System and method for monitoring strain & pressure

a technology of strain and pressure measurement and monitoring system, which is applied in the field of system and method for measuring strain and/or pressure in underground formations, can solve the problems of inability to measure in-situ, inconvenient calibration, and fracture of rock matrix,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

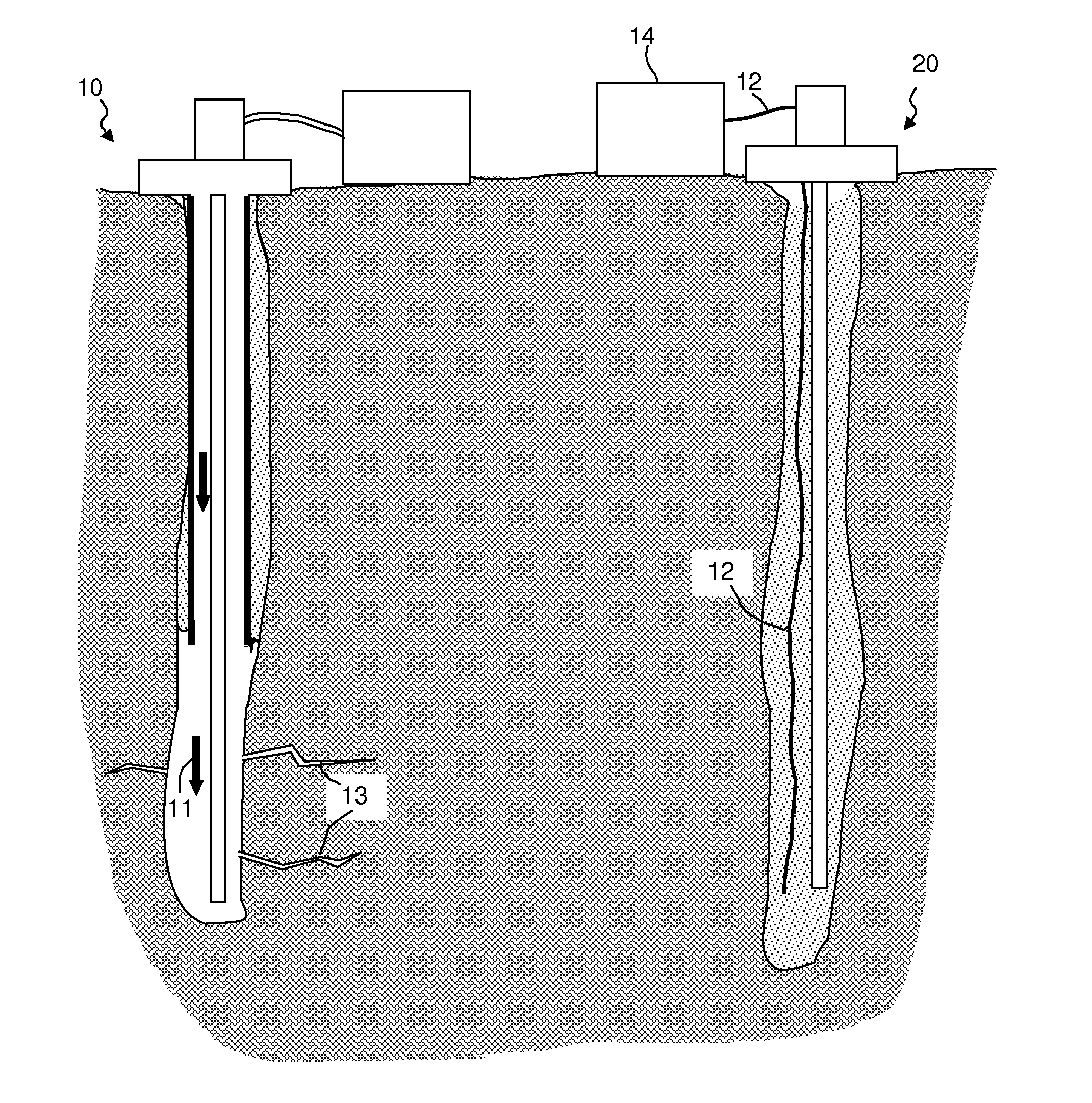

example 1

[0029]According to a first exemplary embodiment, distributed OTDR sensing can be used to detect hydraulic fracturing according to the following workflow:[0030]deploy one or more DAS fibers in one or more wells in the vicinity of an intended hydraulic fracturing operation;[0031]prior to hydraulic fracturing in the area, record noise levels along the fiber as a control measurement;[0032]upon initiation of pumping of fracture fluids, for any or all fracture stages and fluid types, including mini-frac (or test frac), record the strain field as measured by the DAS system, for all locations in the well where the formation can be affected by the fracture operation;[0033]simulate the strain field as a function of time and space using a geomechanical simulation;[0034]from the results of the simulation, make a prediction of the axial strain measurements at the places where the DAS fibers have made the measurements;[0035]compare the predictions and measurements and adjust t...

