Novel assembled integral-type hollow shear wall structure

A shear wall, integral technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of self-heavy components, unsuitable quality assurance, and no material saving, so as to improve the building assembly rate and facilitate large-scale promotion. , The effect of reducing the amount of on-site work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

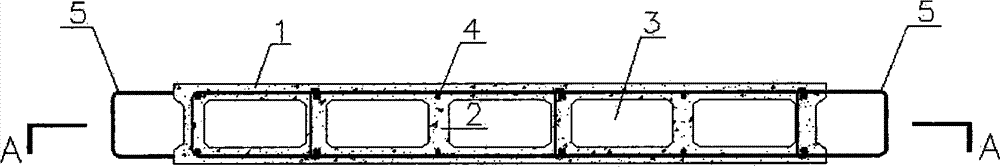

[0038] exist figure 1 Among them, the side walls (1) on both sides and 6 longitudinal ribs (2) form 5 cavities (3). ; The thickness of the side wall (1) is 40 mm, the thickness of the longitudinal rib (2) is 50 mm, and the distance between the ribs is 250 mm; the transverse distribution rib (5) is double-layered, located in the center of the side wall (1), extending out from the side of the prefabricated wall panel to form a " U” shaped anchor bar.

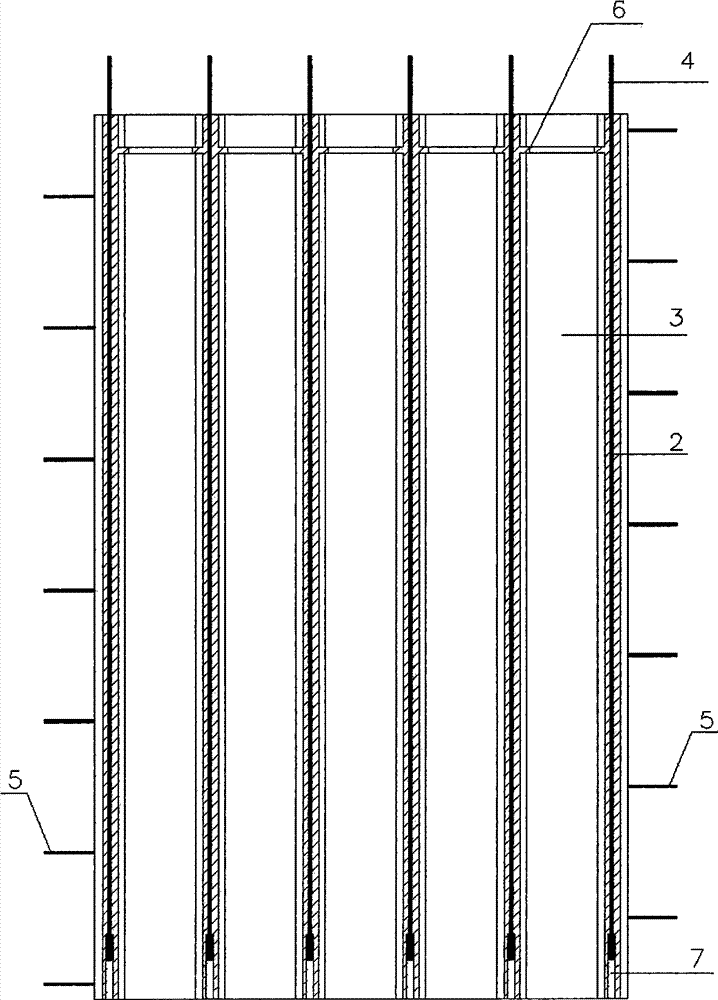

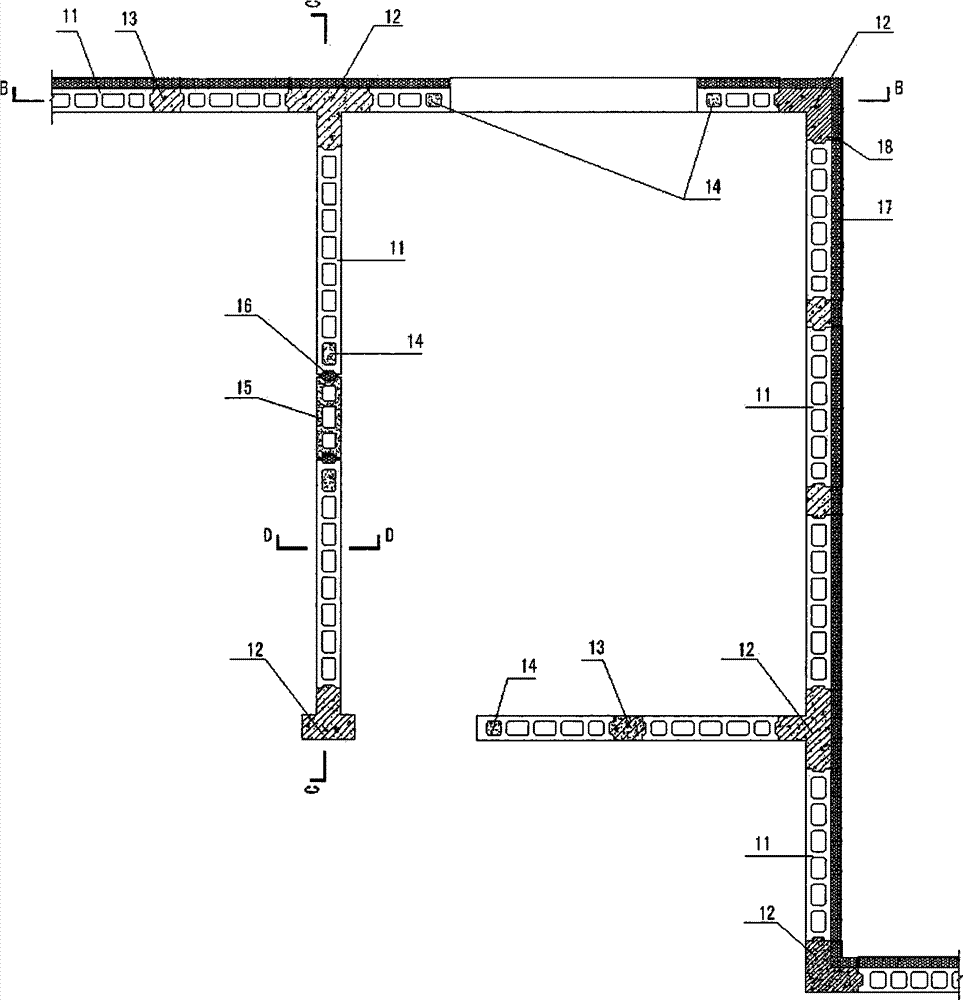

[0039] exist figure 2 Among them, the horizontal "U"-shaped anchor bars on both sides of the wall panels are dislocated and extended to avoid the anchor bars of adjacent wall panels fighting during the installation process; the vertical steel bars (4) are double-layered, corresponding to the longitudinal ribs (2) On the inner side of the transverse steel bar, the top protrudes from the prefabricated wallboard to form a connecting steel bar, and the bottom is connected with the connecting sleeve (7) by wire; the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com