Patents

Literature

361 results about "Rapid assessment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

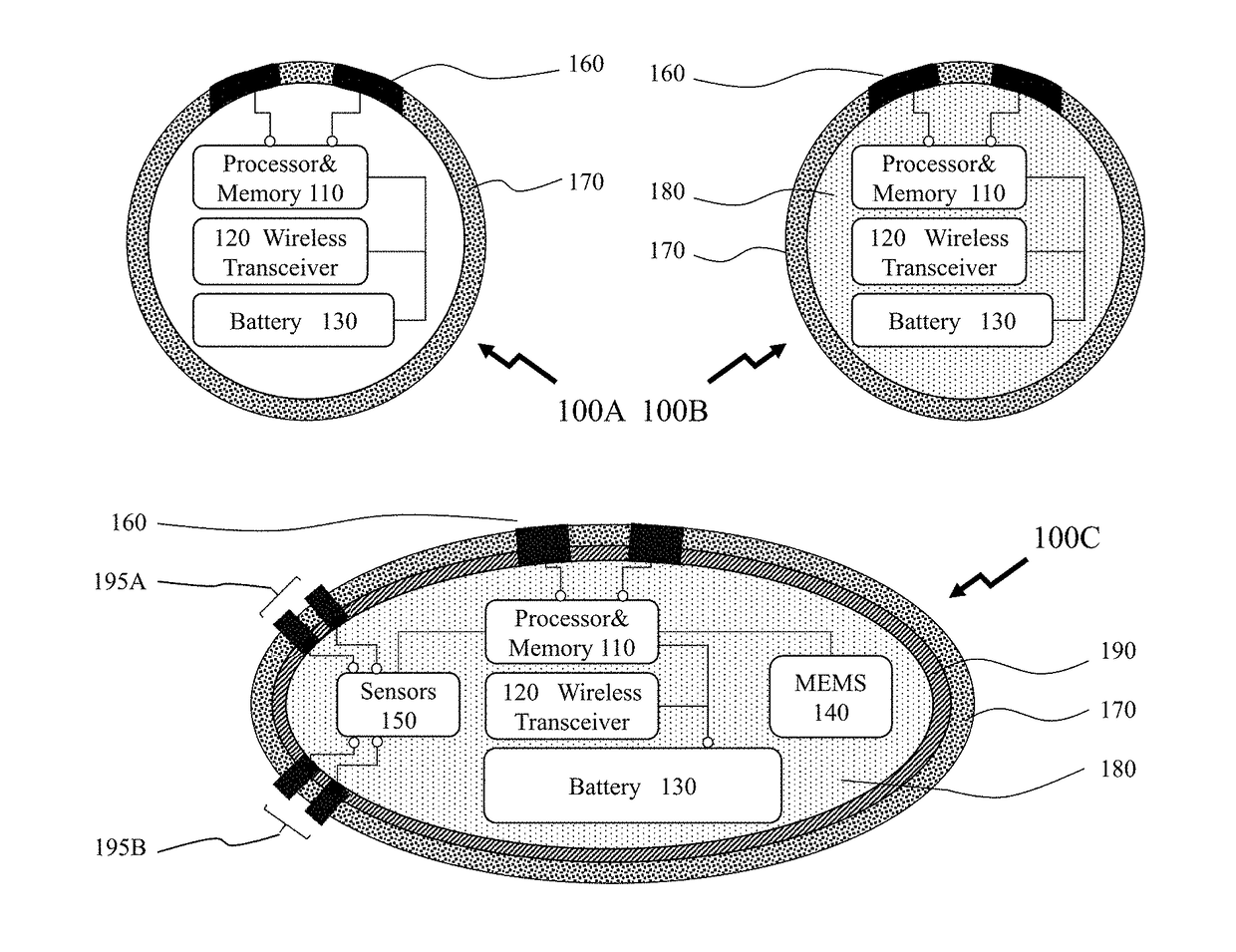

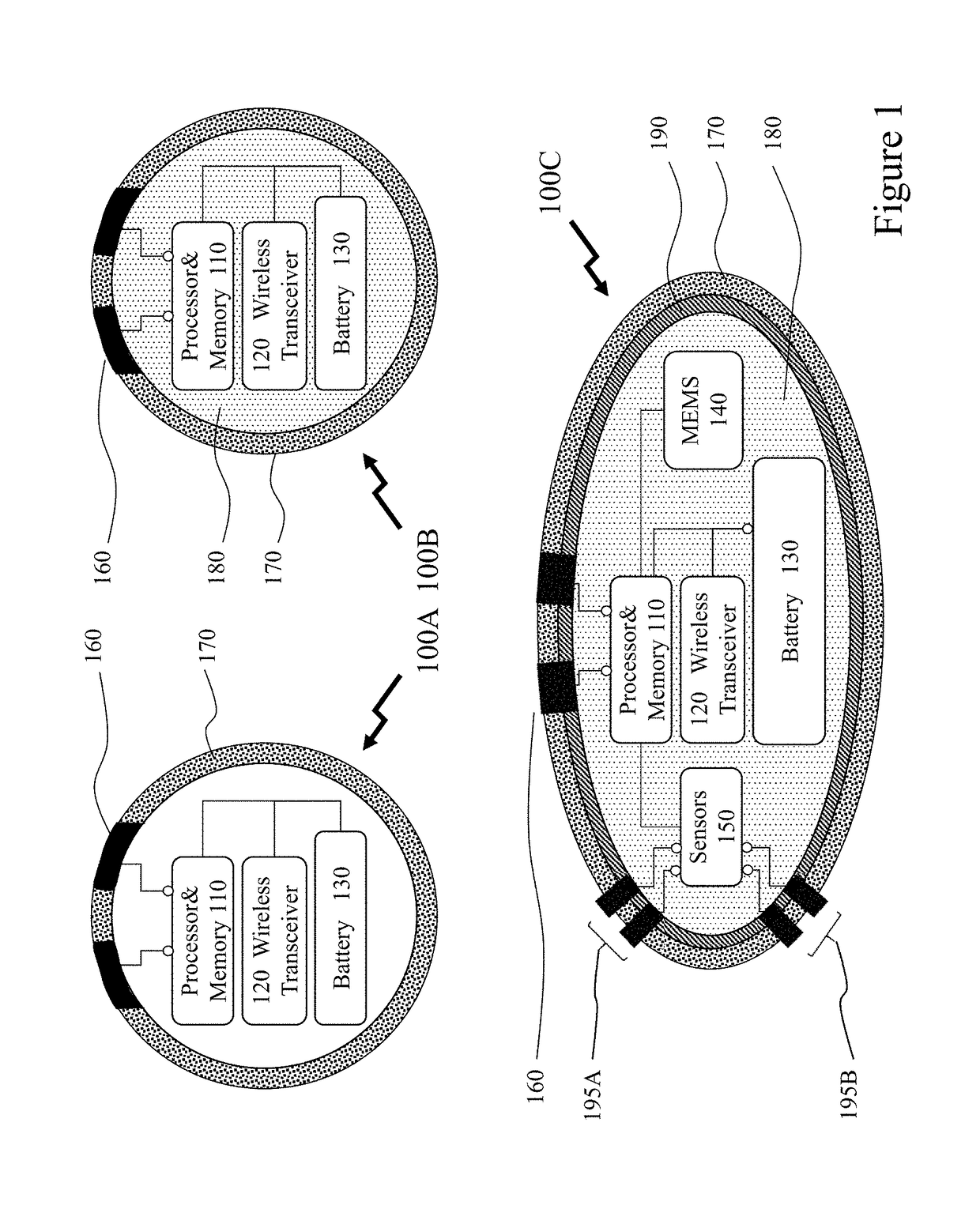

Systems, Methods and Devices for the Rapid Assessment and Deployment of Appropriate Modular Aid Solutions in Response to Disasters.

InactiveUS20110130636A1Rapid deploymentElectric testing/monitoringRemote controlled aircraftTriageModularity

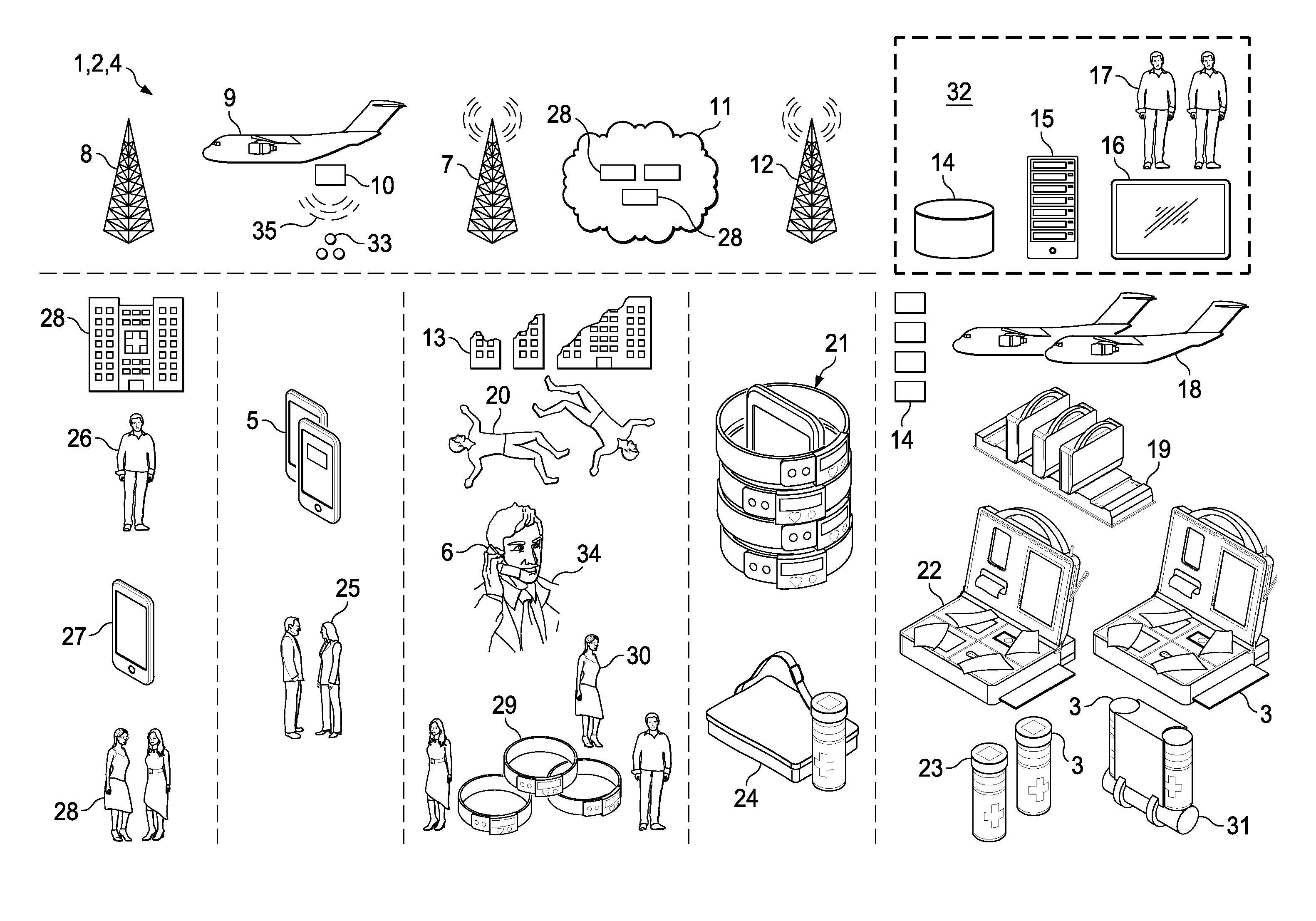

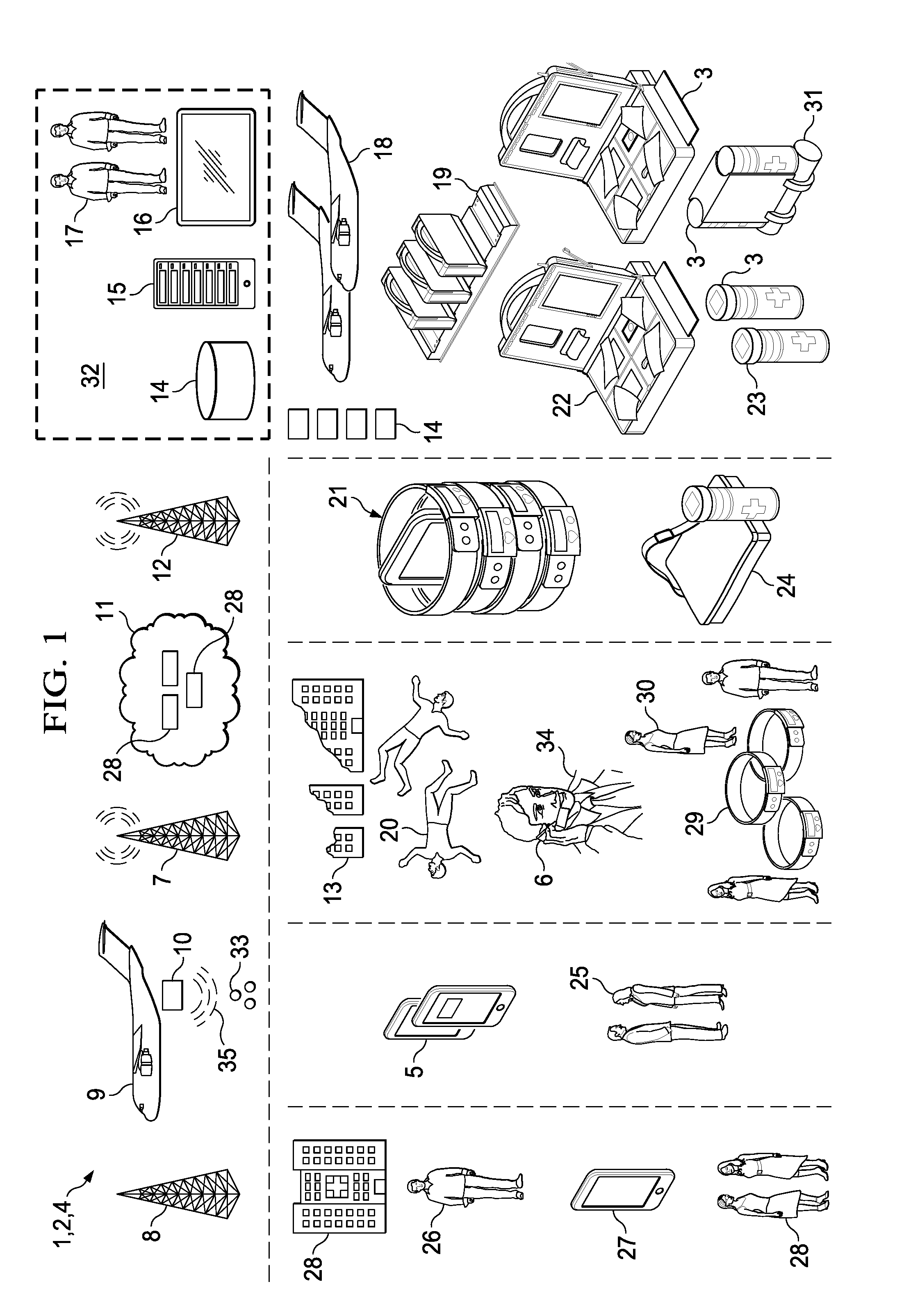

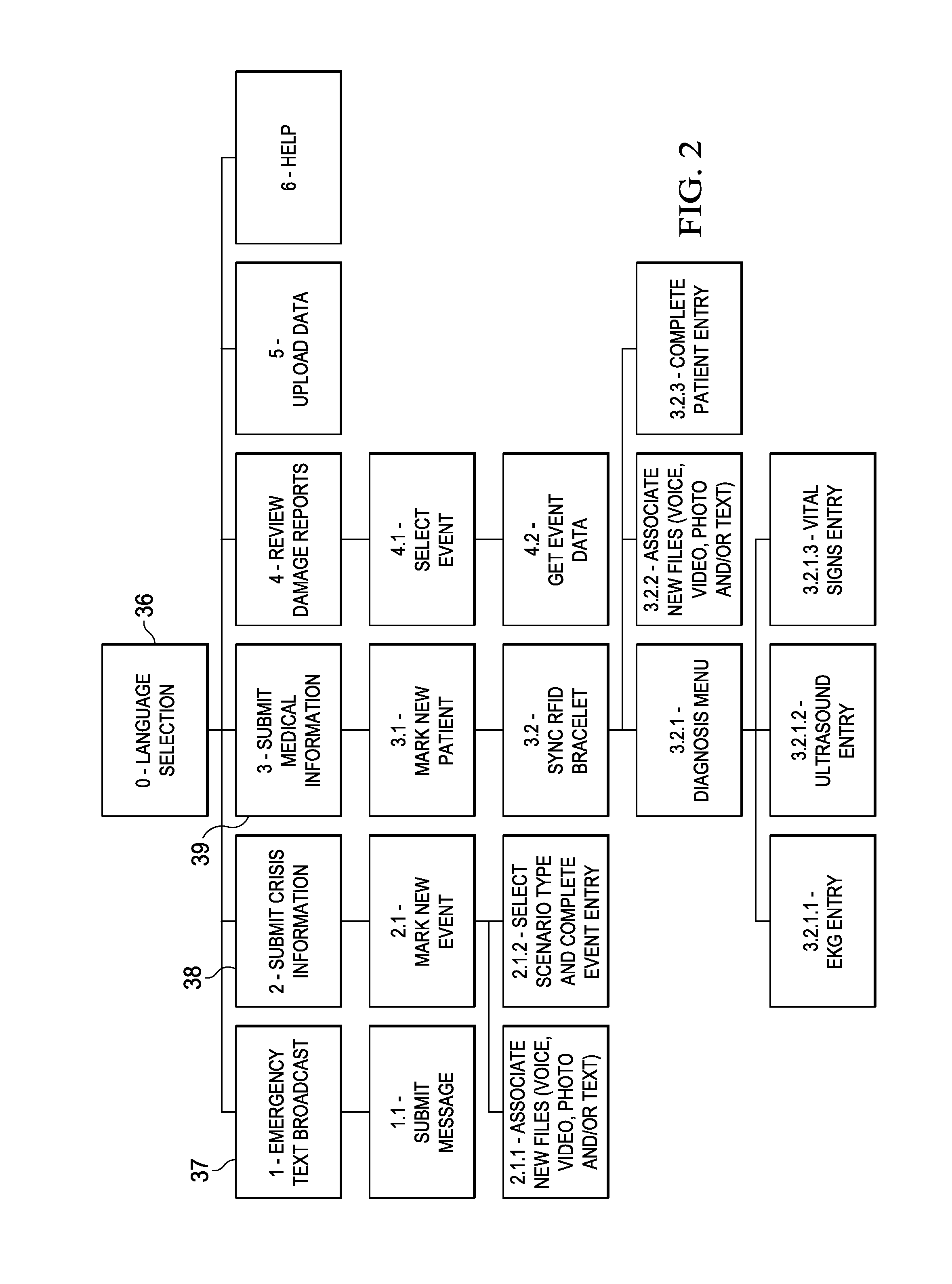

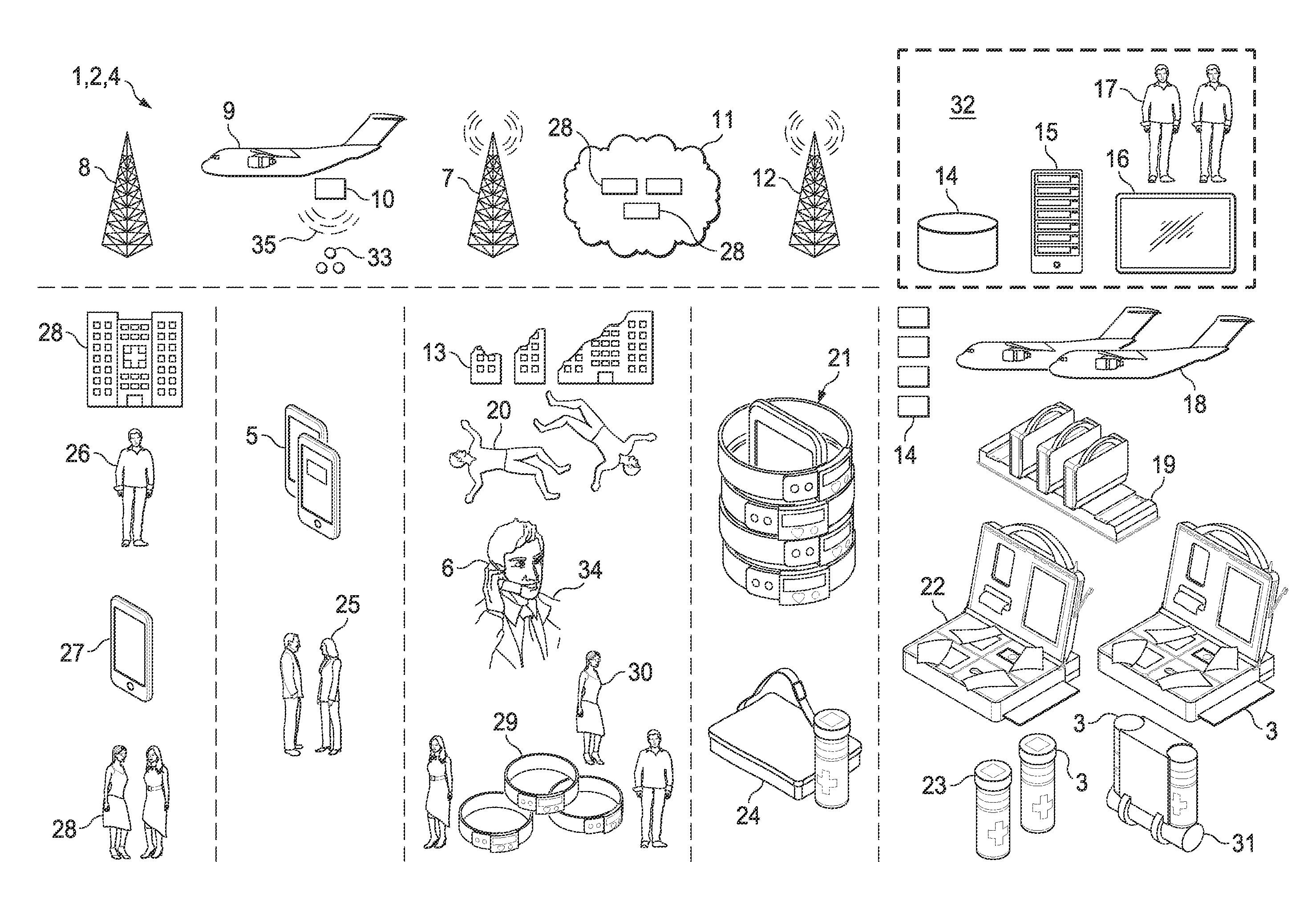

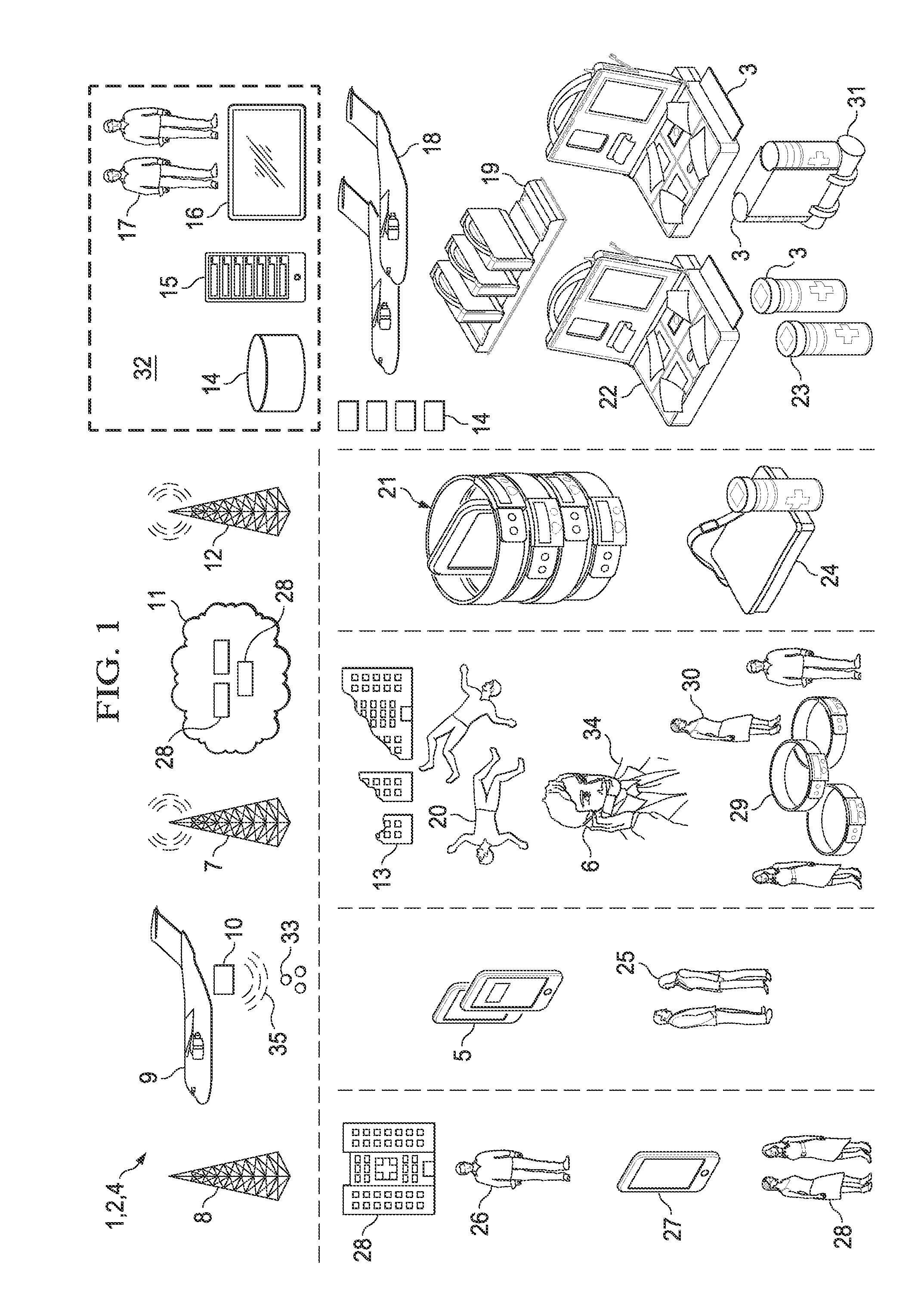

The invention relates generally to systems, devices and methods for global disaster response, more particularly to the rapid detection, qualified assessment and monitoring of disasters and electronic triage of victims, communication, alert and evacuation systems, provision of suitable modular sensing or medical aid solutions, and their rapid deployment via delivery platforms such as disaster messaging formats and resources on client mobile phone applications or physically via remote operated vehicles (unmanned aerial sea or land systems) or targeted air delivery.

