Pipe gallery construction process

A construction technology and pipe gallery technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as groundwater seepage and affecting construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

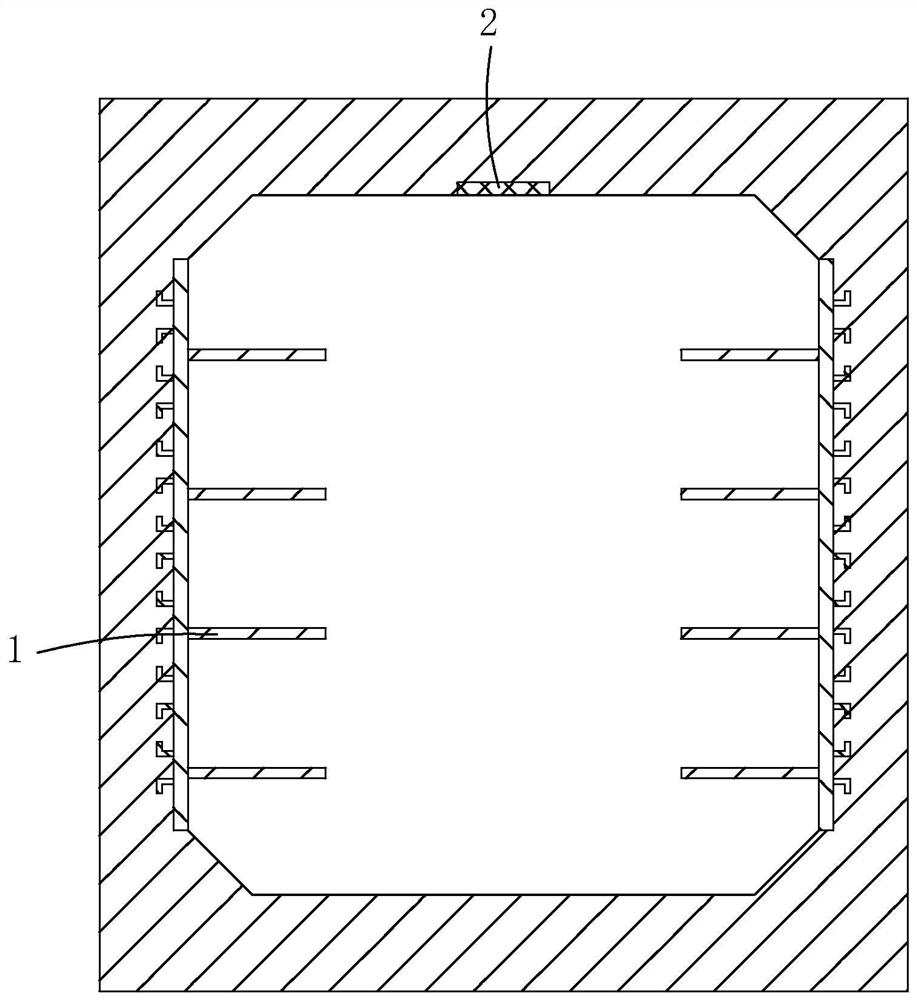

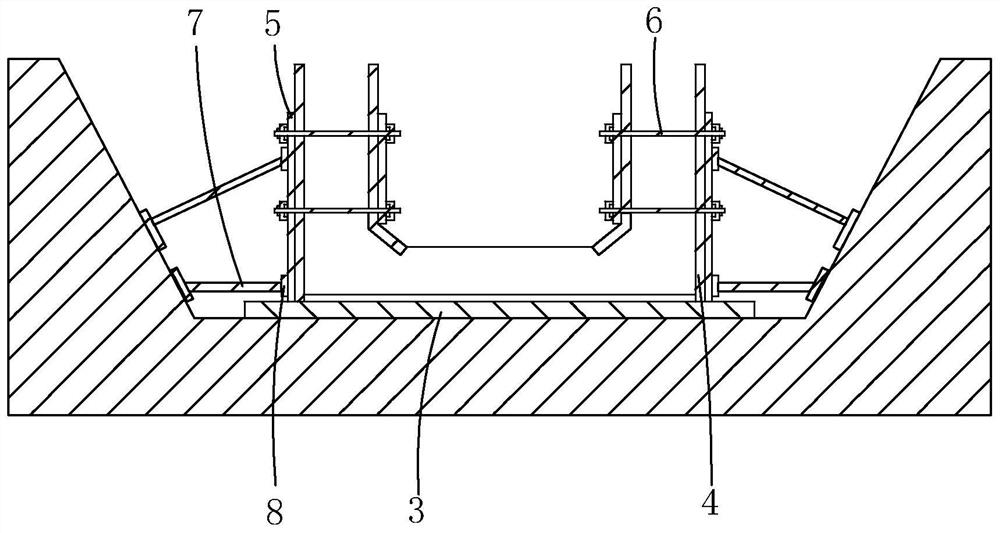

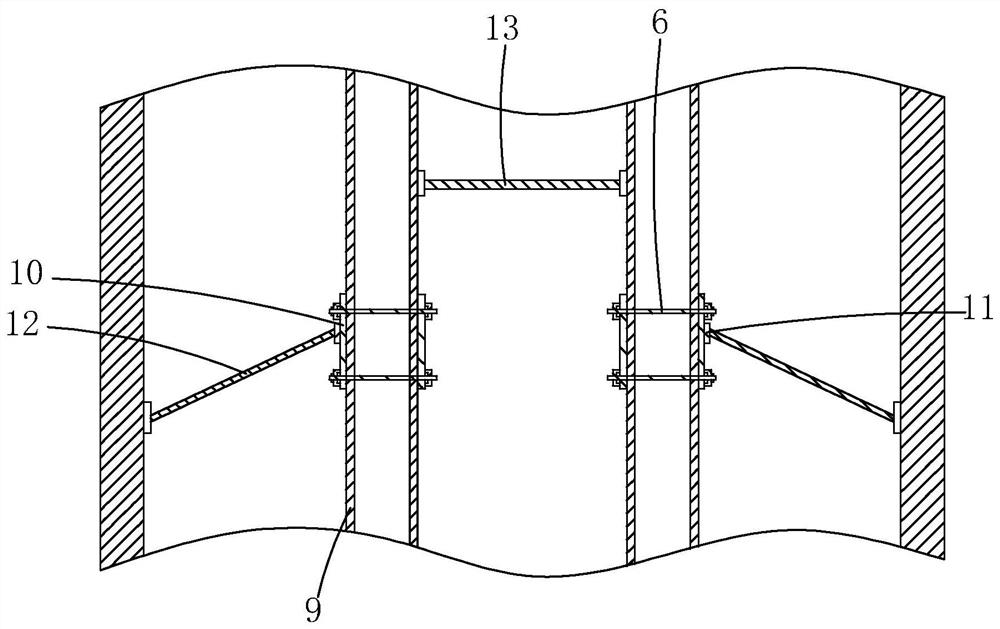

[0079] The following is attached Figure 1-3 The application is described in further detail.

[0080] The embodiment of the present application discloses a pipe gallery construction process, and the process steps of the pipe gallery construction process are as follows:

[0081] S1, measurement and setting out;

[0082] S2. Trench excavation: For positions where the excavation depth is not greater than 8m, use slopes and soil nail walls to support the slope; for positions where the excavation depth is greater than 8m and the slope distance is limited, use Larsen steel plates piles or bored piles for support;

[0083] S21. Measure the centerline of the setting-out and fixed-pipe gallery;

[0084] S22, foundation pit precipitation and support;

[0085] S23. According to the center line of the pipe gallery and the requirements of the grading coefficient, set out the sideline of the trench excavation of the pipe gallery;

[0086] S24, foundation pit excavation;

[0087] S25. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com