Light-weight steel structure house and construction method thereof

A technology for steel structures and houses, which is applied in the direction of basic structure engineering, building components, building structures, etc. It can solve the problems that the end of the floor slab cannot be welded with the truss beam, the thermal insulation performance of the outer wall cannot be reflected, and the unfavorable correction of the prefabricated structure, etc. , to achieve the effect of improving construction efficiency, increasing service life and facilitating dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

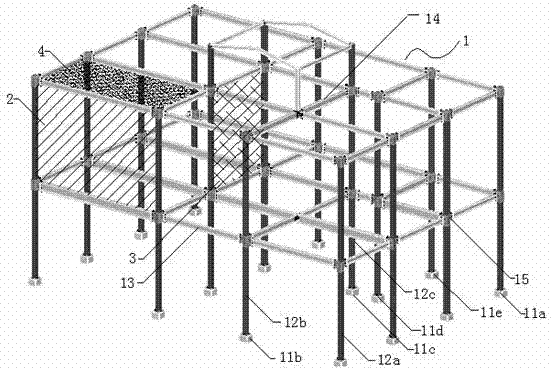

[0085] The light-weight steel structure house of this embodiment, as image 3 As shown, it includes a house frame 1, a double-layer exterior wall panel 2, an interior wall panel 3 and a lightweight floor slab 4.

[0086] The house frame 1 includes a foundation composed of several poured concrete blocks 11. In this embodiment, three sets of parallel and equidistant concrete block groups are provided, and each group of concrete block groups is composed of four uniformly distributed concrete blocks 11a. , there are also concrete blocks 11b and 11c at the center between two adjacent groups of concrete blocks, and the concrete blocks 11b and 11c are respectively located on the same level as the first and third concrete blocks in the concrete block groups There is also a concrete block 11d between the third concrete block 11a and the concrete block 11c in the side concrete block group, and the concrete block 11d is set close to the concrete block 11c; Also be provided with concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com