Coal bed gas mining novel technology

A technology of coalbed methane and new technology, which is applied in the development of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of small influence range of wellbore, less gas desorption, and inability to desorb, etc., to improve single well production, The effect of reducing mining costs and expanding the scope of coal seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

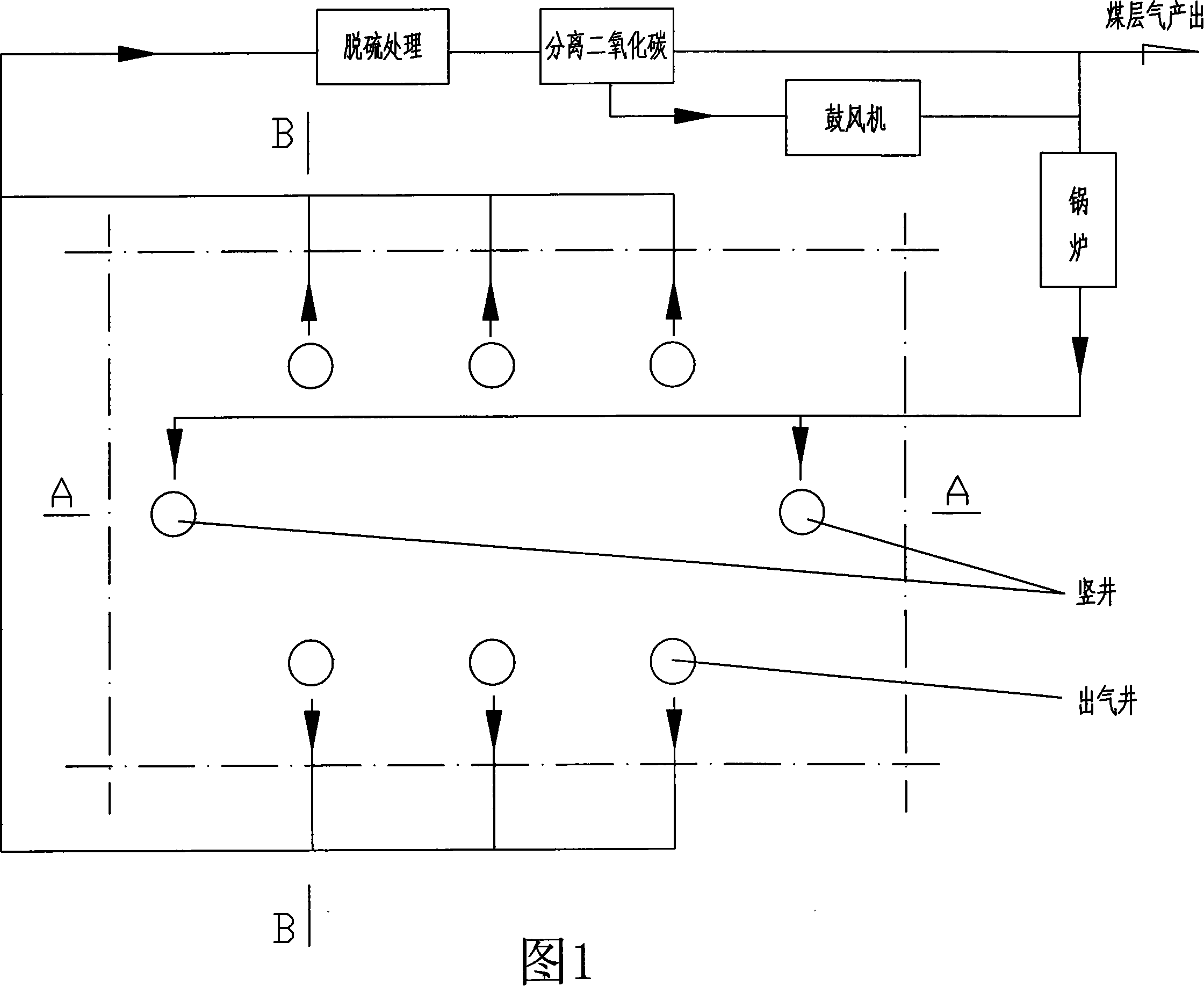

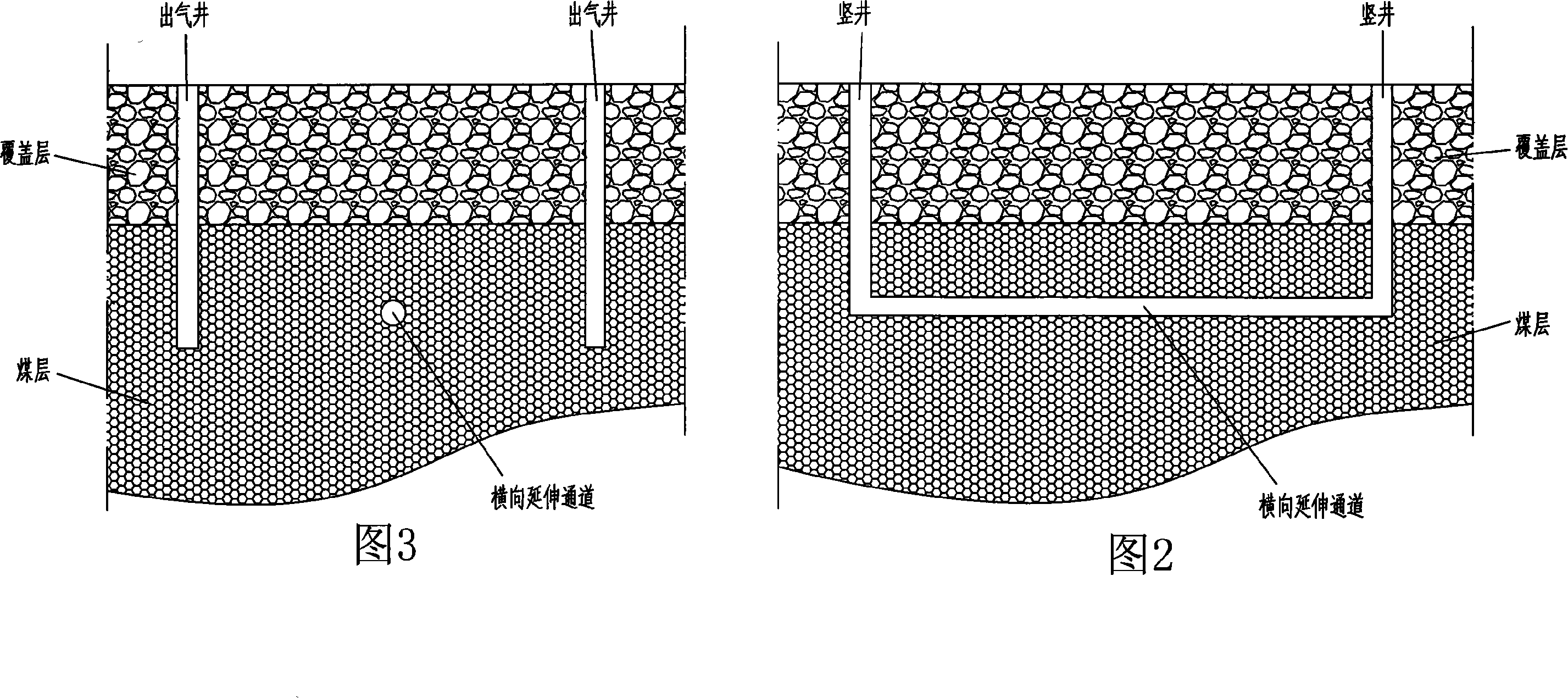

[0027] As shown in Fig. 1, Fig. 2 and Fig. 3, it is a preferred embodiment of the present invention. In this embodiment, the air intake shaft includes two vertical shafts arranged at intervals, and the two vertical shafts are connected through a transversely extending passage, wherein the vertical shaft Drilling from the ground to the underground coal seam, the horizontal extension channel is located in the underground coal seam; there are three gas outlet wells on both sides of the lateral extension channel, and the three gas outlet wells on each side are arranged along the direction of the lateral extension channel. Set at intervals between them, and set at the same interval between gas outlet wells on the same side.

[0028] According to needs, only one vertical shaft can be arranged in the air intake shaft, and multiple vertical shafts can also be arranged at intervals along the extension channel. Similarly, as required, the gas outlet wells can also be arranged only on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com