Patents

Literature

63results about How to "Good cropping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for display screen production

InactiveCN105397852AGuaranteed cropping effectSimple croppingMetal working apparatusEngineeringMechanical engineering

The invention discloses a device for display screen production. The device for display screen production comprises a rotary shaft, N cutting knives and a driving unit, wherein the rotary shaft is horizontally arranged; the N cutting knives are all installed on the rotary shaft and distributed in the axis direction of the rotary shaft in a rowed mode; the driving unit is connected with the rotary shaft so as to drive the rotary shaft to move horizontally and rotate; the movement track of the rotary shaft driven by the driving unit is perpendicular to the axis of the rotary shaft. The device for display screen production is simple in structure, convenient to use, good in display screen cutting effect and high in efficiency.

Owner:合肥愿与网络技术有限公司

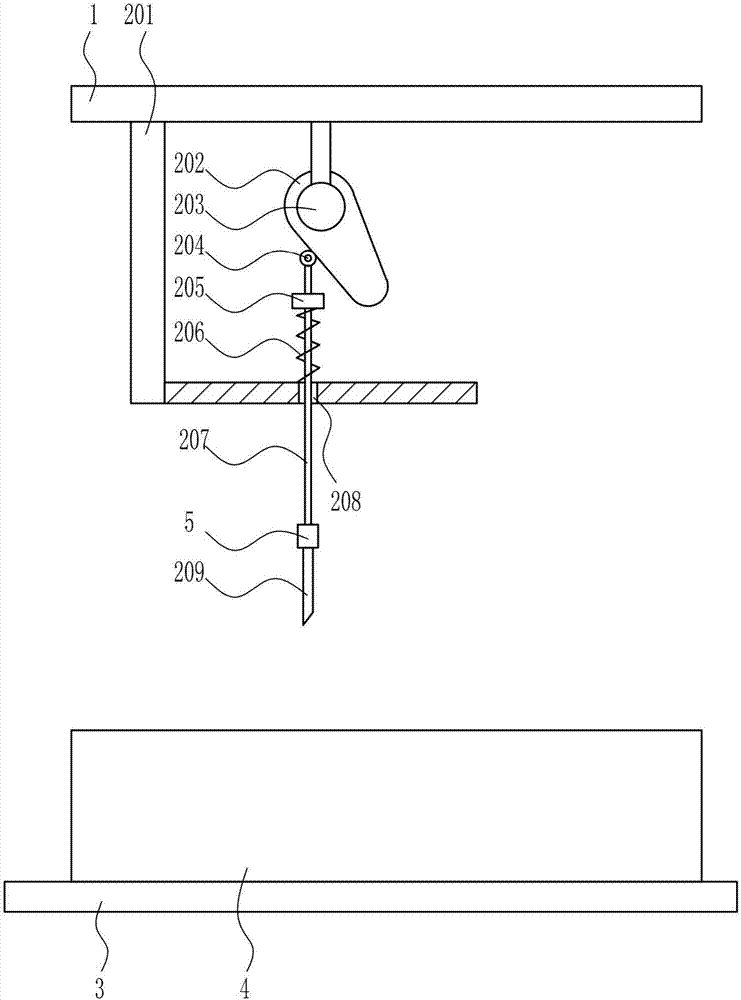

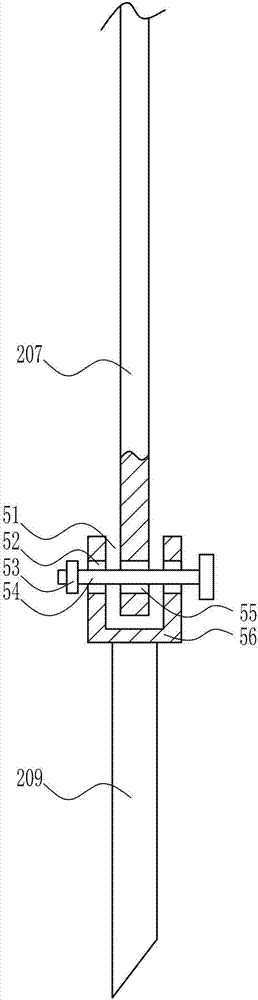

