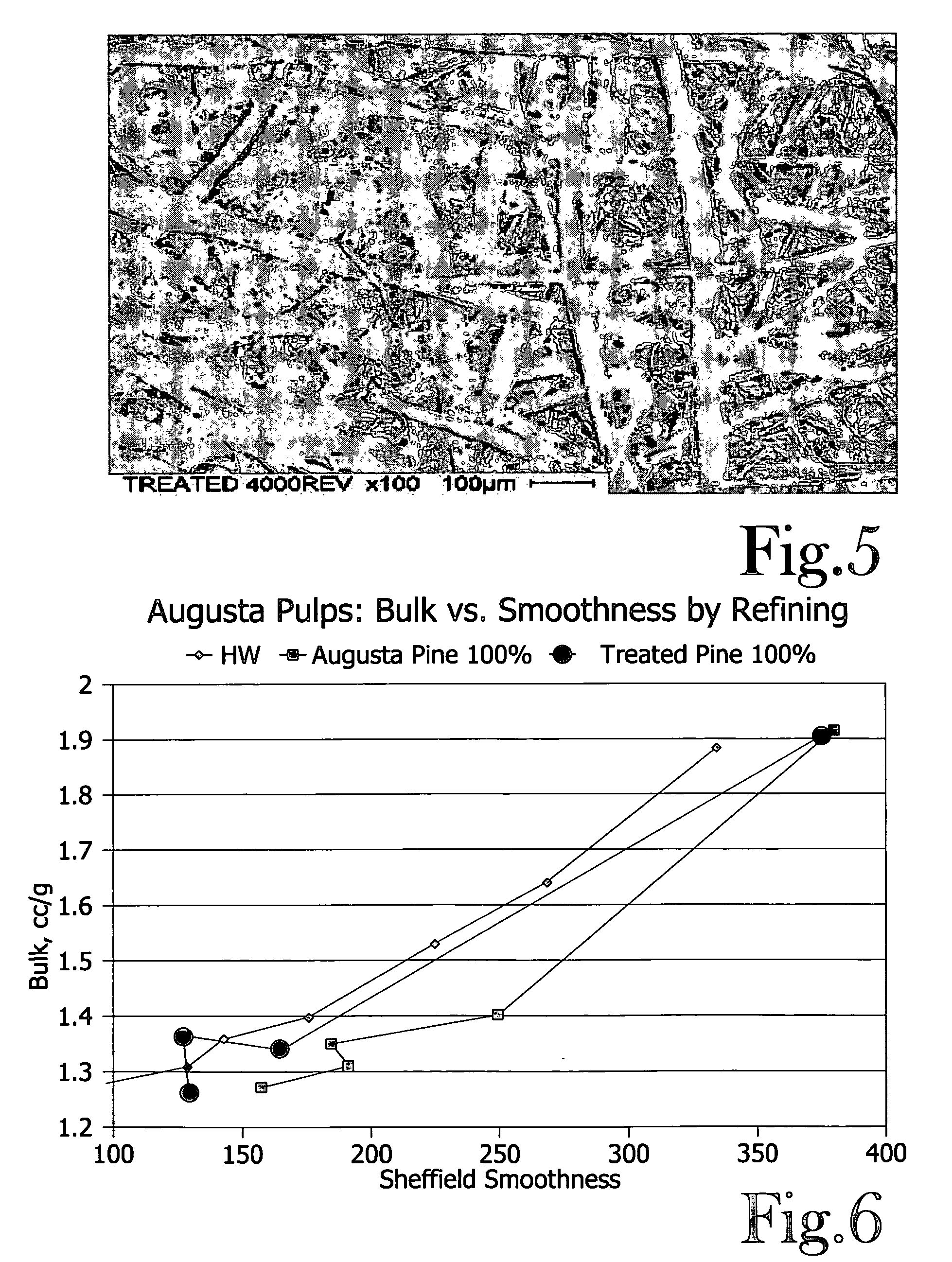

[0042] To illustrate fiber morphology (beyond fiber length distributions) and fiber collapsibility, SEM (scanning electron microscopy) images were made of the hand sheet surface of treated vs. the control (untreated) softwood pulps, compared at 4000 Revs of PFI refining. These microphotographs are depicted in FIGS. 4 (untreated) (control) and 5 (treated) and demonstrate that the treated pine fibers are much more collapsed, or flattened, as compared to the fiber of the control. The collapsed and flattened fibers are desirable for making paper or paperboard with superior surface and printing properties. Some broken or cut fibers (fiber ends) can...

example 3

[0043] Bleached southern pine pulp was treated with 1% hydrogen peroxide catalyzed by 0.006% Fe(II) at pH 4 as in the Example 2 above. The treated pulps were PFI refined, and made into hand sheets for paper physical property evaluations. Results are shown in Table II.

TABLE IIBasisTearExtensionalWeight,Bulk,SheffieldFactorStiffness,g / m2cc / gSmoothness100*gf / g / m2lbs / in.Treated Pine Pulp730 CSF151.91.90375.6190.92960(Unrefined)556 CSF155.21.34165.3111.94780421 CSF154.41.36127.2103.45050304 CSF155.21.26129.798.15210Control Pine Pulp740 CSF162.41.91380270.93490(Unrefined)661 CSF155.61.40249.6193.64020625 CSF159.91.35185.3188.74340569 CSF158.51.31191.6167.44540443 CSF155.91.27157.8170.24340Bleached Hardwood Pulp615 CSF1661.8833352.32040584 CSF163.11.64268.687.92520544 CSF164.91.53224.41002840507 CSF161.01.40175.2112.63030462 CSF160.51.36142.2126.93010427 CSF162.81.31127.8107.83480362 CSF163.91.27389123.63320

[0044] From this table, it is noted that the treated pine, after refined to ˜560 ...

example 4

[0047] The treated pine as in Example 3 above, refined to 560 CSF, was also mixed with hardwood pulp of a range of freeness, to investigate the mixed furnish paper properties such as bulk and smoothness. The results are listed in Table III.

TABLE IIISheffield SmoothnessBulk, cc / g10% Treated Pine (560 CSF) +3231.8390% Hardwood3081.83171.21.37137.81.3320% Treated Pine (560 CSF) +3021.7580% Hardwood231.81.5182.81.43136.61.3250% Treated Pine (560 CSF) +3181.7950% Hardwood182.41.41163.41.38147.61.29

[0048]FIG. 9 plots the bulk-smoothness curve of the mixed pulp furnish (data from Table III), along with 100% pine and hardwood curves (data from Table II). It is obvious that the treated pine can be used to replace substantial amounts of hardwood pulp. The exact amount of hardwood replacement in the paper mill, however, may also be affected somewhat by the nature, type and optimization of commercial refiners.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com