Chitosan-graphene oxide composite gel and preparation method thereof

A graphene composite and chitosan technology, applied in the field of materials, can solve problems such as incomplete classification, and achieve good self-healing properties, good mechanical properties, and stable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of chitosan-graphene oxide composite gel, comprising the following steps:

[0037] S1, at room temperature, take by weighing 0.3g chitosan, be dissolved in 9.2g content and be that the volume fraction is 2% dilute acetic acid solution, be placed in constant temperature water bath pot and stir for 1.5 hours after dissolving, obtain chitosan solution; The temperature of the water bath is 25°C

[0038] S2. Preparation of mineralized collagen powder: Slowly add 0.055mol of phosphoric acid solution to the collagen solution; stir it at 25°C, and add calcium chloride solution dropwise at the same time; add dropwise during the stirring process after the addition Sodium hydroxide aqueous solution, so that the pH value of the solution is 7; put it aside for 4 hours, remove the supernatant, wash and filter, freeze-dry and grind to obtain mineralized collagen powder; the PO4 3- The ratio of the calcium-phosphorus moles of the solution and the calcium ion aqueo...

Embodiment 2

[0043] A preparation method of chitosan-graphene oxide composite gel, comprising the following steps:

[0044] S1, at room temperature, take by weighing 0.3g chitosan, be dissolved in 9.2g content and be that the volume fraction is 2% dilute acetic acid solution, be placed in constant temperature water bath pot and stir for 1.5 hours after dissolving, obtain chitosan solution; The temperature of the water bath is 25°C

[0045] S2. Preparation of mineralized collagen powder: Slowly add 0.055mol of phosphoric acid solution to the collagen solution; stir it at 25°C, and add calcium chloride solution dropwise at the same time; add dropwise during the stirring process after the addition Sodium hydroxide aqueous solution, so that the pH value of the solution is 7; put it aside for 4 hours, remove the supernatant, wash and filter, freeze-dry and grind to obtain mineralized collagen powder; the PO 4 3- The ratio of the calcium-phosphorus moles of the solution and the calcium ion aqu...

Embodiment 3

[0050] A preparation method of chitosan-graphene oxide composite gel, comprising the following steps:

[0051] S1, at room temperature, take by weighing 0.3g chitosan, be dissolved in 9.2g content and be that the volume fraction is 2% dilute acetic acid solution, be placed in constant temperature water bath pot and stir for 1.5 hours after dissolving, obtain chitosan solution; The temperature of the water bath is 25°C.

[0052] S2. Preparation of mineralized collagen powder: Slowly add 0.055mol of phosphoric acid solution to the collagen solution; stir it at 25°C, and add calcium chloride solution dropwise at the same time; add dropwise during the stirring process after the addition Sodium hydroxide aqueous solution, so that the pH value of the solution is 7; put it aside for 4 hours, remove the supernatant, wash and filter, freeze-dry and grind to obtain mineralized collagen powder; the PO 4 3- The ratio of the calcium-phosphorus moles of the solution and the calcium ion aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

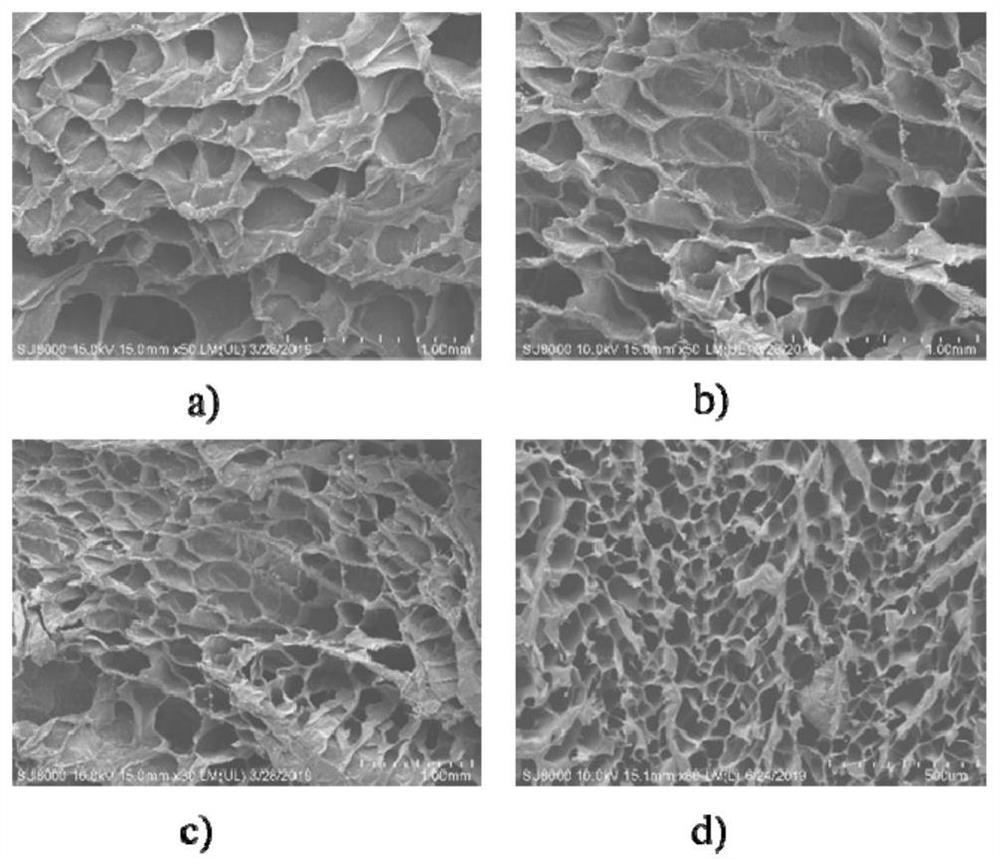

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com