Owner:DANIEL SIMON R +4

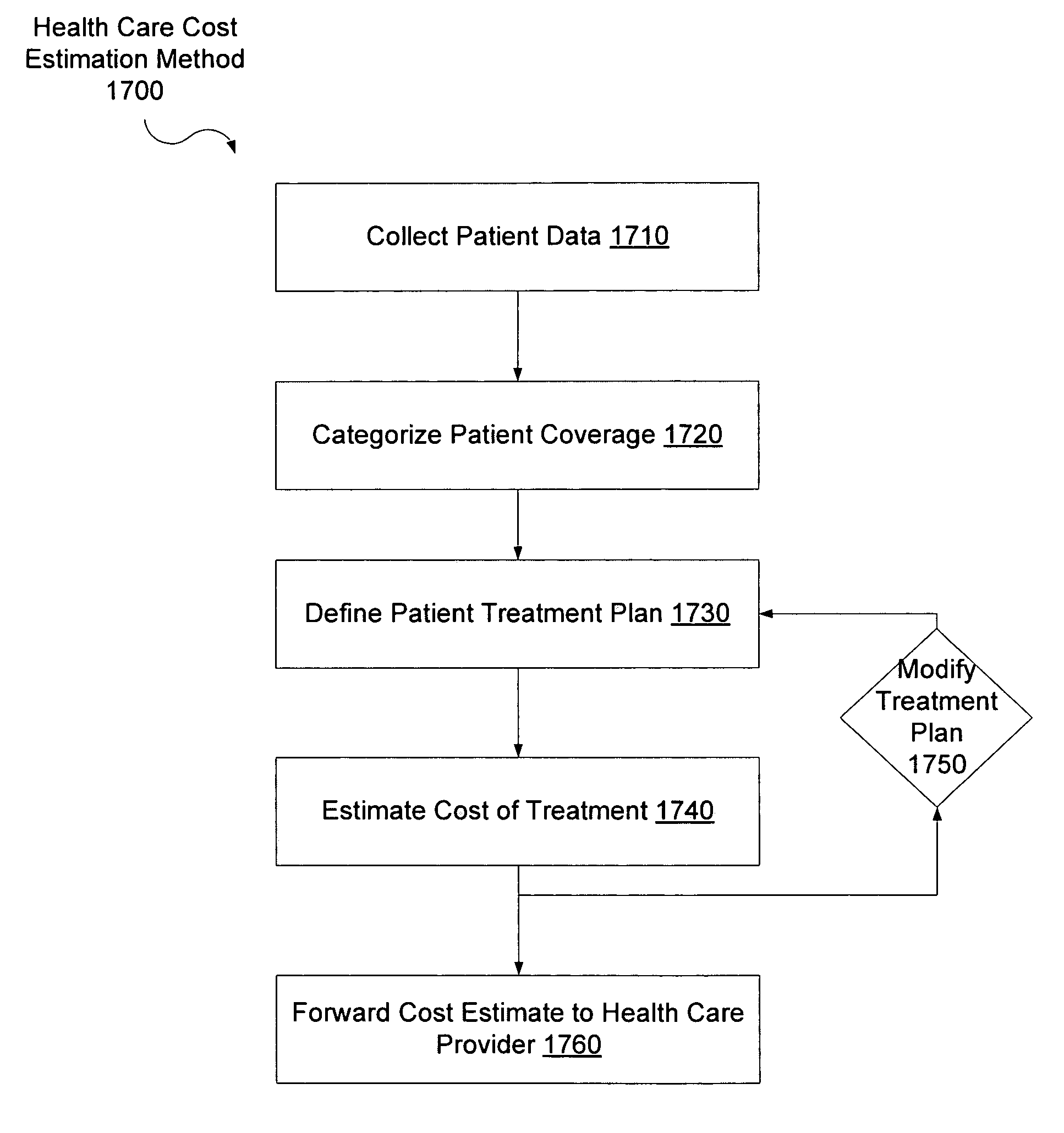

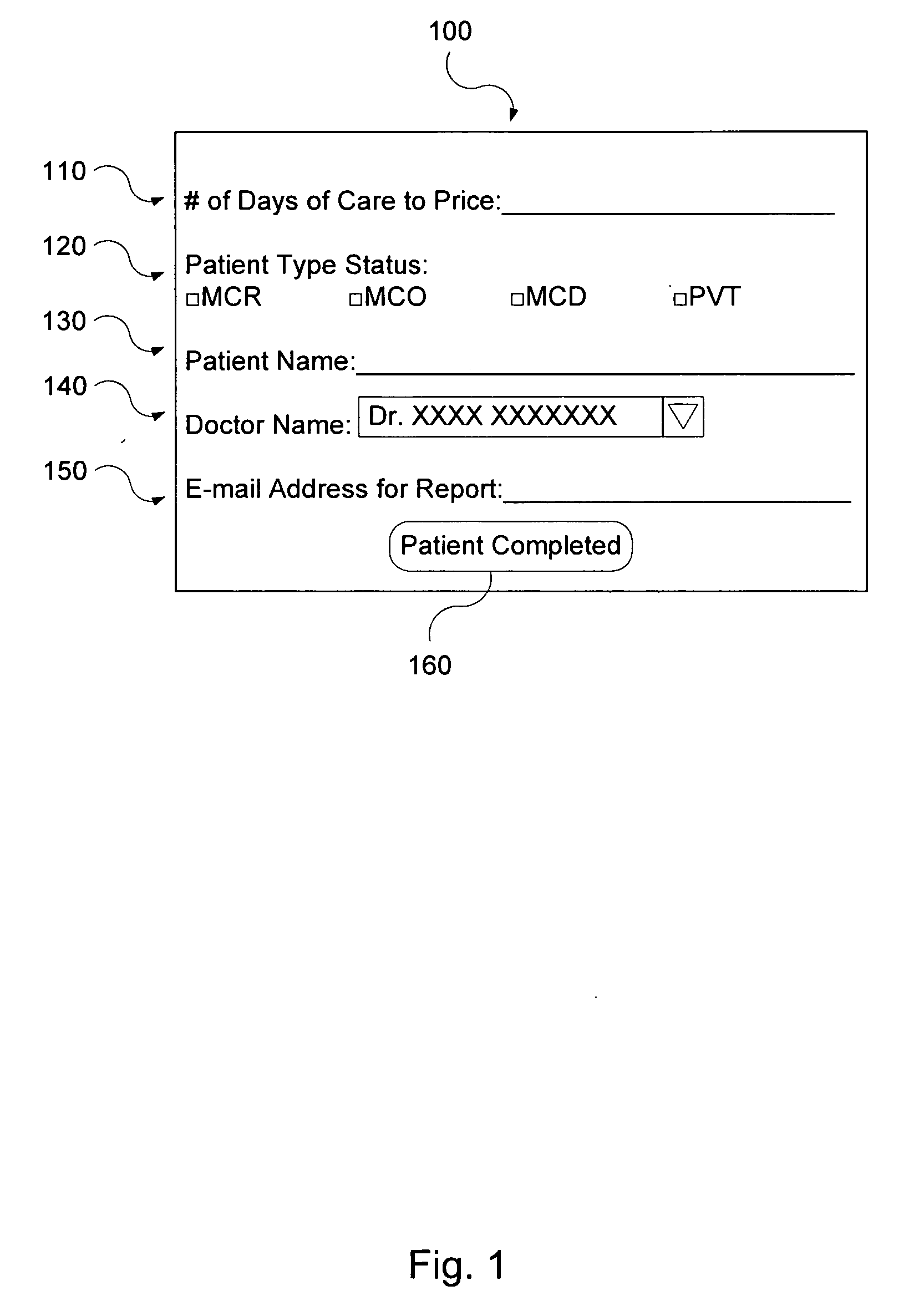

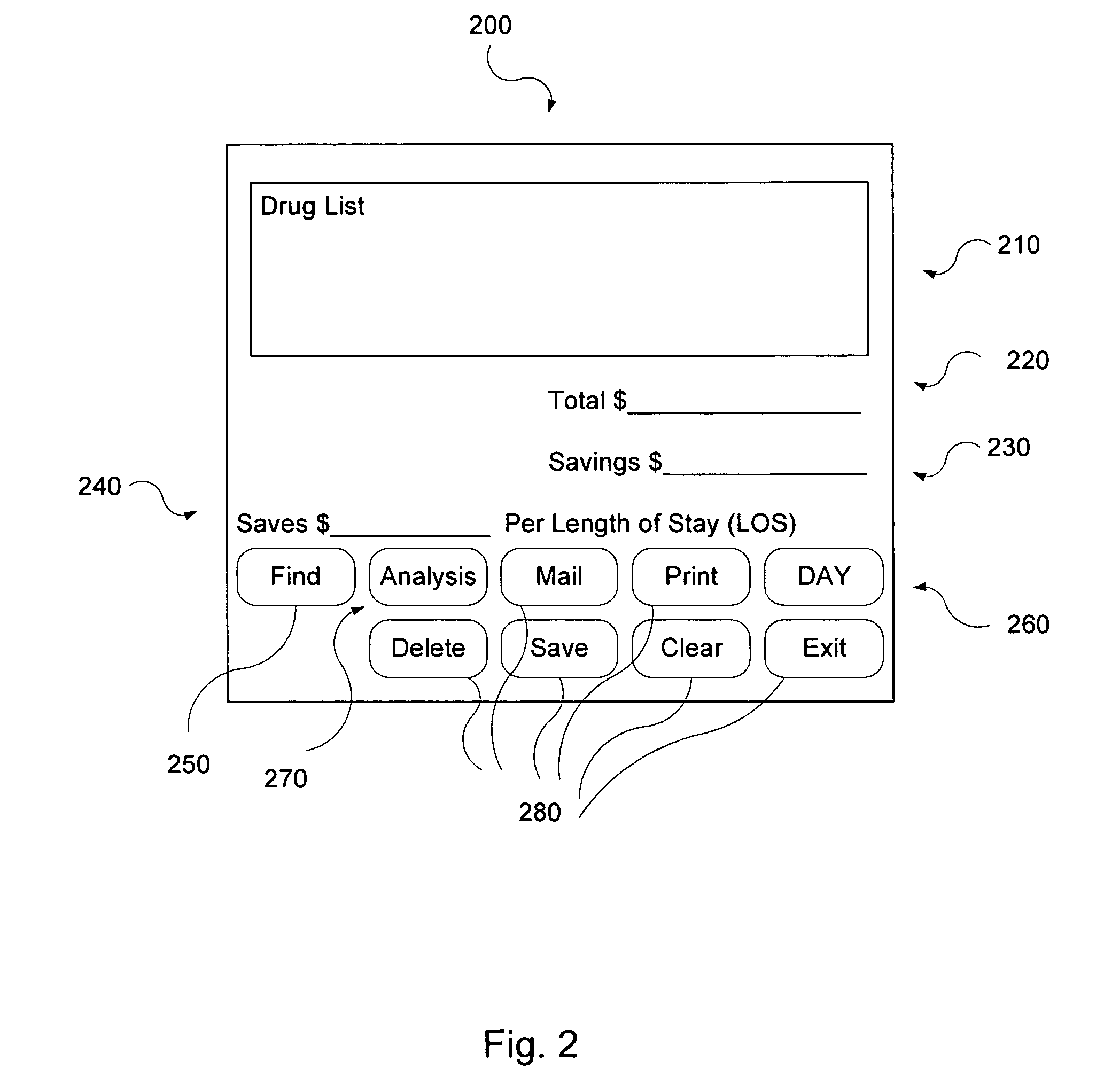

Preadmission health care cost and reimbursement estimation tool

InactiveUS20060080139A1Reduces nursing timeSpeed up admission processFinanceDrug referencesRegimenResource utilization

A cost estimation tool, preferably a handheld computer, prices and evaluates the financial impact of new residents' prior to admission. Immediate access to this information and built-in therapeutic substitution and clinical advisories provides the opportunity to optimize pharmaceutical regimens prior to admission. In addition, an abbreviated Resource Utilization Group (RUG) evaluation function provides a rapid assessment tool to project reimbursement under the Medicare Prospective Payment System (PPS). A user may enter a complete drug regimen and estimate the costs for the regimen. Similarly, managed care reimbursement from managed care organizations (MCOs) to be analyzed. Also, drug cost may be estimated through a MEDICAID Preferred Drug List database that identifies potential Non-Preferred drugs that may be non-compensable. The present invention further transmits results wirelessly to health care providers.

Owner:WOODHAVEN HEALTH SERVICES

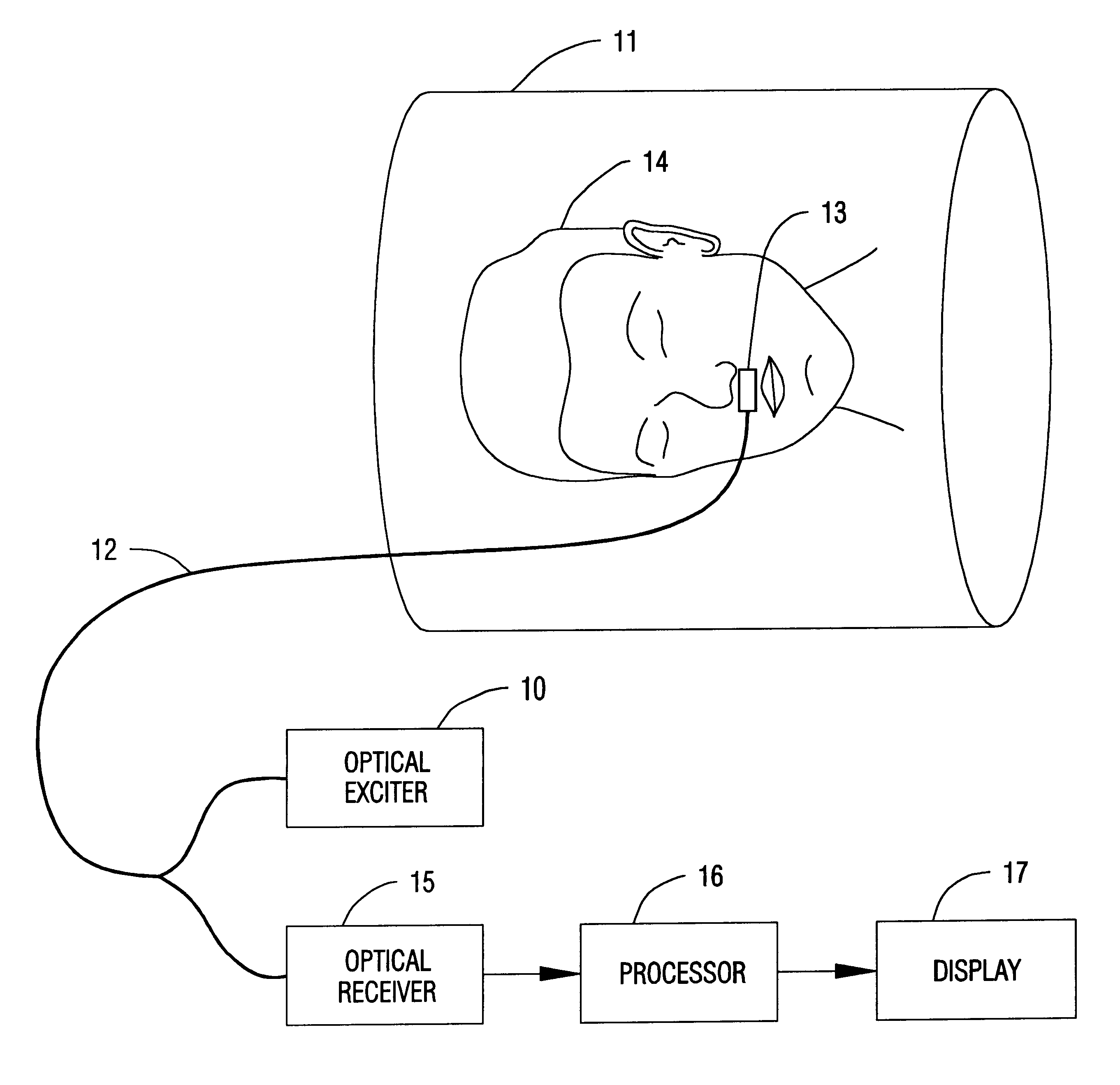

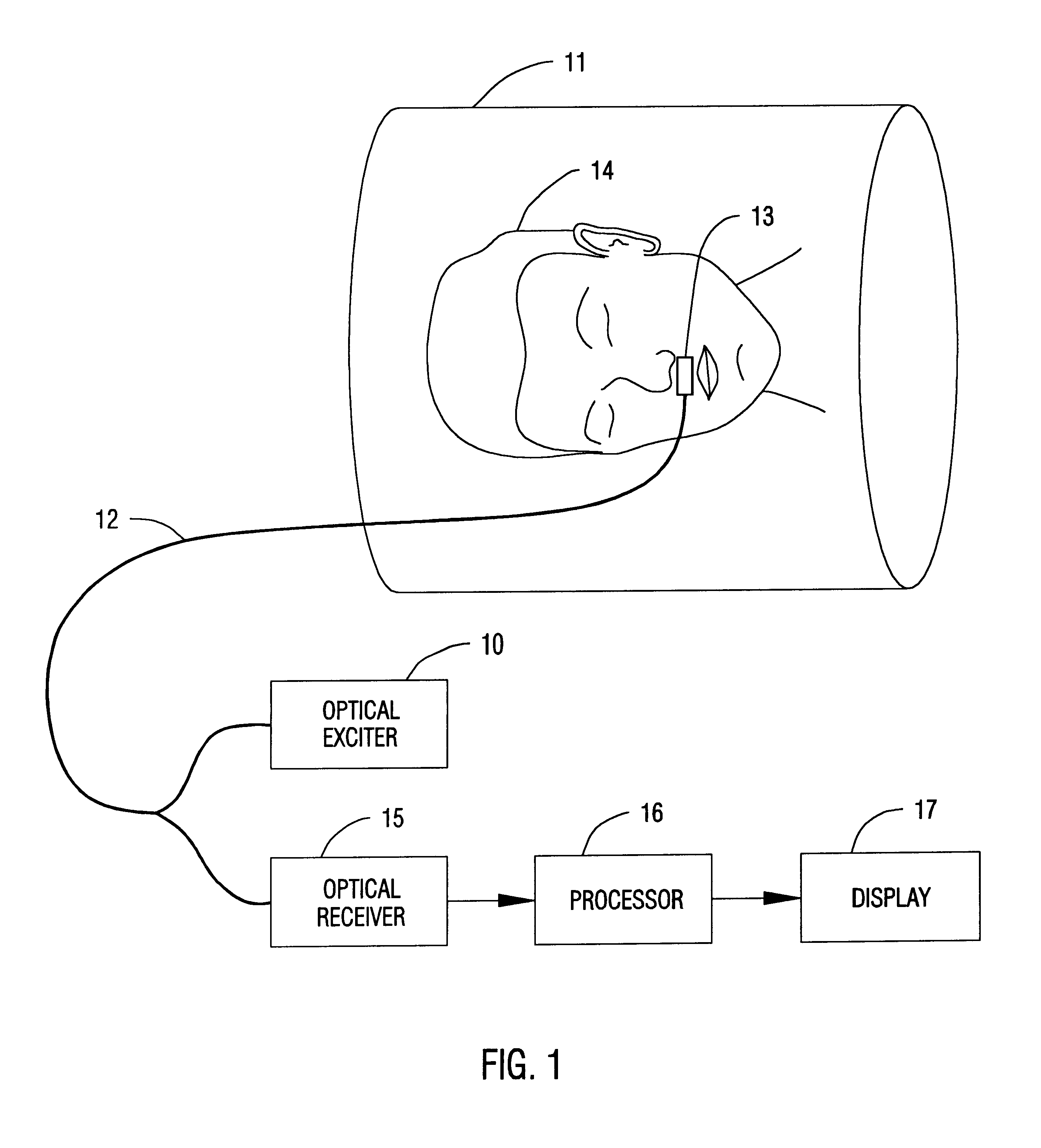

Method and apparatus for monitoring the breathing of a patient during magnetic resonance imaging

A breath sensor utilizes optical fibers to detect the flow of a patients respiratory airstream. As it has no conductive or magnetic parts, it can be used on patients within the bore of a magnetic resonance imaging system for simple, safe, and rapid assessment of a patient's breathing.

Owner:M2X

Friction wear test method and apparatus for cylinder liner piston ring component

InactiveCN1789963AEliminate the effects ofPrecise frictionMachine part testingInvestigating abrasion/wear resistanceThermal insulationPiston ring

The invention discloses a friction and abrasion testing method and equipment of cylinder piston ring element in the friction and abrasion testing technique domain, which is characterized by the following: adapting mechanic radial loading construction method and equipment to test the cylinder and piston ring element; adding liquid through heating the cylinder cavity to keep thermal; fixing the friction force sensor on the test machine rack directly; eliminating the measuring result influence of friction force by inertia force of moving component to gain more precise friction force; segregating the friction force sensor and cylinder through thermal-insulation material; setting the cooler to prevent the rack temperature from elevating and the temperature of friction force sensor from exceeding the highest working temperature. The invention is used as the rapid assessment method in the lab developing procedure of cylinder piston ring.

Owner:DALIAN MARITIME UNIVERSITY

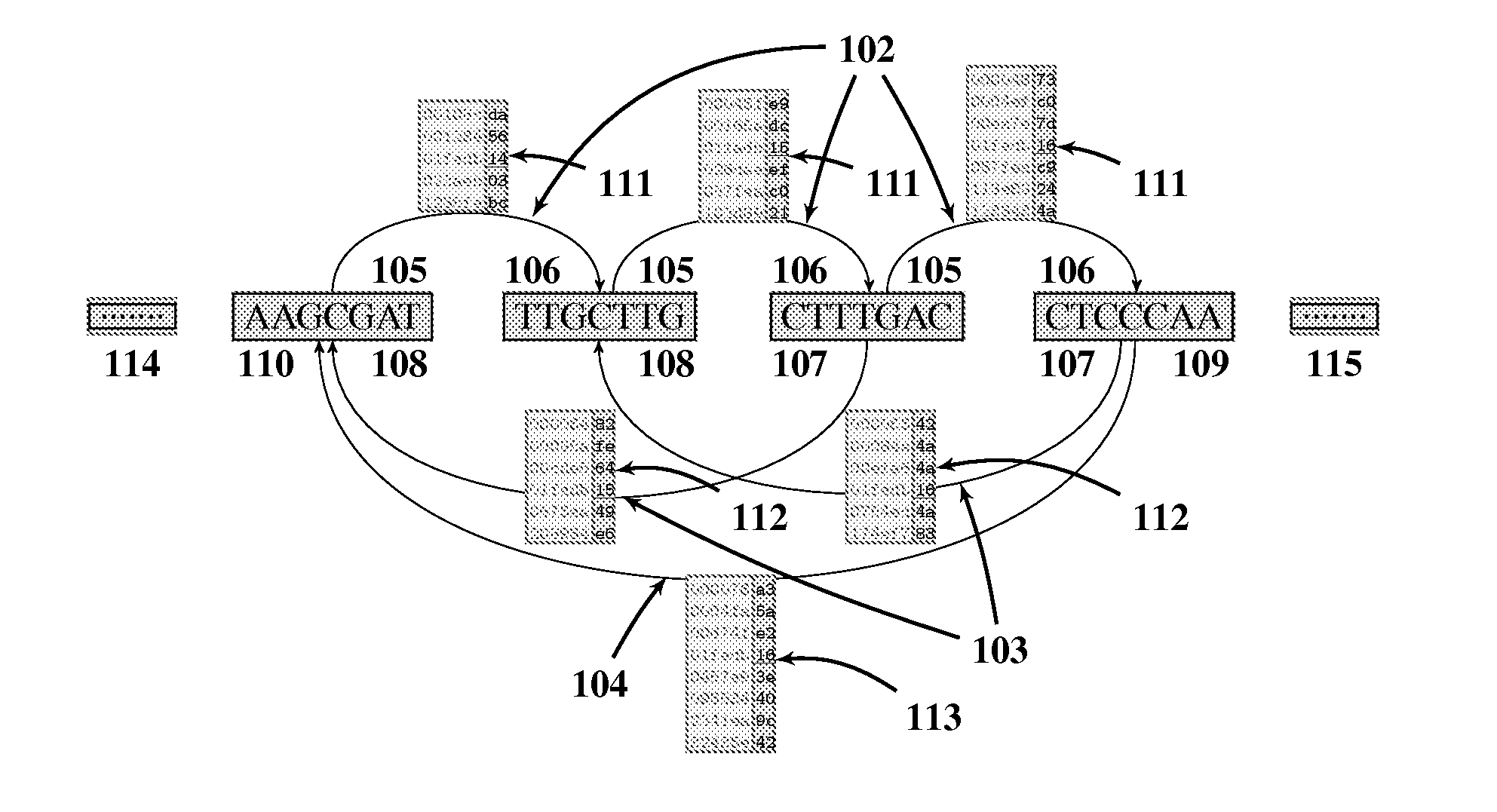

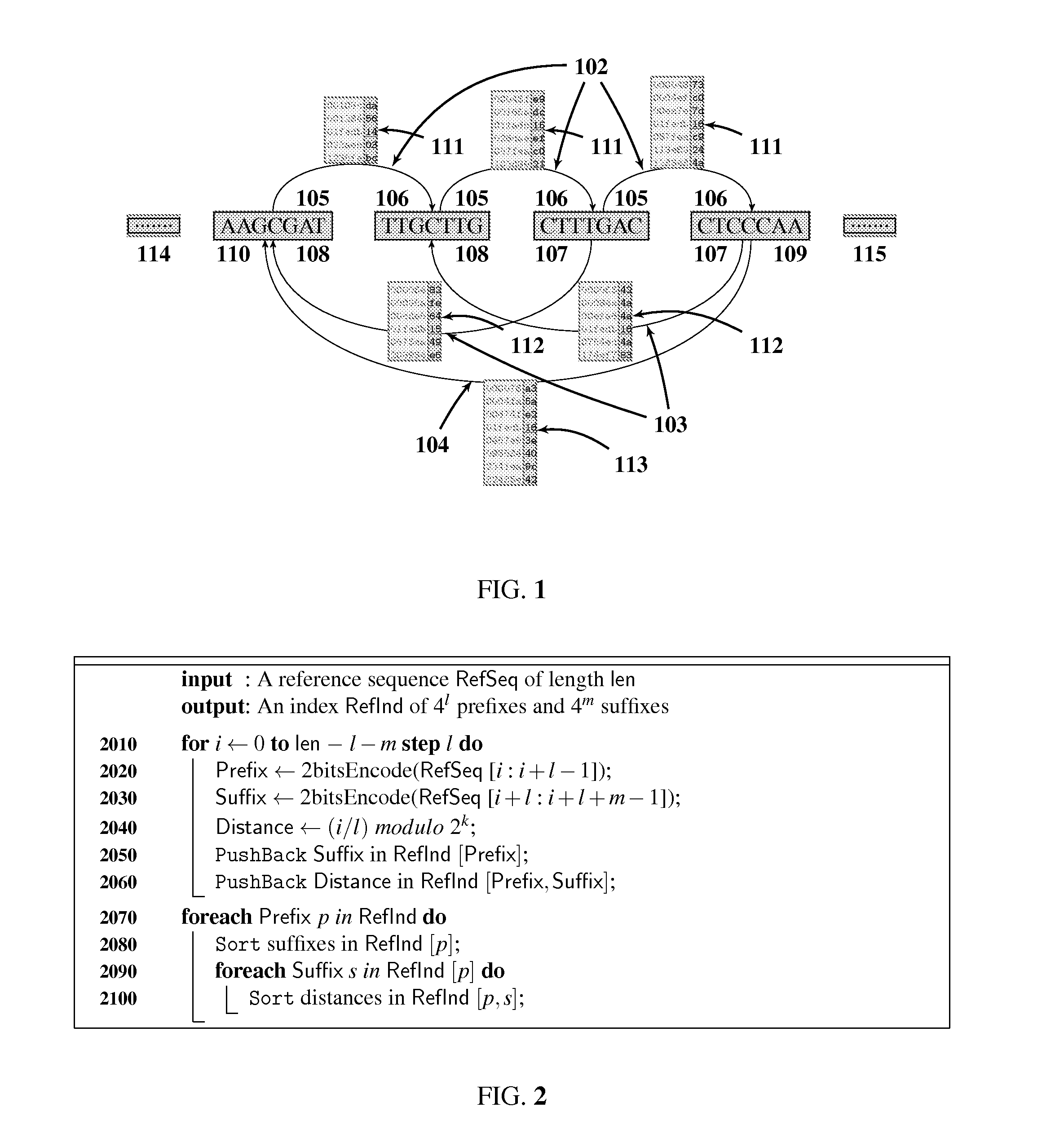

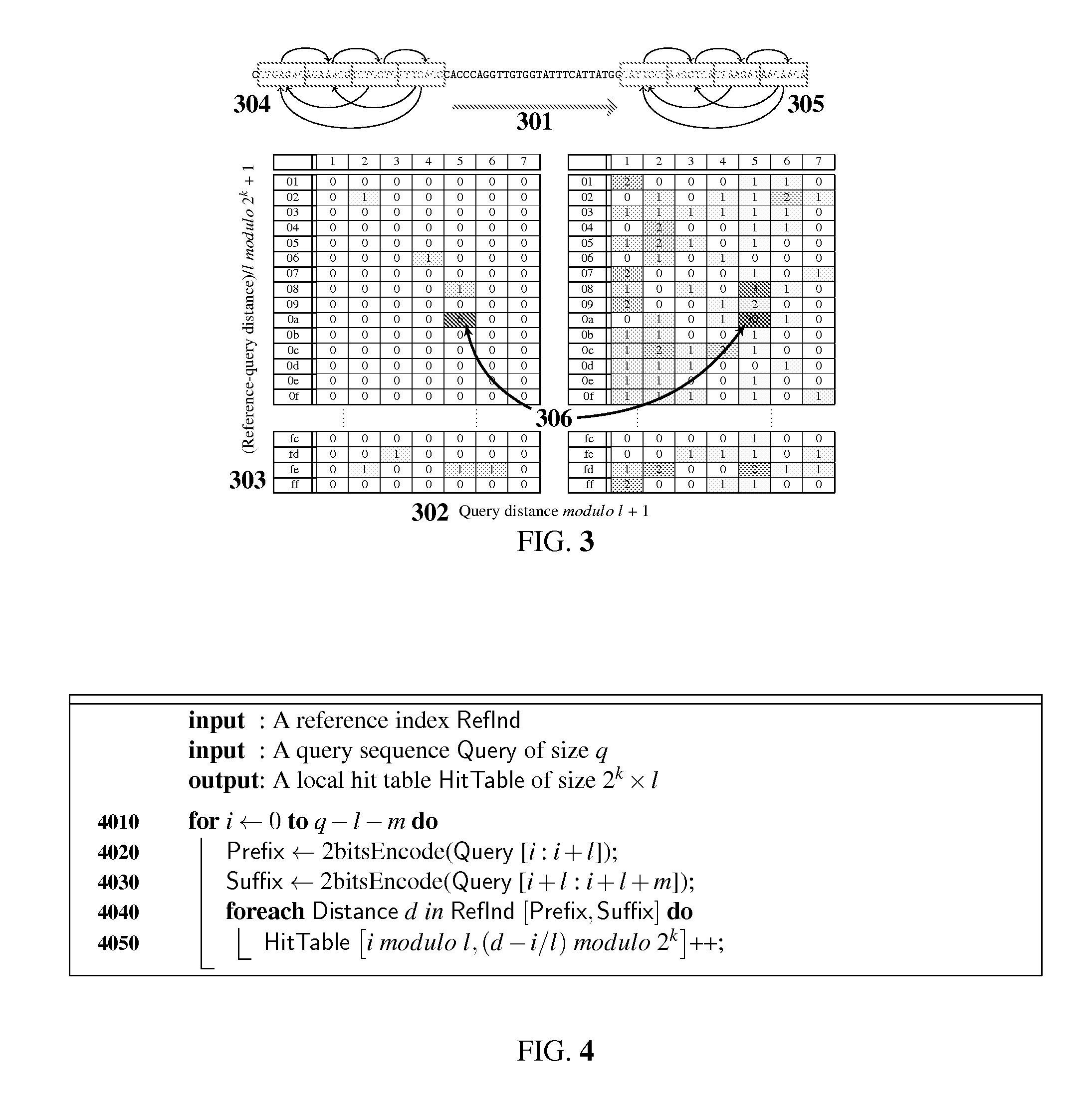

Method for rapid assessment of similarity between sequences

InactiveUS20130091121A1Increase query sensitivityImprove error toleranceDigital data processing detailsSequence analysisReference genome sequenceData mining

Genomic sequence matching and alignment techniques are disclosed. In one embodiment, an index of a reference sequence is constructed that represents all transitions from a single l-mer prefix to multiple m-mer suffixes. This index data structure may take a variety of forms, including an array or a tree. The base position of each transition from l-prefix to m-suffix is recorded in k-bit masked form. The positions data structure may take a variety of forms as well, including an array or a tree. The l-prefix, m-suffix and k-position index is used for rapid assessment of similarity between a query and a reference genomic sequence by means of a table of local hits.

