Environment-friendly plush fabric dyeing method and residual color paste treatment technology thereof

A dyeing method and an environmentally friendly technology, which is applied in the processing of textile materials, liquid/gas/steam textile materials, and textile material drums, can solve problems such as waste of resources, unsatisfactory color brightness and hand feeling, and environmental pollution. The effect of high brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

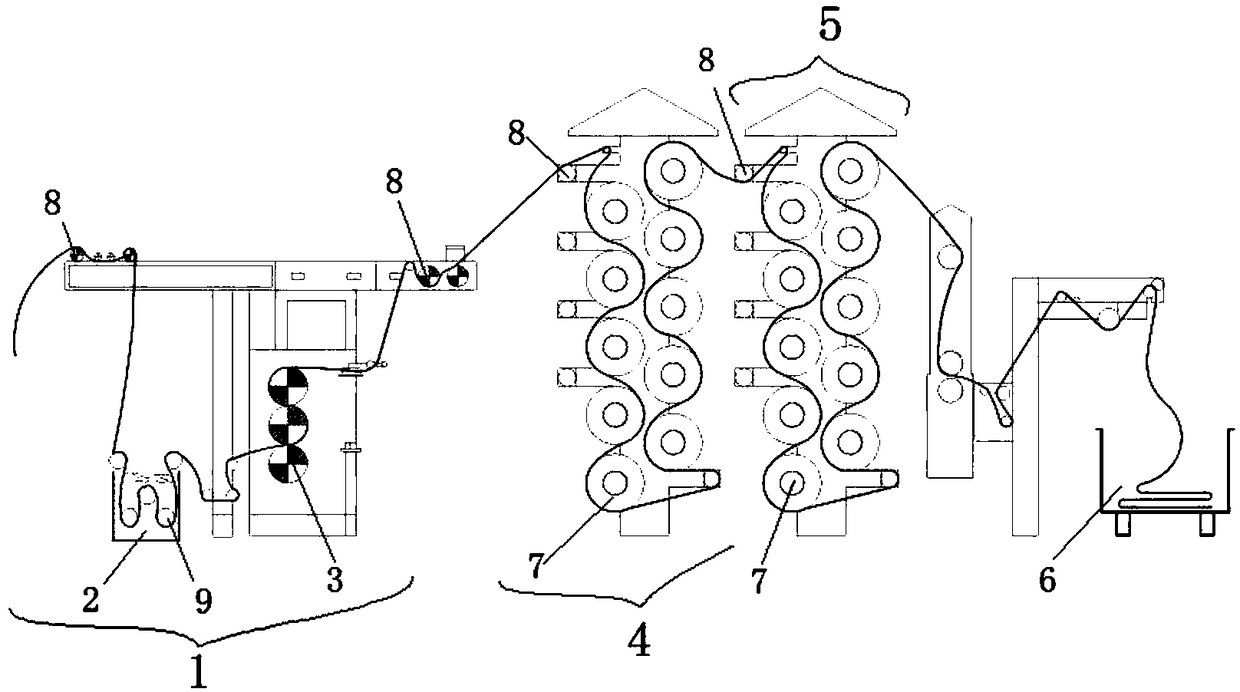

[0031] Embodiment 1: see figure 1 , now a kind of environment-friendly plush fabric dyeing method provided by the present invention is described, comprises the following steps:

[0032] Step 1: Pretreat the white gray cloth of plush cloth;

[0033] Step 2: making color paste from high-temperature dye and pouring it into the rolling groove 2 of the padding car 1;

[0034] Step 3: Import the pretreated white gray cloth into the rolling groove 2 inside the rolling car 1 through the cloth roller 8 at the front end of the rolling car, and carry out fast starvation high-permeability absorption of dyes in the rolling groove 2 driven by the mop roller 9 Dyeing is completed to obtain dyed cloth and residual color paste;

[0035] Step 4: Dry the initial color development: through the cloth roller 8 at the upper and rear end of the pad car 1, the dyed cloth is transported to the first group of continuous drying barrels 4 for the first drying, and the plush cloth with preliminary color ...

Embodiment 2

[0051] Example 2: see figure 1 , now a kind of environment-friendly plush fabric dyeing method provided by the present invention is described, comprises the following steps:

[0052] Step 1: Pretreat the white gray cloth of plush cloth;

[0053] Step 2: making color paste from high-temperature dye and pouring it into the rolling groove 2 of the padding car 1;

[0054] Step 3: Import the pretreated white gray cloth into the rolling groove 2 inside the rolling car 1 through the cloth roller 8 at the front end of the rolling car, and carry out fast starvation high-permeability absorption of dyes in the rolling groove 2 driven by the mop roller 9 Dyeing is completed to obtain dyed cloth and residual color paste;

[0055] Step 4: Dry the initial color development: through the cloth roller 8 at the upper and rear end of the pad car 1, the dyed cloth is transported to the first group of continuous drying barrels 4 for the first drying, and the plush cloth with preliminary color dev...

Embodiment 3

[0071] Embodiment 3: see figure 1 , now a kind of environment-friendly plush fabric dyeing method provided by the present invention is described, comprises the following steps:

[0072] Step 1: Pretreat the white gray cloth of plush cloth;

[0073] Step 2: making color paste from high-temperature dye and pouring it into the rolling groove 2 of the padding car 1;

[0074] Step 3: Import the pretreated white gray cloth into the rolling groove 2 inside the rolling car 1 through the cloth roller 8 at the front end of the rolling car, and carry out fast starvation high-permeability absorption of dyes in the rolling groove 2 driven by the mop roller 9 Dyeing is completed to obtain dyed cloth and residual color paste;

[0075] Step 4: Dry the initial color development: through the cloth roller 8 at the upper and rear end of the pad car 1, the dyed cloth is transported to the first group of continuous drying barrels 4 for the first drying, and the plush cloth with preliminary color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com