Method for recycling papermaking waste residues

A papermaking waste residue and recycling method technology, which is applied in the direction of paper recycling, papermaking, recycling technology, etc., can solve the problems of unfavorable large-scale popularization and use, complicated process steps, and high equipment cost, so as to facilitate large-scale popularization and application, The effect of simple process and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

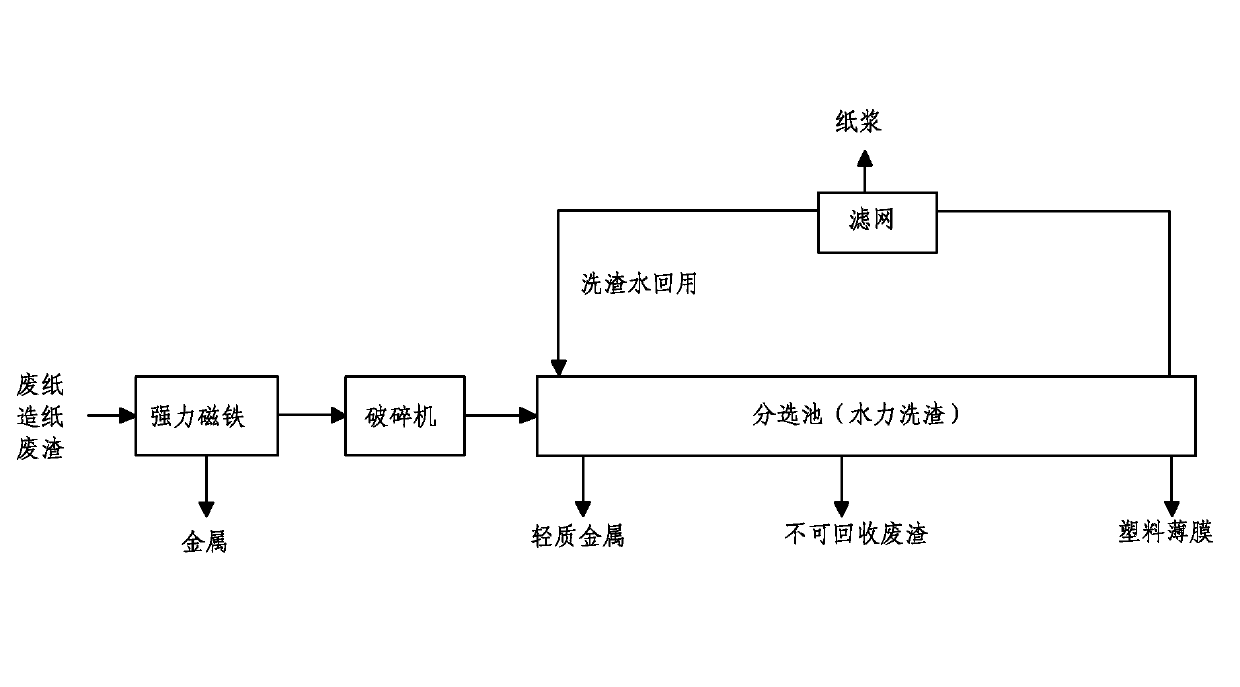

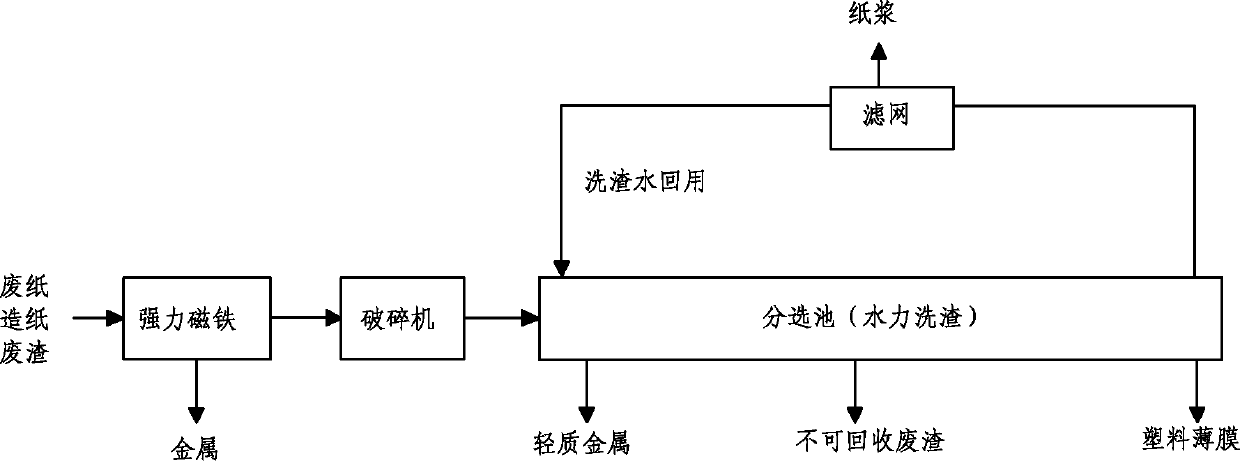

[0025] like figure 1 As shown, a method for recycling papermaking waste slag in this embodiment includes the following processing steps: Impurity removal: use a suspended permanent magnet iron remover with a magnetic strength of 8000 gauss to remove and recycle the metal in papermaking waste slag; use a belt conveyor to The paper-making waste after removing impurities is transported to the crusher, and the conveying speed of the belt conveyor is 25 m / min; Crushing: put the paper-making waste after removing impurities into the crusher, so that the paper-making waste is fully crushed, and the diameter of the crushed paper-making waste is 3cm; slag washing, sorting and recovery: under the action of hydraulic impact, papermaking waste slag can settle and recover light metals that cannot be magnetically attracted by permanent magnetic iron remover at the front of the sorting tank, and can settle and recover gray sand in the middle of the sorting tank Cloth residues and other non-re...

Embodiment 2

[0028] like figure 1 As shown, a method for recycling papermaking waste slag in this embodiment includes the following processing steps: Impurity removal: use a suspended permanent magnet iron remover with a magnetic strength of 10,000 gauss to remove and recycle metals in papermaking waste slag; use a belt conveyor to The papermaking waste slag after impurity removal is transported to the crusher, and the conveying speed of the belt conveyor is 30m / min; crushing: put the papermaking waste slag after the impurity removal into the crusher, so that the papermaking waste slag is fully broken, and the diameter of the papermaking waste slag after crushing is 5cm; slag washing, sorting and recovery: under the action of hydraulic impact, the papermaking waste can settle and recover light metals that cannot be magnetically attracted by the permanent magnet iron remover at the front of the sorting tank, and can settle and recover gray sand rags in the middle of the sorting tank Residue...

Embodiment 3

[0030] like figure 1 As shown, a method for recycling papermaking waste slag in this embodiment includes the following processing steps: Impurity removal: use a suspended permanent magnet iron remover with a magnetic strength of 15,000 gauss to remove and recycle the metal in papermaking waste slag; use a belt conveyor to The paper-making waste after removing impurities is transported to the crusher, and the conveying speed of the belt conveyor is 30 m / min; Crushing: put the paper-making waste after removing impurities into the crusher, so that the paper-making waste is fully crushed, and the diameter of the crushed paper-making waste is 8cm; slag washing, sorting and recovery: under the action of hydraulic impact, papermaking waste slag can settle and recover light metals that cannot be magnetically attracted by permanent magnetic iron remover at the front of the sorting tank, and can settle and recover gray sand in the middle of the sorting tank Cloth residues and other non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com