Owner:QUALG

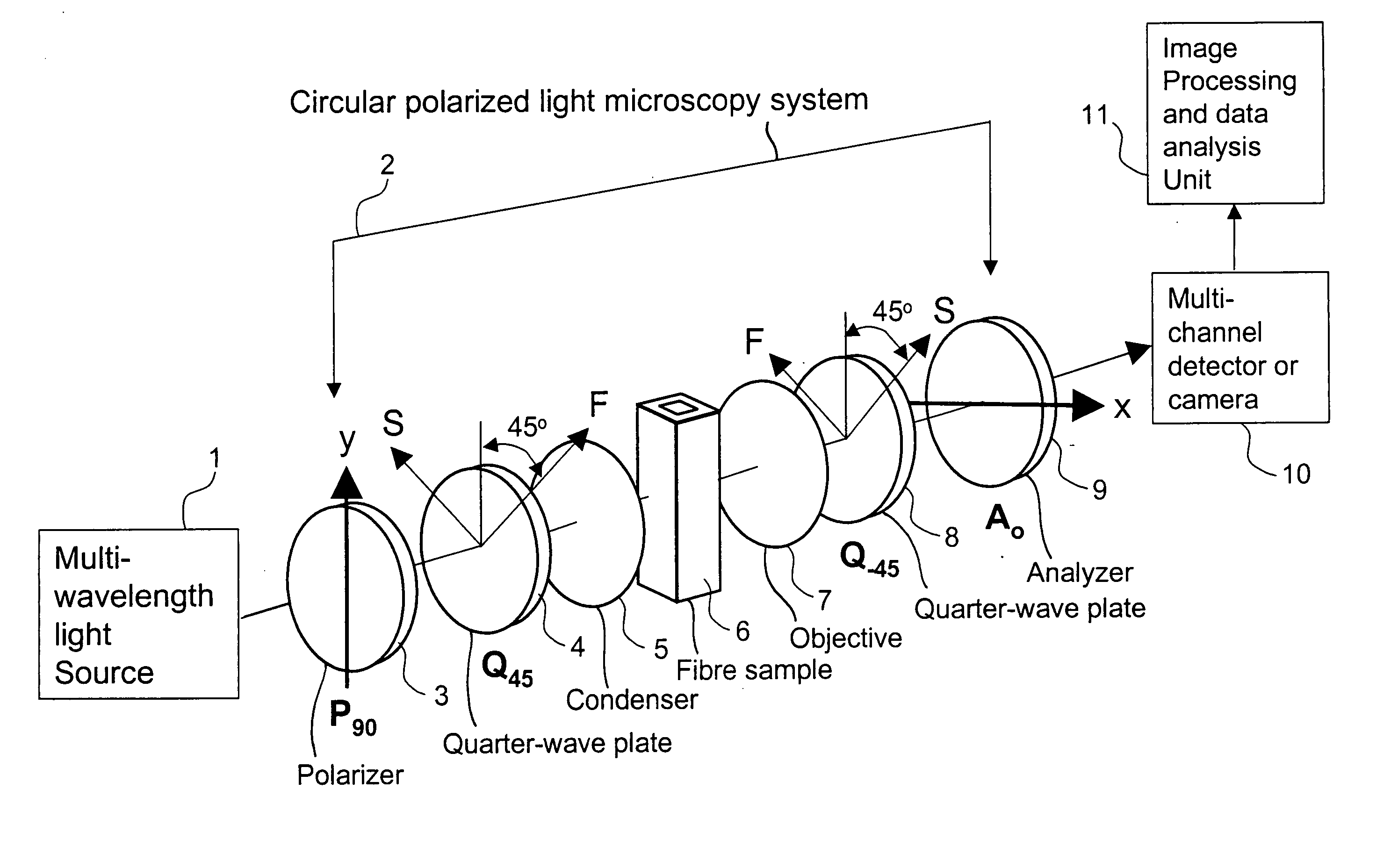

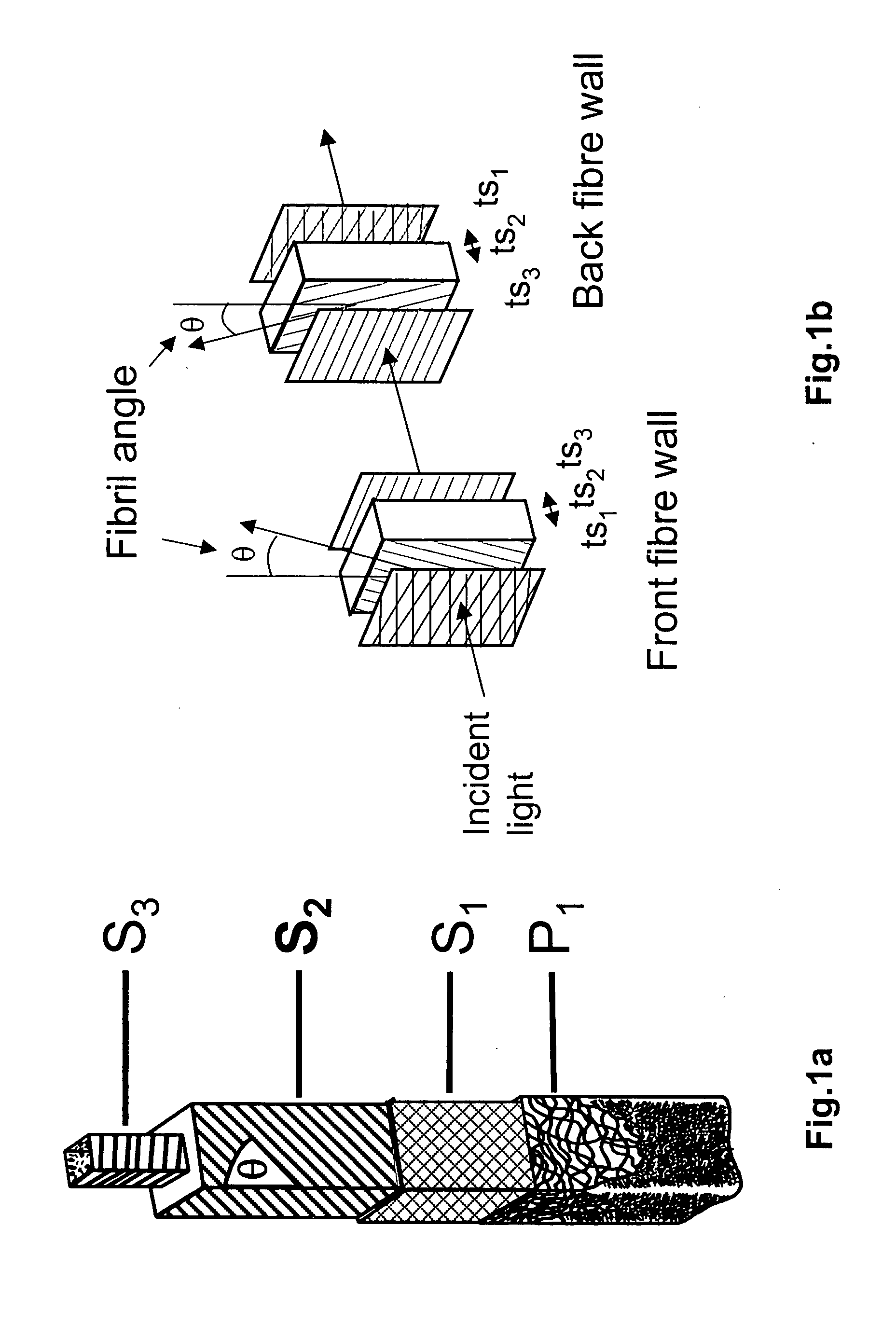

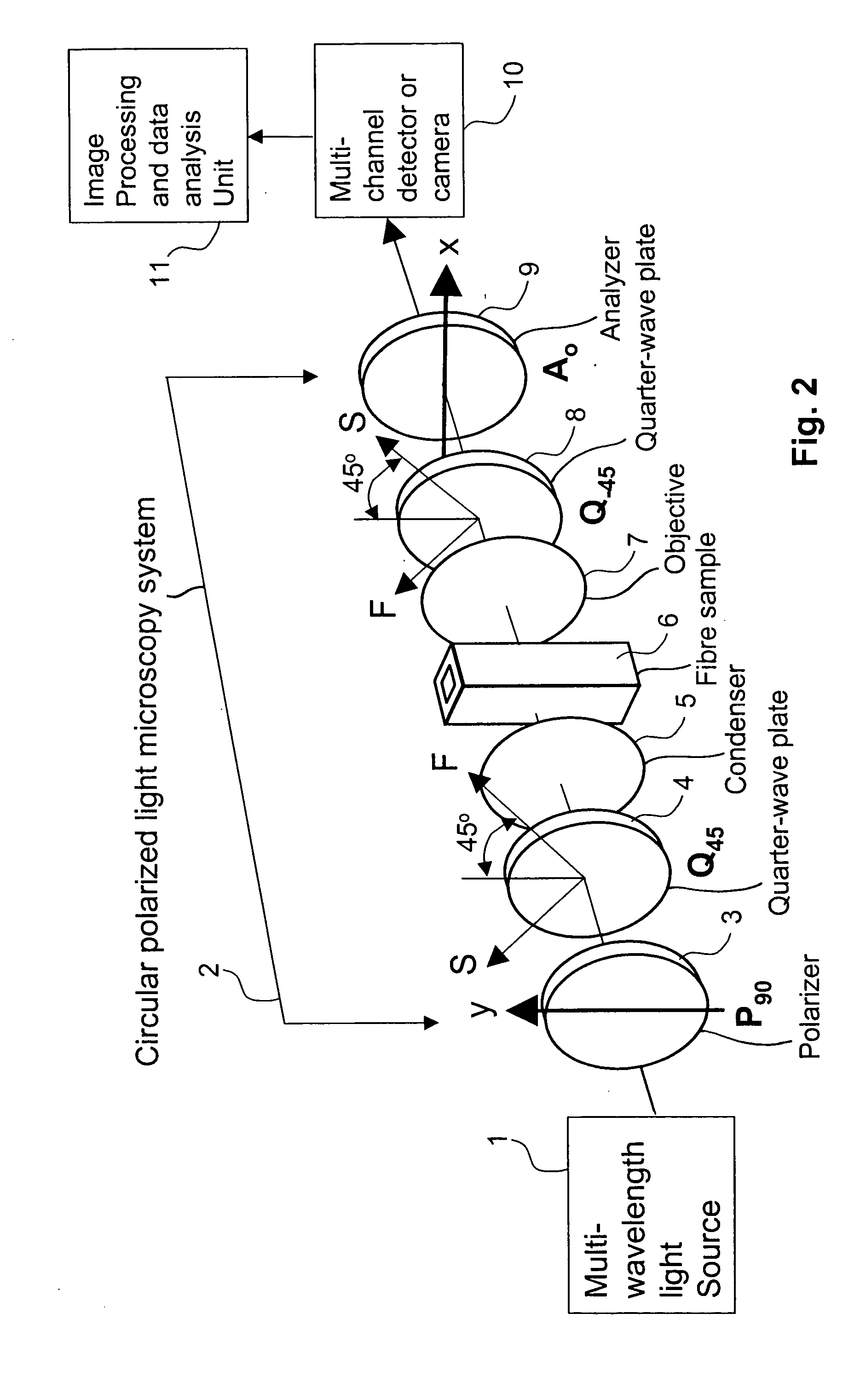

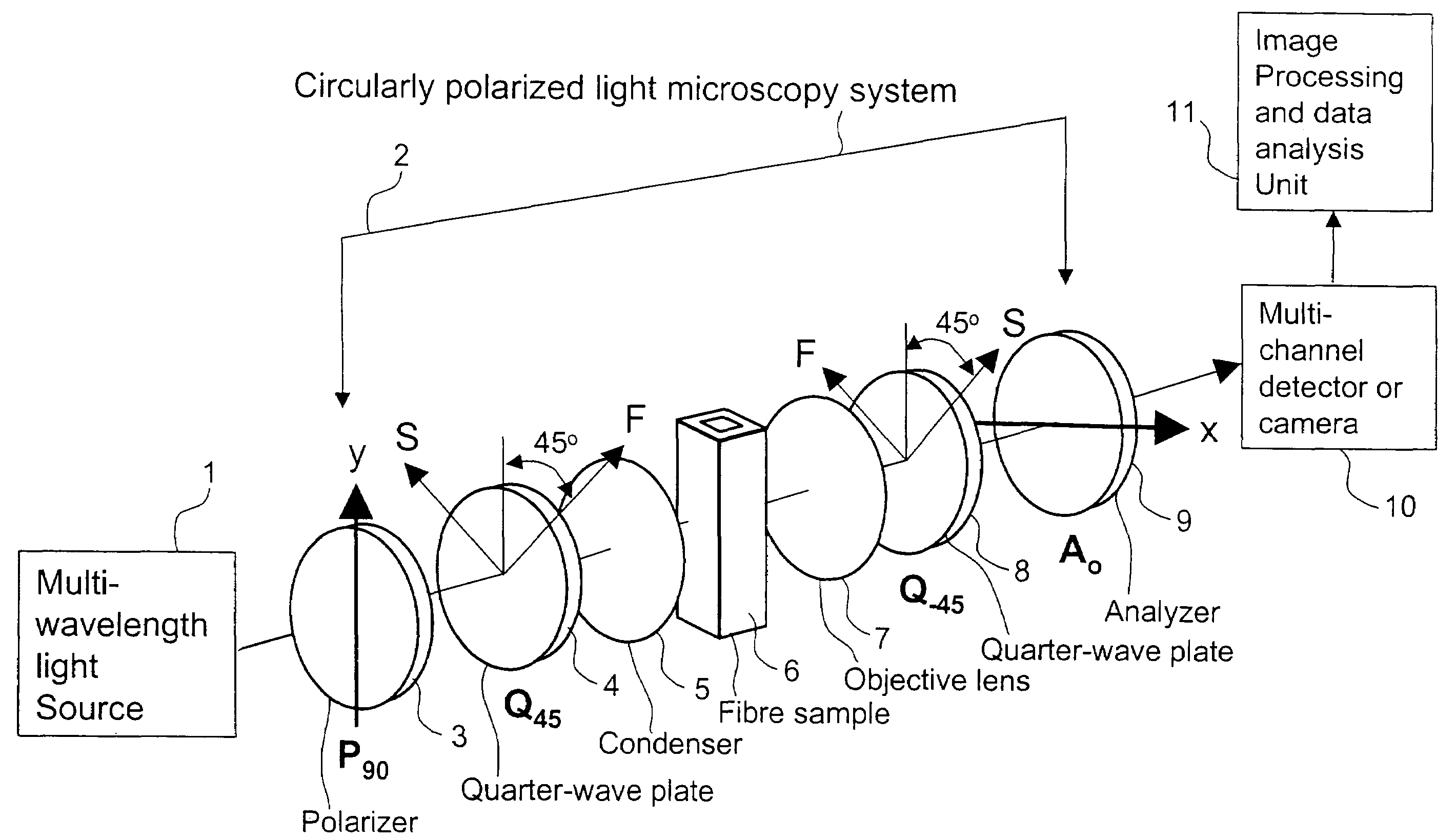

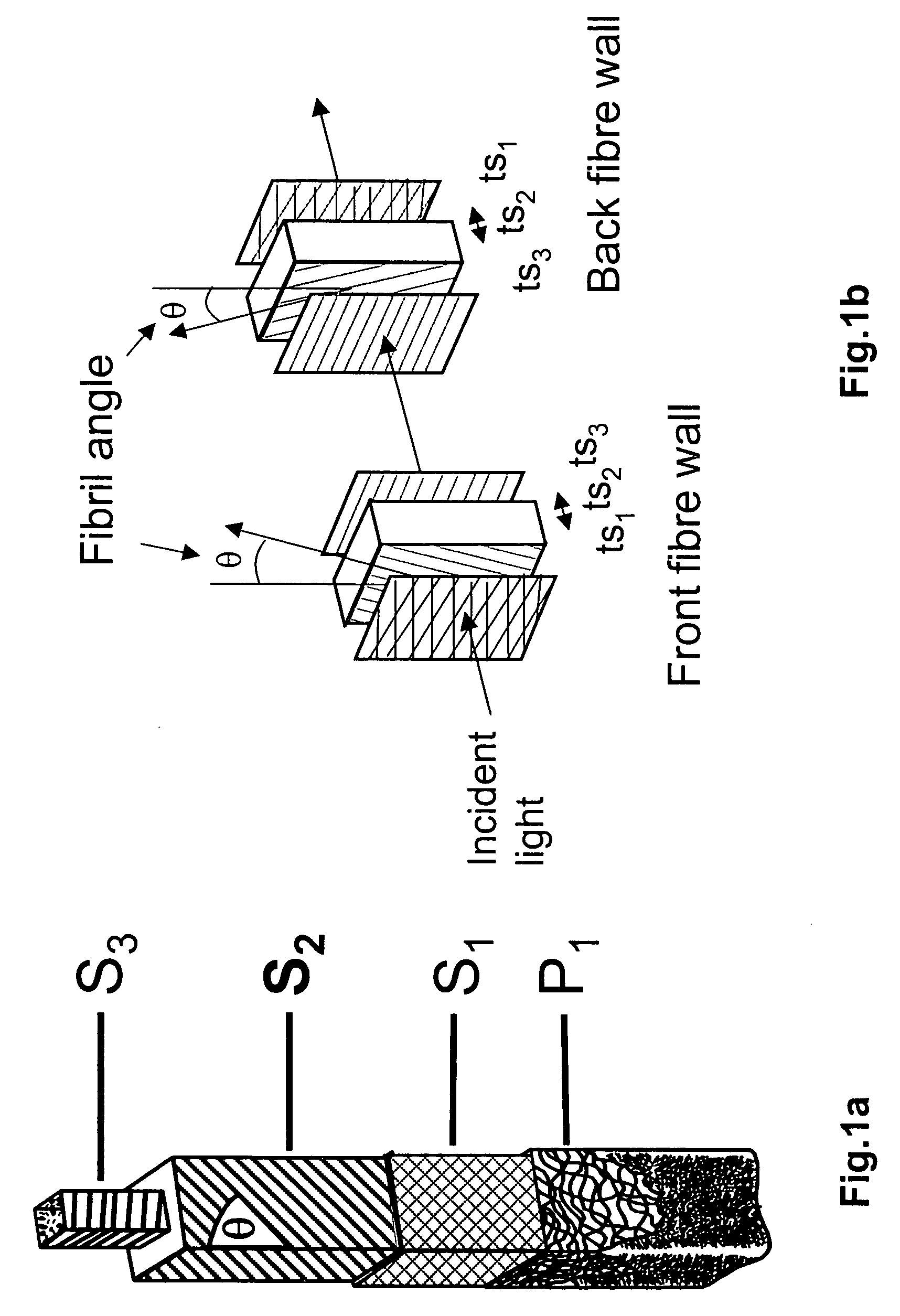

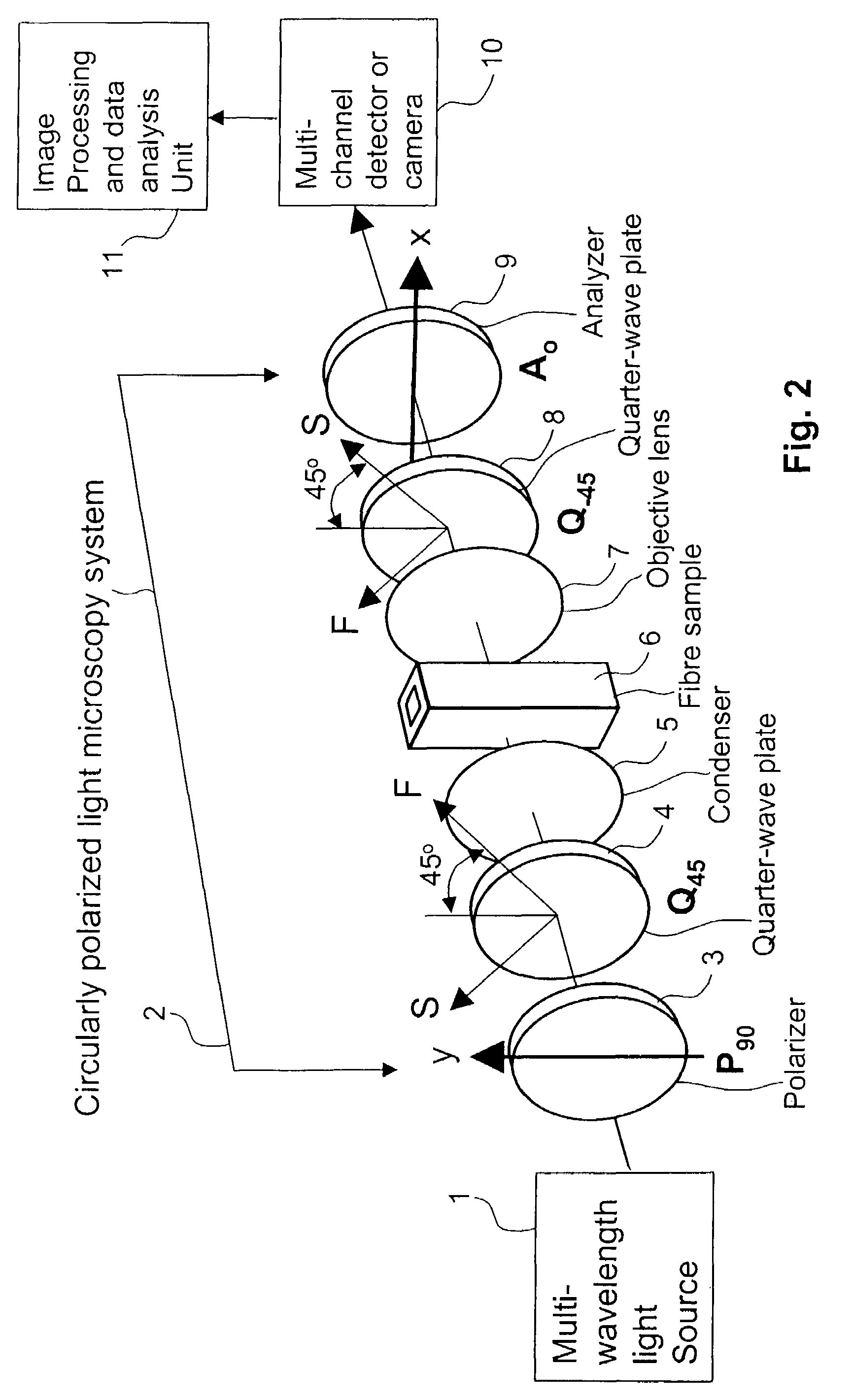

Circular polarized light method and device for determining wall thickness and orientations of fibrils of cellulosic fibres

ActiveUS20050122514A1Polarisation-affecting propertiesPhase-affecting property measurementsFibrilData analysis system

This invention provides a novel, rapid method and device for determining the relative phase retardation of a multi-layered specimen, which is related to the thicknesses of its layers and walls, and the orientations of its optical axes. An intact wood pulp fibre is a typical multi-layered birefringent specimen. This new method is based on the change of polarization of polarized light that passes through a specimen composed of birefringent layers with different optical axis orientations, such as directions of cellulosic microfibrils oriented differently in various layers of wood fibres. In particular, a novel solution is found to relate the emerging light intensity from an intact wood fibre to the incident light intensity, the wavelength of the light, and the relative phase retardations of various layers and orientations of their cellulosic microfibrils, such as fibril angle, in a circular polarized light system. This new method evaluates the transmitted light intensities of multiple predetermined wavelengths simultaneously to determine the optical and physical properties of a multi-layered specimen being measured. A device for determining the relative phase retardation (retardance) of fibre walls and the fibril angle of intact wood fibres in accordance with the presented invention comprises a light source with well defined multi-wavelengths, an achromatic circular polarized light system, appropriate imaging optics, a multi-channel camera such as a digital color camera that has two or more wavelength (color) detection channels, and an image processing and data analysis system. The measurements take advantage of the birefringence of cellulosic microfibrils, and thus require neither sample preparation nor high resolution optics. Specimen alignment is not required as specimens such as wood fibres are evaluated under circular polarized light. Compared with other methods, this invention is more rapid, accurate, and robust. This method can be automated, and implemented in a fibre flow-through system, thus allowing a rapid assessment of wood pulp fibre properties (on-line in real time).

