Jacket, jacket foundation platform and jacket construction method

A foundation platform and jacket technology, applied in jacket, jacket foundation platform and jacket construction field, can solve the problems of manpower, material and financial resources, increase investment cost of offshore wind power, etc., to facilitate construction, improve stability and anti-fatigue ability and the effect of reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

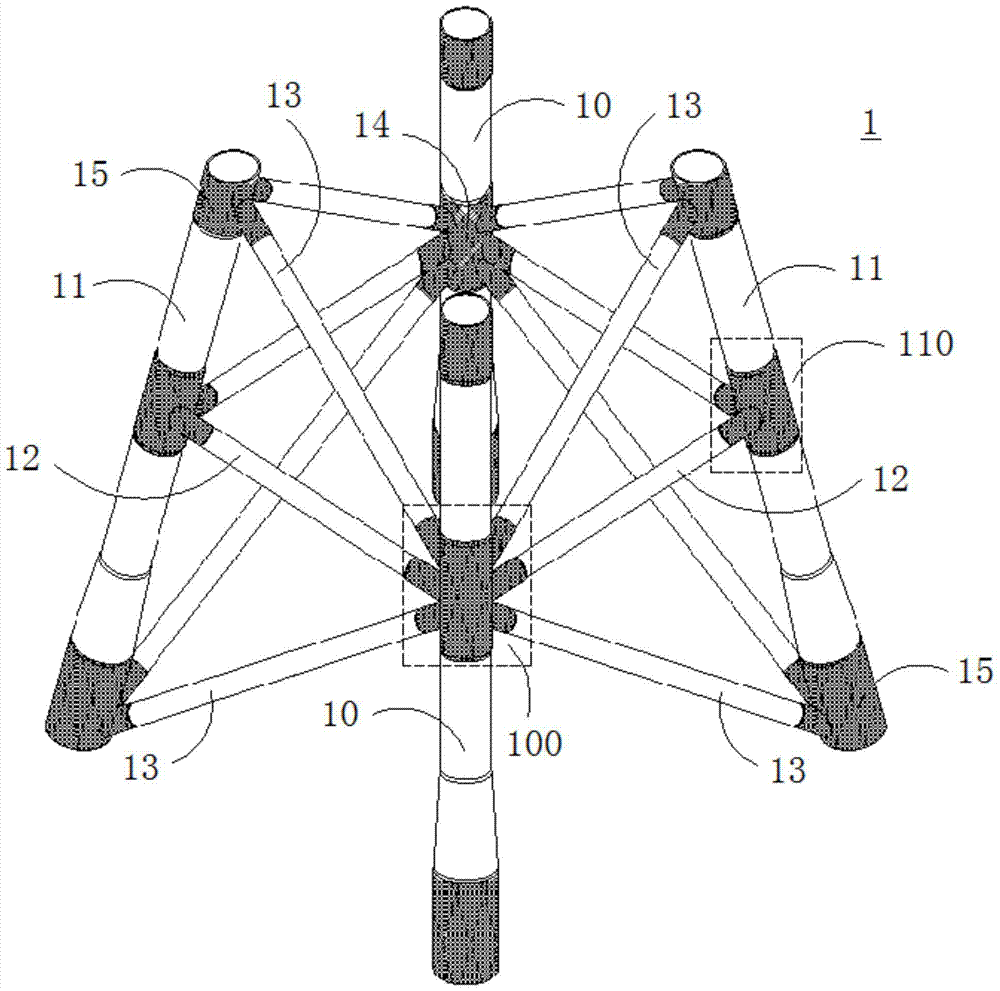

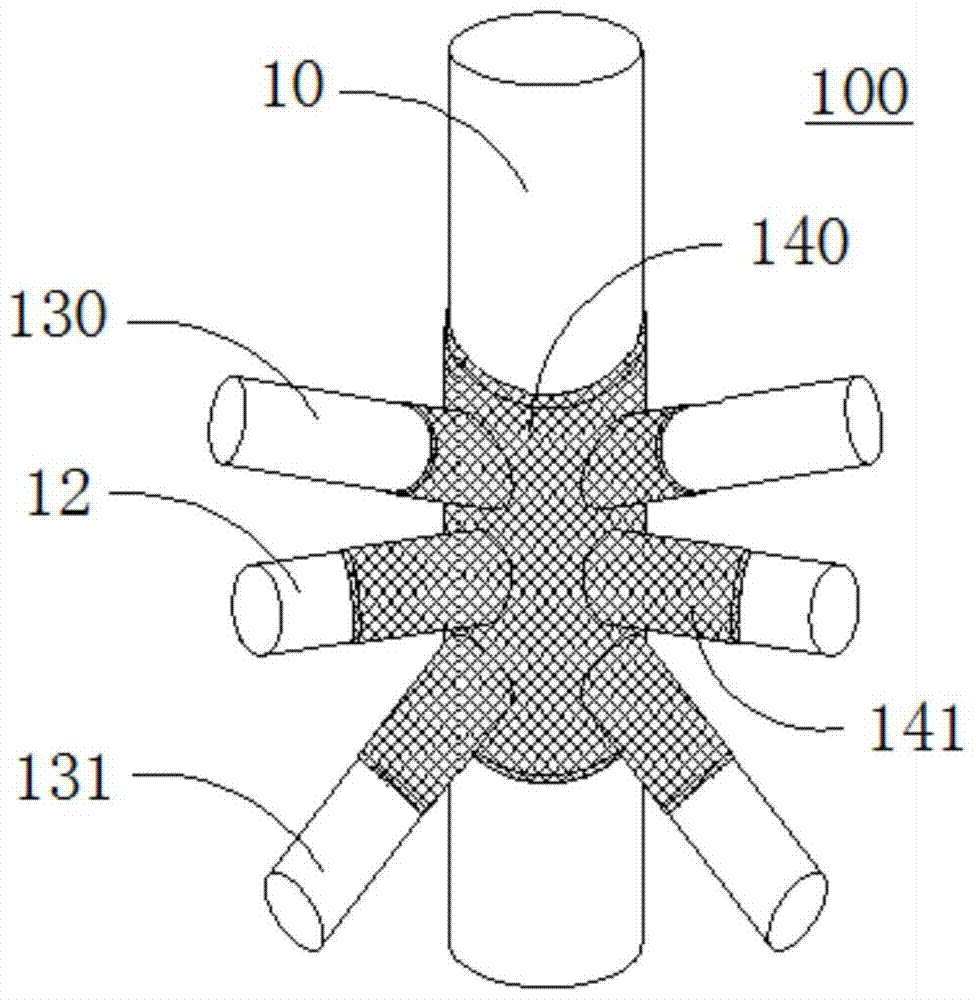

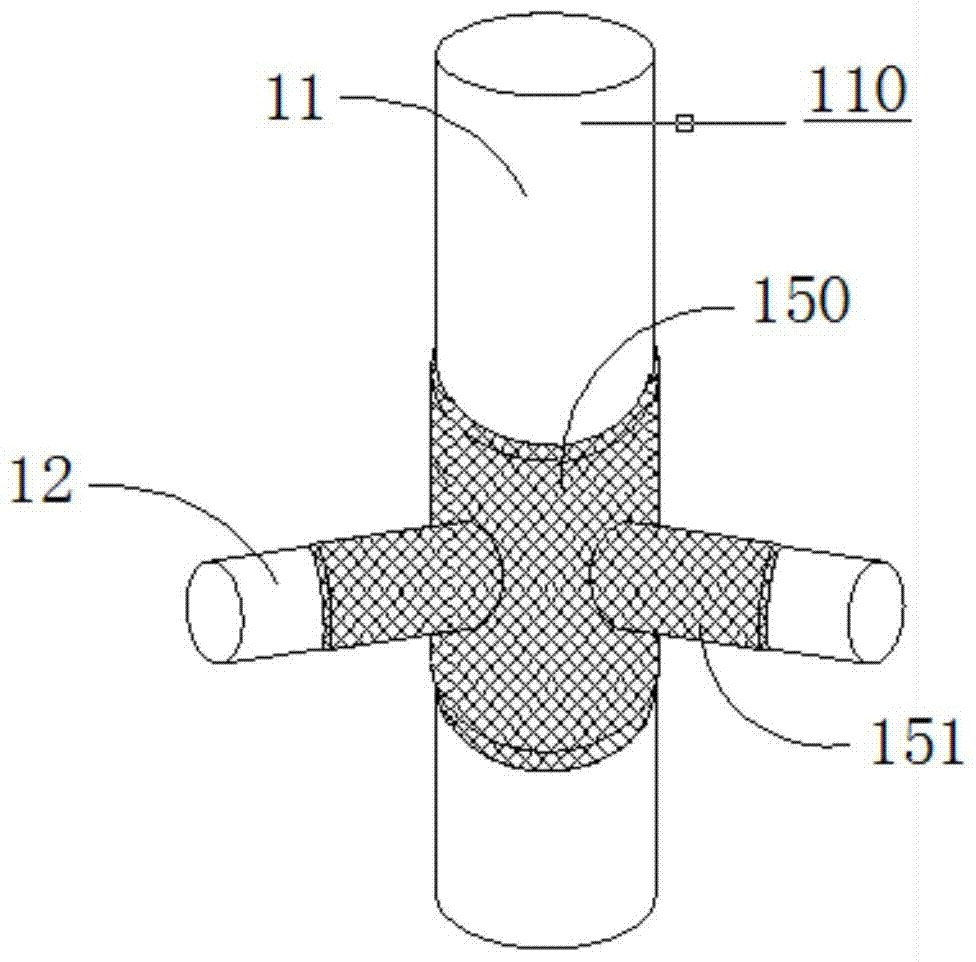

[0032] like figure 1 As shown, the present embodiment provides a jacket 1, including at least two main conduits 10 and at least two secondary conduits 11, the primary conduits 10 and secondary conduits 11 are arranged alternately and form a circle, and the adjacent primary conduits 10 The pipe 10 is connected to the secondary conduit 11 through the intermediate strut 12, and several diagonal struts 13 are also arranged between the adjacent primary conduit 10 and the secondary conduit 11, with the connection point between the intermediate strut 12 and the primary conduit 10 as the second A node 100 , several diagonal braces 13 are connected between the main conduit 10 and the secondary conduit 11 in a fan shape with the first node 100 as the center. In the above-mentioned jacket 1, the middle strut 12 plays the role of connecting the main conduit 10 and the secondary conduit 11, and the fan-shaped arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com