Detection method of lithium ion battery performance

A technology of lithium-ion battery and detection method, applied in the direction of secondary battery, secondary battery repair/maintenance, secondary battery charging/discharging, etc. Ignore security risks and other issues to achieve the effect of improving identification and prevention capabilities, shortening evaluation time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Perform the following tests on high energy density polymer lithium-ion batteries:

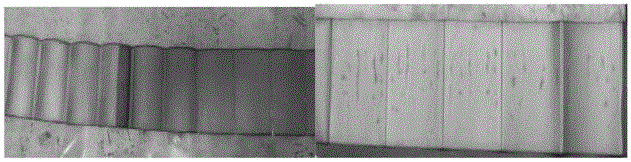

[0086] Charge at 0.2C at 0°C, discharge at 0.5C, cycle 3 times, dissect and detect lithium deposition. The results show that serious lithium deposition occurs on the surface of the negative electrode, indicating that the internal impedance of the battery is too large and the service life is not good. presents a security risk.

[0087] The lithium analysis diagram on the surface of the battery is shown in figure 1 , where the left picture is the lithium analysis map on the front surface of the battery negative electrode, and the right picture is the lithium analysis map on the back surface of the battery negative electrode.

Embodiment 2

[0089] Perform the following tests on high energy density polymer lithium-ion batteries:

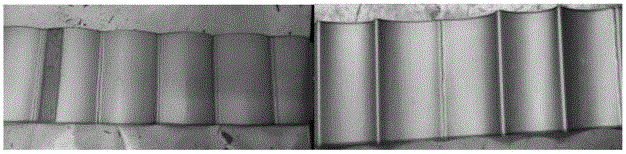

[0090] Charge at 0.2C at 0°C, discharge at 0.5C, cycle 20 times, dissect and detect the lithium deposition. The results show that there are more lithium deposition on the surface of the negative electrode, indicating that the internal impedance of the battery is large and the service life is not good. , a security risk.

[0091] The lithium analysis diagram on the surface of the battery is shown in figure 2 , where the left picture is the lithium analysis map on the front surface of the battery negative electrode, and the right picture is the lithium analysis map on the back surface of the battery negative electrode.

Embodiment 3

[0093] For high energy density polymer lithium-ion battery products, the following methods are used for rapid detection:

[0094] Charge at 0.2C at 0°C, discharge at 0.5C, cycle 15 times, dissect and analyze lithium; there is no lithium analysis on the surface of the negative electrode;

[0095] Charge at 0.3C at 5°C, discharge at 0.5C, cycle 15 times, dissect and analyze lithium; there is no lithium analysis on the surface of the negative electrode;

[0096] Charge at 1.0C at 15°C, discharge at 0.5C, cycle 15 times, dissect and analyze lithium; there is no lithium analysis on the surface of the negative electrode;

[0097] Charge at 1.5C at 25°C, discharge at 0.5C, cycle 15 times, dissect and analyze lithium; there is no lithium analysis on the surface of the negative electrode;

[0098] The lithium analysis diagram on the surface of the battery is shown in image 3 , where the left picture is the lithium analysis map on the front surface of the battery negative electrode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com