Prefabricated slab and column mortise and tenon type connecting joint and installation method

A technology of connecting joints and mortise and tenon joints, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of high cost, large labor costs, and low assembly level, and achieve strong applicability, cost savings, and savings material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

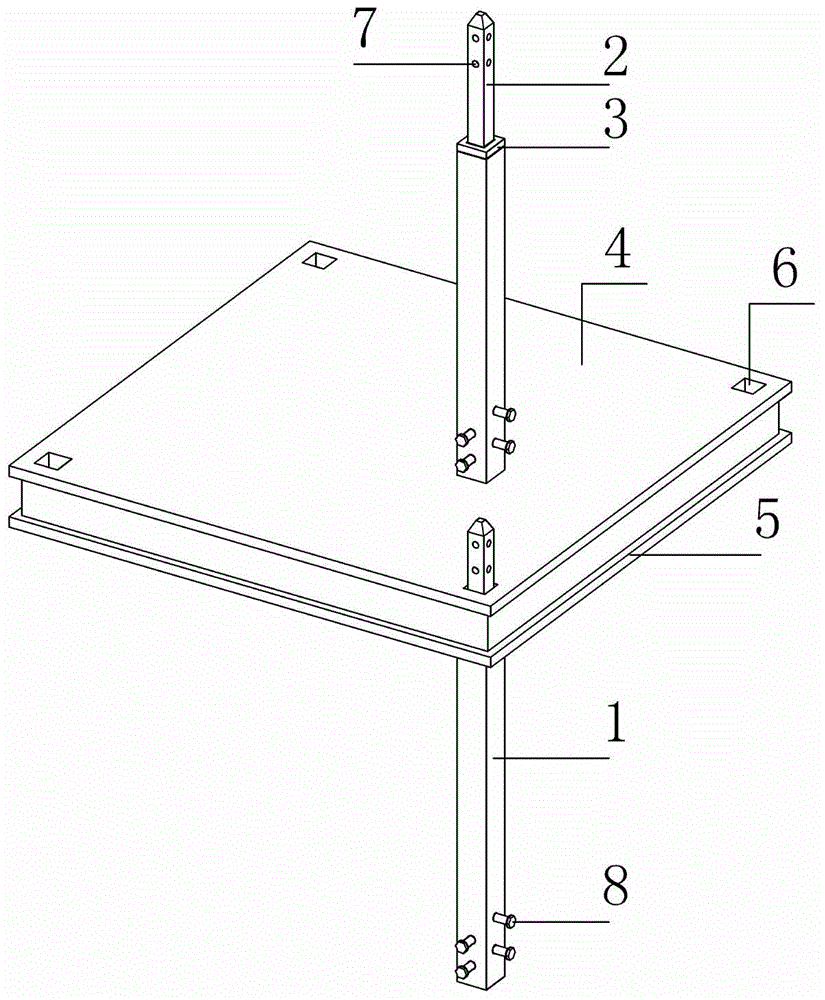

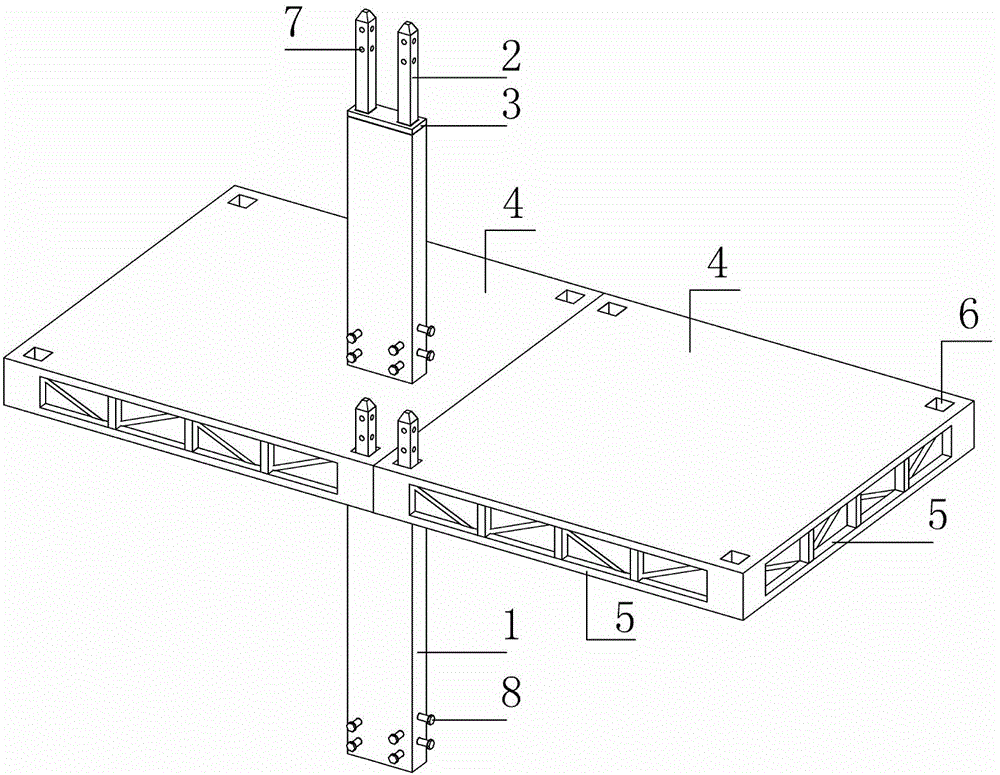

[0021] Such as Figure 1-2 As shown, a prefabricated slab-column mortise-and-mortise joint, which comprises a composite frame column (1), a floor slab (4), and high-strength bolts (8).

[0022] The composite frame column (1) is a factory prefabricated part, and the composite frame column (1) includes a column body, a column tenon (2), a column end sealing plate (3), and a bolt hole (7). The column end sealing plate (3) is a steel plate, and bolt holes (7) are reserved on the bottom of the column body and the column tenon (2). The column tenon (2) is on the same central axis as the column body, and the cross-sectional shapes of the two can be the same or different. The cross section of the column tenon (2) is smaller than that of the column body; shaped structure, to facilitate the up and down insertion of the composite frame column (1) in place. The column end sealing plate (3) is welded on the top of the column body, and the bottom end of the column tenon (2) is welded on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com