Long rail laying and welding construction technology under conditions of large temperature difference and strong wind and sand

A construction technology and long rail technology, which is applied in the direction of laying track, track, track maintenance, etc., which can solve the problems of long construction period, difficult control of welding quality, and poor construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

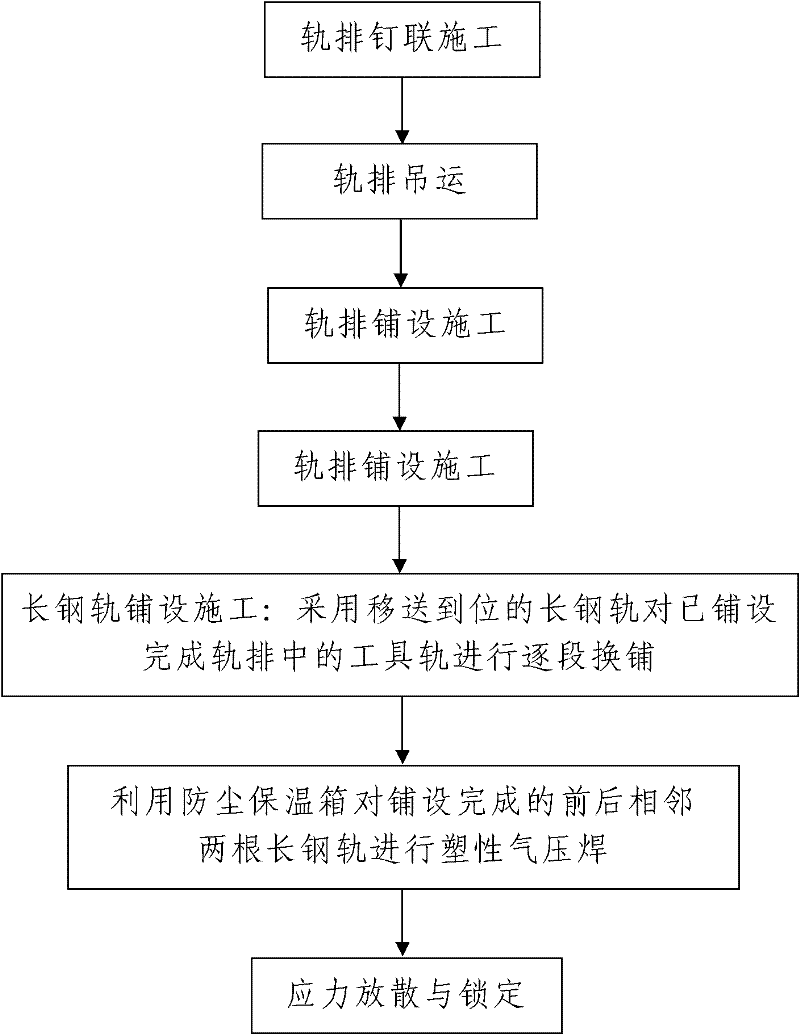

[0069] Such as figure 1 The long rail laying and welding construction process shown in the condition of large temperature difference and strong wind and sand includes the following steps:

[0070] Step 1, the rail row nailing construction, adopts the rail row nailing connection line and according to the conventional rail row nailing construction method, continuously nails the construction of multiple rail rows used for construction; the rail row includes a plurality of sleepers and is installed on Two tool rails on a plurality of said sleepers.

[0071] Step 2. Lifting and transportation of rail row: During the construction process of rail row nailing in step 1, hoisting equipment and transport vehicles are used to transport the completed rail row to the laying site in batches.

[0072] Step 3, track laying construction: use the track laying machine and follow the conventional laying method of the track, lay the track delivered to the laying site, and obtain the track laid by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com