Production methods of intermediate-frequency oriented silicon steel ultra-thin strip and steel substrate of intermediate-frequency oriented silicon steel ultra-thin strip

A technology of grain-oriented silicon steel and ultra-thin strip, which is applied in the field of preparation of ultra-thin strip of grain-oriented silicon steel for intermediate frequency and its steel substrate, and can solve the problems of growth, small grain size of Goss, and deterioration of performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

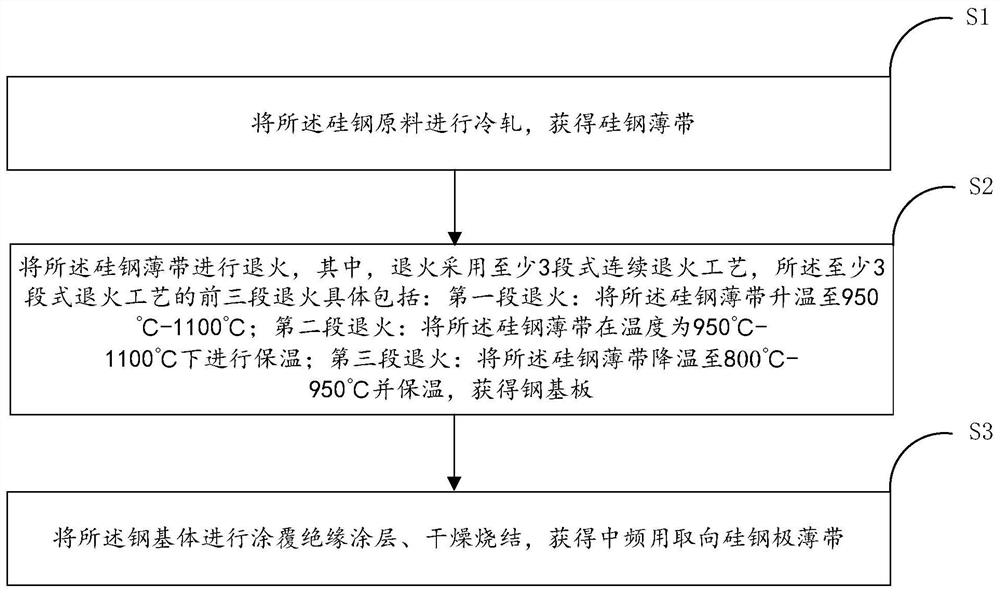

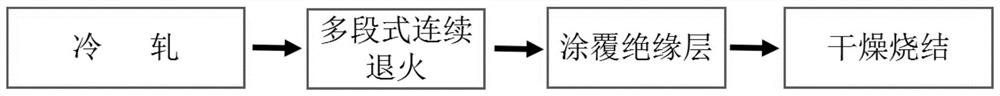

[0035] According to a typical implementation of the present invention, a method for preparing an ultra-thin strip of oriented silicon steel for intermediate frequency is provided, the method comprising:

[0036] S1. Cold rolling silicon steel raw materials to obtain silicon steel strips;

[0037] As an optional embodiment, the raw material of the silicon steel is a high magnetic induction oriented silicon steel without a bottom layer.

[0038] With the above design, the pickling link is avoided, thereby realizing energy saving and environmental protection.

[0039] As an optional implementation mode, the magnetic induction intensity B800 of the high magnetic induction grain-oriented silicon steel without a bottom layer is ≥ 1.88T, and the thickness of the high magnetic sense grain-oriented silicon steel without a bottom layer is 0.23mm-0.35mm.

[0040] The reason for controlling the magnetic induction intensity B800≥1.88T of high magnetic induction grain-oriented silicon stee...

Embodiment 1-3

[0068] A method for preparing an ultra-thin strip of oriented silicon steel for intermediate frequency, the method is as follows:

[0069] Grain-oriented silicon steel with a thickness of 0.27mm is adopted, (the magnetic properties of the base metal are as shown in the table below);

[0070] S1. Cold rolling into a thin strip with a specification of 0.08mm: specifically, rolling with a 20-high reversing rolling mill, rolling in two passes: the reduction rate of the first pass is 40%, and the reduction rate of the second pass is 40%. The rate is 60%;

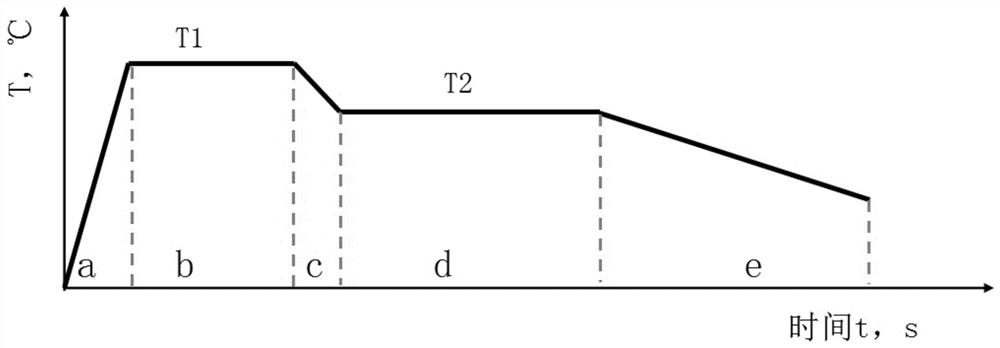

[0071] S2. Adopt 4-stage continuous annealing process; the specific parameters of each stage are as follows, and the atmosphere in the furnace is a pure nitrogen atmosphere with a dew point of -25°C;

[0072] S3. coating an insulating coating;

[0073] S4. drying and sintering.

[0074]

Embodiment 4-6

[0076] A method for preparing an ultra-thin strip of oriented silicon steel for intermediate frequency, the method is as follows:

[0077] Grain-oriented silicon steel with a thickness of 0.23 mm is adopted (the magnetic properties of the base metal are as shown in the table below);

[0078] S1. Cold rolling into a thin strip of 0.05mm specification: specifically, using a 20-high reversing rolling mill for rolling, two-pass rolling: the reduction rate of the first pass is 40%, and the reduction rate of the second pass is 40%. The rate is 60%;

[0079] S2. Adopt 4-stage continuous annealing process; the specific parameters of each stage are as follows, and the atmosphere in the furnace is a pure nitrogen atmosphere with a dew point of -20°C;

[0080] S3. coating an insulating coating;

[0081] S4. drying and sintering.

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com