Modular assembling type cold-bent thin-wall type steel wall board structural system

A cold-formed thin-walled steel, modular technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor seismic performance, poor vibration comfort of floor slabs, low assembly degree, low cost, etc., to reduce on-site operations The effect of increasing the quantity and improving the assembly rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

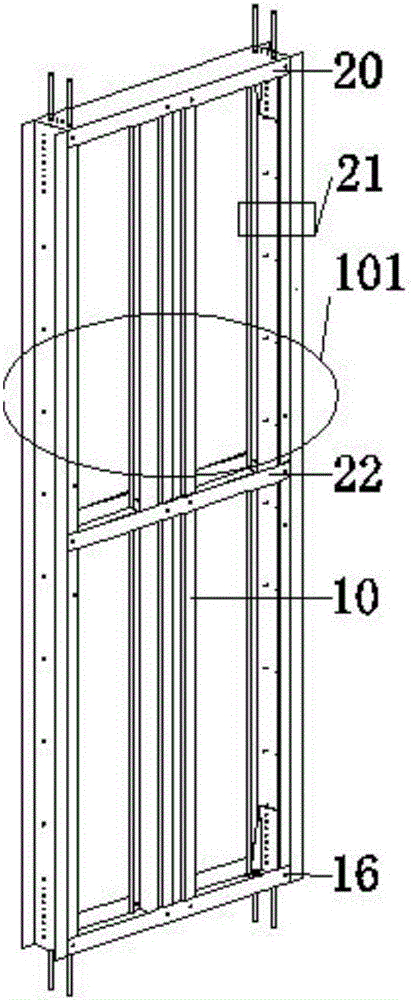

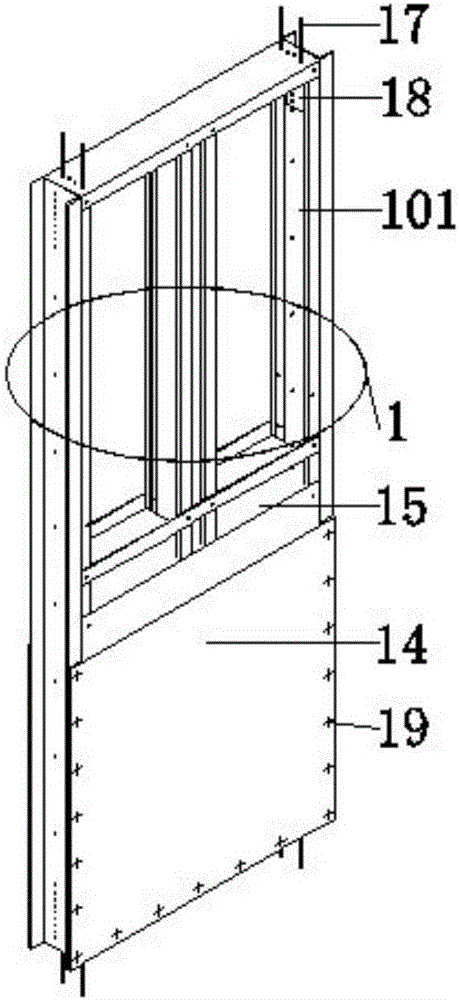

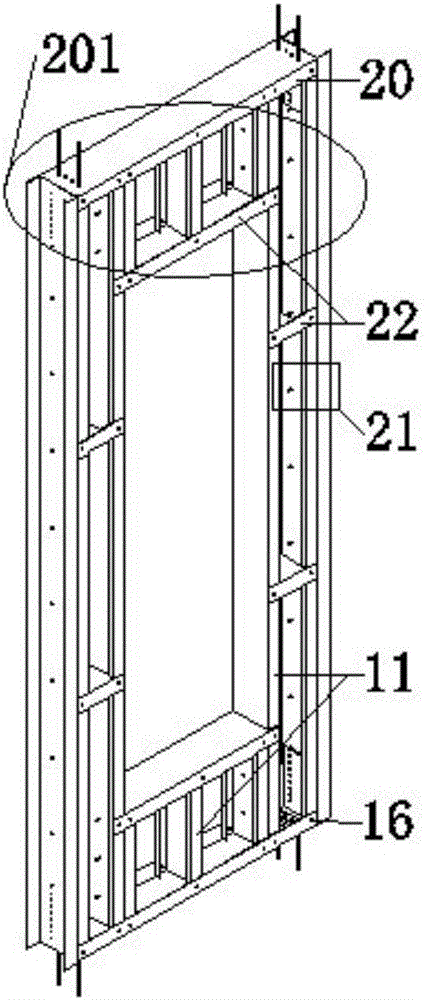

[0052] The production method of the wall module:

[0053] During the specific implementation, firstly, the required C-shaped steel is cut and processed in the factory, and the attached figure 1 , 3 , 11, 12 connect the C-shaped steel through lock riveting (16) to form the common wall center column (10), the hole-shaped wall center column (11), the L-shaped wall center column (12), and the T-shaped wall body Center column (13); then according to the module size (1.2m) of the wall module, blank the horizontal guide rail (20), the vertical side column (21), the lateral support (22), and the diagonal brace (23), and the above-mentioned component attached figure 1 , 3 , 5, and 7 are pre-positioned on the factory assembly line and connected with lock riveting (16) to form cold-formed thin-walled steel skeletons (101), open-hole cold-formed thin-walled steel skeletons (201), and cold-formed thin-walled steel skeletons (201) Skeleton (301), T-shaped cold-formed thin-walled steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com