Owner:FPINNOVATIONS INC

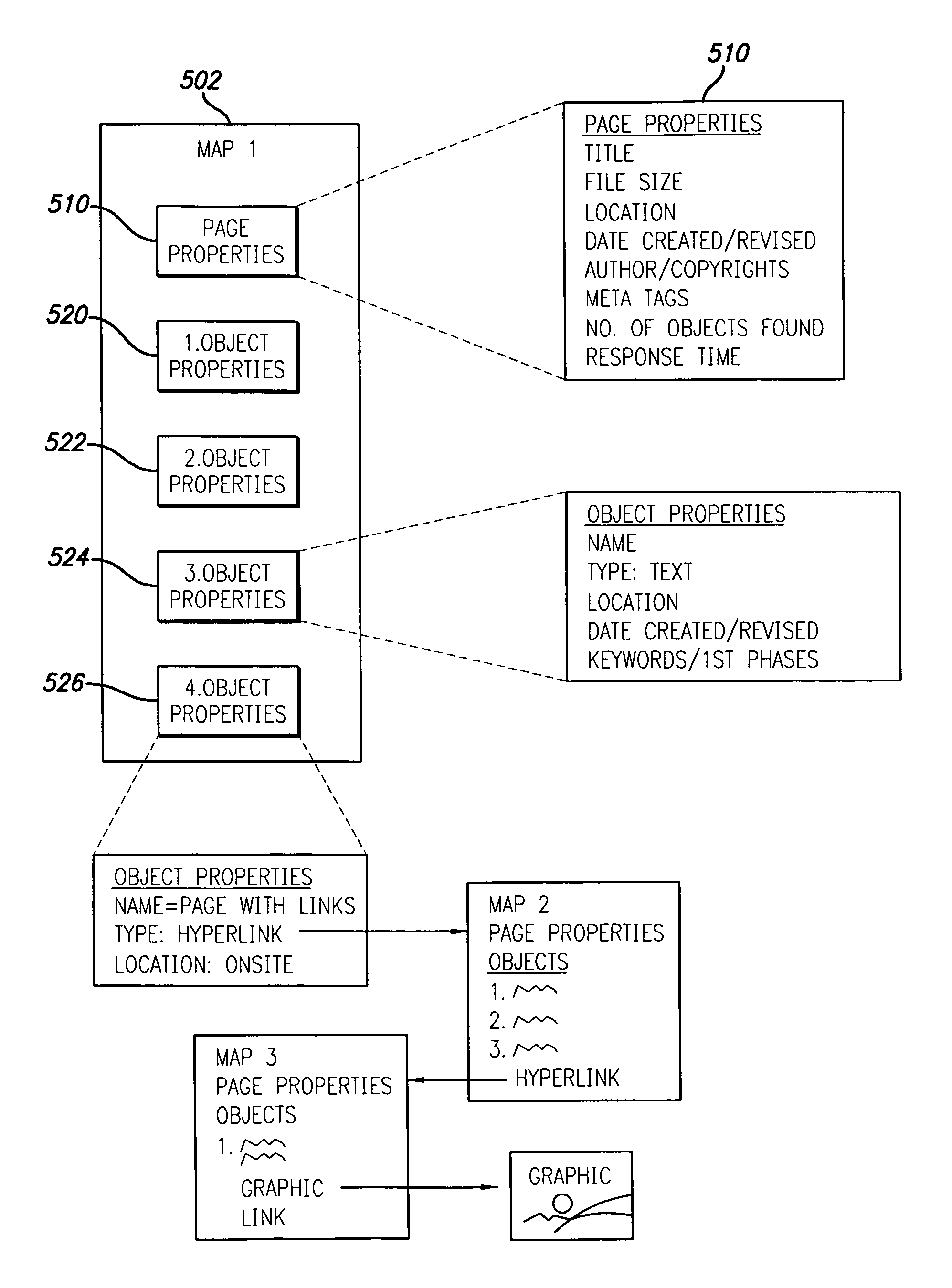

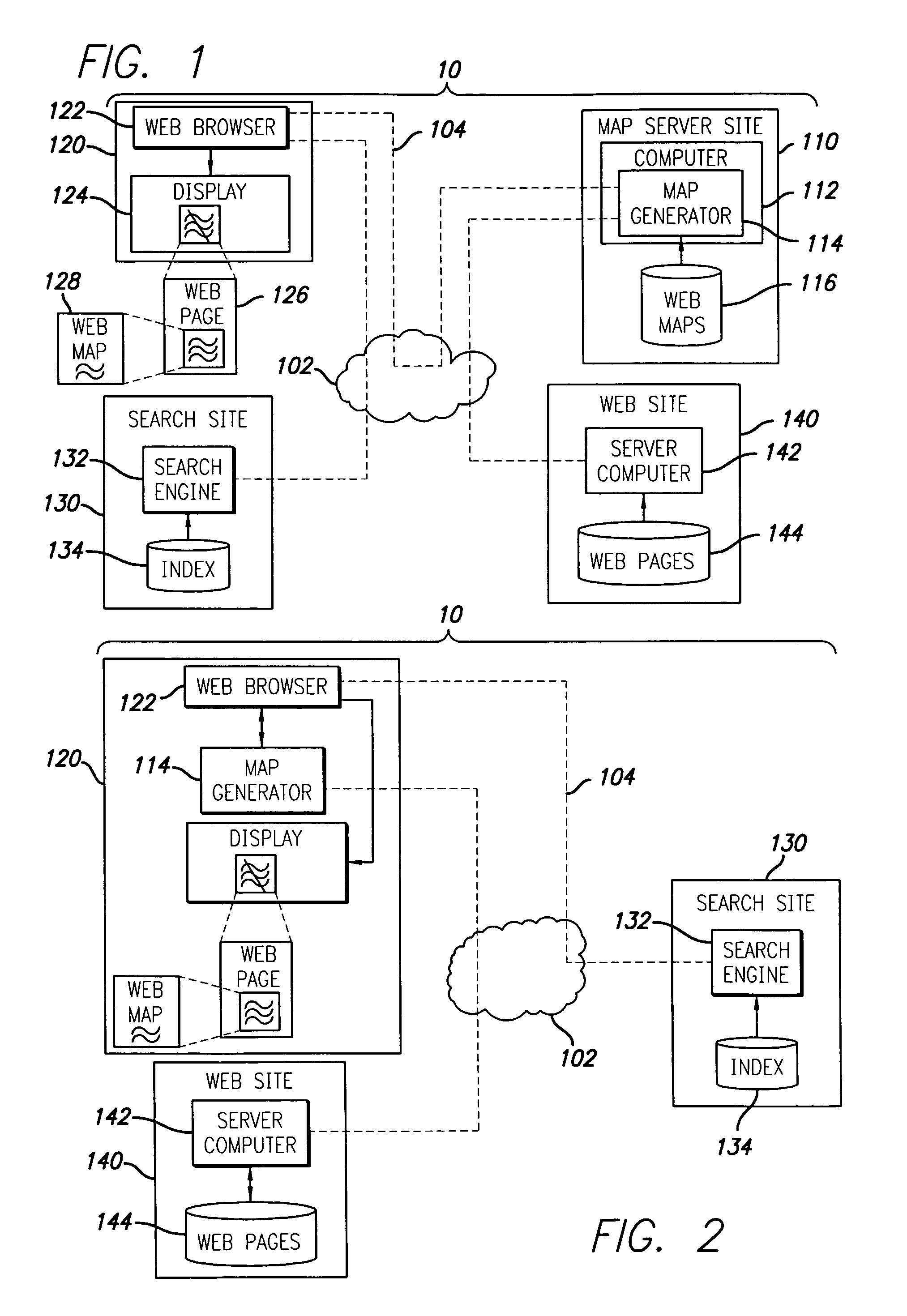

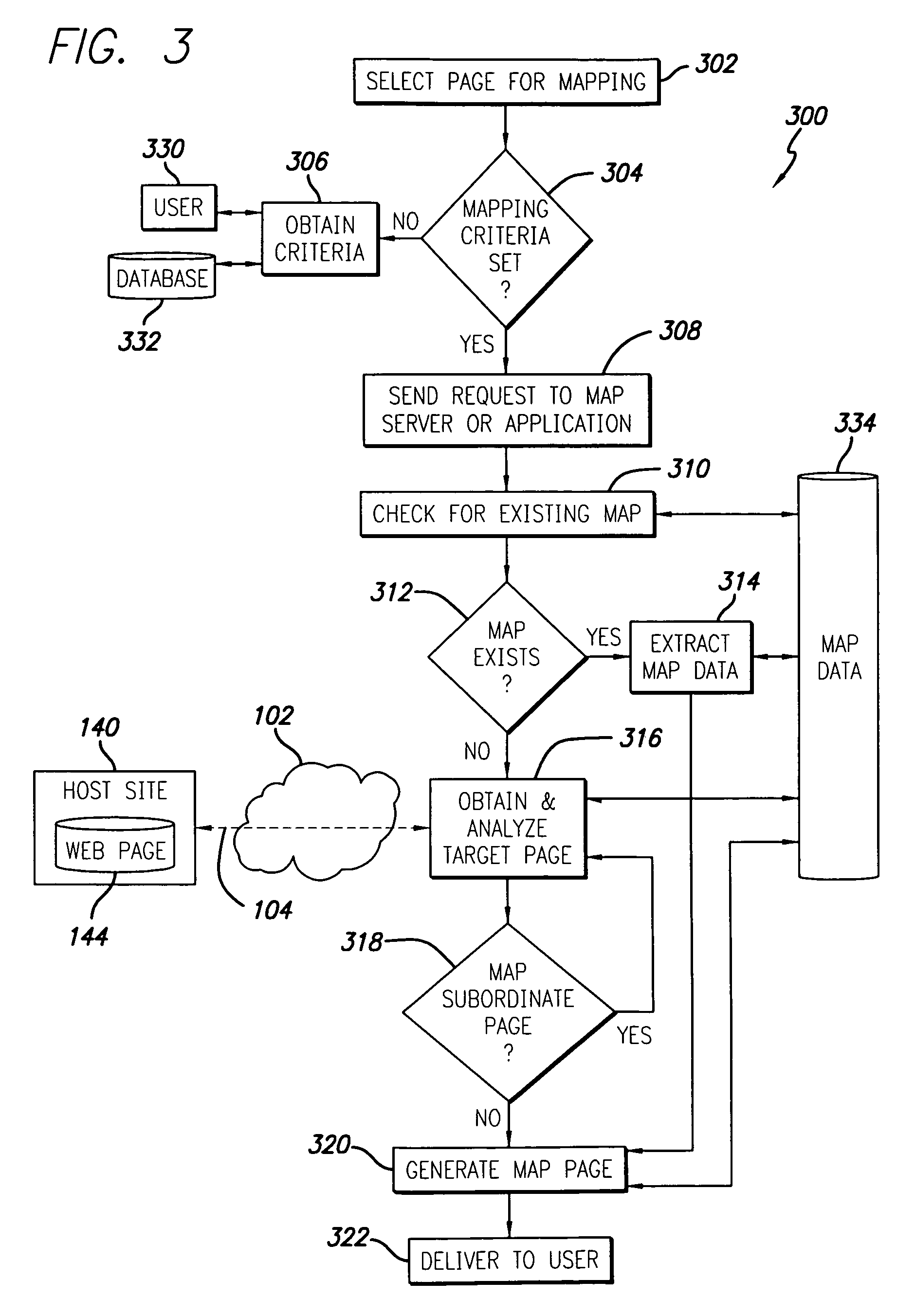

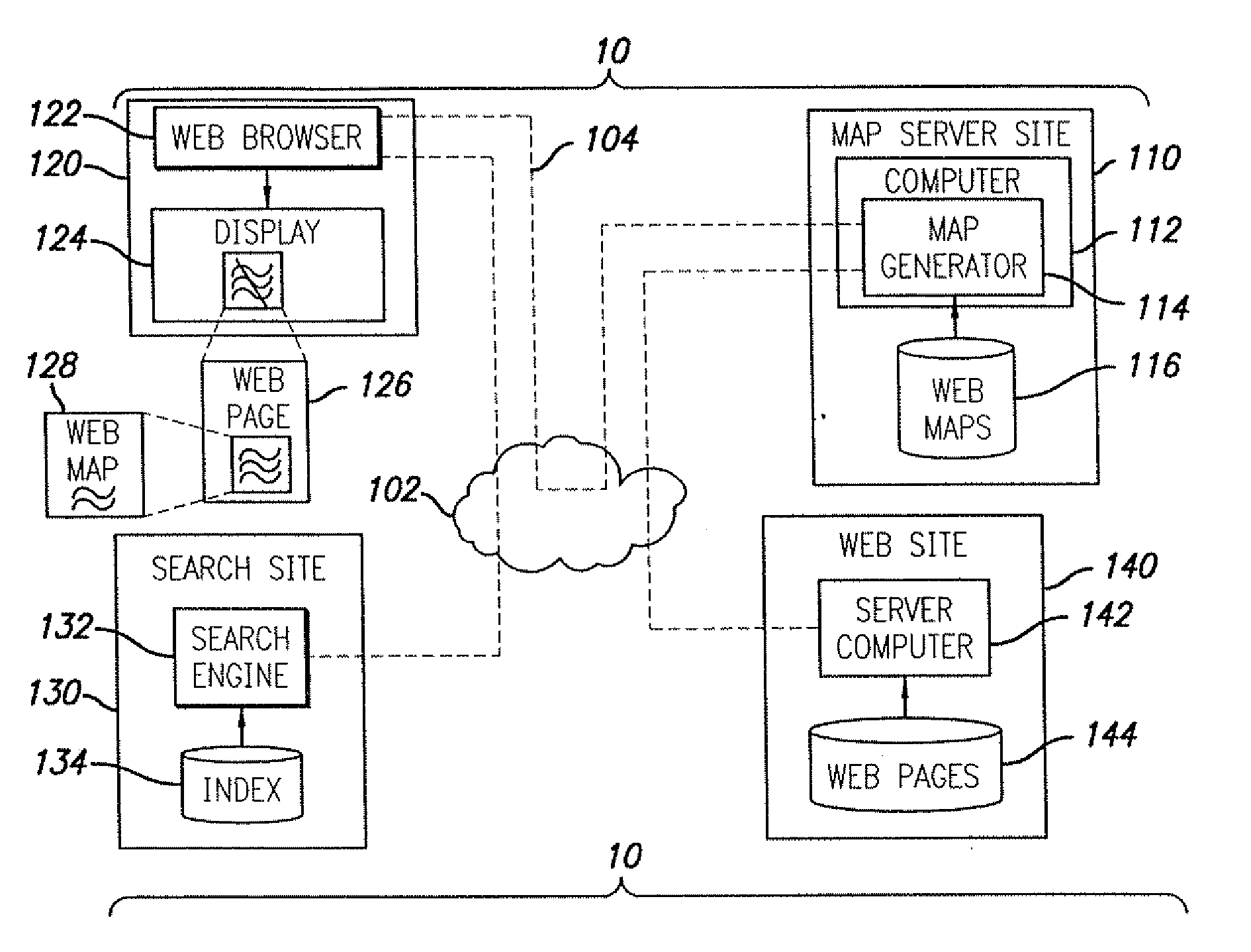

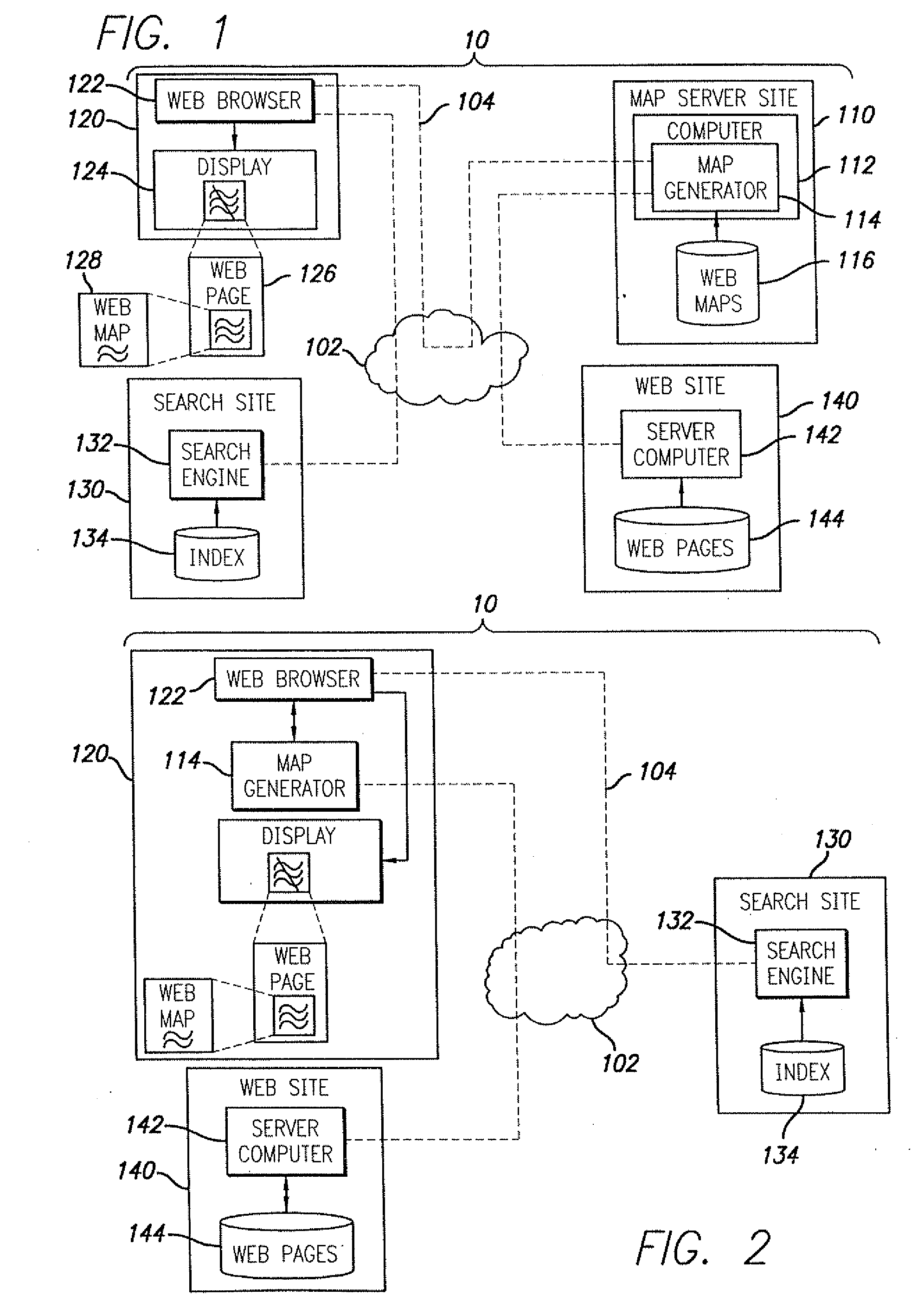

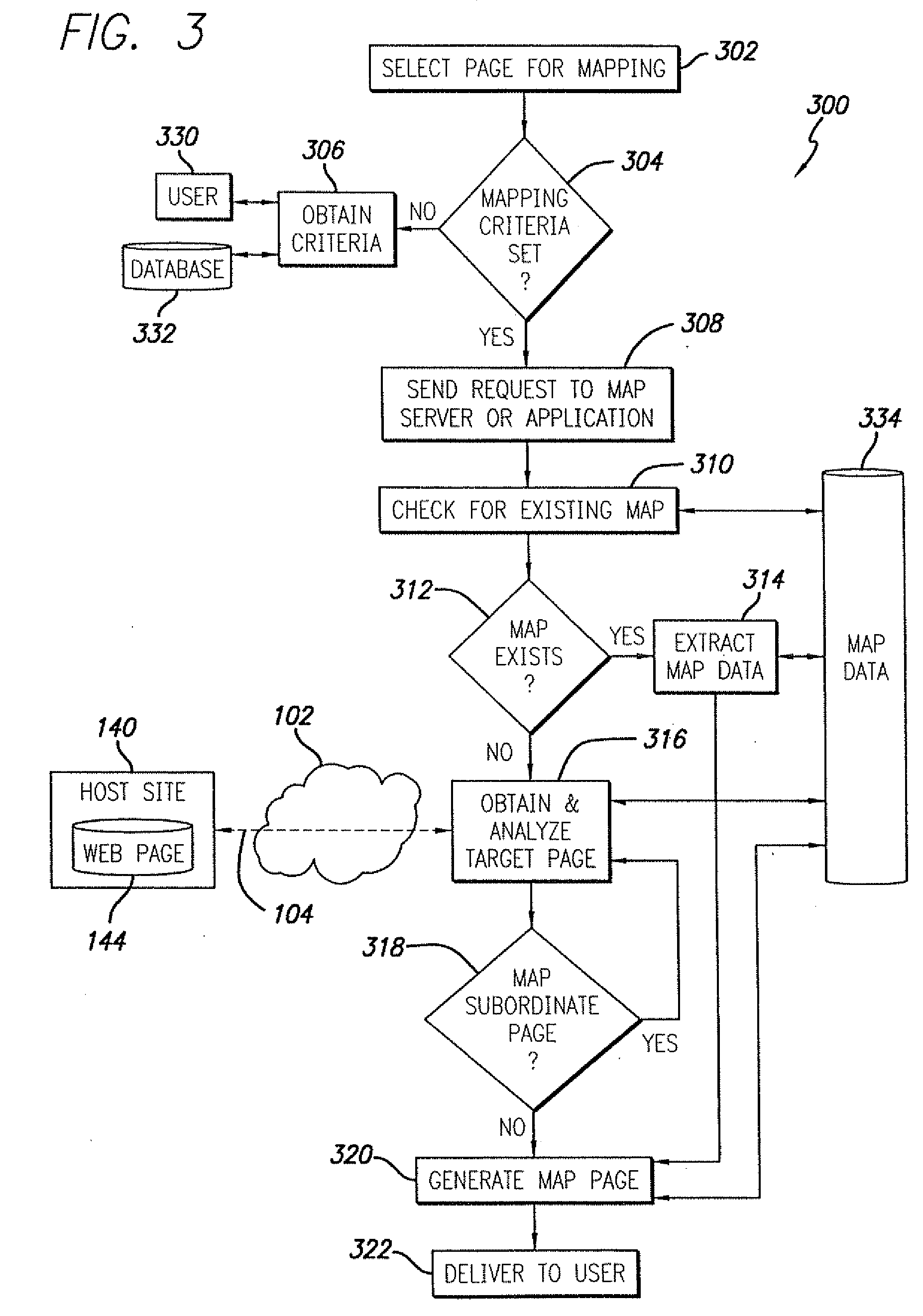

Method and apparatus for mapping a site on a wide area network

InactiveUS7546530B1Facilitates a rapid assessmentFacilitate transmissionData processing applicationsNatural language data processingWeb siteHome page

A method and system for organizing and displaying information about Internet Web pages creates Web maps. The Web maps display a summary of the information that a Web page provides access to, in a format that facilitates a rapid assessment of what may be accessed through a Web site's home page, or through any Web page on the Web site. Preferably, Web maps are displayed on a Web page, or within a frame of a Web page, by an Internet browser application. A set of Web maps may be automatically generated by a search engine or directory in response to a user's search request. Alternatively, a user may request that a Web map be produced for a particular Web page of interest. The Web maps are preferably generated by a Web server, or by an application running in the background of a user's computer, so that the user may perform other tasks on the user's computer while the Web maps are being generated.

Owner:INTELLECTUAL VENTURES I LLC

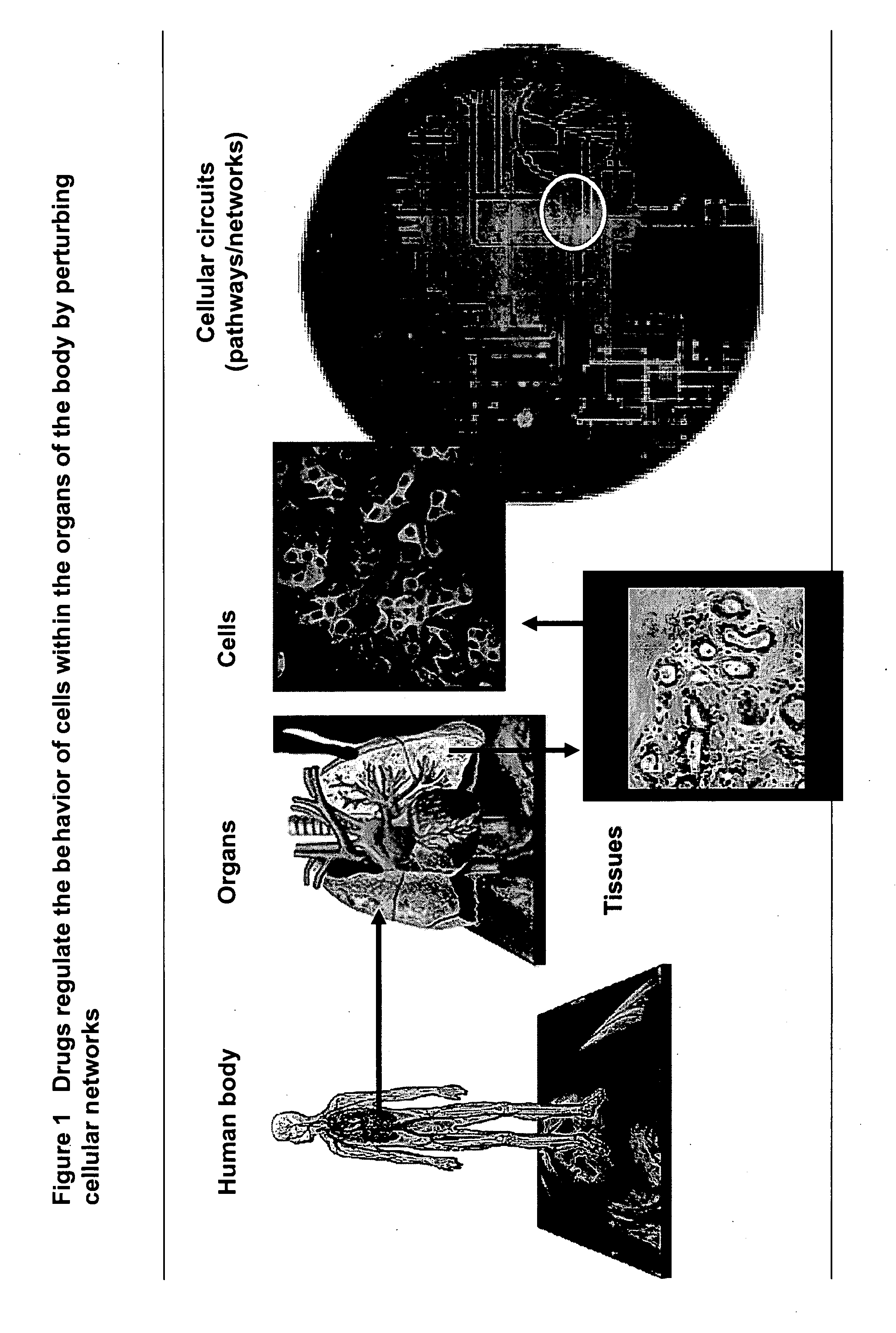

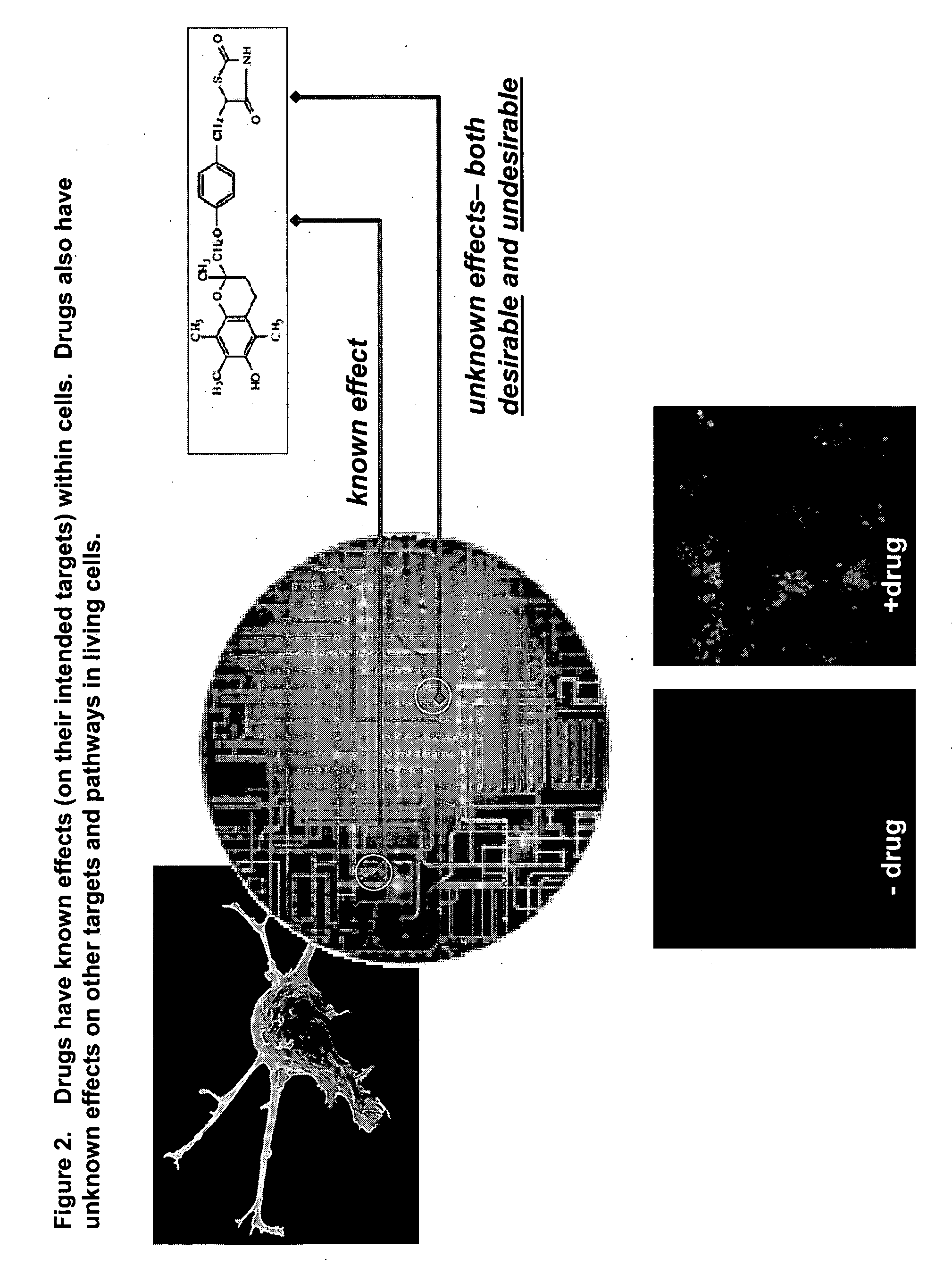

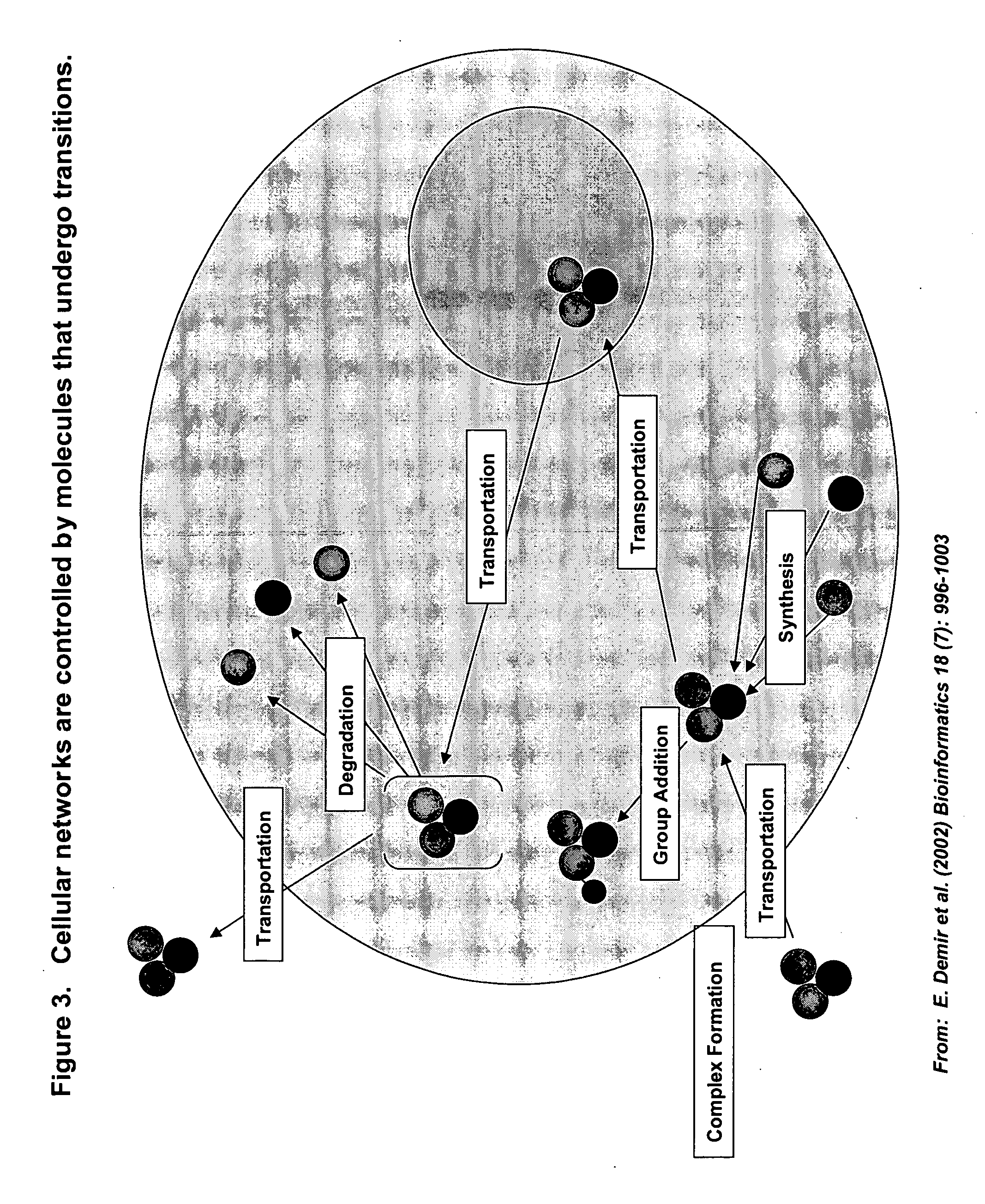

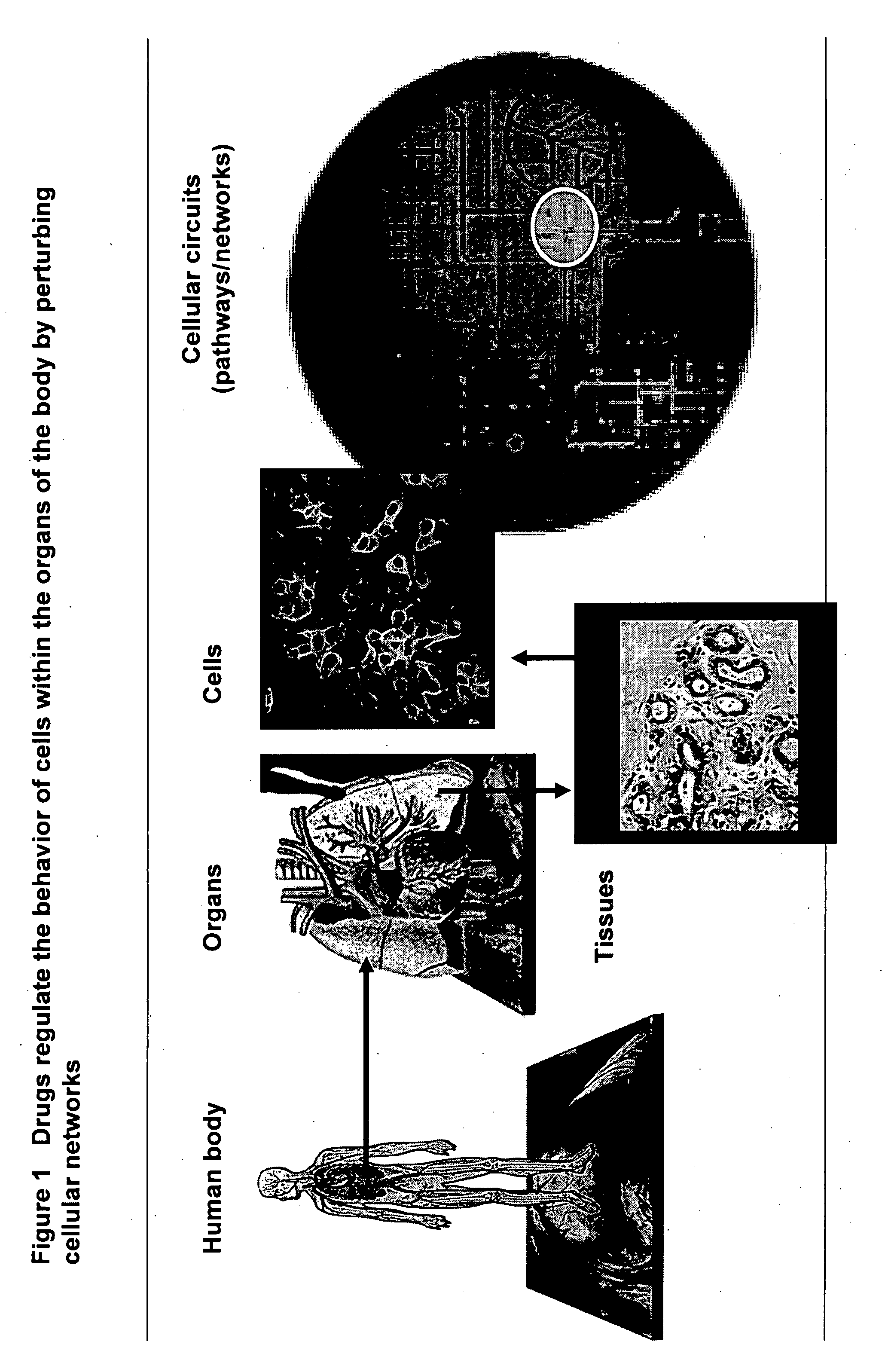

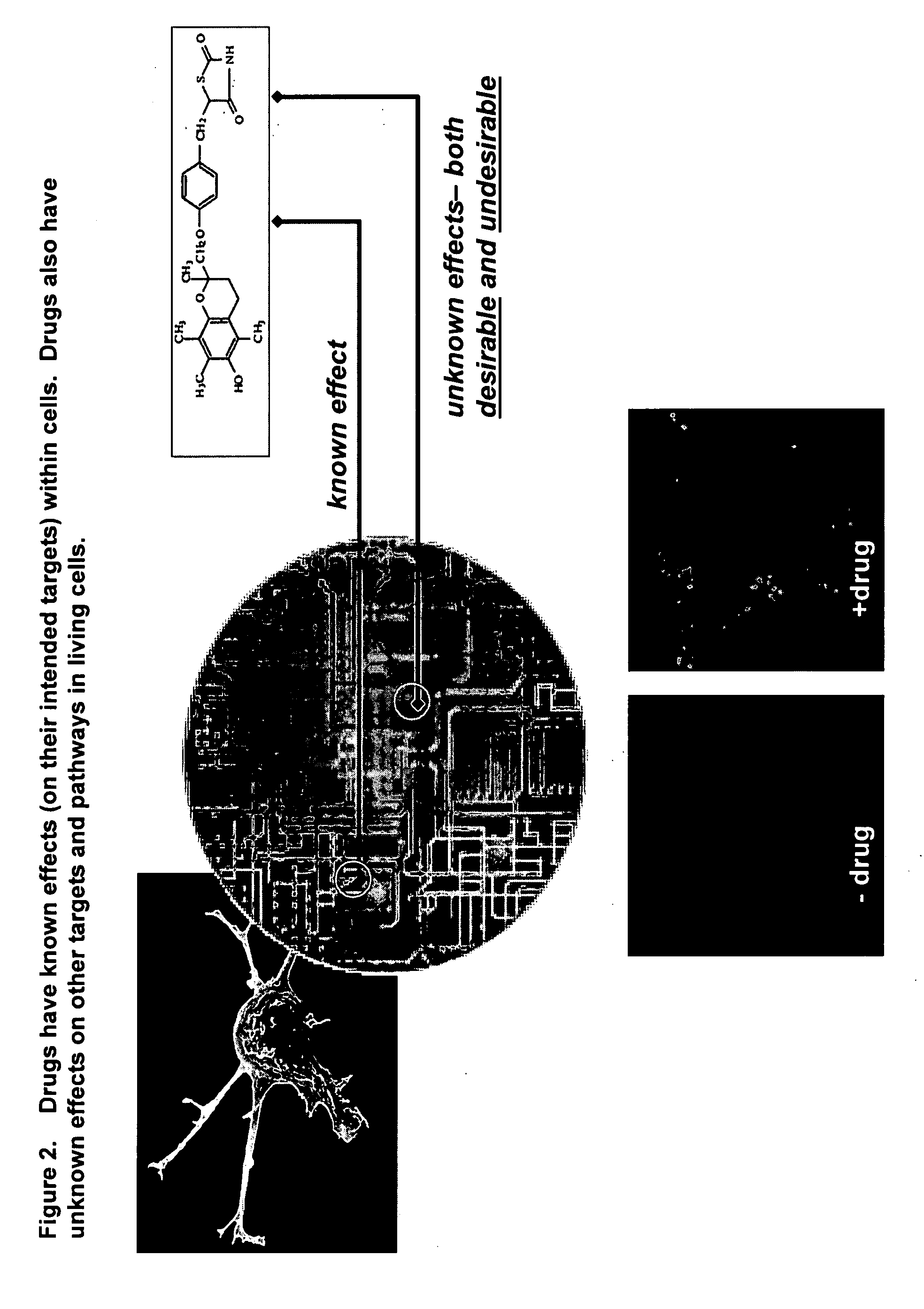

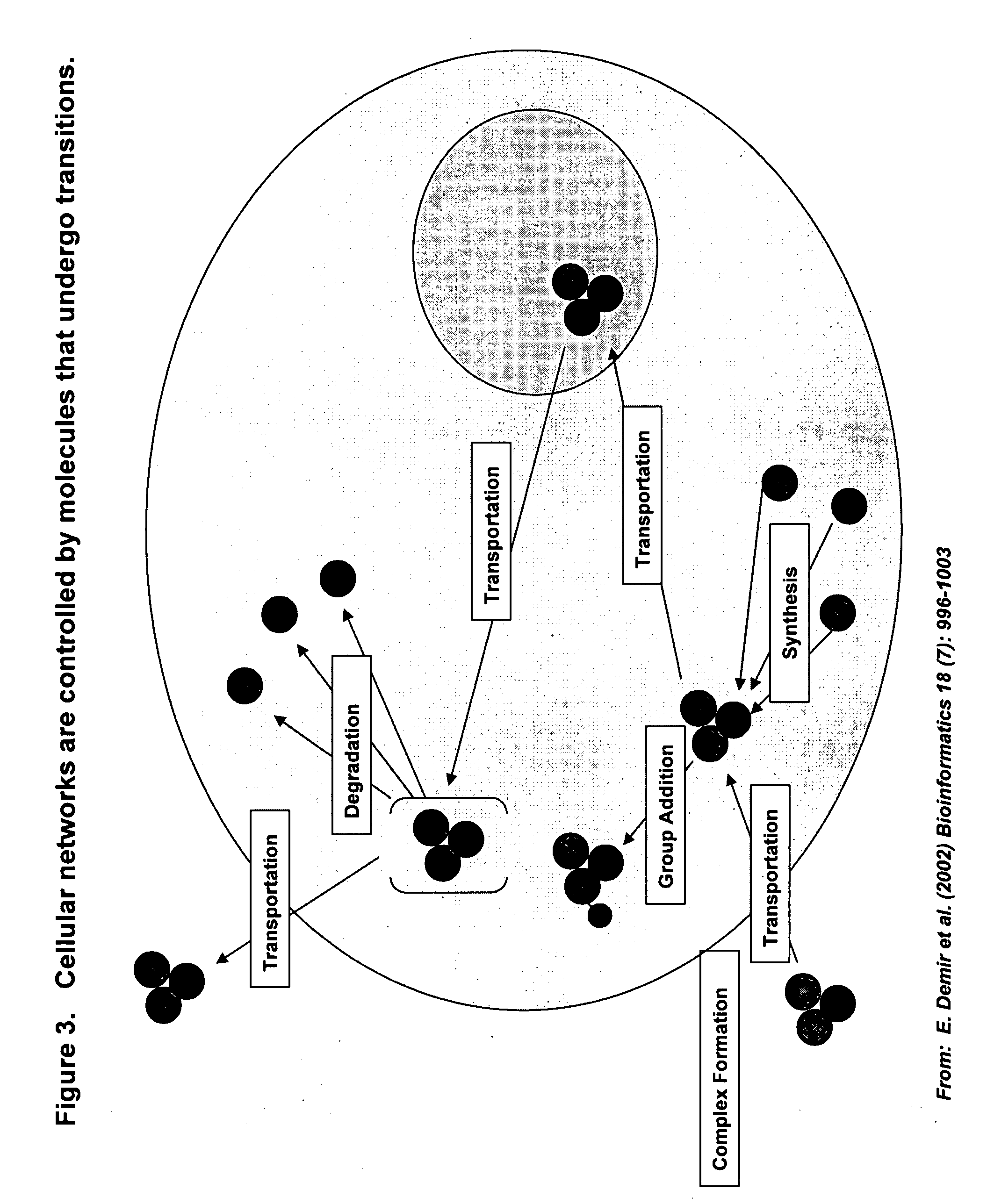

Harnessing network biology to improve drug discovery

InactiveUS20060160109A1Enable optimizationMaterial nanotechnologyPeptide librariesToxicantOn pathway

This invention provides principles, methods and compositions for ascertaining the mechanism of action of pharmacologically important compounds in the context of network biology, across the entire scope of the complex pathways of living cells. Importantly, the principles, methods and compositions provided allow a rapid assessment of the on-pathway and off-pathway effects of lead compounds and drug candidates in living cells, and comparisons of lead compounds with well-characterized drugs and toxicants to identify patterns associated with efficacy and toxicity. The invention will be useful in improving the drug discovery process, in particular by identifying drug leads with desired safety and efficacy and in effecting early attrition of compounds with potential adverse effects in man.

Owner:ODYSSEY THERA INC

Detection method of lithium ion battery performance

InactiveCN106168652AShorten the timeLow costElectrical testingSecondary cells charging/dischargingElectrical batteryEngineering

The invention provides a detection method of lithium ion battery performance. Under different temperatures, charge and discharge processing is carried out on a lithium ion battery with different charge and discharge rates, lithium detection is carried out on the battery after 3-20 times of circulation, the service lifetime of the battery and the charge safety under different temperatures are estimated and predicted according to whether lithium precipitates out on the surface of a cathode in the battery, and the lithium precipitation degree is used to judge the impedance in the battery, so that the risk is rapidly estimated, the time of battery comprehensive performance estimation is shortened, the estimation efficiency is improved, and the cost of battery performance estimation is lowered, the identification and prevention capability of the battery safety risk is improved, and the testing number is only 10-20 pcs.

Owner:LENOVO (BEIJING) LTD

Rapid estimation method for earthquake disaster damage based on GIS technology

InactiveCN1828336AQuick ViewRealize managementSeismic signal transmissionSeismic signal processingGraphicsEstimation methods

Wherein, it relates to a GIS platform, a database, and remote data exchange software. The system can query data, display result, maintains and converts between data and image; it can automatic evaluate loss according to damage sample data, and outputs evaluation report.

Owner:张路平

Systems, Methods and Devices for the Rapid Assessment and Deployment of Appropriate Modular Aid Solutions in Response to Disasters

InactiveUS20150179038A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsComputer moduleStructure of Management Information

An embodiment of a disaster response system is disclosed that includes a communication and monitoring environment (CME). The CME includes an incident command infrastructure, and a communication infrastructure configured to exchange data with the incident command infrastructure. The communication infrastructure includes a network comprising a plurality of sensor assemblies that are configured to wirelessly communicate with the communication infrastructure. The sensor assemblies are configured to acquire data that includes at least one of environmental conditions, motion, position, chemical detection, and medical information. One or more of the sensors are configured to aggregate data from a subset of the plurality of sensors. The CME is configured to detect an incident based on at least the data acquired by the sensor assemblies.

