Testing tool system and testing method for LNG ship liquid cargo compartment three-dimensional board CM nodes

A technology for LNG ships and inspection tooling, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of heavy workload, difficult to directly confirm the centerline assembly or inspection of the three-way plate frame, etc., to achieve rapid assembly And the effect of carrying, improving the inspection pass rate and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below in conjunction with specific embodiments, but the protection scope of the present invention should not be limited thereto.

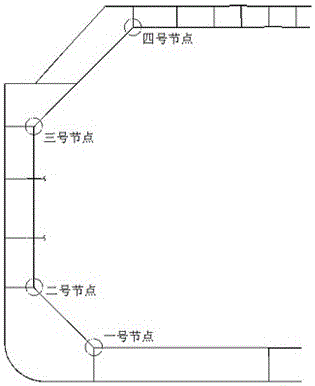

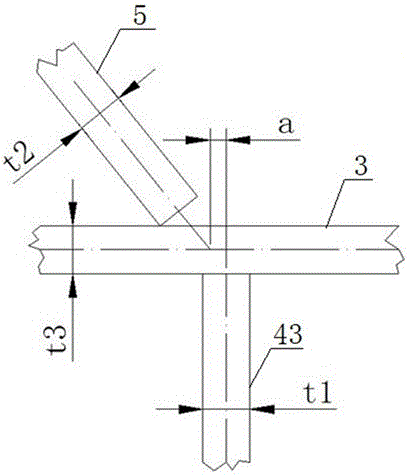

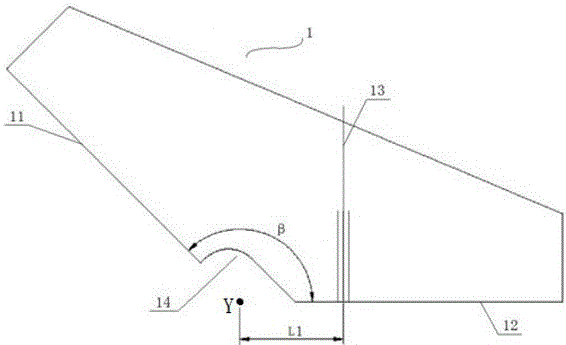

[0031] Such as Figure 3-6 As shown, this embodiment is used for the detection tooling system of the three-way plate CM node of the liquid cargo tank of an LNG ship. The detection tooling system includes an inner card model 1 and an outer card model 2. The inner card model 1 is used for the three The centering of the CM joints in the plate assembly stage, the outer card template 2 is used for the verification of the CM joint inspection stage after the three-way plate welding of the liquid cargo tank of the LNG ship, and the three-way plate includes a transverse plate 3, a vertical plate 4 and Slant plate 5, the included angle between described transverse plate 3 and inclined plate 5 is α, engraves on transverse plate 3 the first reference line 31 perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com