Special-shaped beam column node template and engineering template equipping method thereof

A special-shaped beam-column and arc-shaped formwork technology is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., which can solve the problem that the front and rear formwork cannot be interchanged, which is not conducive to saving and environmental protection, and increases construction investment. and other problems, to achieve the effect of good anti-deformation ability, smooth joints, and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

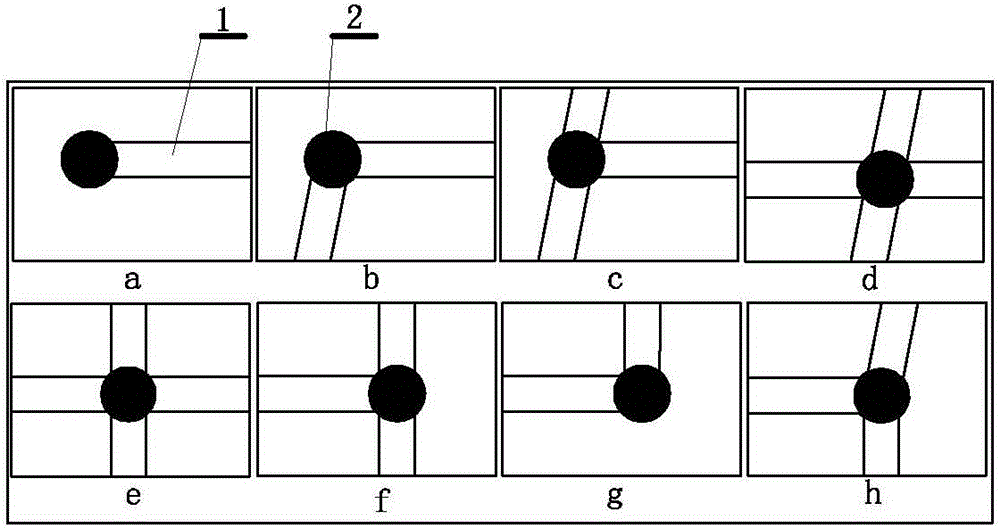

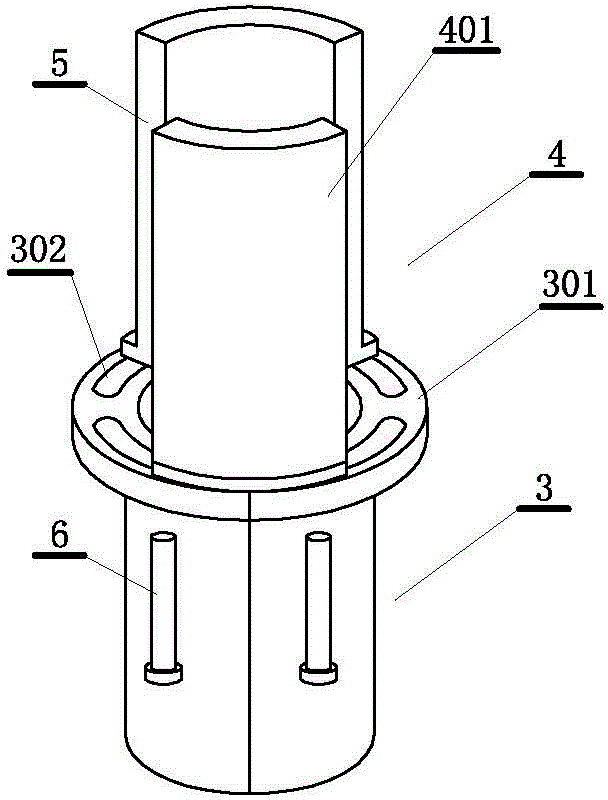

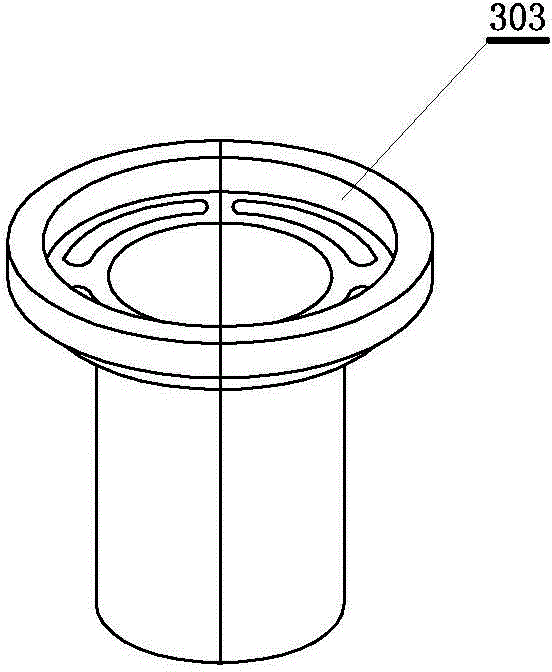

[0049] When the floor appears during construction figure 1 The beam 1 column 2 structure shown in a, b, c, d, e, f, g, and h is not uniform. When the node supports the template, there will be many different structures. Here we call the support template Special-shaped beam-column node template; this embodiment is a special-shaped beam-column node template, the column is a circular column with the same circular size, and the beam is a rectangular beam; figure 2 As shown, the node template is a steel template, including a bottom mold 3 that is used to close and hug and connect with a column and an upper mold 4 that is fixedly connected to the bottom mold. A circle is provided at the upper port of the bottom mold at 90 degrees outward. An annular platform 301, wherein a long arc through hole 302 is provided on the annular platform surface, and the upper mold includes a multi-segment arc-shaped template 401. The multi-segment arc-shaped template is adjusted and spliced along the in...

Embodiment 2

[0056] An engineering template configuration method for the special-shaped beam-column node template described in embodiment 1. The content in the embodiment is also the content of this embodiment. The method includes bottom mold making equipment and upper mold making equipment, and the bottom mold is used with The uprights are closed and hugged and connected. The upper mold includes a multi-segment arc template. The multi-segment arc template and the bottom mold are connected to the upper end of the column to form multiple beam interface nodes in different directions; the bottom mold has the same specifications, and the technology used in its production is a general technology; The mold has to face different beam exits, and the construction of the floor is to be constructed in stages. Due to the inconsistency of the upper mold, the upper mold production will be a big expense. In order to realize the recyclability of the upper mold in the sectional construction, the embodiment T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com