Owner:DANIEL SIMON R +4

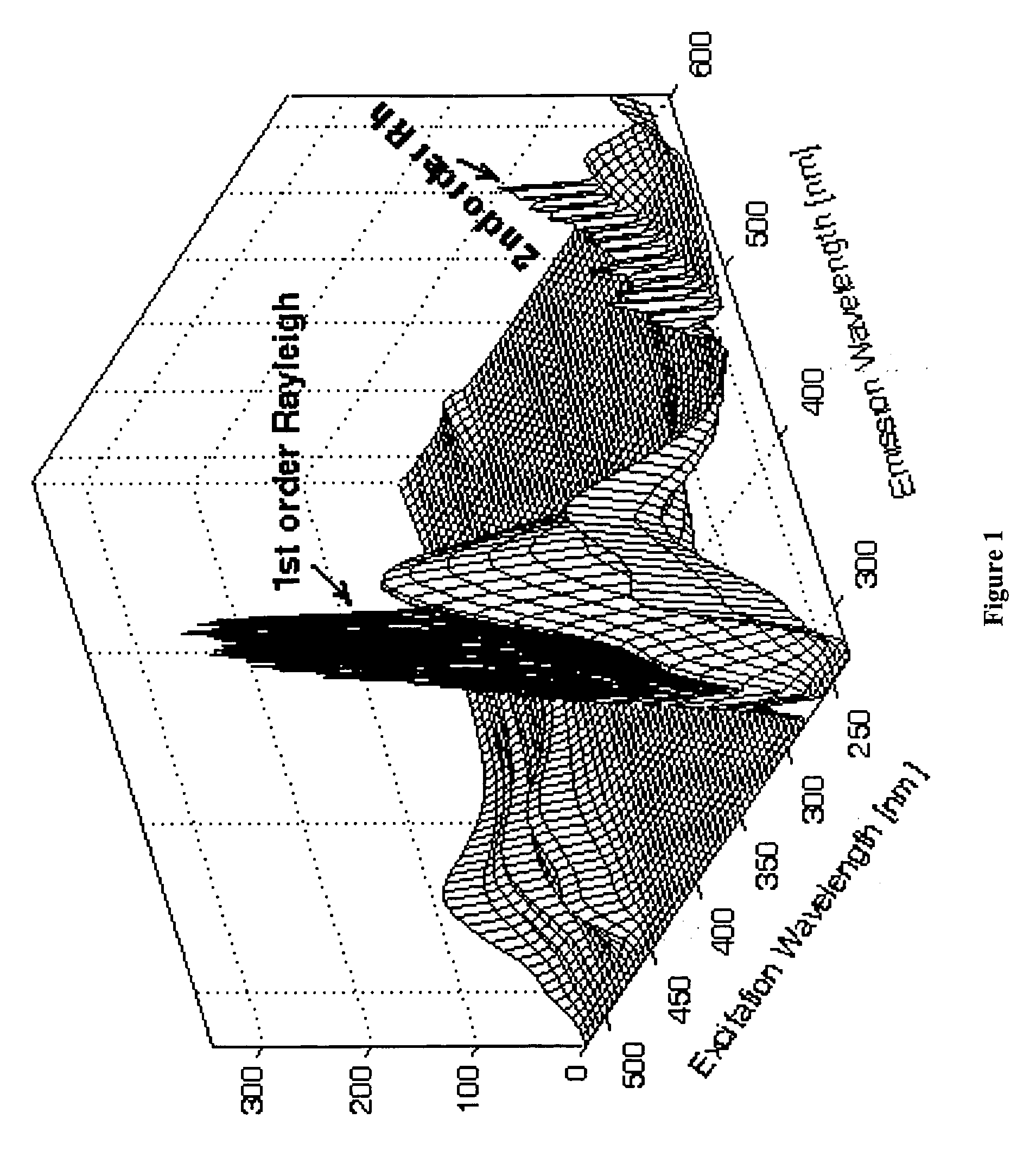

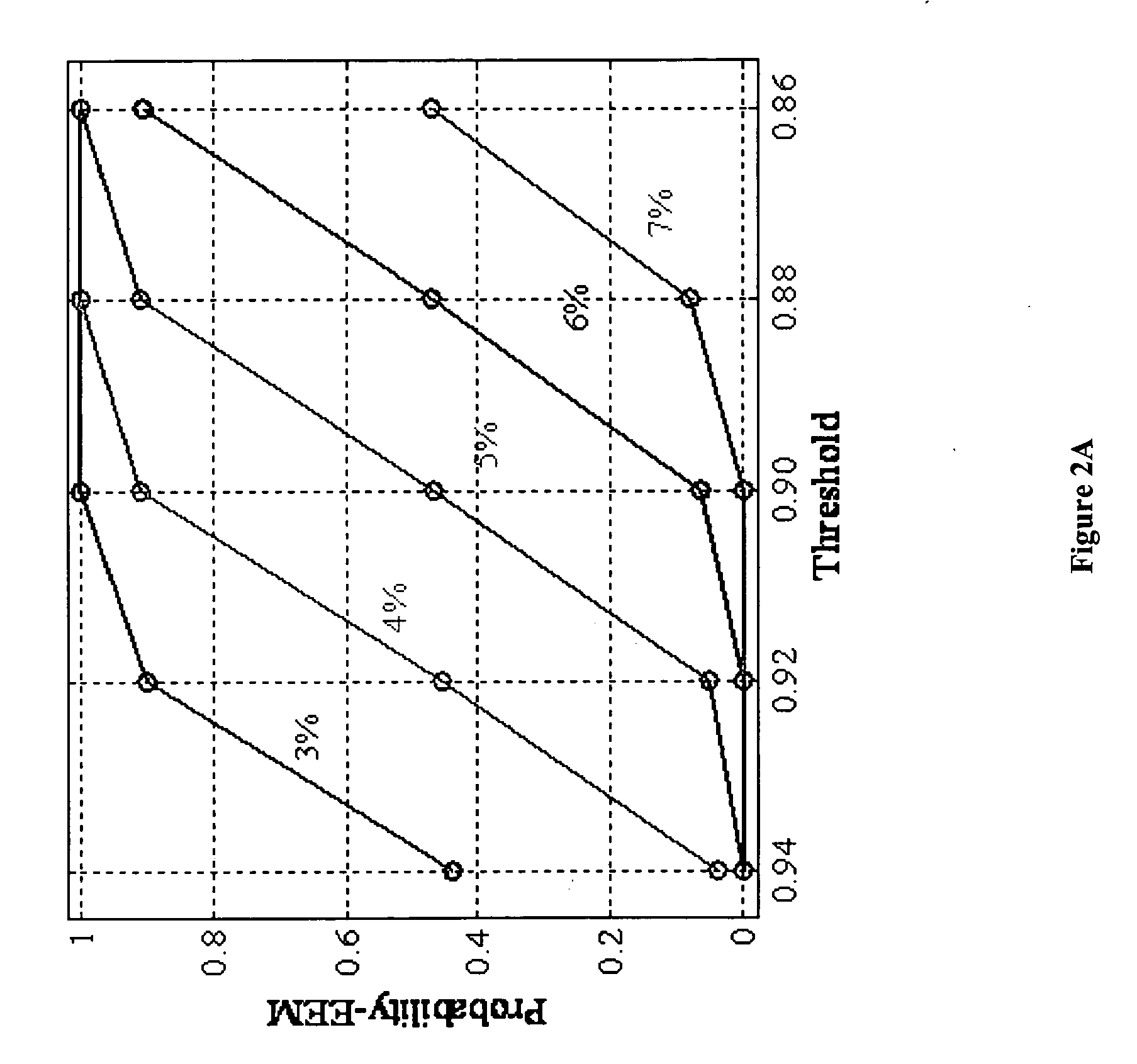

Similarity index: a rapid classification method for multivariate data arrays

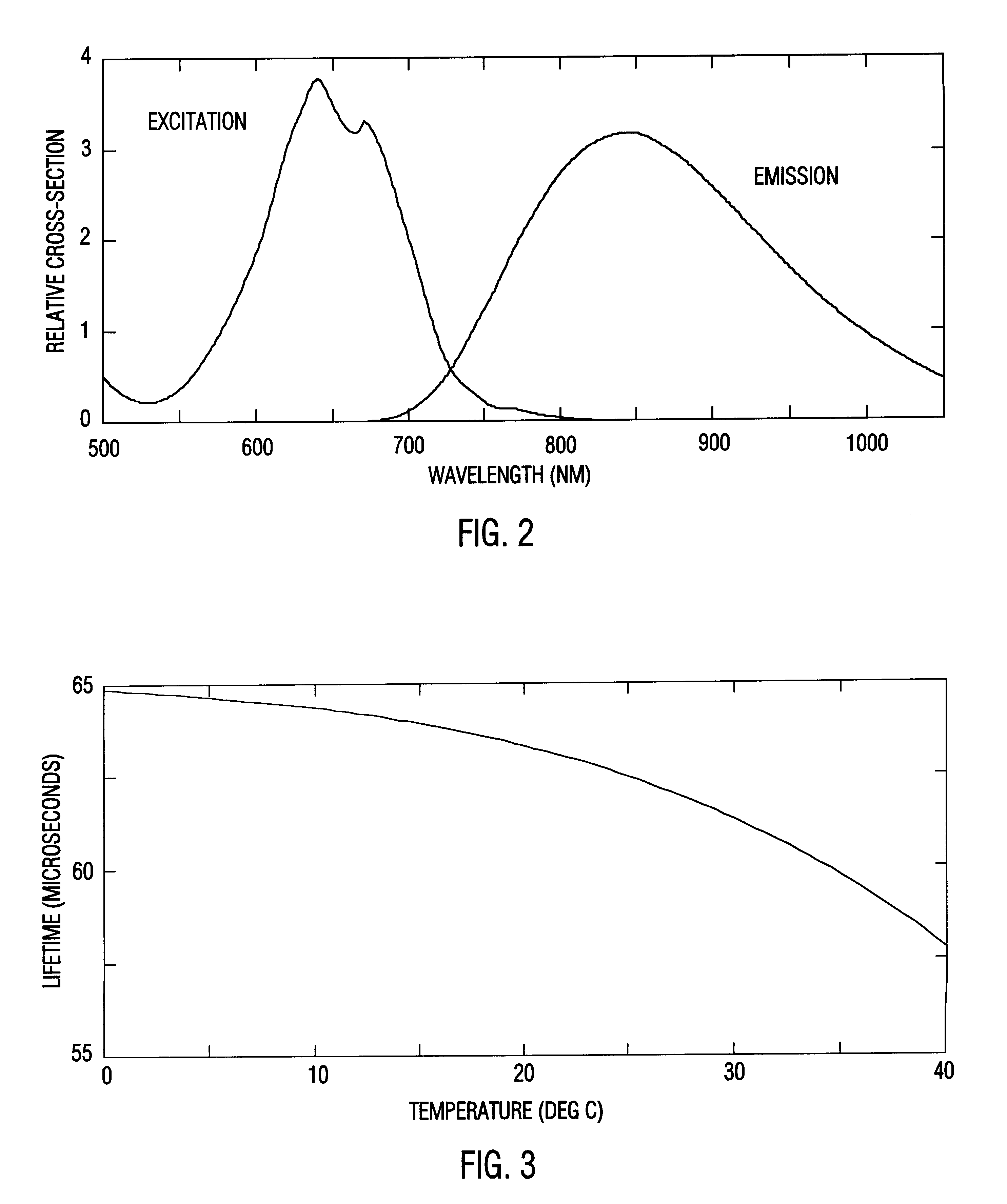

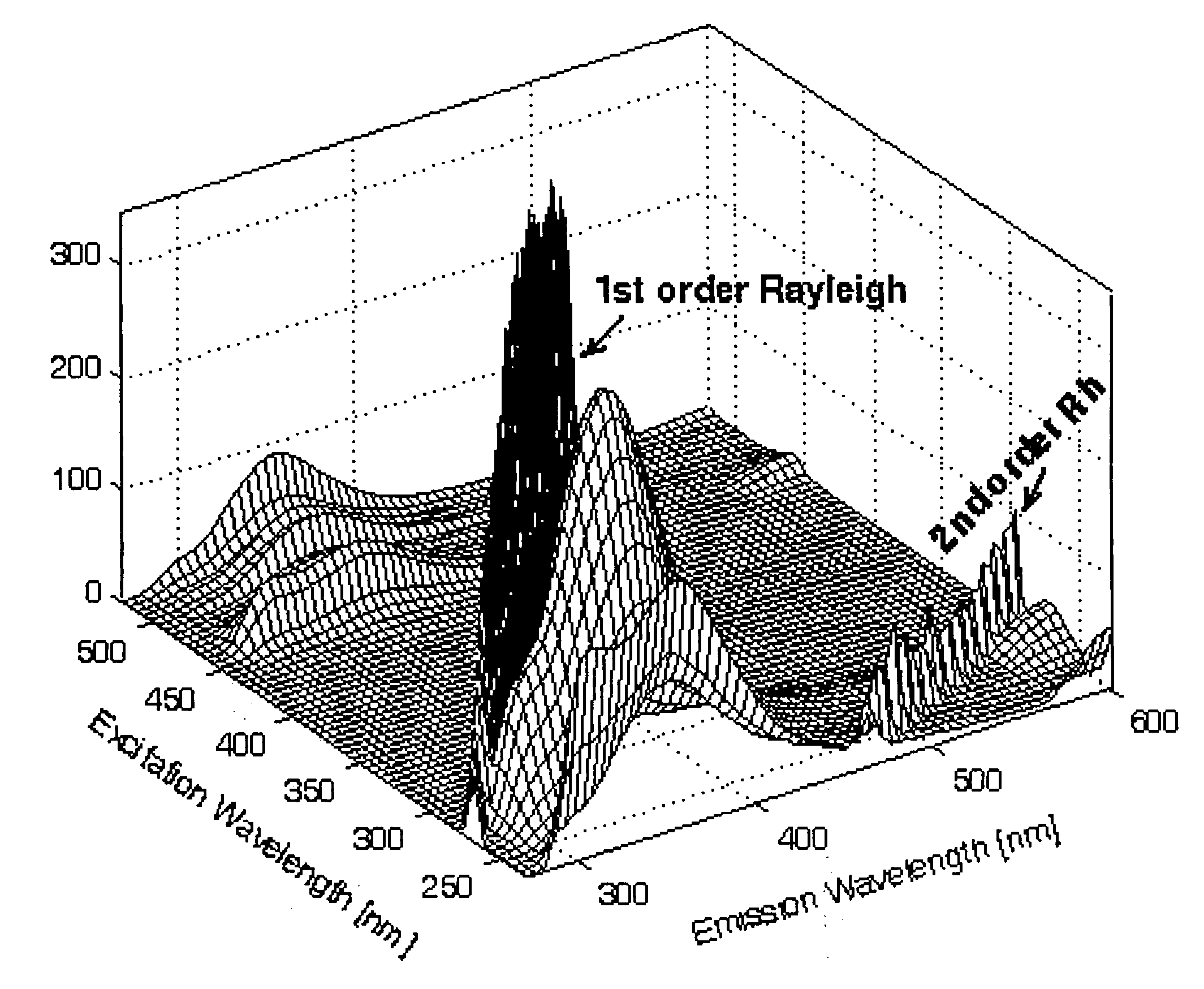

InactiveUS20090306932A1Rapid classification and analysisDigital computer detailsRaman scatteringData setSpectroscopy

Similarity Index: a rapid classification method for multivariate data arrays The present invention is directed to a method of determining the similarity between a first multivariate data set and a second multivariate data set. The method is versatile and can be applied to a number of different multivariate data sets, for example, a spectroscopy multivariate data set. In particular, the method may be applied to rapidly assess the similarity between fluorescence spectroscopy multivariate data sets. The method comprises the steps of representing the data of a first and a second multivariate data set in matrix form to yield a multivariate data matrix, wherein each multivariate data matrix has the same dimensions. Subsequently, the magnitude of an additive and subtractive combination of each multivariate data matrix is calculated. The concept of a penalty parameter is introduced to set a detectable limit of variance between said first multivariate data set and said second multivariate data set. The penalty parameter is ascribed a value and is used in combination with the magnitude of an additive and subtractive combination of each multivariate data matrix to determine a similarity value. The determined similarity value indicates the variance between said first multivariate data set and said second multivariate data set.

Owner:THE NAT UNIV OF IRELAND GALWAY

Map based estimations, and information search

InactiveUS20060122767A1Accurately visualizedAccurate visualizationRoad vehicles traffic controlNavigation instrumentsUser needsWork site

Typically a family relocating to a new place is faced in making a number of decisions with respect to identifying a location to live. Identification of such a location, is dependent on the distances from places of work and the amenities available at the various locations that fit the distances criteria. During the process of identification there is a need to generate the routes between the locations for a quick assessment of the commuting involved between the locations and even generate the driving instructions between the locations so marked on the map. Current software maps and related software do not have an easy way to identify the regions on the map that meet the distance criteria and then to connect the address on the map to specific information. The current invention creates an easy way to use a map to, estimate distances of the various towns / cities around the target locations. generate routes connecting locations and directions without having to know the zip codes to the locations visually marked on the map and generate driving directions associated with the routes. research amenities availability around the target location. create report consolidating the information pertinent to the user needs. Using a map that can be marked enables an easy graphical method of identifying areas that meet the distance criteria, the connecting routes and obtain information associated with the areas pertinent to the user requirements.

Owner:ATHALYE RAVI G A

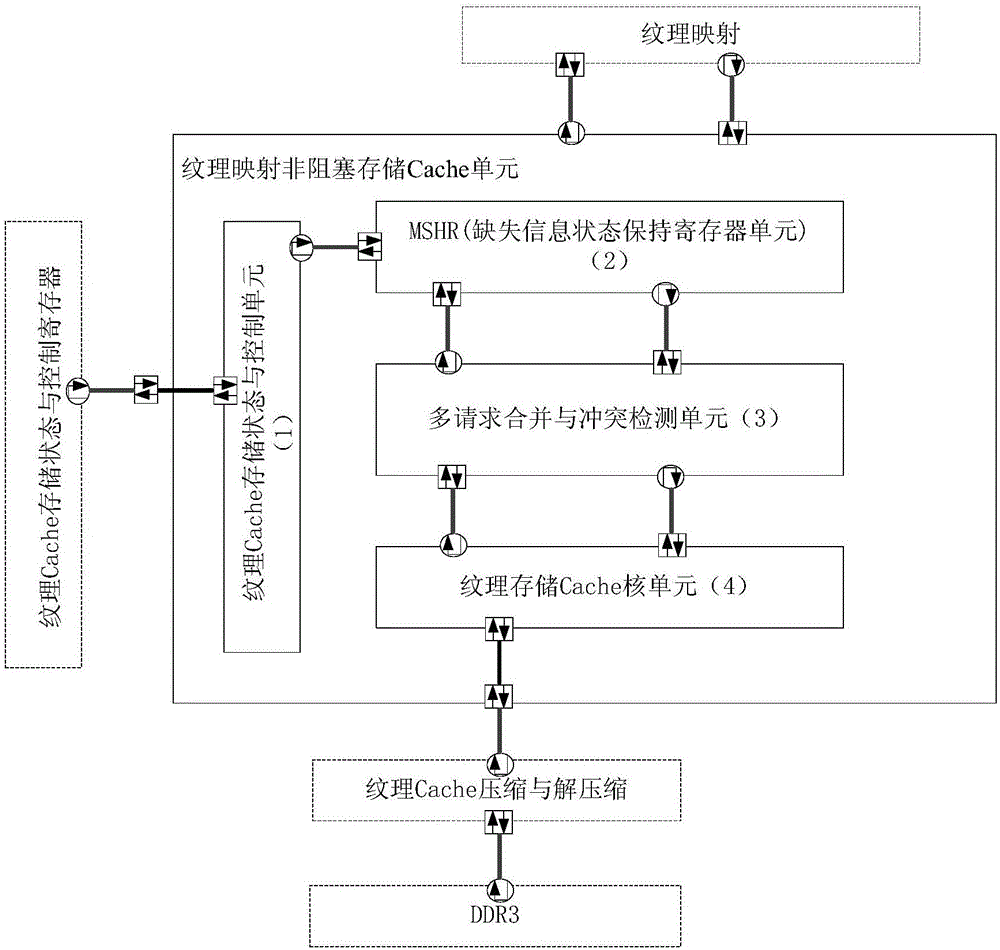

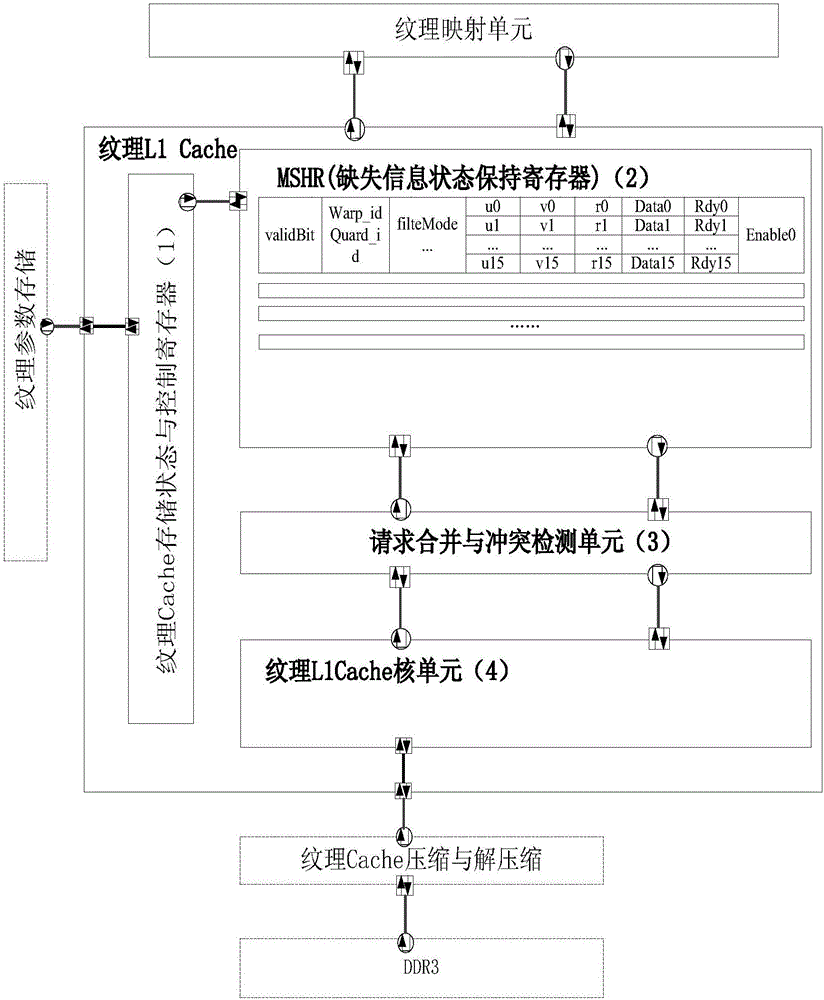

Modeling structure of GPU texture mapping non-blocking memory Cache

ActiveCN106683158AAchieving massive parallelismRealize requirementsImage memory managementProcessor architectures/configurationCollision detectionSignal design

The invention belongs to the field of computer figures, and provides a modeling structure of a GPU texture mapping non-blocking memory Cache. The modeling structure comprises a texture Cache storage status and control unit (1), a missing information status handling register memory cell (MSHR) (2), a multi-request combination and collision detection unit (3), and a texture memory Cache core unit (4). Hardware modeling with accurate periods is conducted on a texture memory Cache access process, parallel processing of texture access request data is realized through a multi-process mode including input request collision detection, request combination and division, multiple ports, multiple Banks and non-blocking flowing, and large-scale parallelism and high throughput demands of texture access data are met effectively. Moreover, the modeling structure effectively avoids configuration of complex circuit signal design and rapid assessment large-scale hardware system, is suitable for system level design and development of circuits in an early age, and provides effective reference for products and functions of the same kind.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

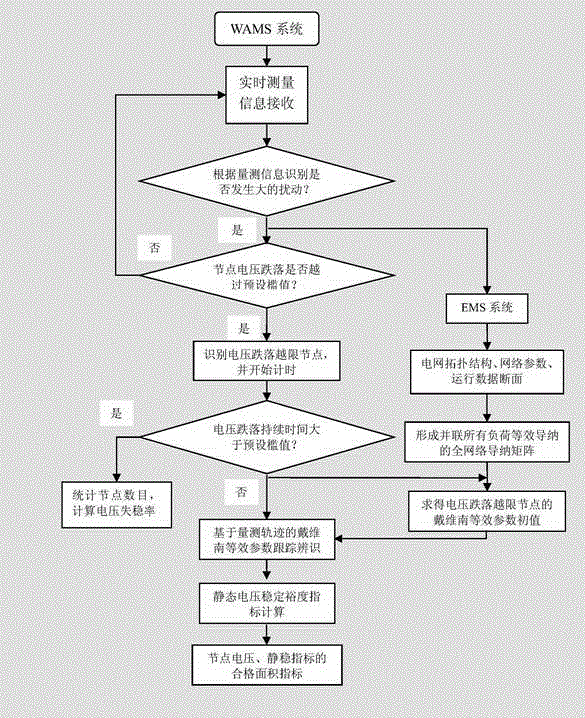

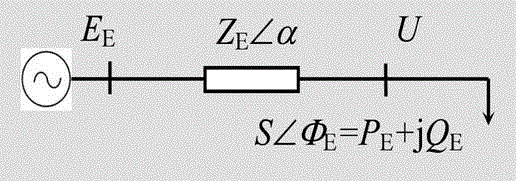

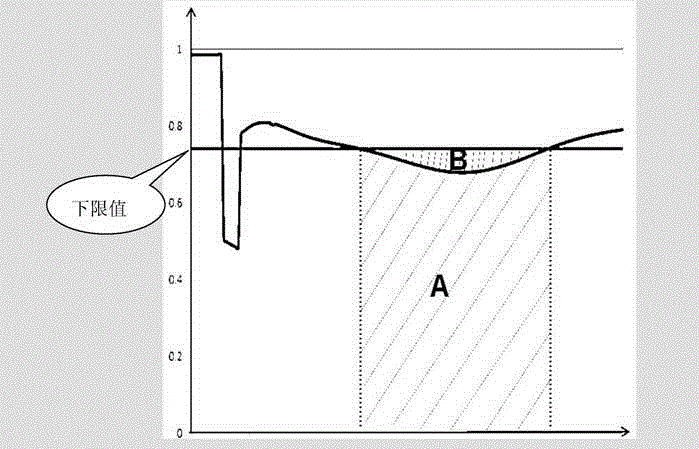

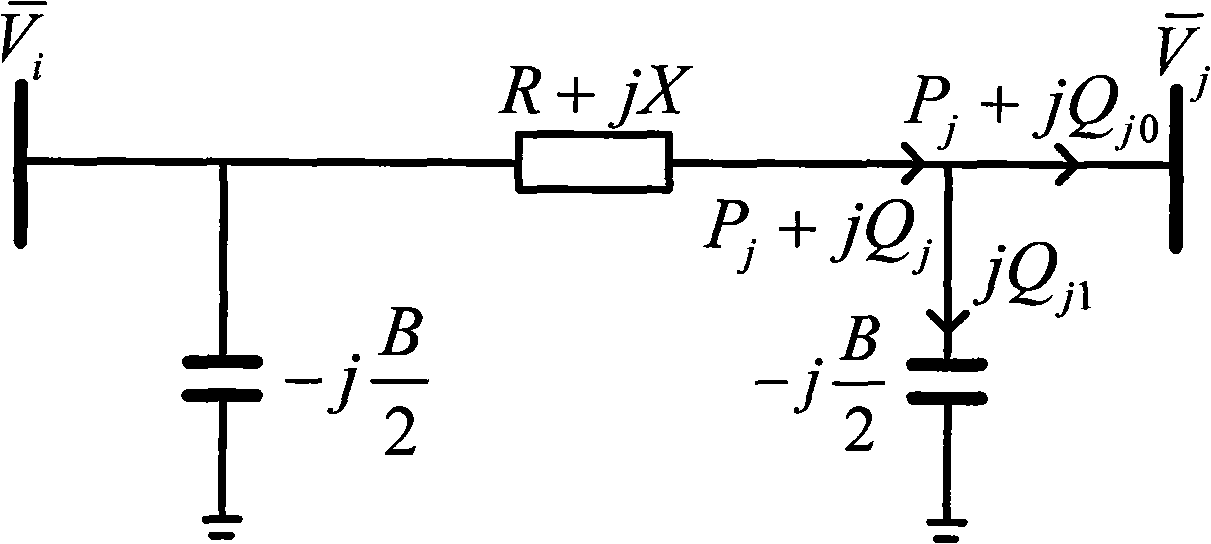

Transient voltage stable on-line assessment method based on WAMS and EMS

ActiveCN105098763AGood effectRealize transient voltage support capability assessmentSpecial data processing applicationsAc network circuit arrangementsEngineeringLoad following power plant

The invention relates to a transient voltage stable on-line assessment method based on a WAMS (Wide Area Measurement System) and an EMS, comprising: obtaining WAMS real-time power grid measurement information to determine whether a power grid is disturbed; obtaining the topological structure, parameters and power flow operation information of a current power grid from an EMS when the power grid is disturbed so as to calculate a full admittance matrix concerning load equivalent admittance; according to the WAMS measurement information, running statistics on nodes having a voltage dip exceeding a preset threshold value, obtaining Thevenin equivalent parameters of statistic nodes based on full admittance matrix inversion to be used as an initial value to track Thevenin equivalent parameter identification of the WAMS measurement information and static state voltage stable margin index calculation, and calculating a transient voltage dip acceptability area index; and running statistics on nodes having a power grid node voltage dip exceeding a preset threshold value and having a dip duration greater than a preset threshold value, and determining the occupancy of power grid disturbance transient voltage instability nodes. The method can rapidly and effectively realize the stable and rapid assessment of a transient voltage.

