Packaging box full-automatic pasting and assembling production equipment

A kind of production equipment, fully automatic technology, applied in the direction of packaging, transportation and packaging, box making operation, etc., can solve the problems of large area, large manpower input, slow packaging efficiency, etc., achieve less labor input, higher yield, Good effect of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

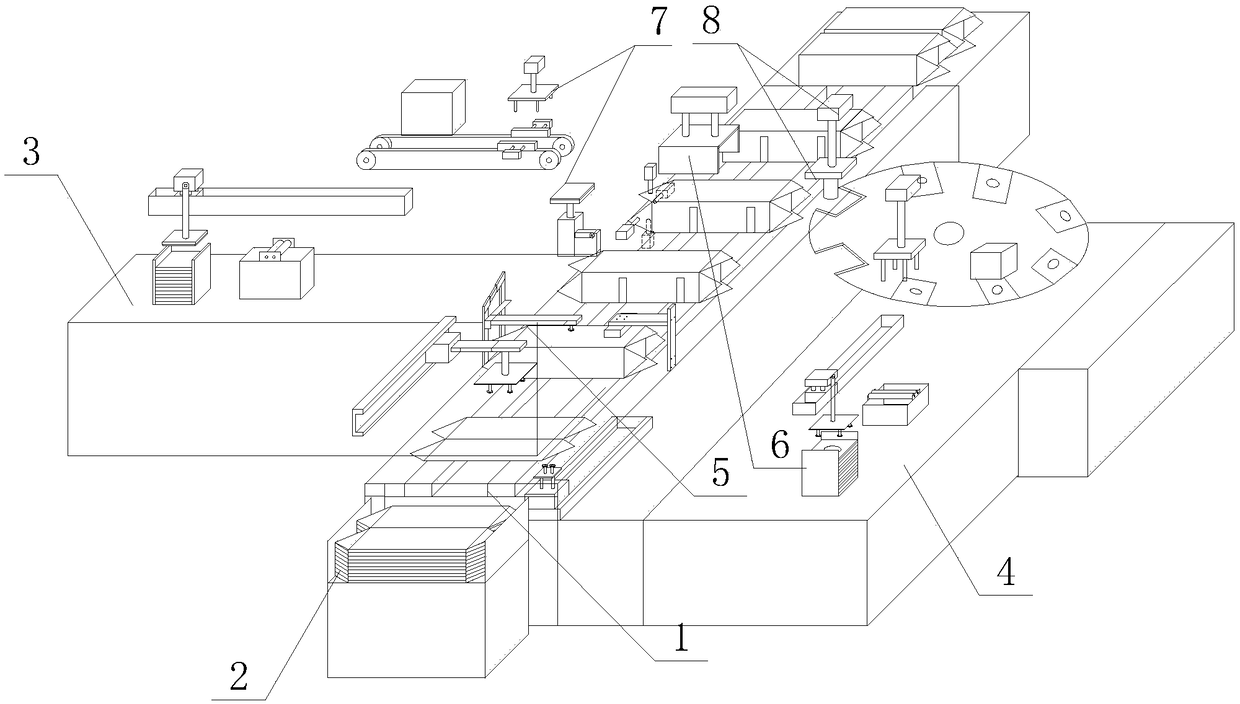

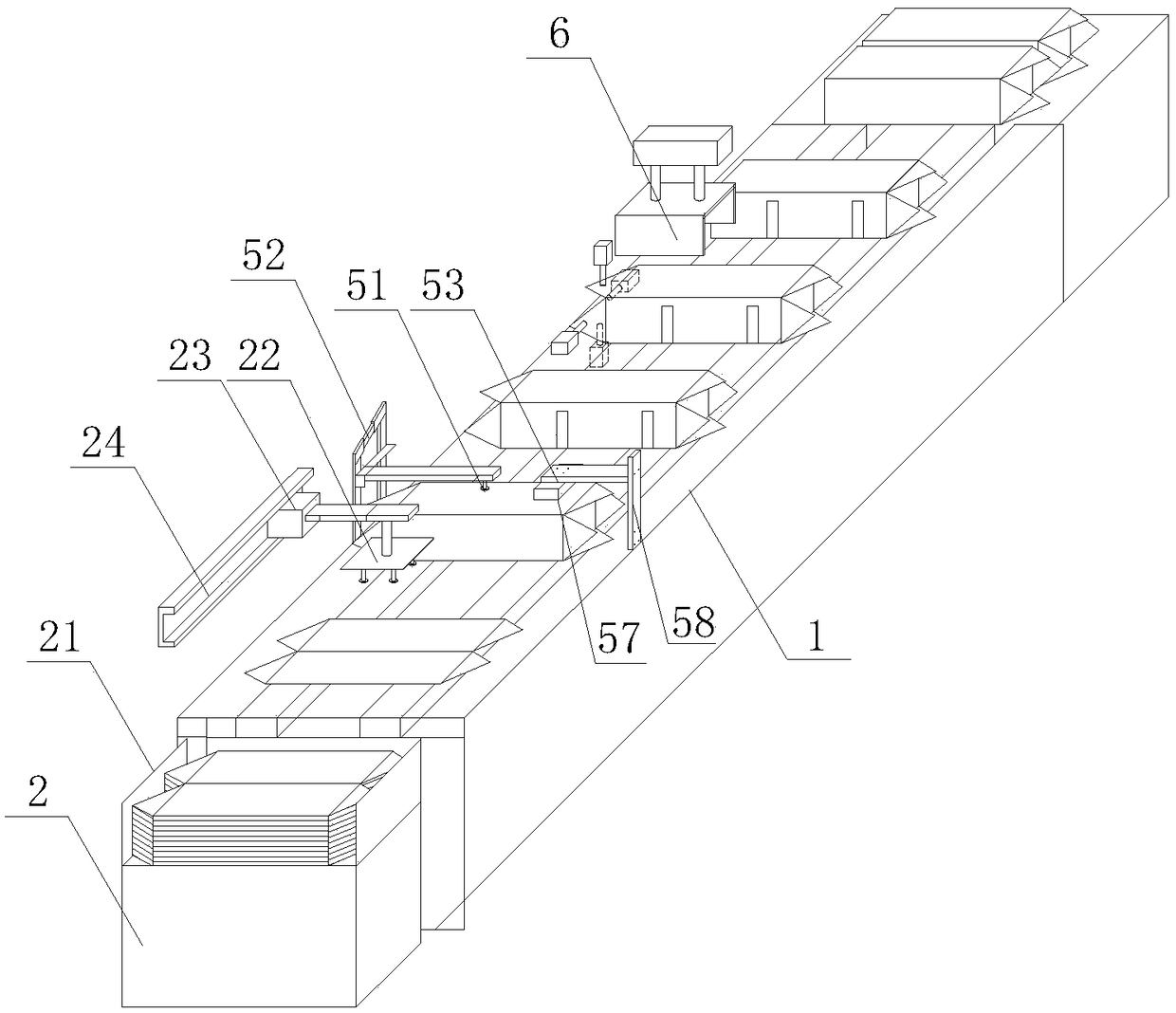

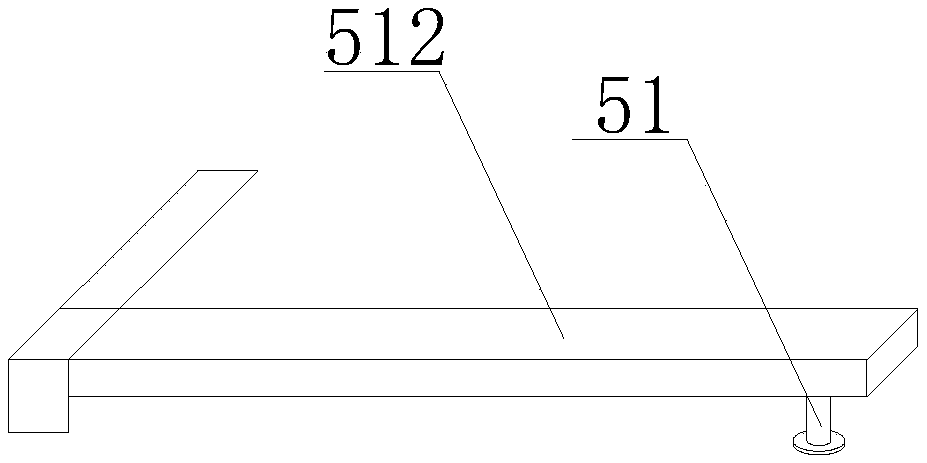

[0029] Embodiment 1: see figure 1 , a fully automatic pasting assembly production equipment for packaging boxes, including a box body transmission line 1, a box body cardboard feeding module 2, a bottom sealing board feeding module 3, an inner lining board feeding module 4, and a bottom sealing board assembly module Group 7 and inner lining plate assembly module 8, the box body cardboard feeding module 2 is located at the entrance of the box body transmission line 1, the exit of the box body transmission line 1 is the finished product stacking area, and the first half of the box body transmission line 1 The second half of the box body transmission line 1 is provided with a positioning module 6 for fixing the box body, and the bottom sealing board feeding module 3 and the inner liner feeding module 4 are respectively located on the left and right sides of the box body transmission line 1, and the bottom sealing board feeding module 3 pushes the bottom sealing board to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com