Industrial robot D-H parameter three-dimensional self-calibration correction device and method

A technology of industrial robots and calibration devices, which is applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of restricting the popularization and application of equipment, achieve high calibration accuracy and convenience of operation, fast and easy to use, and realize pose measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

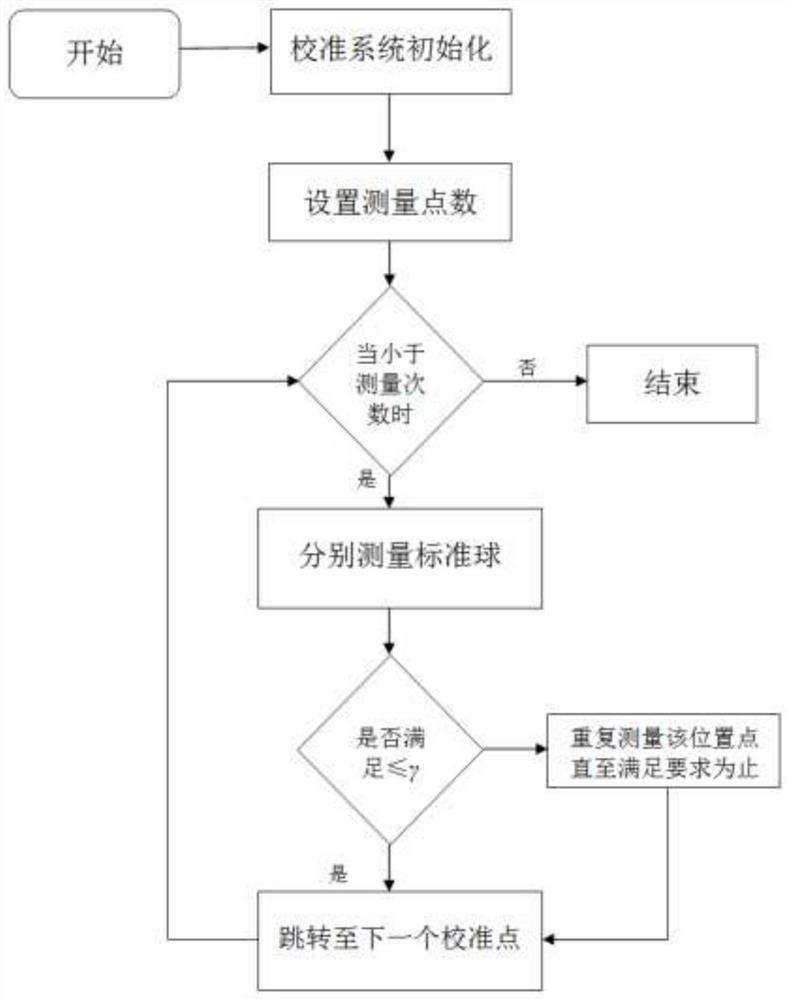

[0033] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

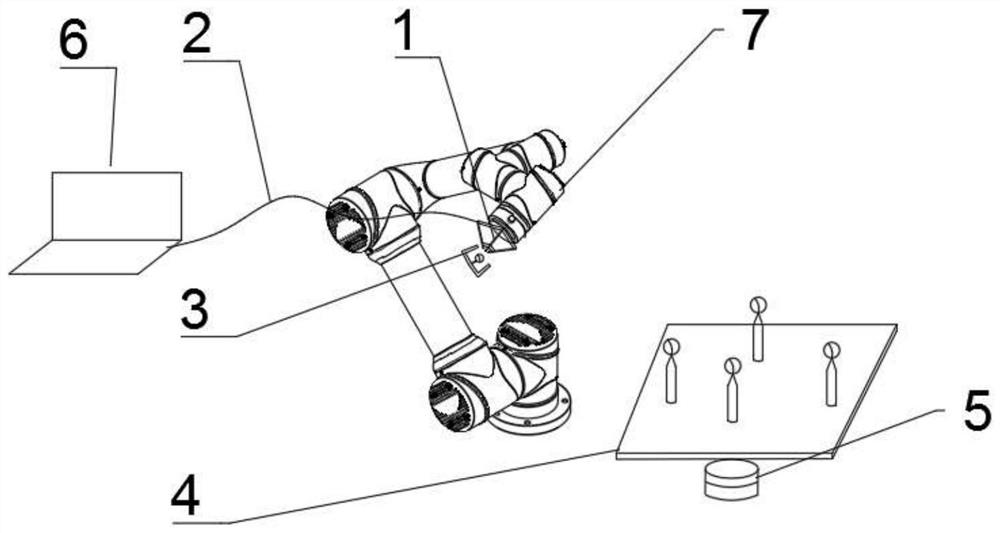

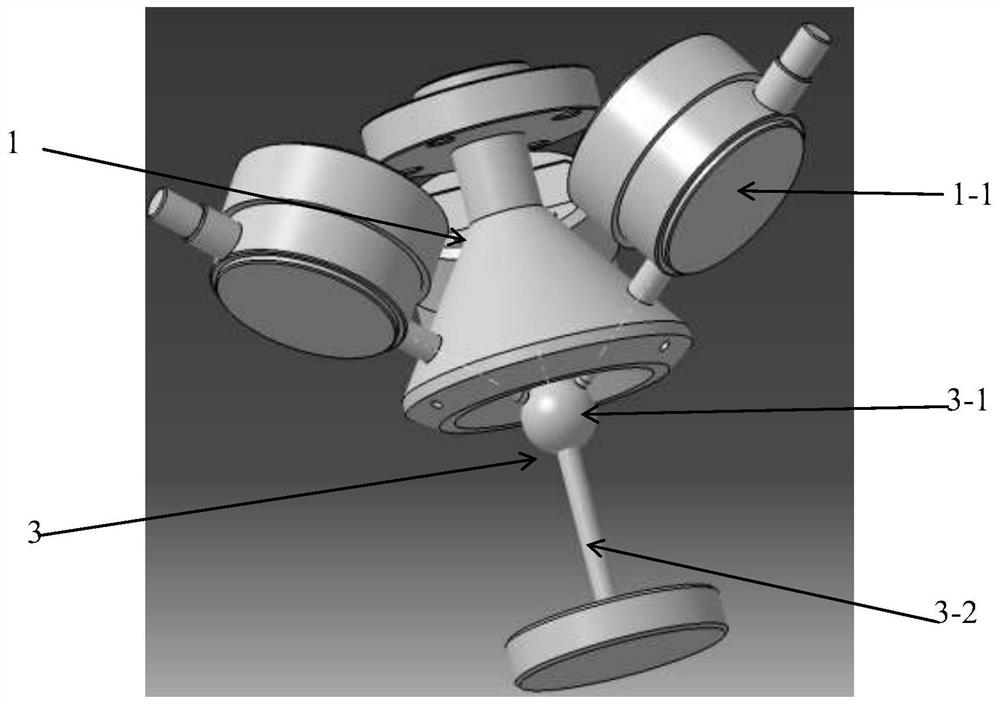

[0034] like figure 1 As shown, an industrial robot D-H parameter 3D self-calibration calibration device includes a three-dimensional calibrator 1, a data transmission cable 2, a zero rapid positioning jig 3, a four-ball calibration station 4, a three-dimensional angle adjustment device 5 and a control computer 6.

[0035] The three-dimensional calibrator 1 consists of three mutually perpendicular high-precision grating displacement sensors, each high-precision grating displacement sensor connected to the control computer 6 through the data transmission cable 2;

[0036] The three-dimensional calibrator 1 is mounted on the end of the calibrated industrial robot 7, and four standard balls on the four-ball calibration table 4 are measured. High-precision positioning can be performed with the standard ball for the robot's TCP point.

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com