Owner:STATE GRID CORP OF CHINA +2

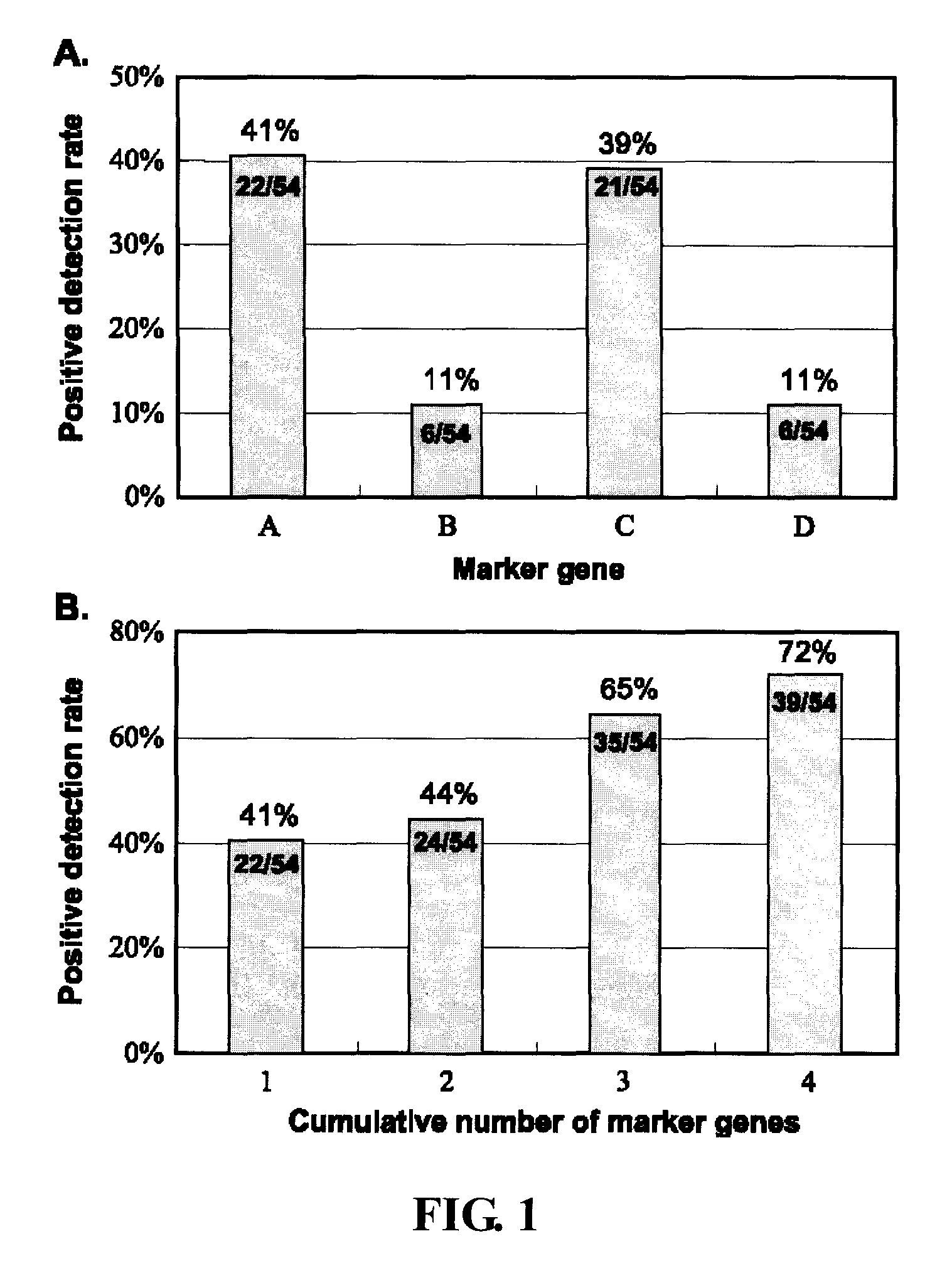

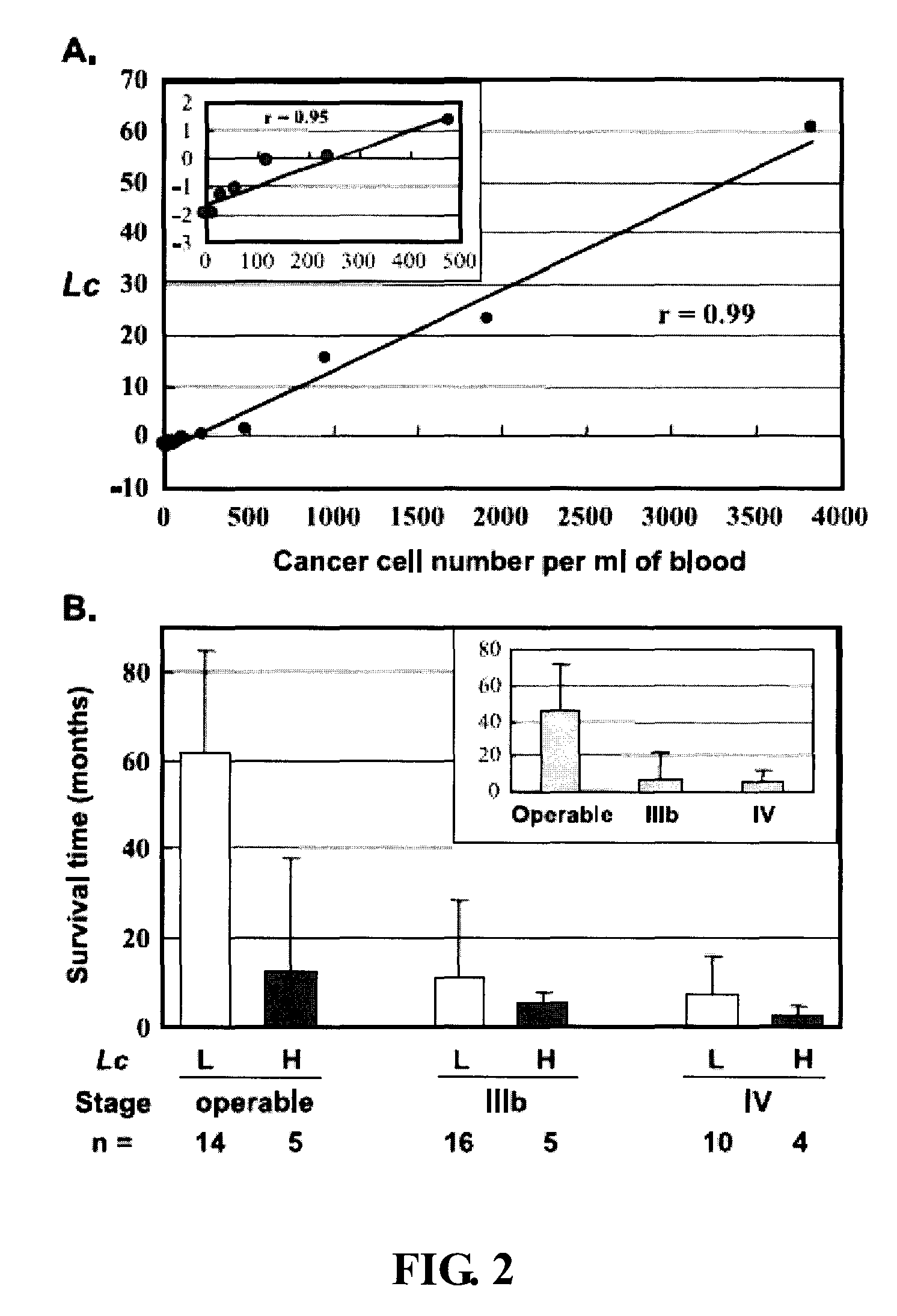

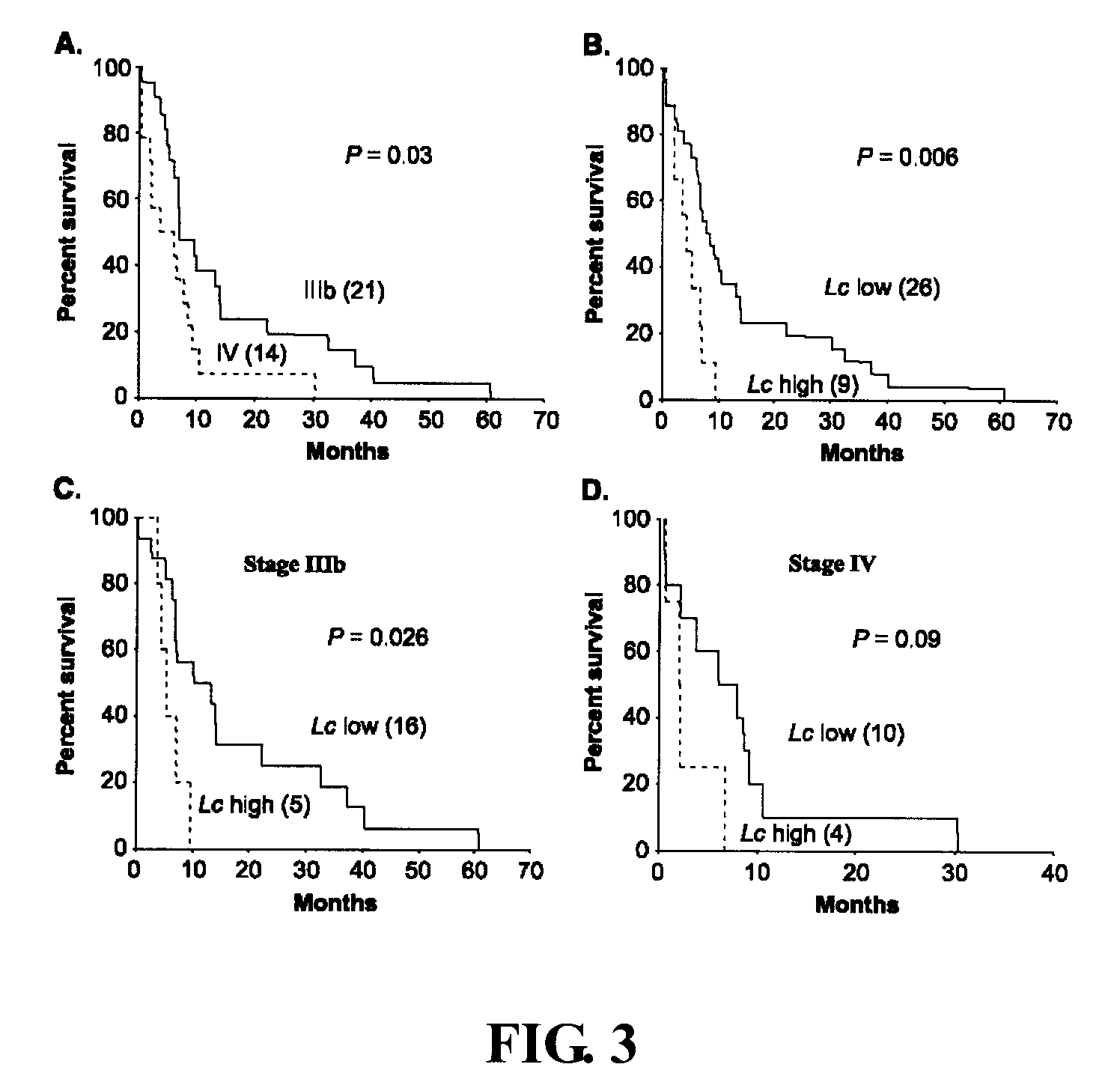

Rapid efficacy assessment method for lung cancer therapy

InactiveUS20070048750A1Rapid efficacy assessmentHigh correlationMicrobiological testing/measurementBiological testingSequence databaseEfficacy

Owner:NAT INST OF HEALTH REPRESENTED BY THE SEC OF THE DEPT OF HEALTH & HUMAN SERVICES NAT INST OF HEALTH

Method and apparatus for mapping a site on a wide area network

InactiveUS20090094327A1Faster network connectionSmall sizeData processing applicationsNatural language data processingWeb siteWeb service

A method and system for organizing and displaying information about Internet Web pages on Web maps are disclosed. Web maps display a summary of the information that a Web page provides access to, in a format that facilitates a rapid assessment of what may be accessed through a Web site's home page, or through any Web page on the Web site. Preferably, Web maps are displayed on a Web page, or within a frame of a Web page, by an Internet browser application. A set of Web maps may be automatically generated by a search engine or directory in response to a user's search request. Alternatively, a user may request that a Web map be produced for a particular Web page of interest. The Web maps are preferably generated by a Web server, or by an application running in the background of a user's computer, so that the user may perform other tasks on the user's computer while the Web maps are being generated.

Owner:INTELLECTUAL VENTURES I LLC

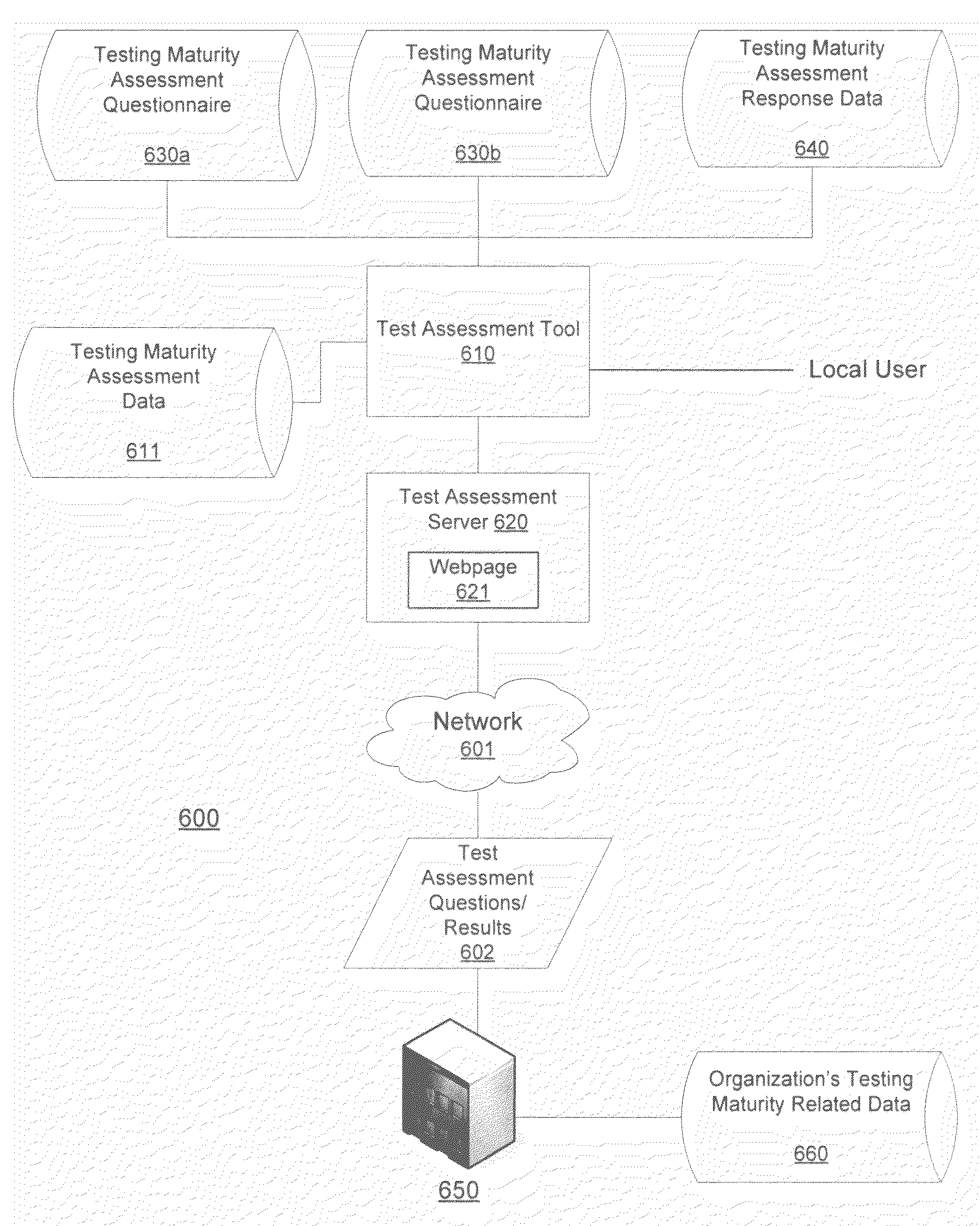

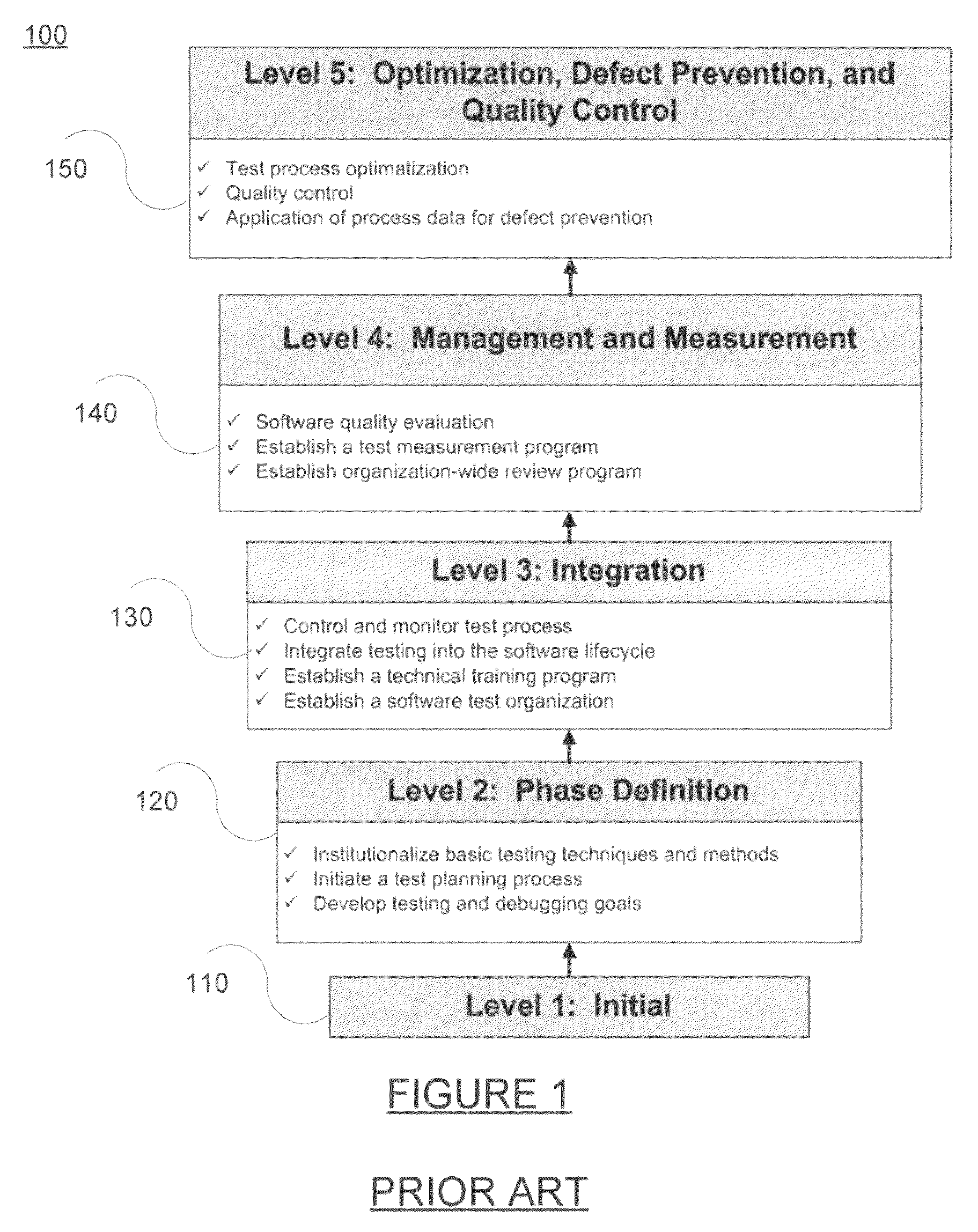

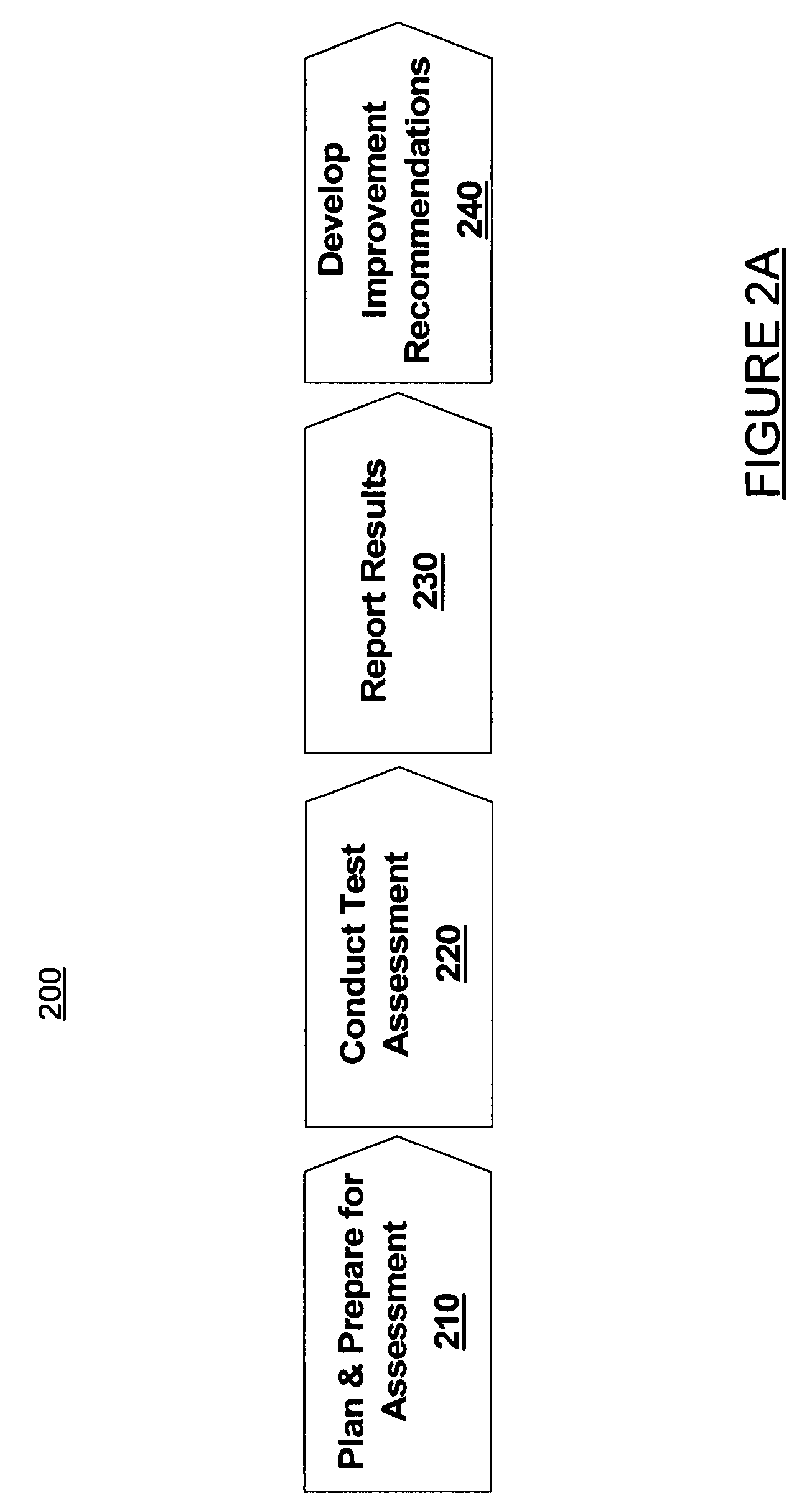

Software testing capability assessment framework

ActiveUS8869116B2Make up for deficienciesEase of evaluationHardware monitoringSoftware testing/debuggingTesting Maturity ModelData mining

Owner:ACCENTURE GLOBAL SERVICES LTD

Identifying off-target effects and hidden phenotypes of drugs in human cells

InactiveUS20070212677A1Enable optimizationMicrobiological testing/measurementBiological testingHuman bodyToxicant

This invention provides principles, methods and compositions for ascertaining the mechanism of action of pharmacologically important compounds in the context of network biology, across the entire scope of the complex pathways of living cells. Importantly, the principles, methods and compositions provided allow a rapid assessment of the on-pathway and off-pathway effects of lead compounds and drug candidates in living cells, and comparisons of lead compounds with well-characterized drugs and toxicants to identify patterns associated with efficacy and toxicity. The invention will be useful in improving the drug discovery process, in particular by identifying drug leads with desired safety and efficacy and in effecting early attrition of compounds with potential adverse effects in man.

Owner:ODYSSEY THERA INC

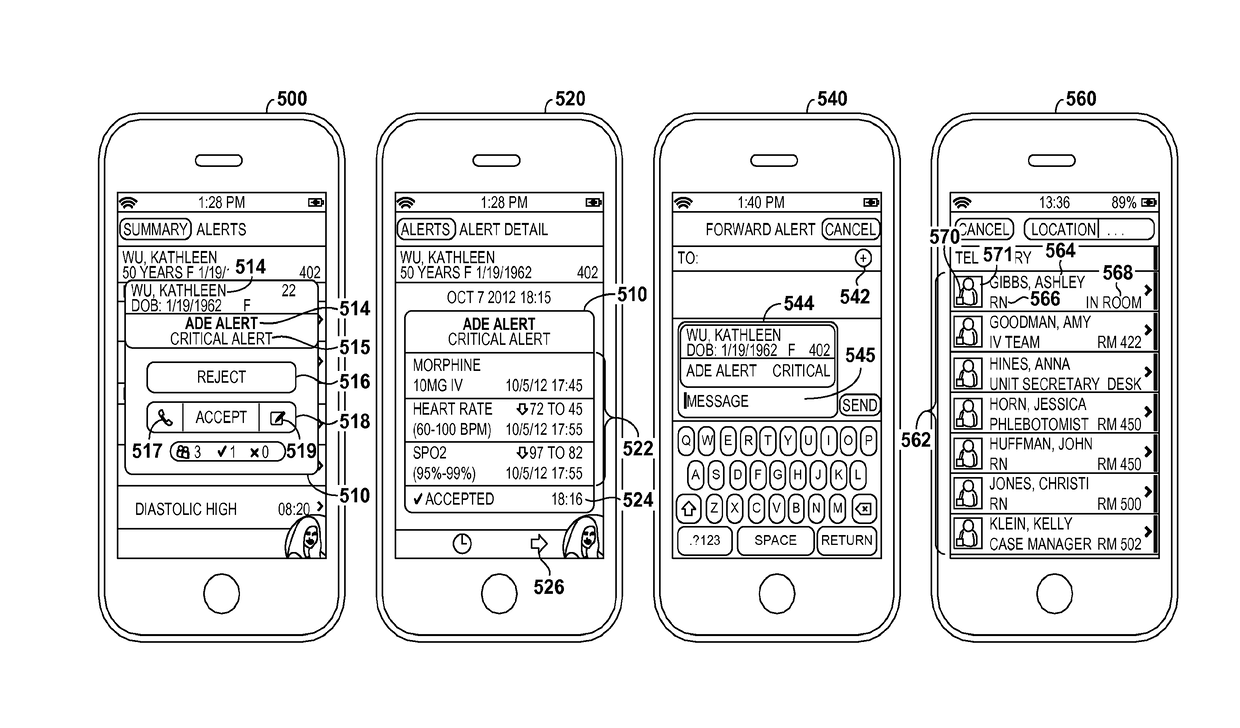

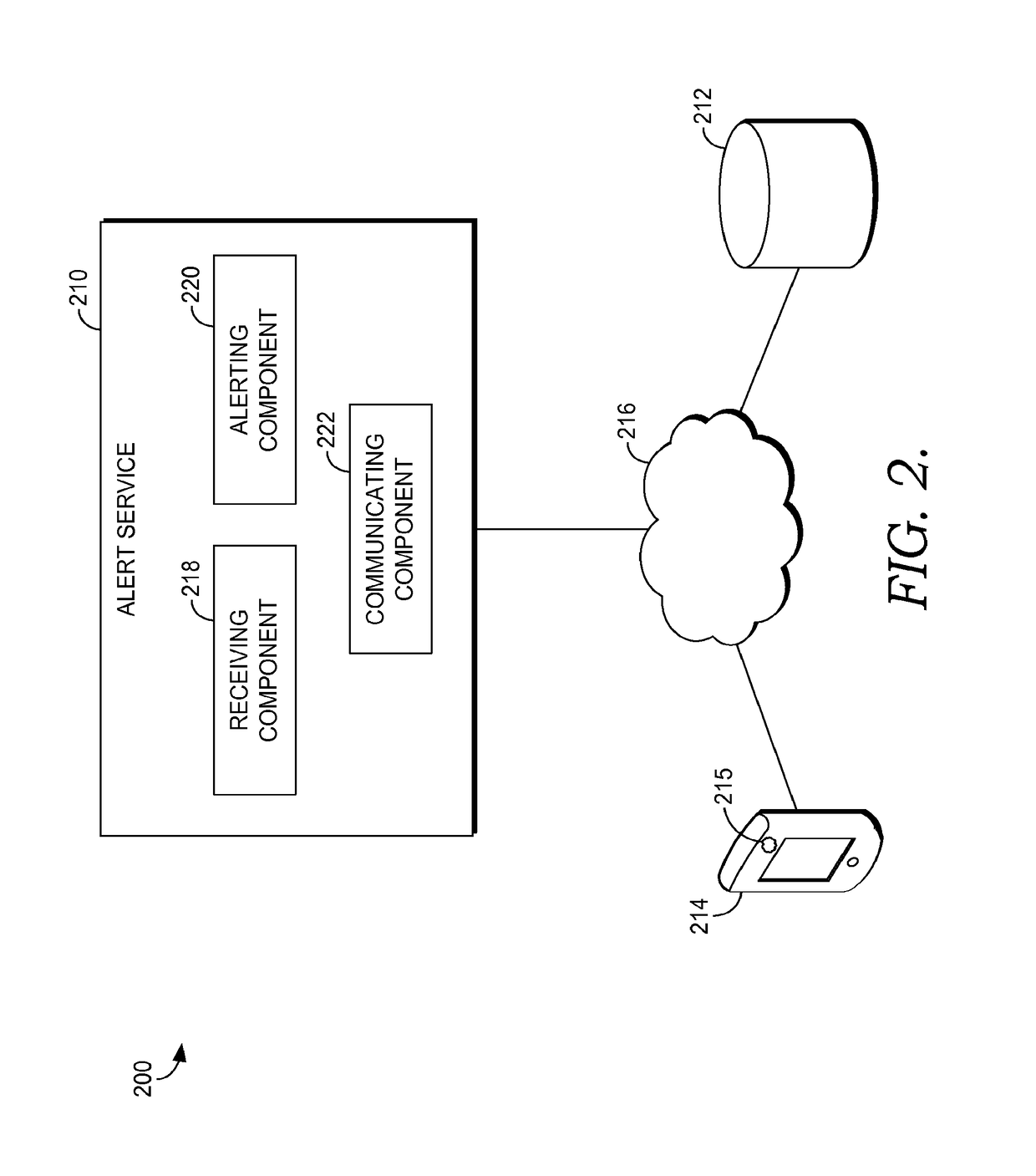

Alert Management Utilizing Mobile Devices

ActiveUS20170109989A1Well formedCurrent supply arrangementsSubstation equipmentCaregiver personAlert management

Methods, computer systems, and computer-storage medium are provided for managing patient alerts using a mobile device. A mobile device associated with a patient caregiver receives a critical alert related to the patient, and the alert is presented on the mobile device. The alert includes important contextual information that enables the caregiver to make a quick assessment of how to effectively address the alert. The alert includes options for accepting the alert or rejecting the alert. Acceptance of the alert enables the caregiver to communicate the alert to selected caregivers that can assist in managing the alert. Rejecting the alert causes the alert to be automatically communicated to additional caregivers associated with patient.