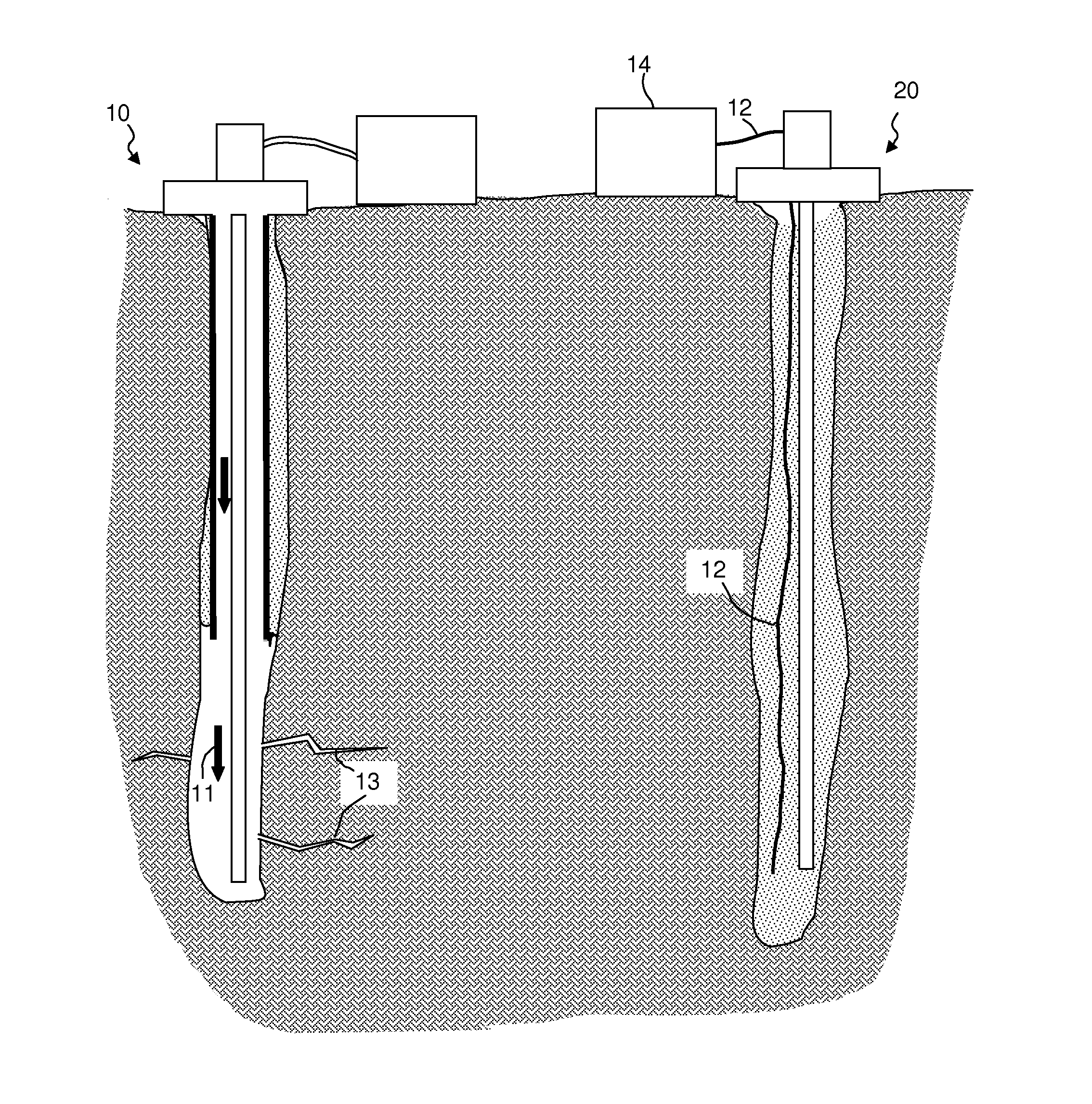

example 2

Depletion

[0040]According to a second exemplary embodiment, the inventive methods are used to measure time-dependent strain in a depleting field. More specifically, the inventive methods provide a way to measure moderate resolution differential depletion in a reservoir. The cost and availability of fiber optic sensors, allows construction of an areal picture of depletion induced strain.

[0041]Thus, according to this embodiment, distributed OTDR sensing can be used to detect and monitor field depletion according to the following workflow:[0042]deploy one or more DAS fibers in one or more wells in the vicinity of an intended hydraulic fracturing operation;[0043]prior to field startup, record noise levels along the fibers as a control measurement;[0044]upon initiation of field depletion, the strain field as measured by the DAS system, for all instrumented wells;[0045]simulate the strain field as a function of time and space using a geomechanical simulation;[0046]from the results of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com