Production process for perspective glass

A production process and see-through glass technology, which is applied to glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of automatic control of paint discharge and closing, uneven coating thickness, and complicated control equipment, so as to avoid waste, Good application effect and wide coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

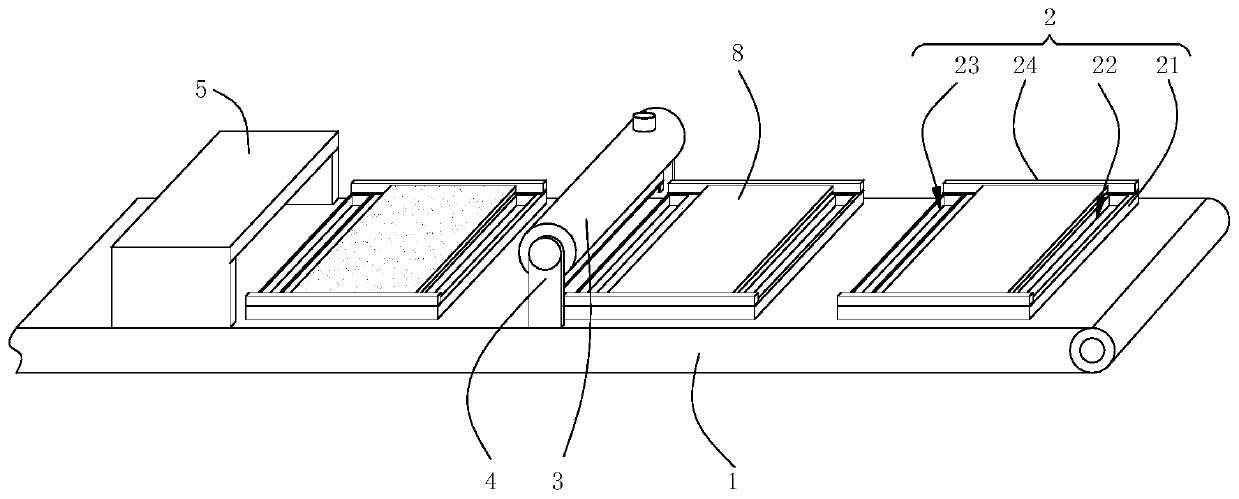

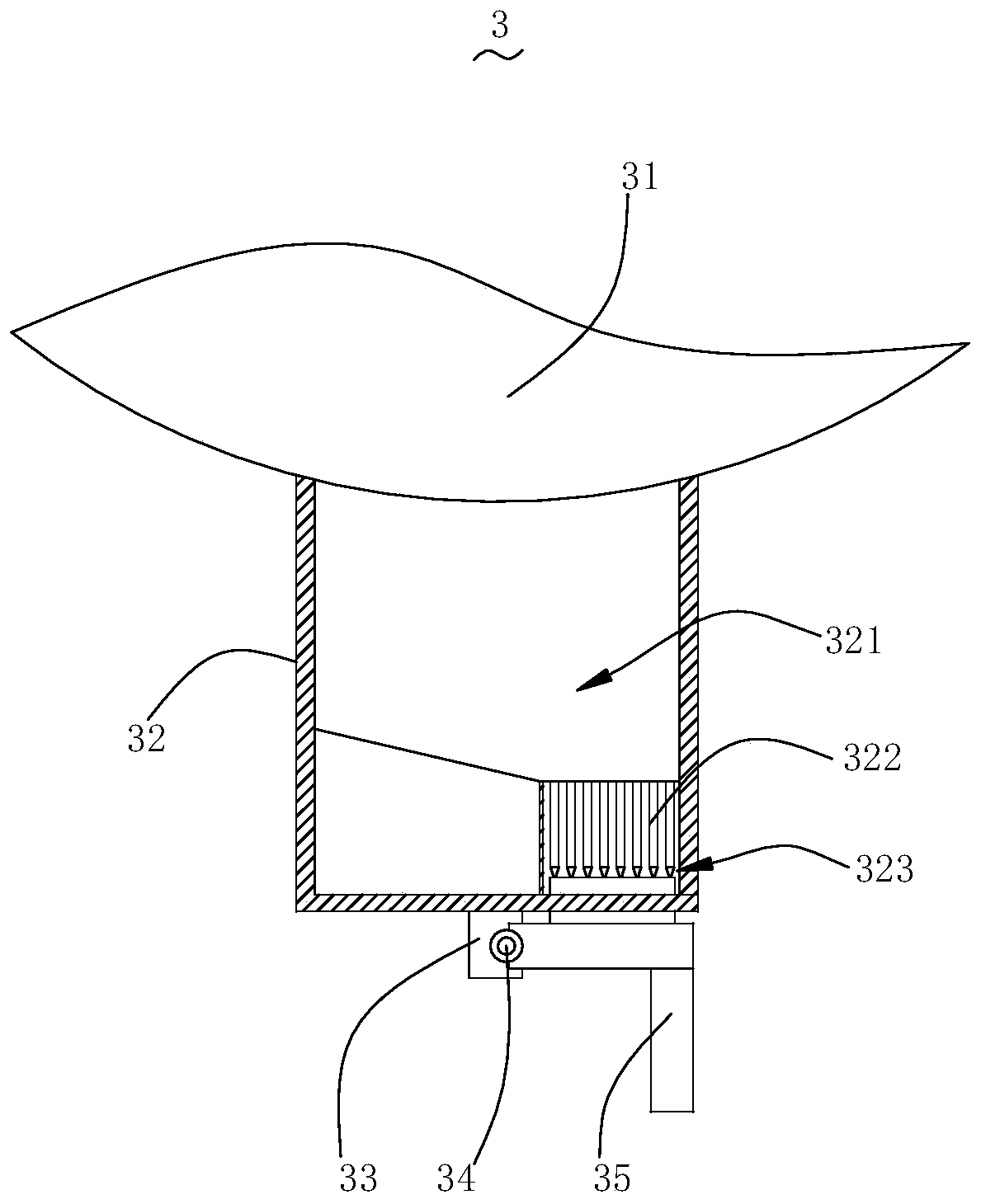

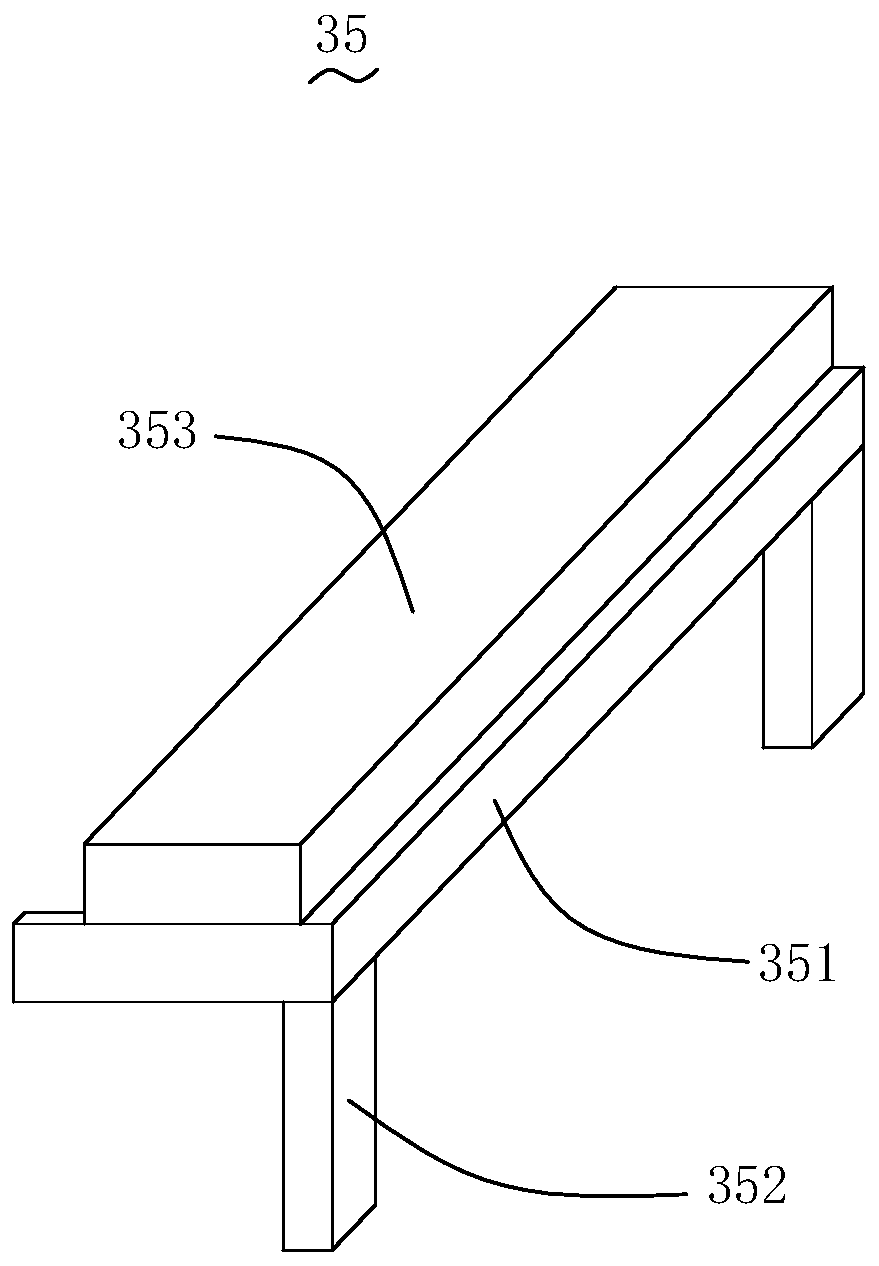

[0038] Such as Figure 1-Figure 7 Shown, a kind of see-through glass production technology of the present invention, this production processing technology comprises the following steps:

[0039] S1, using a crusher to crush the raw materials;

[0040] S2, using a magnetic separator to remove iron impurities in the crushed raw materials in S1;

[0041] S3, putting the raw materials after removing impurities in S2 into a crucible furnace to heat and melt to form liquid glass;

[0042] S4, pouring the liquid glass into a forming mold for cooling and forming to form solid glass;

[0043] S5, putting the solid glass in S4 into a transparent glass processing production line for coating treatment;

[0044] S6, putting the coated glass in S5 into a cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com