Physical simulation device for multiple seam gas well drainage and production and experimental method thereof

A coalbed methane well, physical simulation technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve problems such as experimental result errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

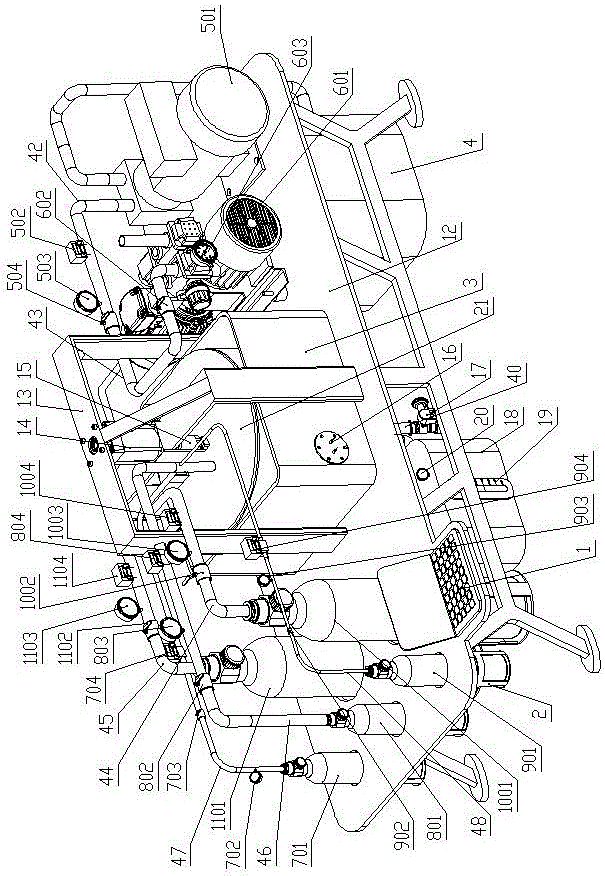

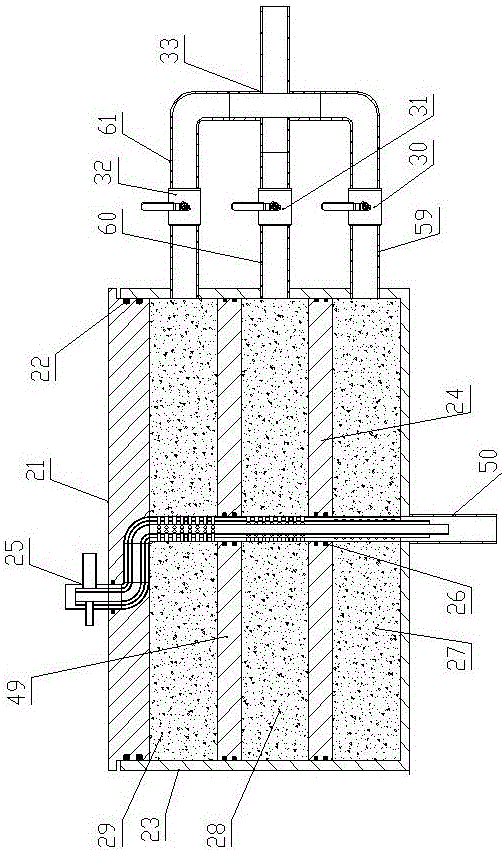

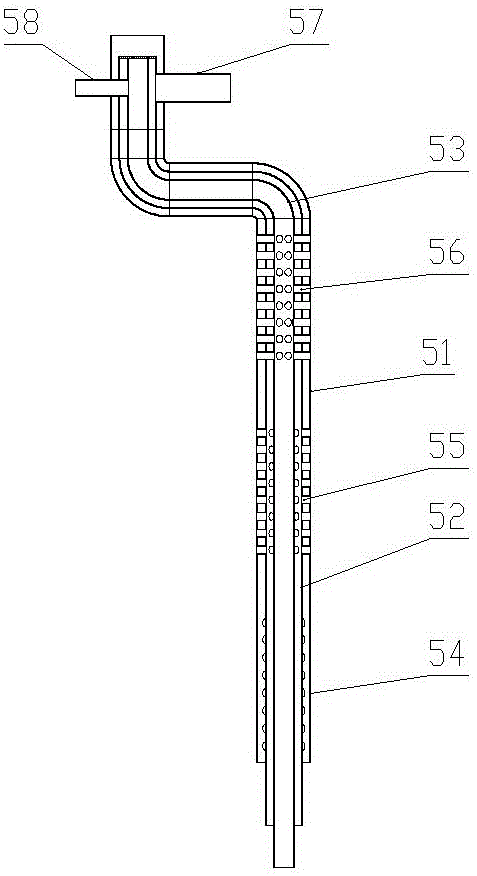

[0043] Such as figure 1 , figure 2 with image 3 As shown, a physical simulation device for the drainage and extraction of a multi-coal coalbed methane well of the present invention includes a control computer 1, an experiment table 12, a hydraulic cylinder support frame 13, a pressurized water pump 501, a vacuum pump 601, a first-level coalbed methane recovery bottle 801, two Level coal bed methane recovery bottle 701, level 3 coal bed methane recovery bottle 901, methane supply cylinder 1001, helium gas storage cylinder 1101, hydraulic cylinder 14, coal seam pressurized water tank 4, return water tank 18, thermal insulation water tank 3 and coal seam pressurization chamber 23. The experiment table 12 is provided with five through holes, and the lower part of the experiment table 12 is fixed with gas cylinder support frames 2 corresponding to the five through holes, the first level coal bed methane recovery bottle 801, the second level coal bed methane recovery bottle 701. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com