1300Mpa grade high tenacity cold-formed steel plate and production method thereof

A production method and high-toughness technology, applied in the metallurgical field, can solve the problems of cold-formed parts affecting the forming quality, hot-formed parts having poor toughness, and affecting structural safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

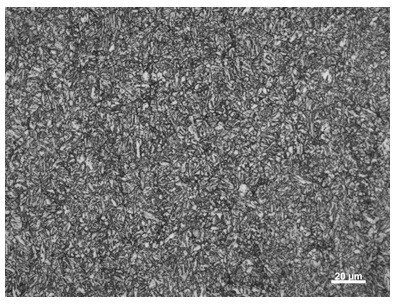

Image

Examples

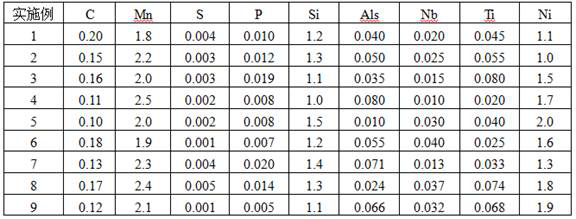

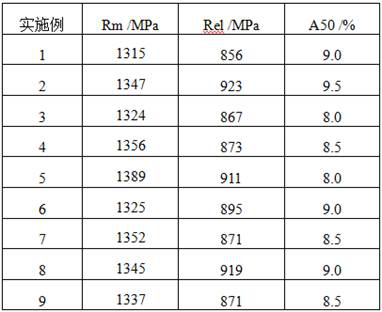

Embodiment 1-9

[0020] The production method of the 1300Mpa grade high-toughness cold-formed steel plate of the present invention comprises steelmaking, continuous casting, heating, rolling, acid rolling, continuous annealing, leveling and stretching and straightening processes. The specific steps are as follows:

[0021] (1) Steelmaking process: including hot metal desulfurization and slag removal, converter smelting, LF furnace refining, RH vacuum treatment;

[0022] (2) Continuous casting process: During the casting process, control the surface and internal quality of the slab to prevent micro-cracks and secondary cracks on the surface of the slab;

[0023] (3) The heating process includes the first heating section, the second heating section, the third heating section and the soaking section. The slab stays in the furnace for 150-250 minutes, the soaking section temperature is 1200-1300°C, and the soaking time is ≥35 minutes.

[0024] (4) Rolling process, including rough rolling, hot coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com