Compound function type bamboo pulp fibre and preparation method thereof

A bamboo pulp fiber and composite function technology, which is applied in the field of composite functional bamboo pulp fiber and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

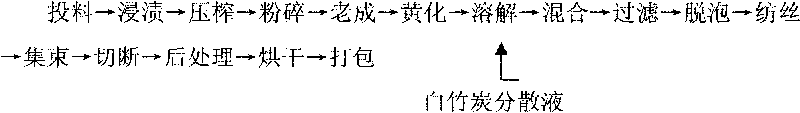

[0017] 1. Process flow: see attached Figure 1

[0018] Present embodiment is that adopting concentration is that 8% white bamboo charcoal dispersion liquid is mixed into viscose in post-dissolution process, and wherein white bamboo charcoal average particle diameter is 0.2 micron, and dispersant agent sodium dodecylbenzene yellow acid add-on 0.5% (to white bamboo charcoal amount) , the addition of white bamboo charcoal powder in viscose is 0.15% (p-methyl cellulose).

[0019] 2. Process parameters:

[0020] Spinning glue index: methyl fiber content 7.6%; total alkali content 4.4%; viscosity 38 seconds; maturity 7.3ml (10% ammonium chloride value).

[0021] Acid bath indicators: sulfuric acid content 137.6g / l; zinc sulfate content 20.6g / l; sodium sulfate content 290g / l; bath temperature 48°C.

[0022] 3. Fiber quality index:

[0023] Dry breaking strength: 2.45CN / dtex Wet breaking strength: 1.38CN / dtex

[0024] Far-infrared emission rate: 83% (inspection based on FZ / T64010...

Embodiment 2

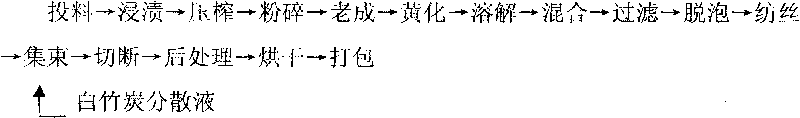

[0028] 1. Process flow: see attached Figure II

[0029] The present embodiment is that the concentration of 15% white bamboo charcoal dispersion is mixed with viscose by means of pre-spinning injection, wherein the average particle diameter of white bamboo charcoal is 1.1 micron, and the addition of dispersant nonylphenol polyoxyethylene is 0.8% (to the amount of white bamboo charcoal). , the addition of white bamboo charcoal powder in viscose is 1.2% (p-methyl cellulose).

[0030] 2. Process parameters:

[0031] Spinning glue index: methyl fiber content 10.2%; total alkali content 6.3%; viscosity 48 seconds; maturity 11.3ml (10% ammonium chloride value);

[0032] Acid bath indicators: sulfuric acid content 98g / l; zinc sulfate content 8.6g / l; sodium sulfate content 280g / l; bath temperature 63°C.

[0033] 3. Fiber quality index:

[0034] Dry breaking strength: 2.34CN / dtex Wet breaking strength: 1.35CN / dtex

[0035] Far-infrared emission rate: 85% (inspection based on FZ / T...

Embodiment 3

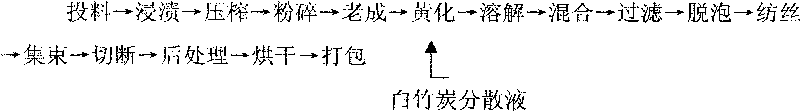

[0039] 1. Process flow: see attached Figure three

[0040] Present embodiment is that adopting concentration is that 85% white bamboo charcoal dispersion liquid is mixed into viscose in post-dissolution process, and wherein white bamboo charcoal average particle diameter is 0.2 micron, dispersing agent sodium polyacrylate add-on 1.9% (to white bamboo charcoal amount), white bamboo charcoal powder The addition amount of body in viscose glue is 8% (p-methyl cellulose amount).

[0041] 2. Process parameters:

[0042] Spinning glue index: methyl fiber content 8.61%; total alkali content 5.52%; viscosity 35 seconds; maturity 10.6 (10% ammonium chloride value);

[0043] Acid bath indicators: sulfuric acid content 123.5g / l; zinc sulfate content 14.6g / l; sodium sulfate content 315g / l; bath temperature 58°C.

[0044] 3. Fiber quality index:

[0045] Dry breaking strength: 2.12CN / dtex Wet breaking strength: 1.16CN / dtex

[0046] Far-infrared emission rate: 94% (inspection based on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com