Owner:CERNER INNOVATION

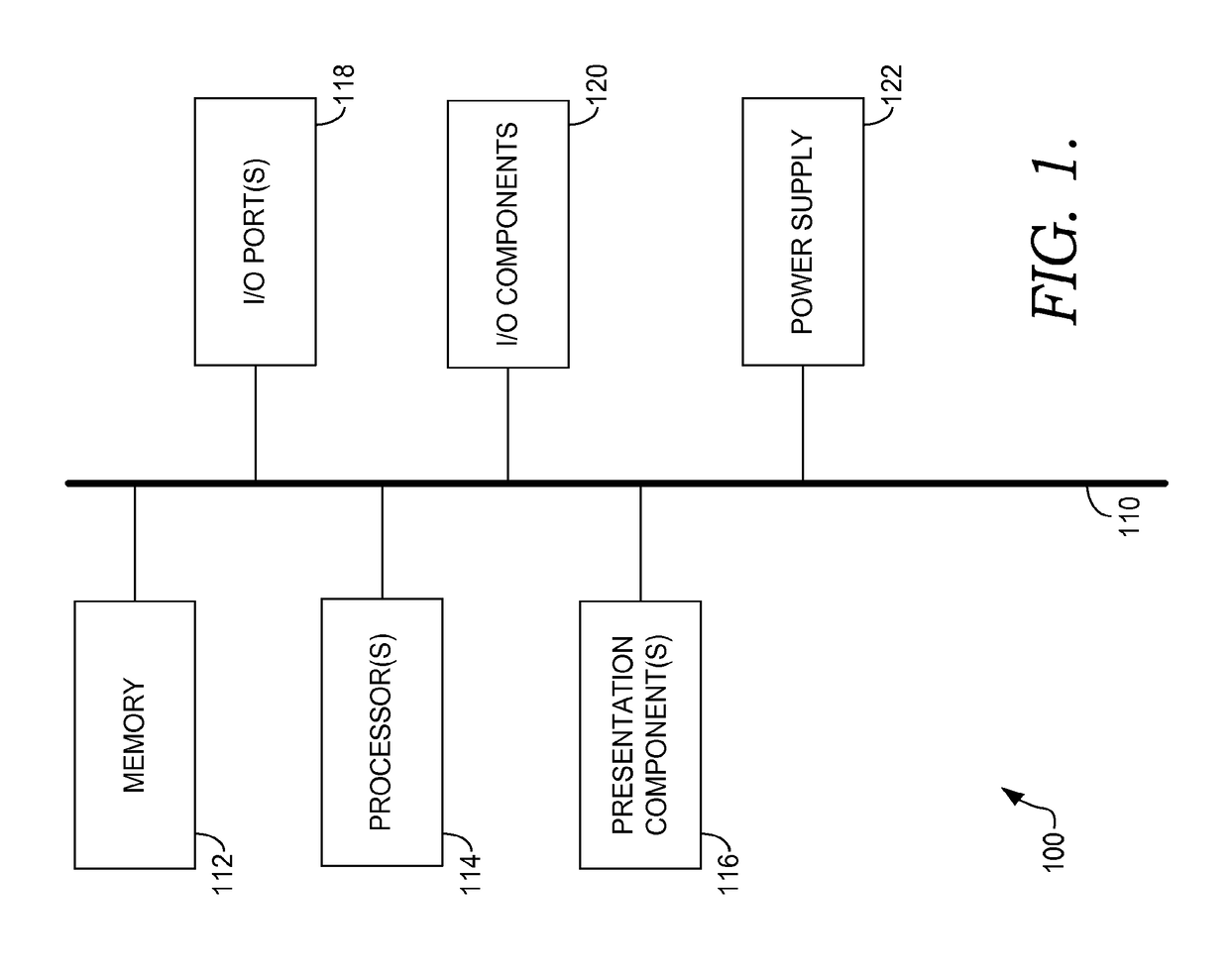

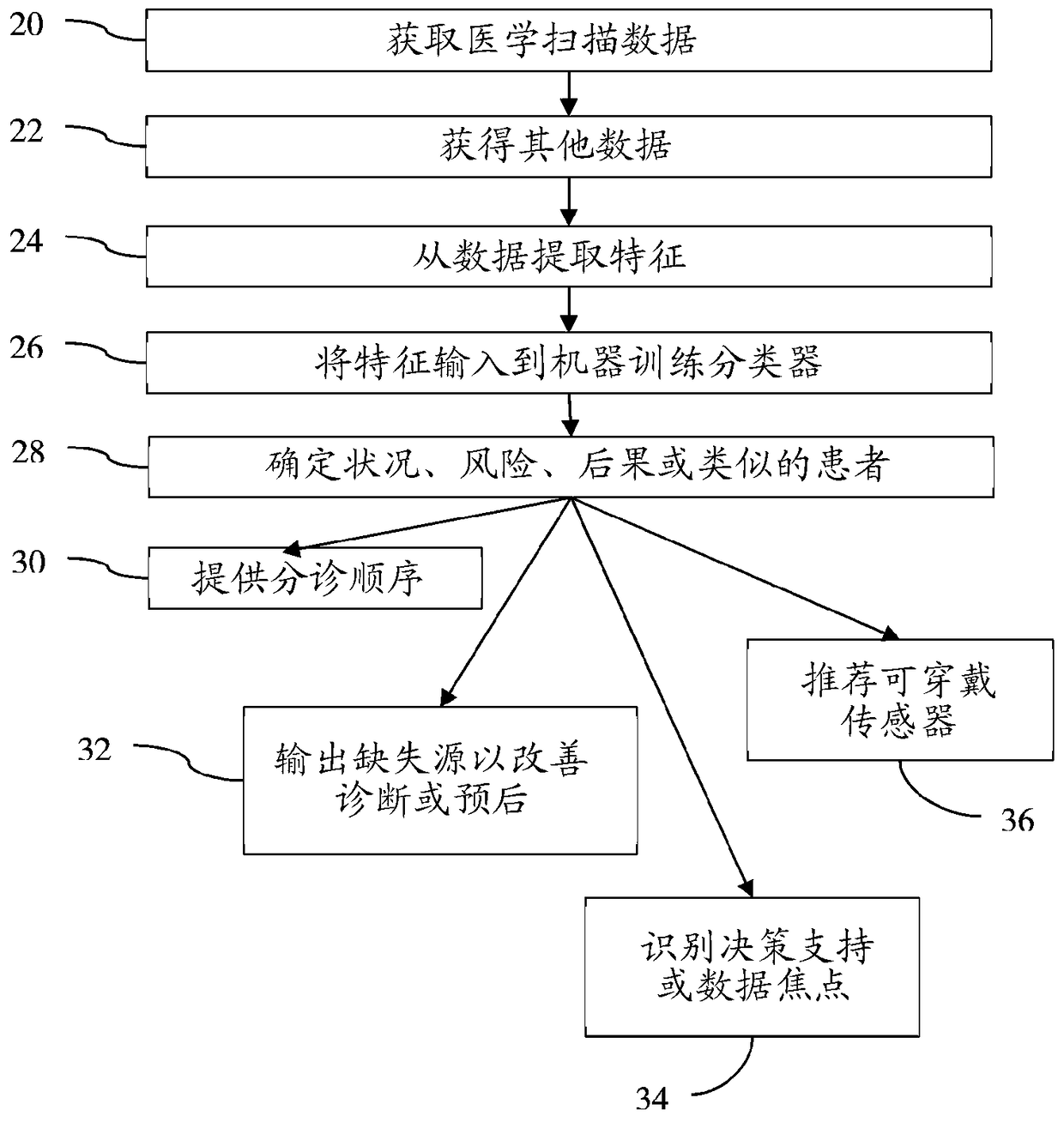

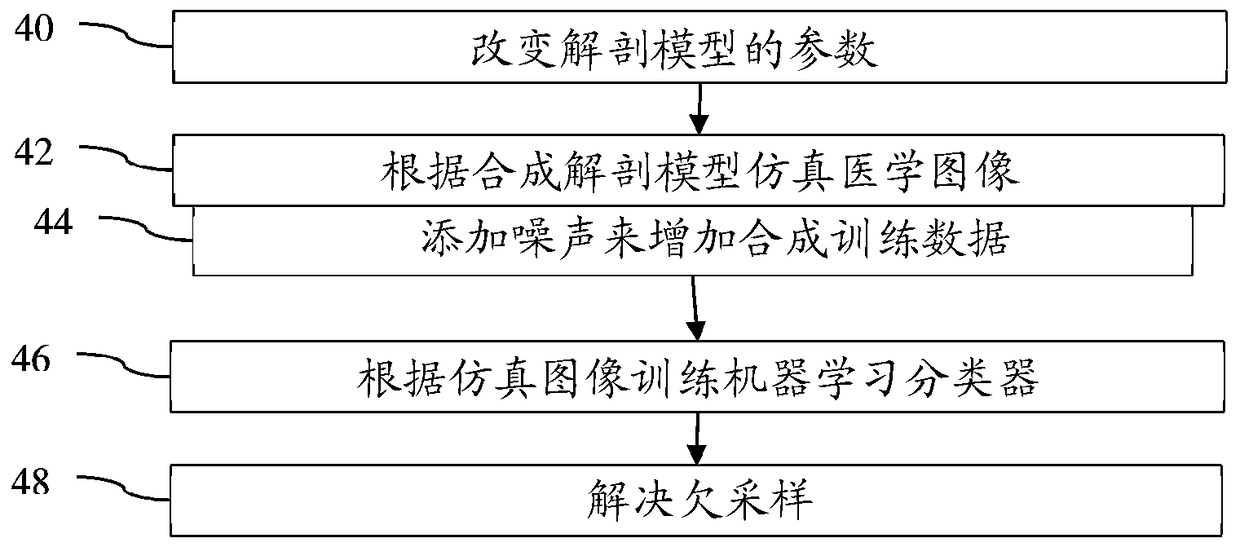

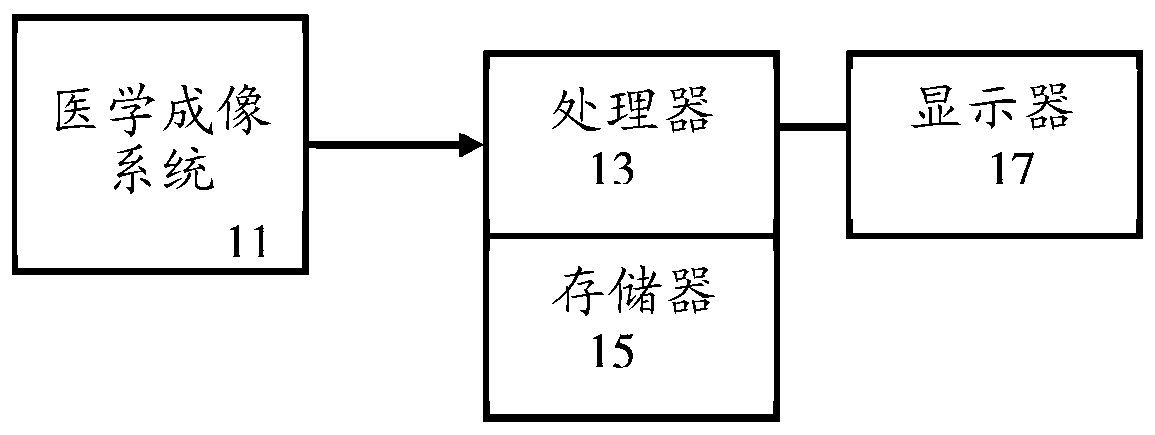

Rapid assessment and outcome analysis for medical patients

Machine learning (46) is used (26) to assess data for a patient in an emergency, providing (28) rapid diagnosis based on a large amount of information. Assistance in triage (30) may be provided. Giventhe large variety of patients and conditions that may occur, the machine learning (46) may rely on synthetically generated (42) images for more accurate prediction. The machine learning (46) may accurately predict (28) even with missing information and may be used to determine (34) what missing information for a given patient is more or less important to obtain.

Owner:SIEMENS HEALTHCARE GMBH

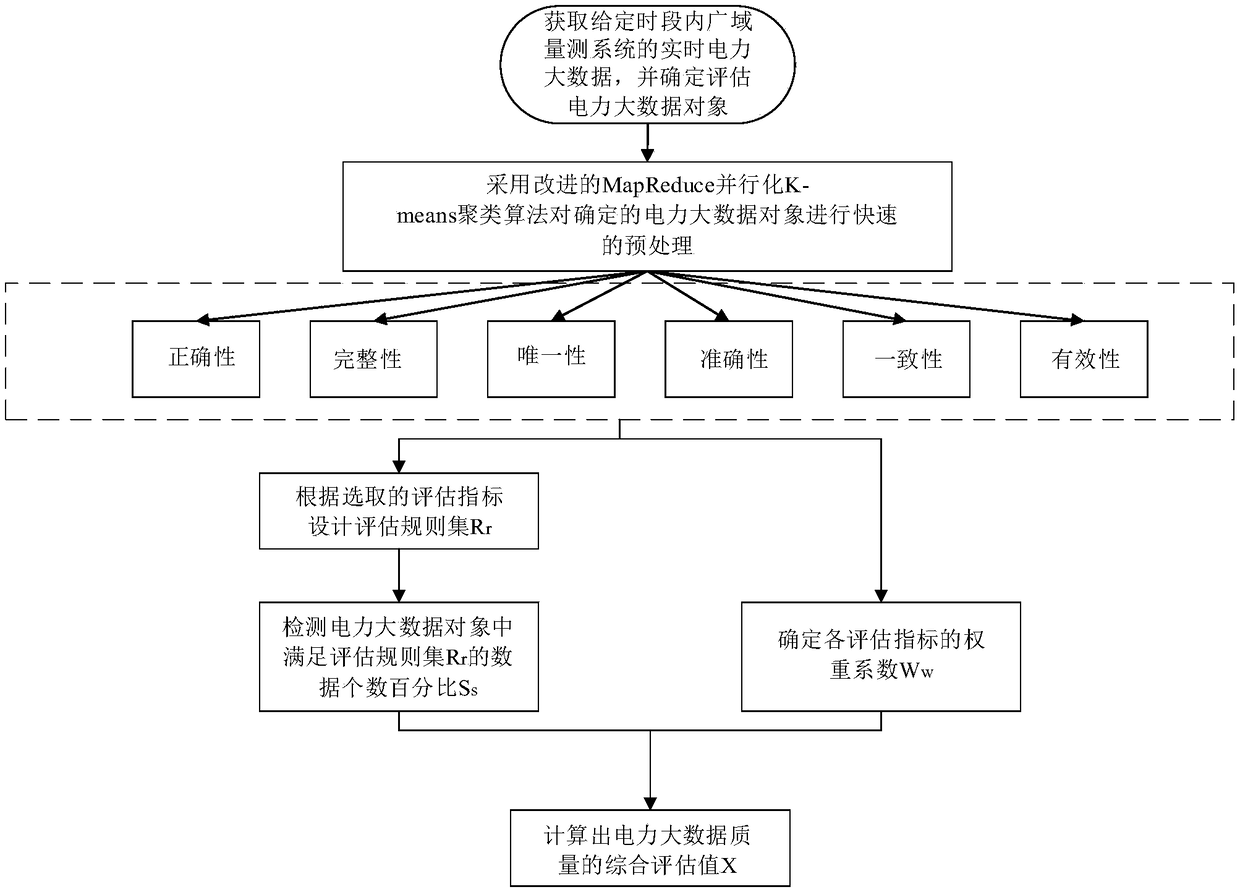

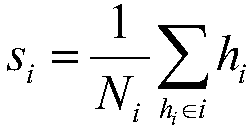

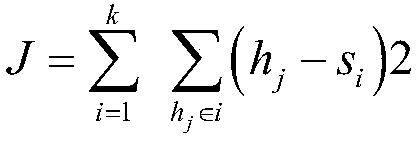

Rapid online assessment method for wide area measurement power big data quality

InactiveCN109492683AEfficient use ofIncrease credibilityCharacter and pattern recognitionResourcesWide areaWeight coefficient

The invention discloses a rapid online assessment method for wide area measurement power big data quality, and belongs to the field of power system big data application, and the method comprises the following steps: obtaining the real-time power big data of a wide area measurement system in a given time period; performing fast preprocessing with improved MapReduce parallel K-means clustering algorithm ; carrying out correctness evaluation by adopting a KNN-based fast density peak abnormal value detection algorithm; carrying out integrity, uniqueness, accuracy, consistency and effectiveness evaluation, and designing an evaluation rule Rr (r = 1, 2, 3... n) corresponding to each index according to the evaluation index Ii; determining a weight coefficient Ww of each evaluation index by utilizing an analytic hierarchy process; and counting the data number percentage Ss meeting the evaluation rule Rr (Ii), and calculating a comprehensive evaluation value X of the power big data quality according to the obtained weight coefficient Ww and the detection result Ss. According to the method, the problem of rapid assessment of the quality of the power big data is solved, and the method is basic work of power grid online application based on the WAMS.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

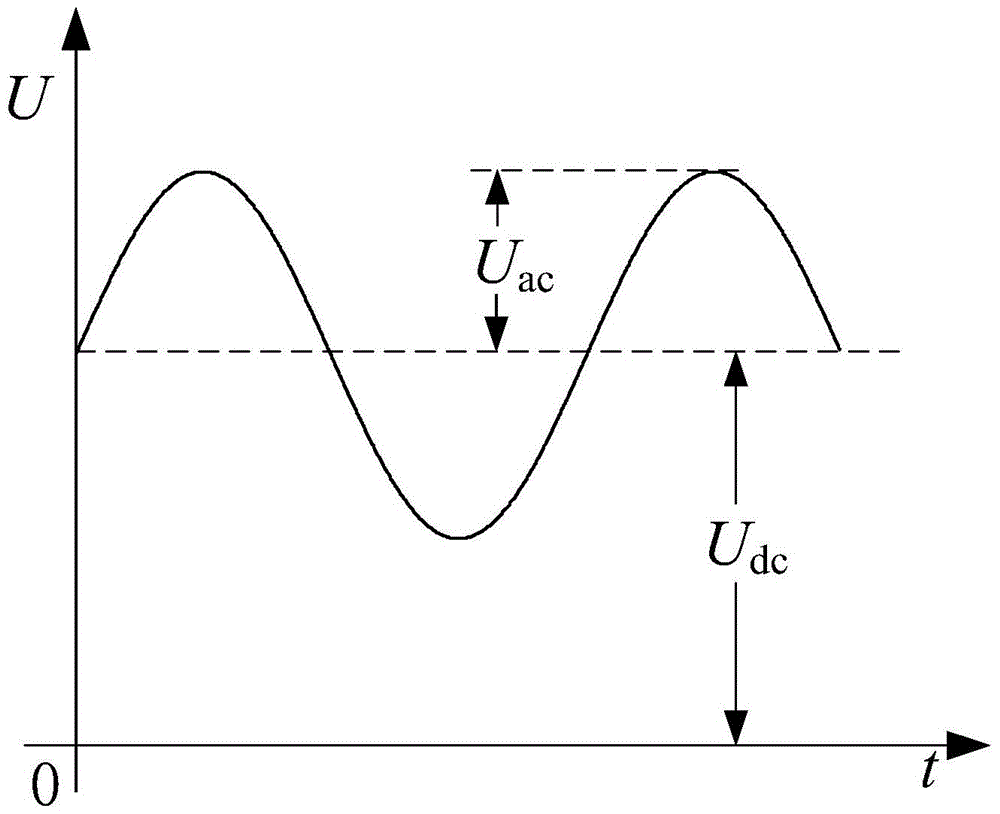

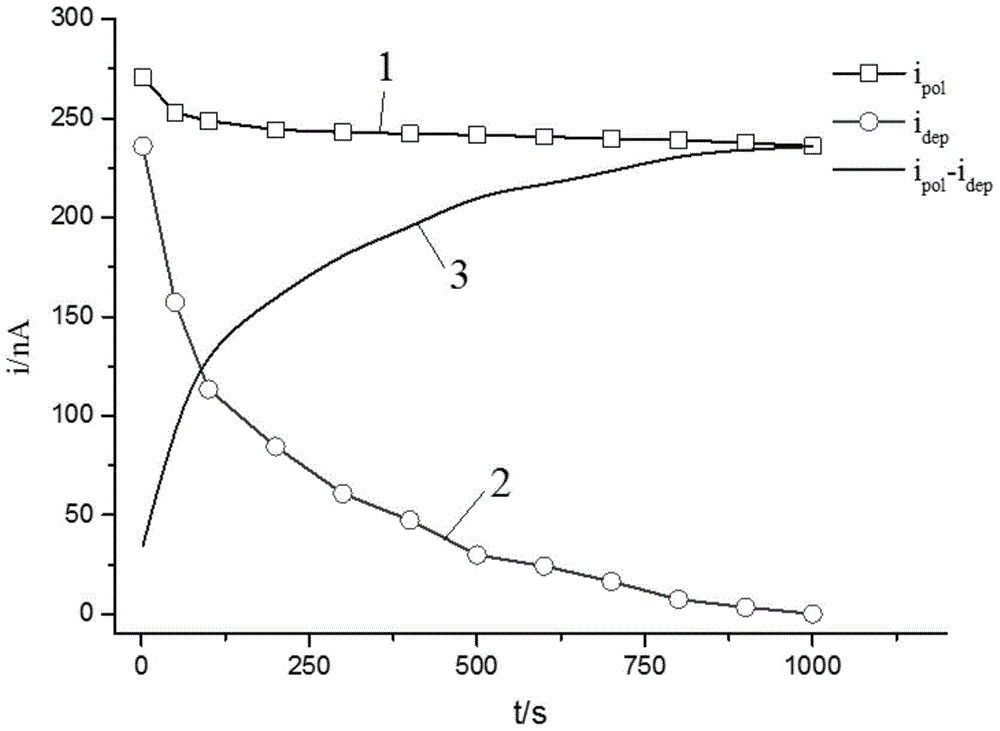

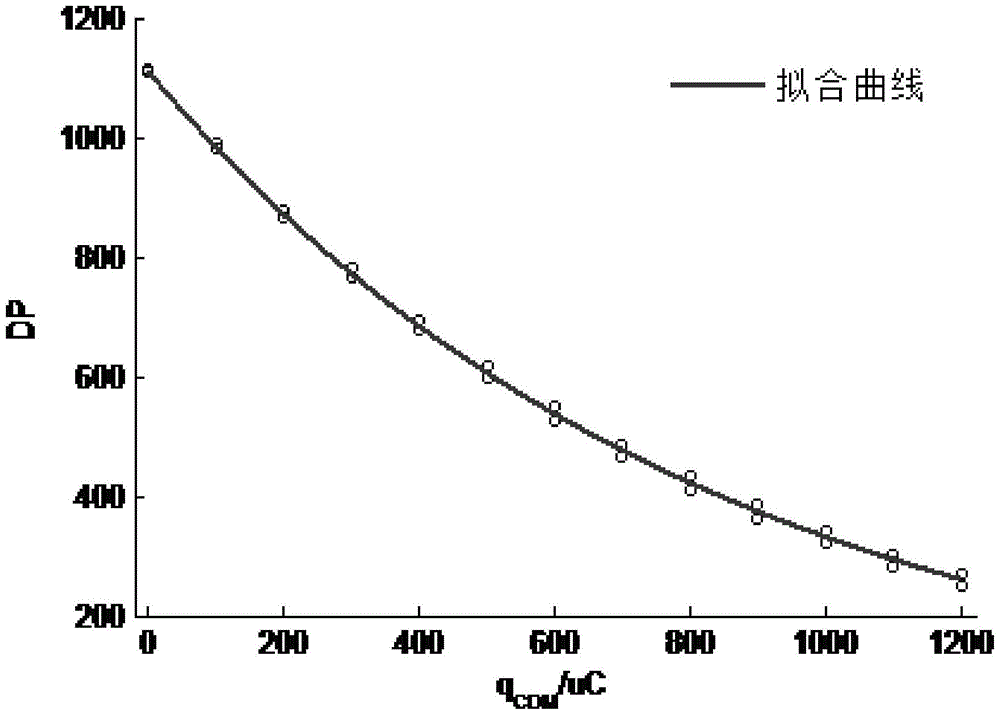

A method for assessing oilpaper insulating aging state on the basis of polarization and depolarization charge differences

ActiveCN105699864AAccurate assessmentRapid assessmentTesting dielectric strengthMaterial analysis by electric/magnetic meansElectricityTransformer

The invention belongs to the technical field of electrical equipment insulation diagnosis, and provides a method for assessing oilpaper insulating aging states on the basis of polarization and depolarization charge differences. A polarization and depolarization charge difference can be calculated through detecting polarization currents and depolarization currents of internal oilpaper insulation of electrical equipment; a degree of polymerization of insulation paper insulation states is represented through the polarization and depolarization charge difference of the paper insulation; assessment of insulation states of the oilpaper insulation is carried out; and thus a damaging assessment method for assessing oilpaper insulation through the degree of polymerization is changed into a lossless assessment method in combination with the polarization and depolarization current method and the polymerization degree method. No dismounting is needed for the electrical equipment with oilpaper insulation as an insulating layer, and for example, lossless, accurate and rapid assessment can be carried out on insulation states of the oilpaper insulation inside a voltage transformer or a high-voltage bushing without cover hanging of the voltage transformer or dismounting of the high-voltage bushing, and thus a basis and a reference are provided for detection of insulation aging states and replacing of the oilpaper insulation inside the electrical equipment.

Owner:DALIAN UNIV OF TECH

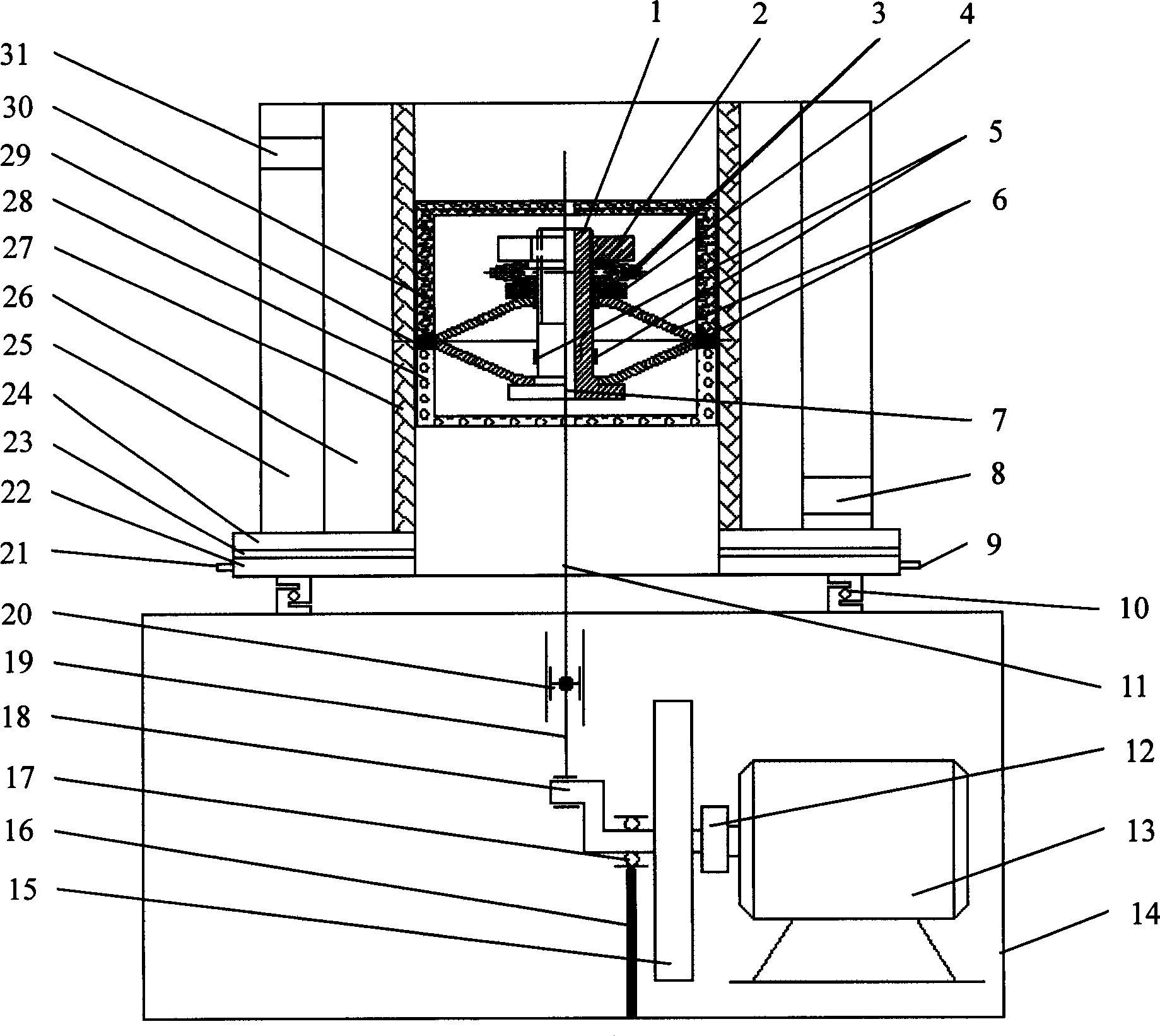

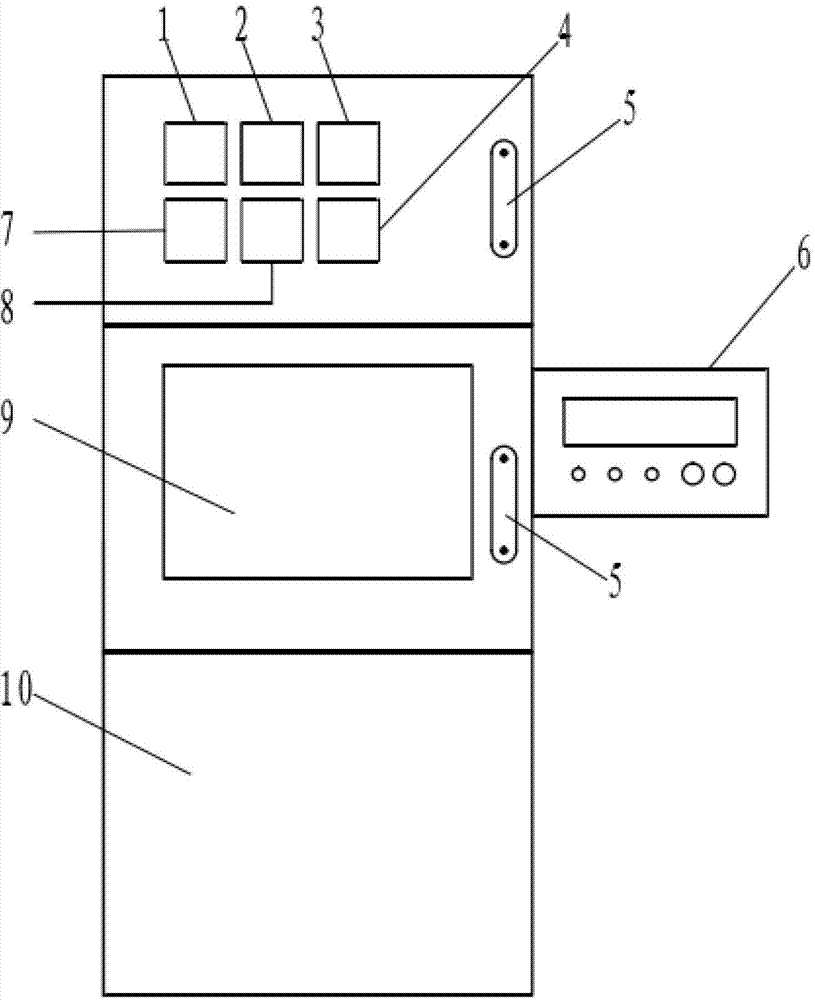

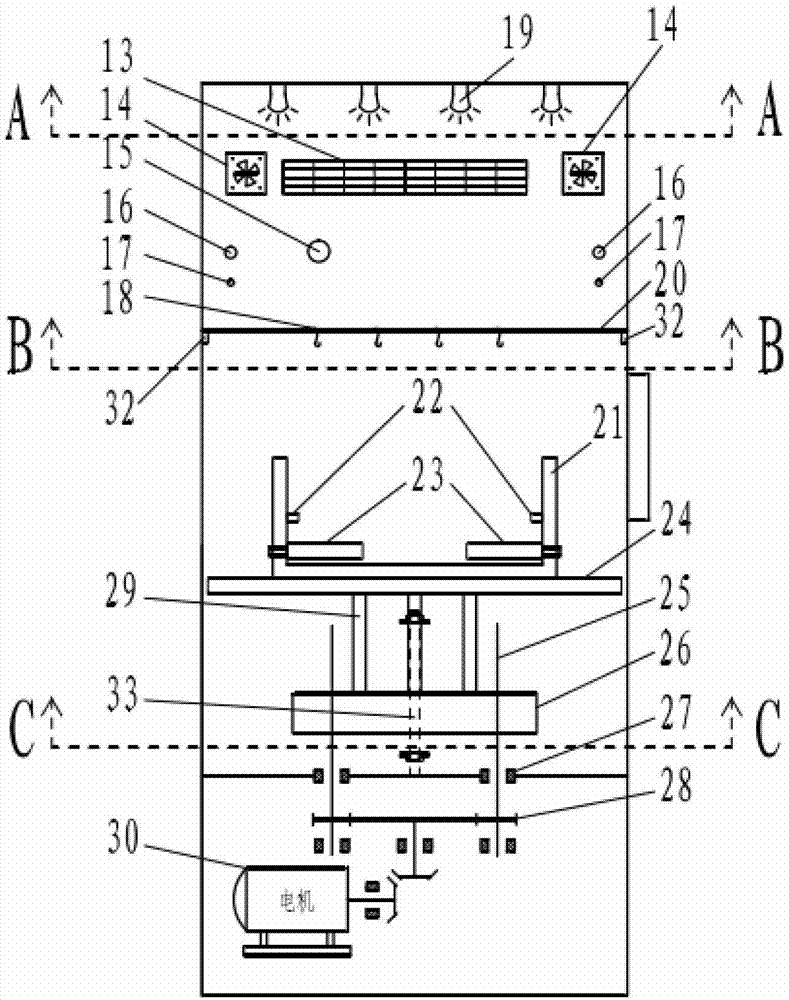

Indoor simulation/rapid assessment device for comprehensive atmospheric environment corrosion

ActiveCN103115864AEasy to controlCompact structureWeather/light/corrosion resistanceTemperature controlCold air

The invention relates to an indoor simulation / rapid assessment device for comprehensive atmospheric environment corrosion, and belongs to the technical field of indoor simulation / rapid assessment devices for the corrosion of materials. The device comprises a control panel, a main work box, an ultraviolet lamp tube, a lifting mechanism, a temperature control and feedback system, a humidity control and feedback system and a hot and cold air system. The temperature control and feedback system, the humidity control and feedback system, the ultraviolet lamp tube and the hot and cold air system are controlled by the control panel to carry out environmental simulation on a test sample in the main work box. The device is simple in structure, low in manufacturing cost, high in work stability and accurate in test parameter control, not only can simulate the corrosion process of a material component under single conditions, such as constant temperature and constant humidity, alternation of wetting and drying and ultraviolet irradiation, but also can simulate the corrosion behaviors and processes of the material component under the synergistic action of multiple factors, and is particularly applicable to the indoor simulation and rapid assessment of the corrosion under the comprehensive action of the multiple factors in an atmospheric environment.

Owner:河北维立方科技有限公司

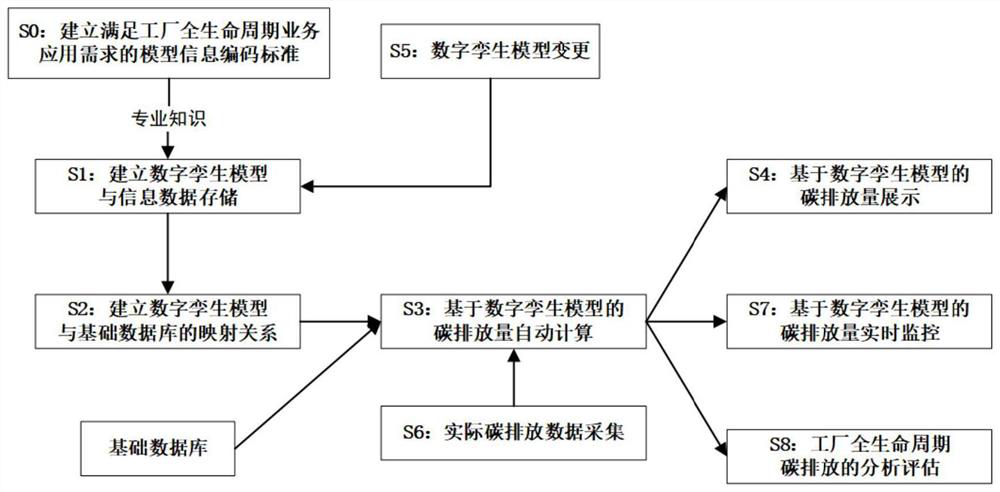

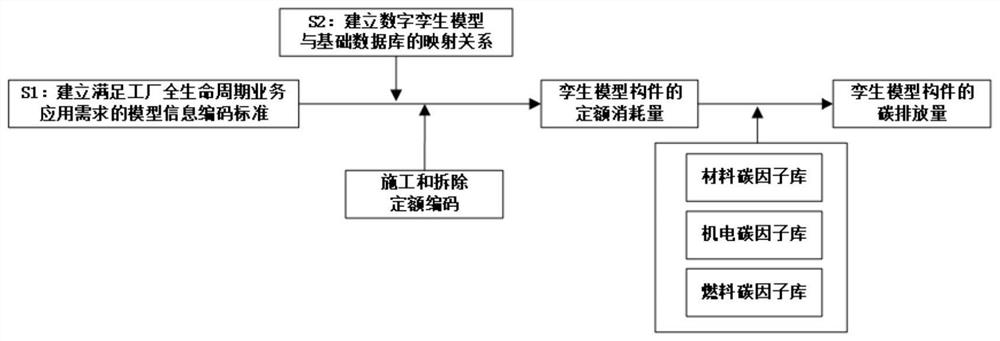

Carbon emission evaluation method and system based on digital twinborn model

PendingCN113435054ARealize automatic calculationGuaranteed accuracyDatabase management systemsTechnology managementData informationDynamic monitoring

The invention discloses a carbon emission evaluation method and system based on a digital twin model, and relates to the technical field of engineering building carbon emission systems. The system comprises a plurality of client terminals, an application server and a database, wherein each client terminal is provided with a user operation interface for technicians to execute related operations such as carbon emission planning, feedback, query, monitoring, evaluation report generation and the like; the application server comprises a plurality of functional modules for carbon emission calculation and is used for data processing, algorithm analysis and interface query of the digital twin model; and the database is used for storing digital twin model information and basic data information. The invention is used for carrying out rapid evaluation, fine calculation and real-time dynamic monitoring on the carbon emission in the whole life cycle of the factory, carbon emission evaluation is carried out based on a digital management platform and non-specific industries, the repeated work of carbon emission calculation can be reduced, the carbon emission accounting efficiency in the whole life cycle of the factory is improved, and the carbon emission calculation fineness and accuracy are ensured.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

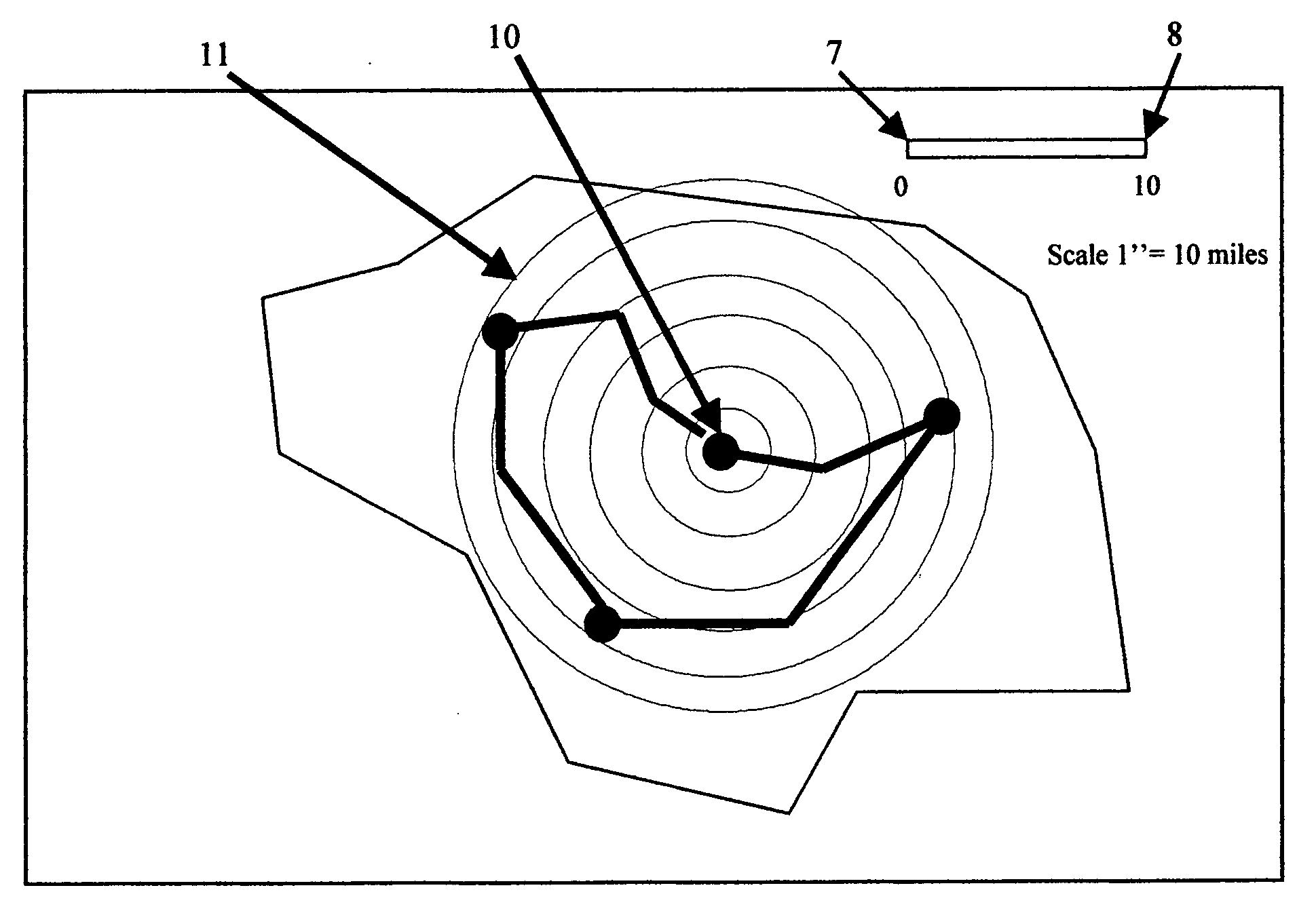

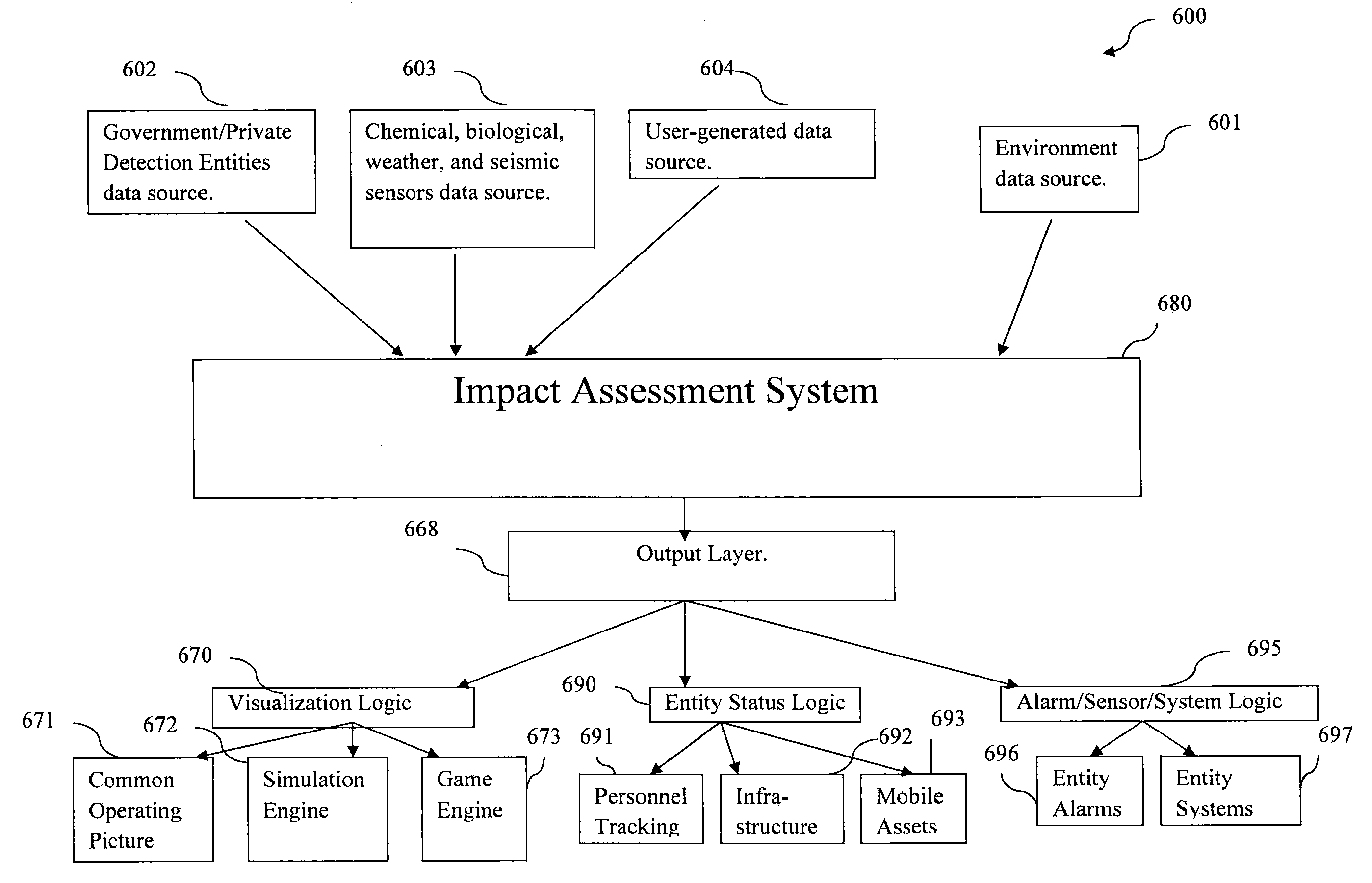

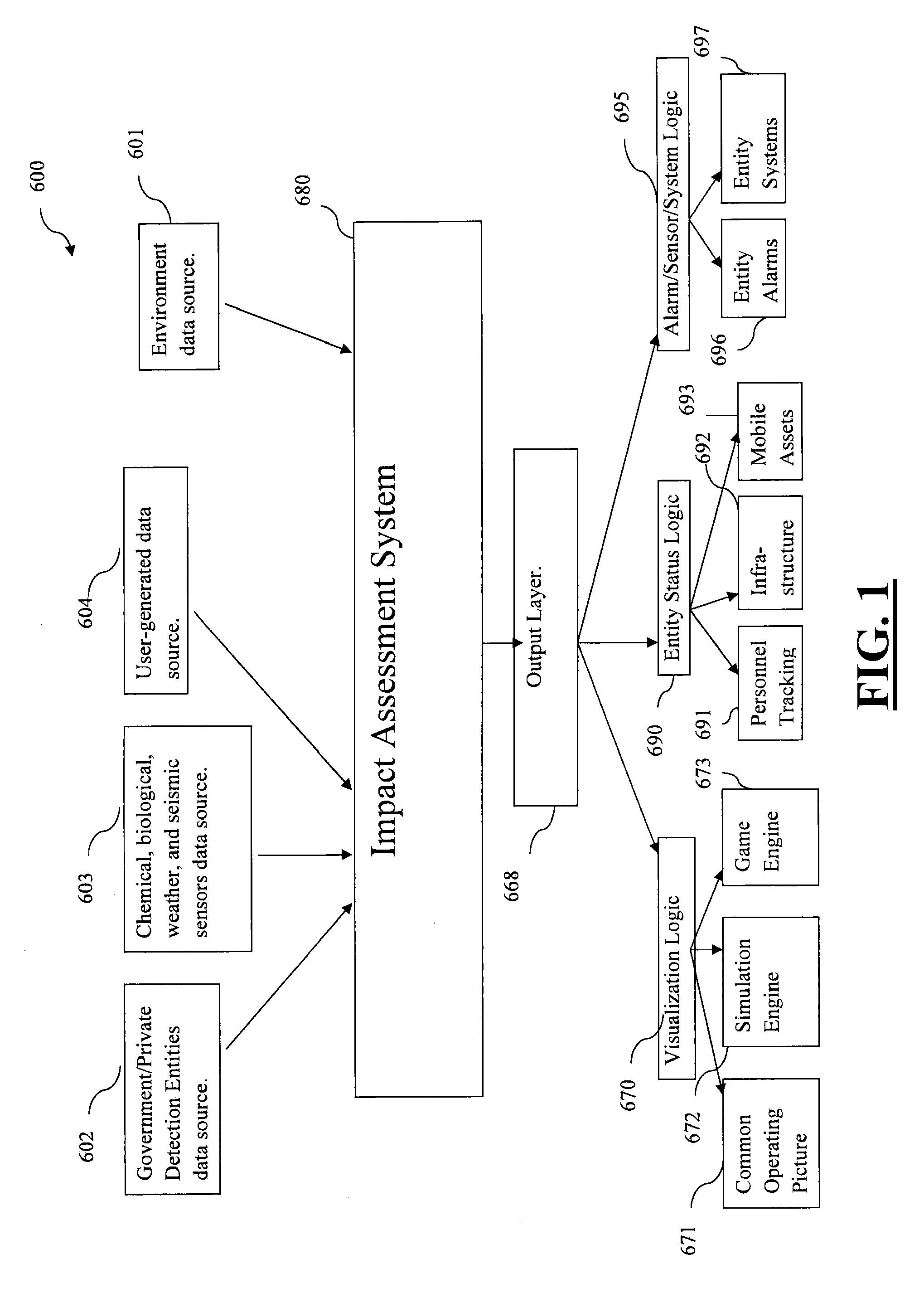

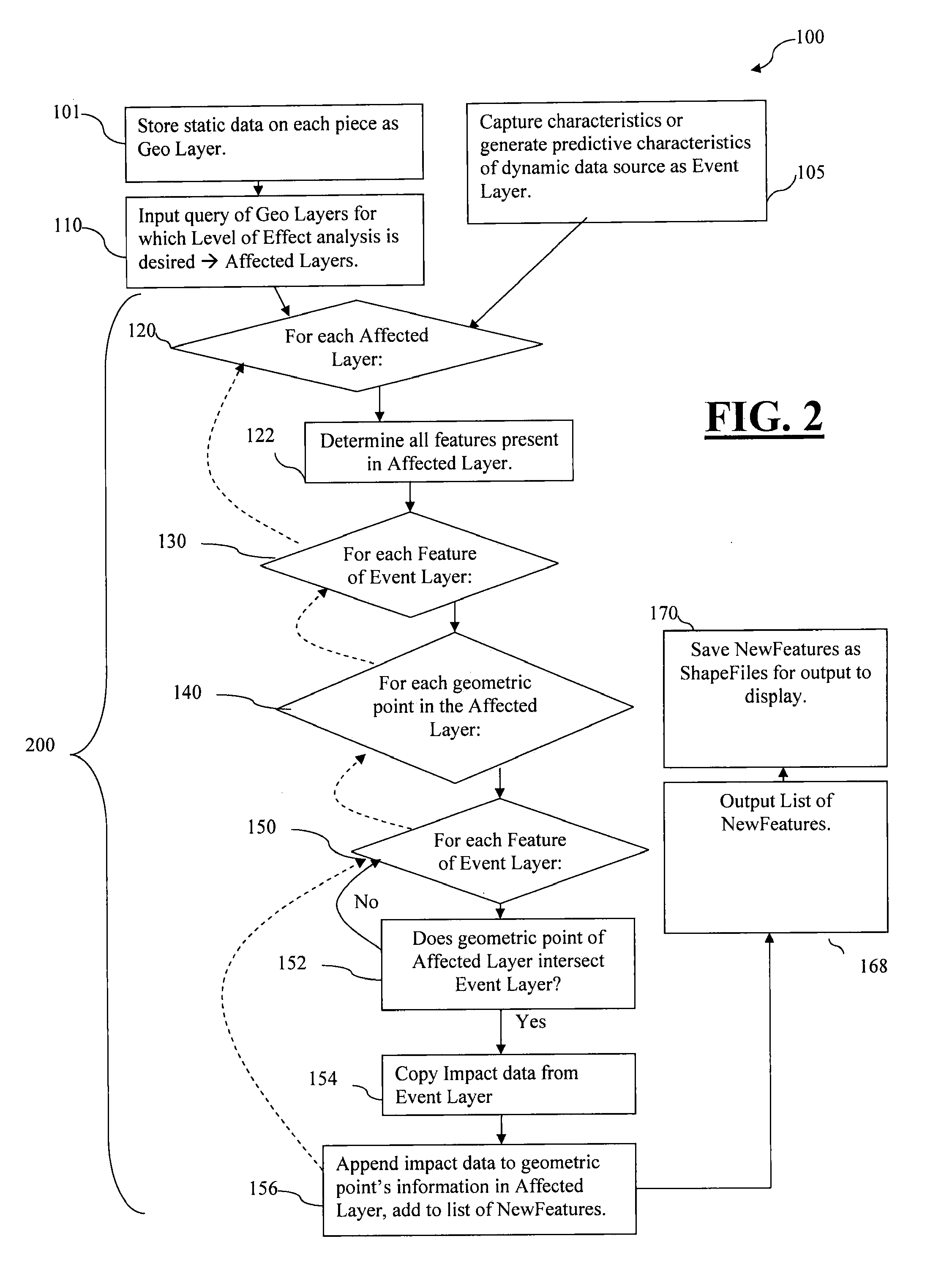

Method, apparatus, and system for rapid assessment

Systems and devices for assessment of an impact by an event on an environment are disclosed. Processes for automated impact assessment are also disclosed. An impact assessment can be performed in computer-generated environments which include data regarding the environment impacted and data regarding the event impacting the environment. Environment data may be represented as a geospatial layer.

Owner:STRATVUE SPV

Circularly polarized light method and device for determining wall thickness and orientations of fibrils of cellulosic fibres

ActiveUS7289210B2Polarisation-affecting propertiesPhase-affecting property measurementsFibrilData analysis system

This invention provides a novel, rapid method and device for determining the relative phase retardation of different layers of a multi-layered specimen, which is related to the thicknesses of its layers and walls, and the orientations of its optical axes. An intact wood pulp fibre is a typical multi-layered birefringent specimen. This new method is based on the change of polarization of polarized light that passes through a specimen composed of birefringent layers with different optical axis orientations, such as directions of cellulosic microfibrils oriented differently in various layers of wood fibres. In particular, a novel solution is found to relate the emerging light intensity from an intact wood fibre to the incident light intensity, the wavelength of the light, and the relative phase retardations of various layers and orientations of their cellulosic microfibrils, such as fibril angle, in a circularly polarized light system. This new method evaluates the transmitted light intensities of multiple predetermined wavelengths simultaneously to determine the optical and physical properties of a multi-layered specimen being measured. A device for determining the relative phase retardation (retardance) of fibre walls and the fibril angle of intact wood fibres in accordance with the presented invention comprises a light source with well defined multi-wavelengths, an achromatic circularly polarized light system, appropriate imaging optics, a multi-channel camera such as a digital color camera that has two or more wavelength (color) detection channels, and an image processing and data analysis system. The measurements take advantage of the birefringence of cellulosic microfibrils, and thus require neither sample preparation nor high resolution optics. Specimen alignment is not required as specimens such as wood fibres are evaluated under circularly polarized light. Compared with other methods, this invention is more rapid, accurate, and robust. This method can be automated, and implemented in a fibre flow-through system, thus allowing a rapid assessment of wood pulp fibre properties (on-line in real time).

Owner:FPINNOVATIONS INC

Embedded wireless monitoring sensors

ActiveUS20170284996A1Address limitationsWeather/light/corrosion resistanceCeramic shaping apparatusFull life cycleProcess integration

Concrete can be one of the most durable building materials where consumption is projected to reach approximately 40 billion tons in 2017 alone. Despite this the testing of concrete at all stages of its life cycle is still in its infancy although testing for corrosion is well established. Further many of the tests today are time consuming, expensive, and provide results only after it has been poured and set. Accordingly, by exploiting self-contained wireless sensor devices, which are deployed with the wet concrete, the in-situ curing and maturity measurement data can be established and employed together with batch specific concrete data to provide rapid initial tests and evolving performance data regarding the concrete cure, performance, corrosion of concrete at different points in its life cycle. Such sensors remove subjectivity, allow for rapid assessment, are integrable to the construction process, and provided full life cycle assessment.

Owner:GIATEC SCI

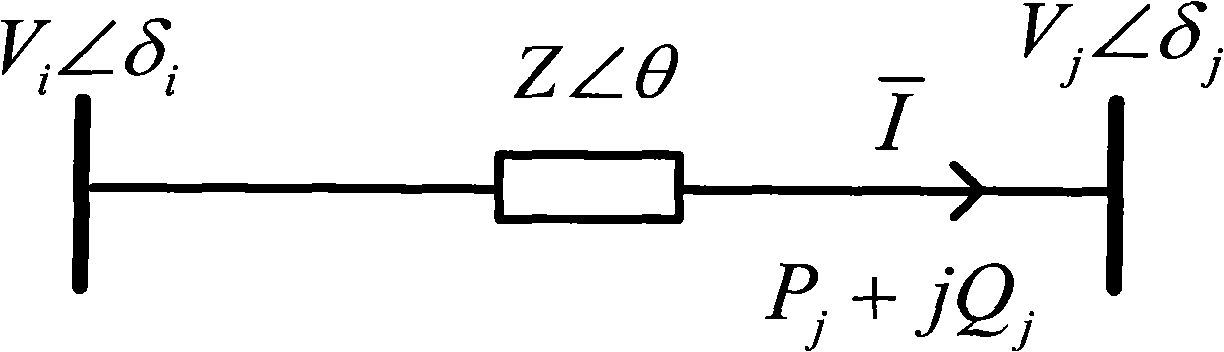

Real time evaluating method of voltage stability

ActiveCN101349731AWide applicabilityImprove accuracyCurrent/voltage measurementElectrical testingLow voltagePower grid

The invention provides a circuit tidal current index for resolving the problems such as that the high circuit tidal current causes the voltage decrease at the bus of the receiving end and the failure about the real solution of the circuit tidal current equation. The circuit tidal current index is applied for real-time voltage stabilization detection to provide a voltage stability real-time evaluation method, based on the circuit tidal current index. The method can simply and quickly evaluate the voltage stability of a power network and can scan and calculate the circuit tidal current index of a full network line to fine the line of low voltage stability in the power network. Applied for the voltage stability real-time detection, the method can provide the change tread of the voltage stability of each line, to determine the initial point of the voltage stability problem.

Owner:CHINA ELECTRIC POWER RES INST +1

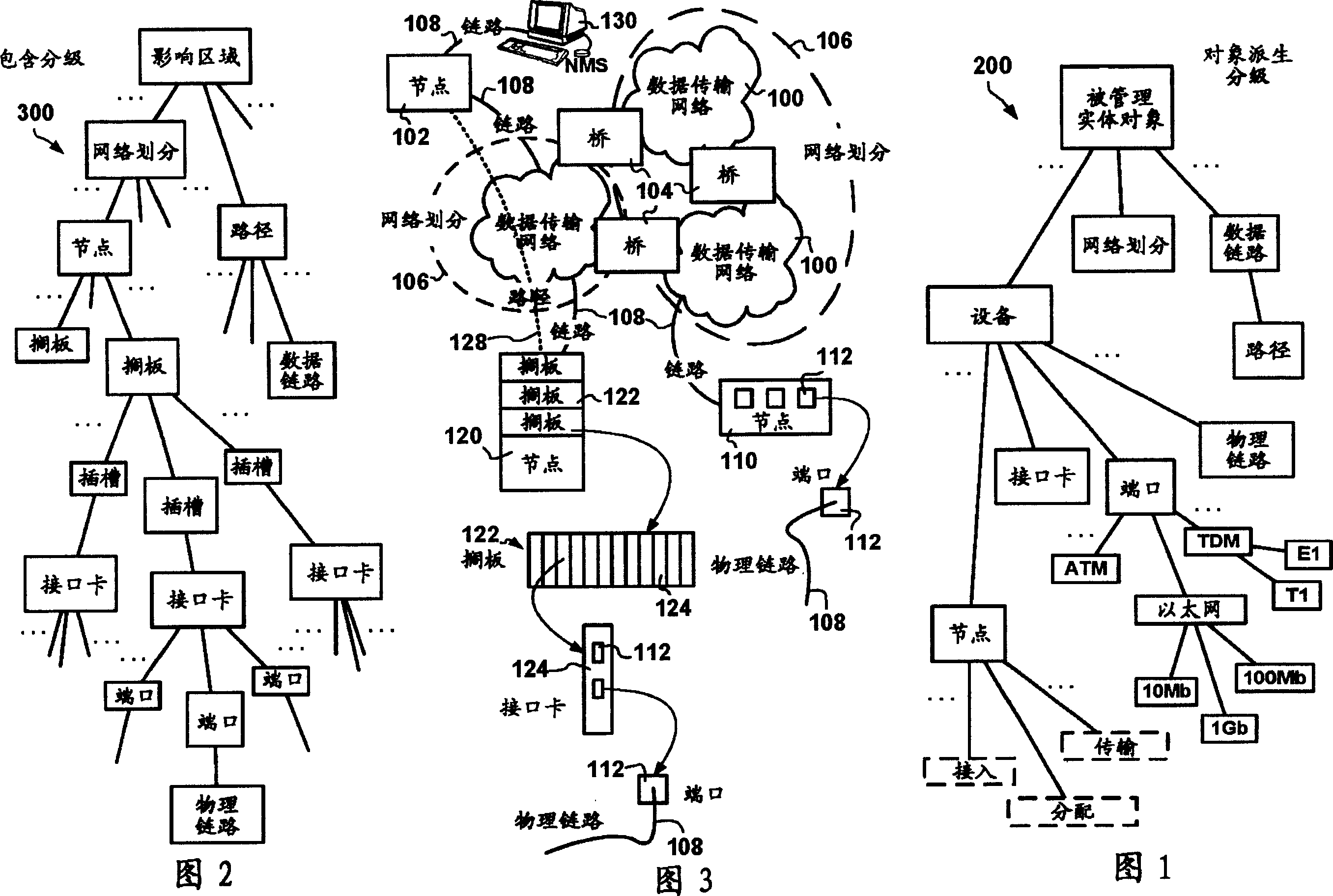

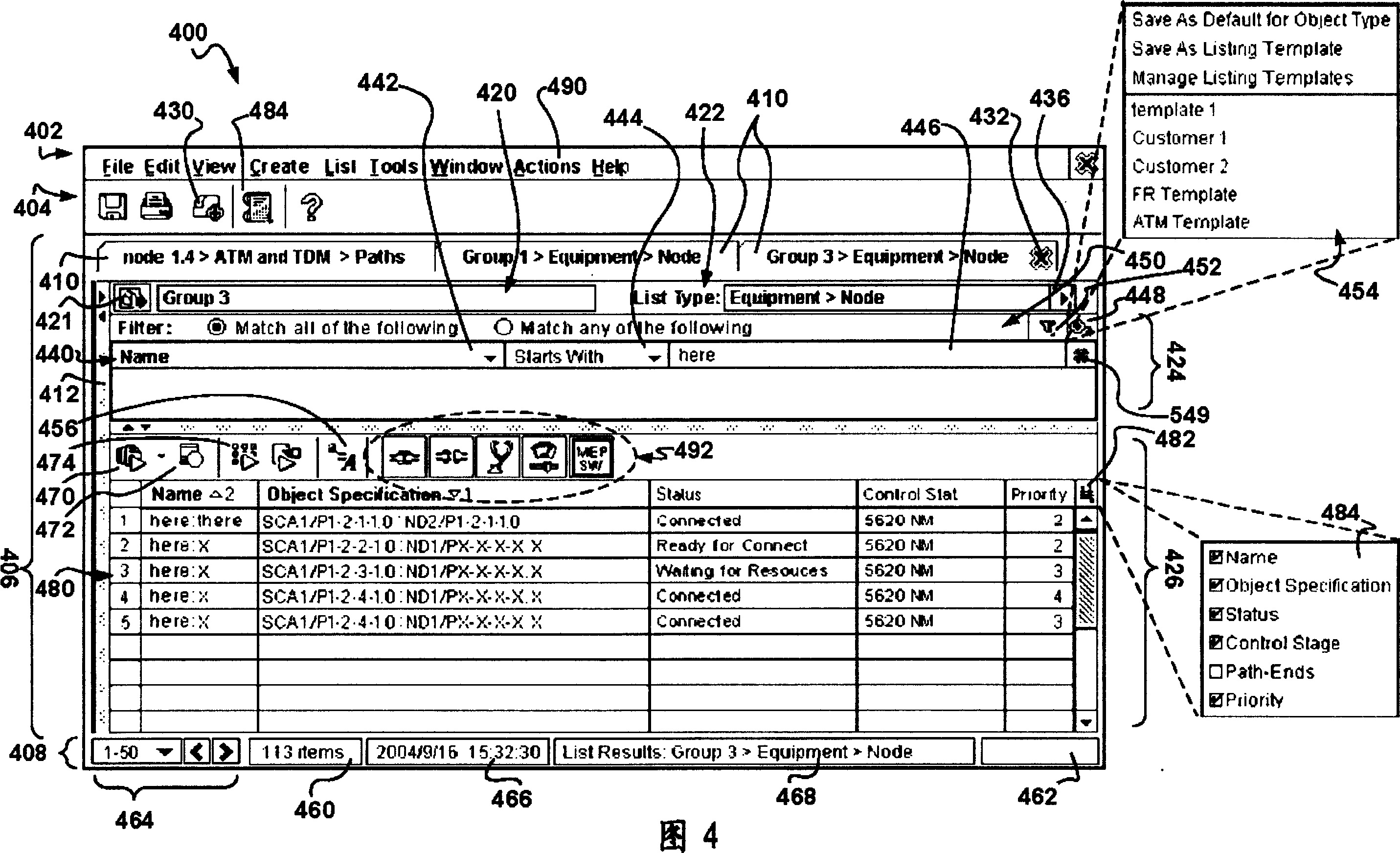

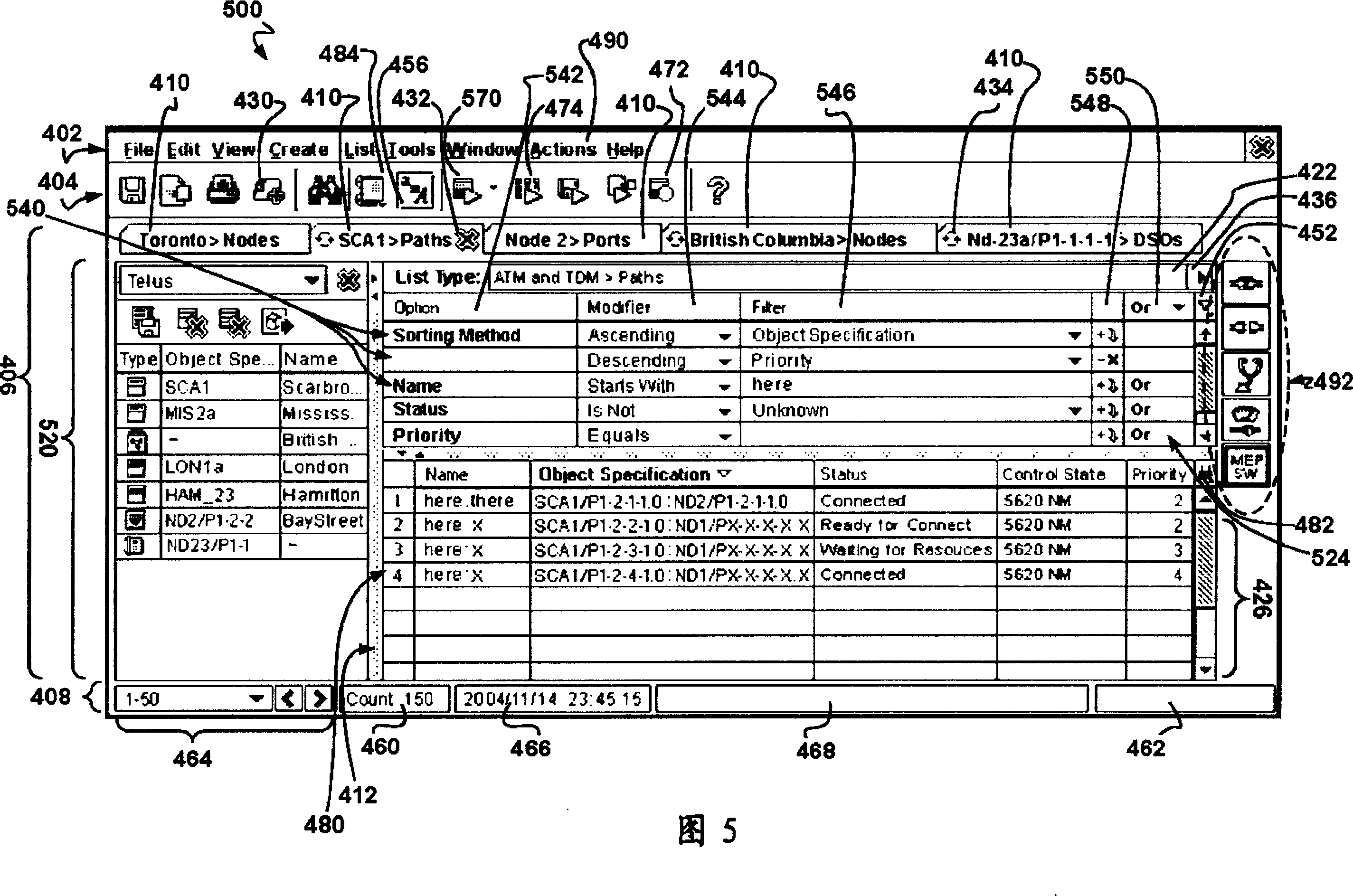

Graphical user interface for generic listing of managed objects

InactiveCN101013954AImprove inefficiencyImprove usabilityData switching by path configurationExecution for user interfacesGraphicsGraphical user interface

Graphical user interface for generic listing of managed objects and methods for efficiently filtering and sorting a large number of managed objects of different object types are presented. A single context-sensitive listing form is employed, the operation and display of which changes dynamically according to the selection of a target object. Whenever the user changes the selected target object, the items of a list type menu change to display the applicable list types. An action menu and / or a context-sensitive tool bar changes based on the selected target object to provide quick access selected object type specific actions. The solution allows users to paste objects into the listing form, perform complex filtering based on the object type used, provide a quick assessment of list filtering effectiveness, and invoke appropriate actions on managed object hits. Advantages of the solution include enhanced complex context-sensitive filtering and sorting capabilities, improved performance in dealing with large lists as well a reduction in window management.

Owner:ALCATEL LUCENT SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com