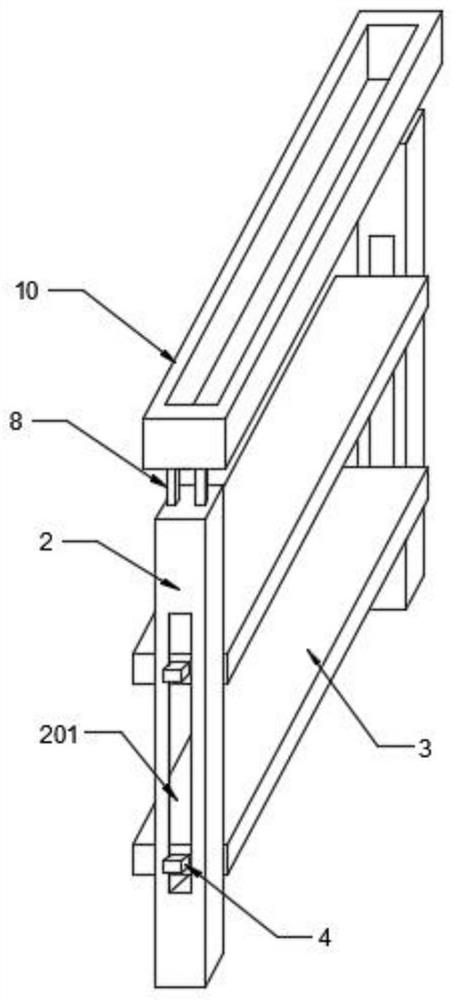

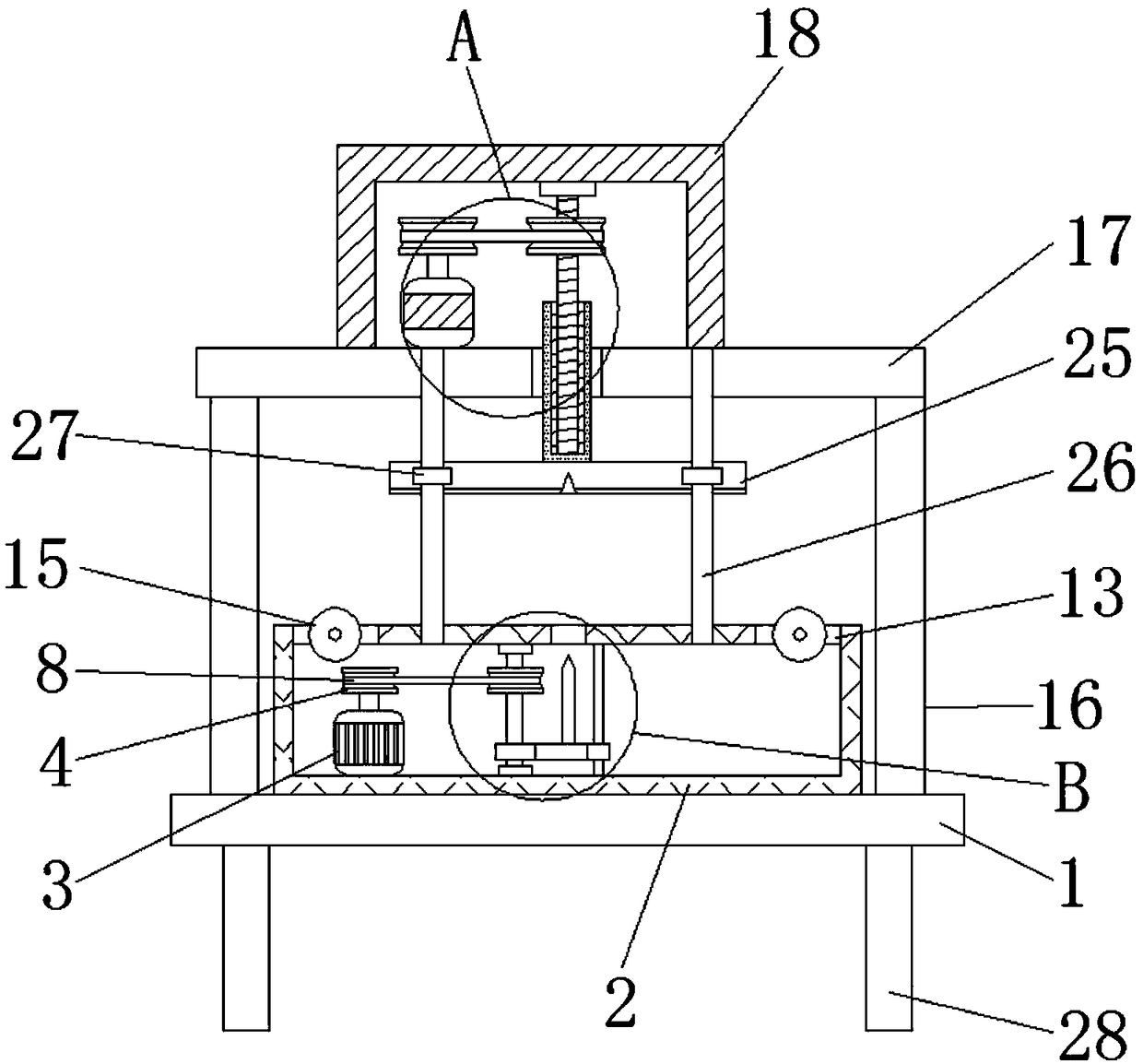

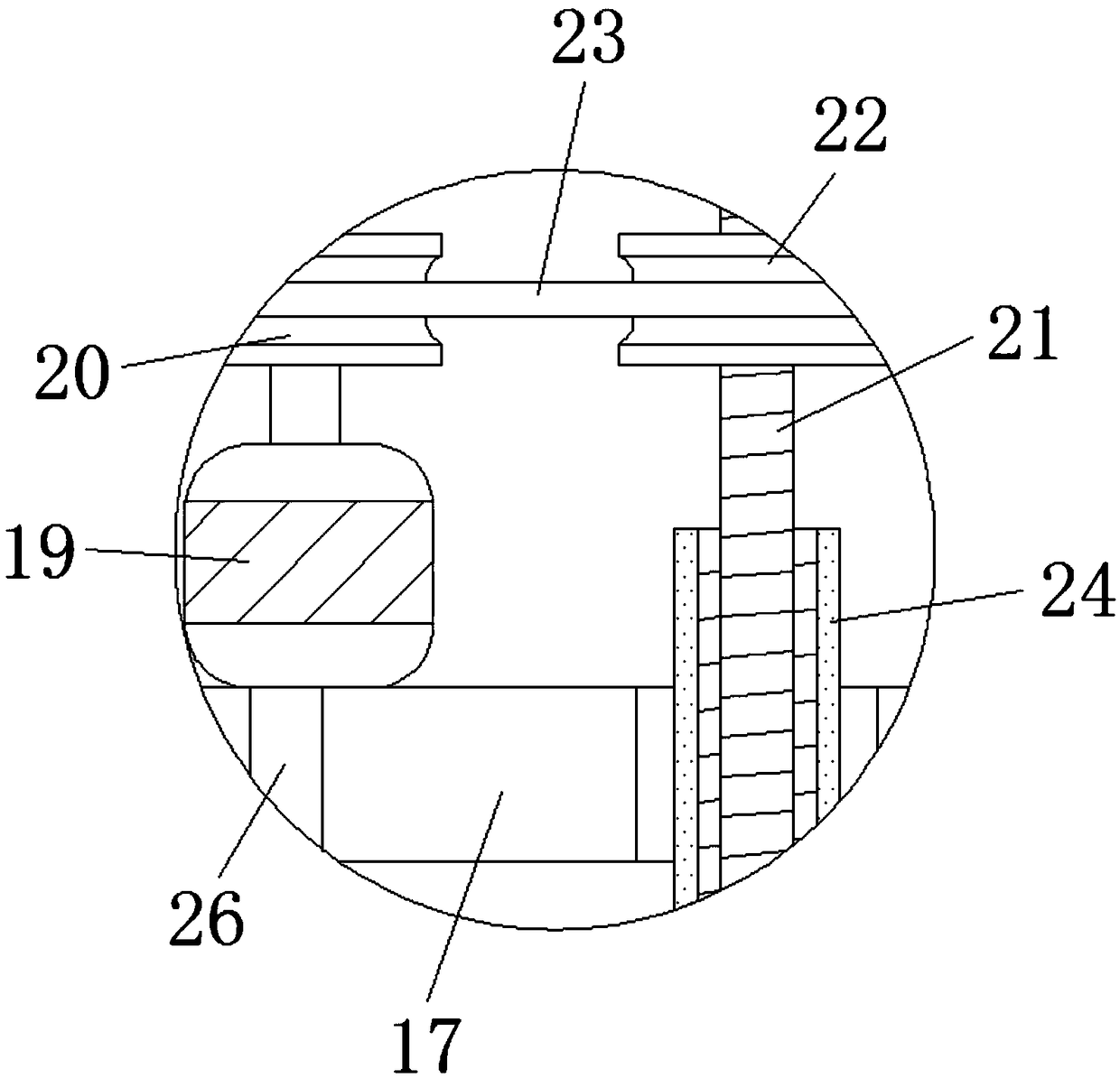

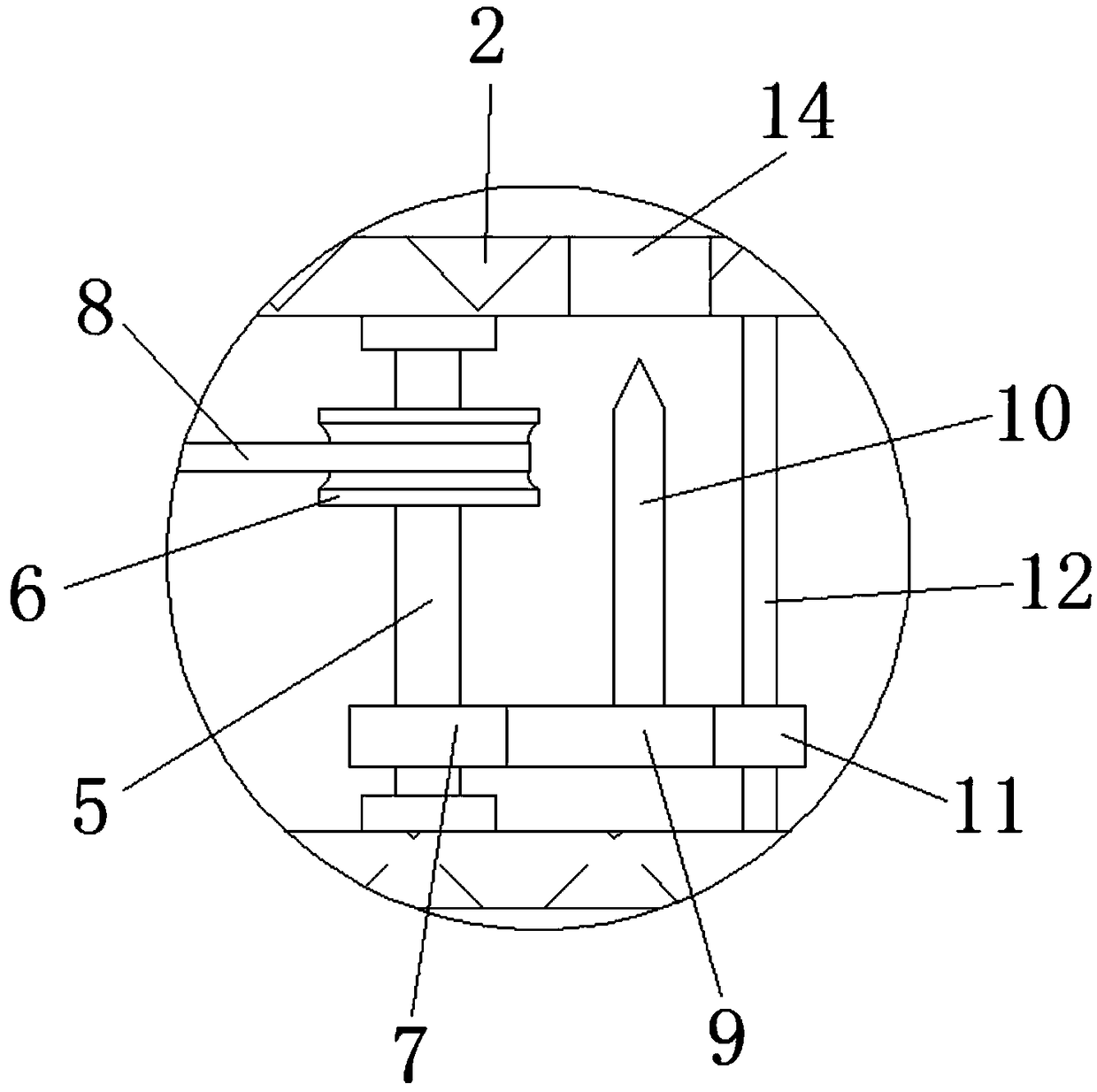

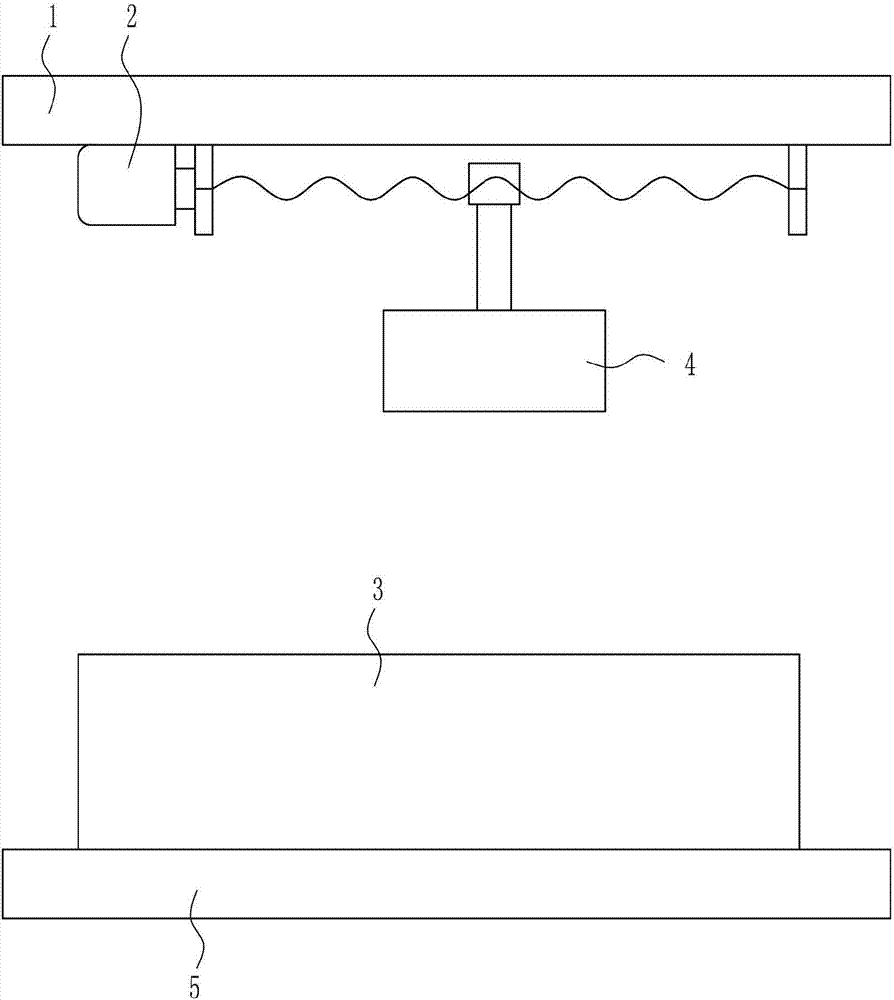

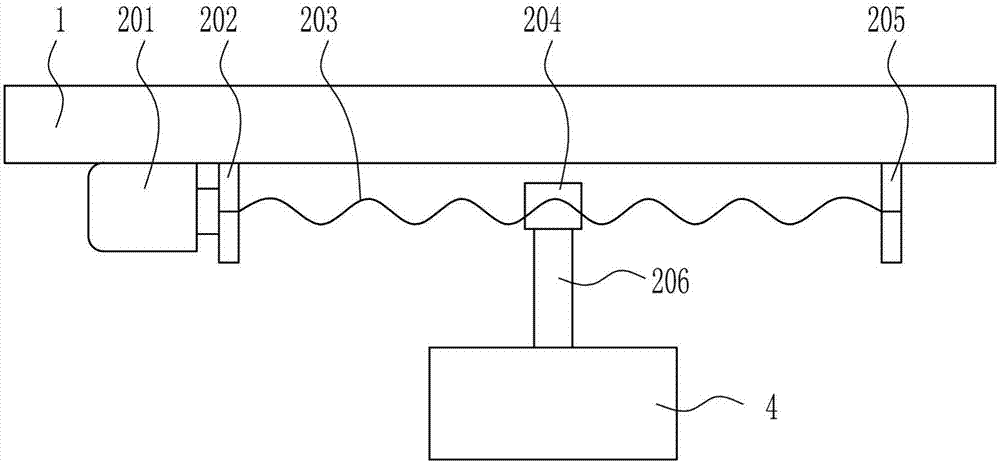

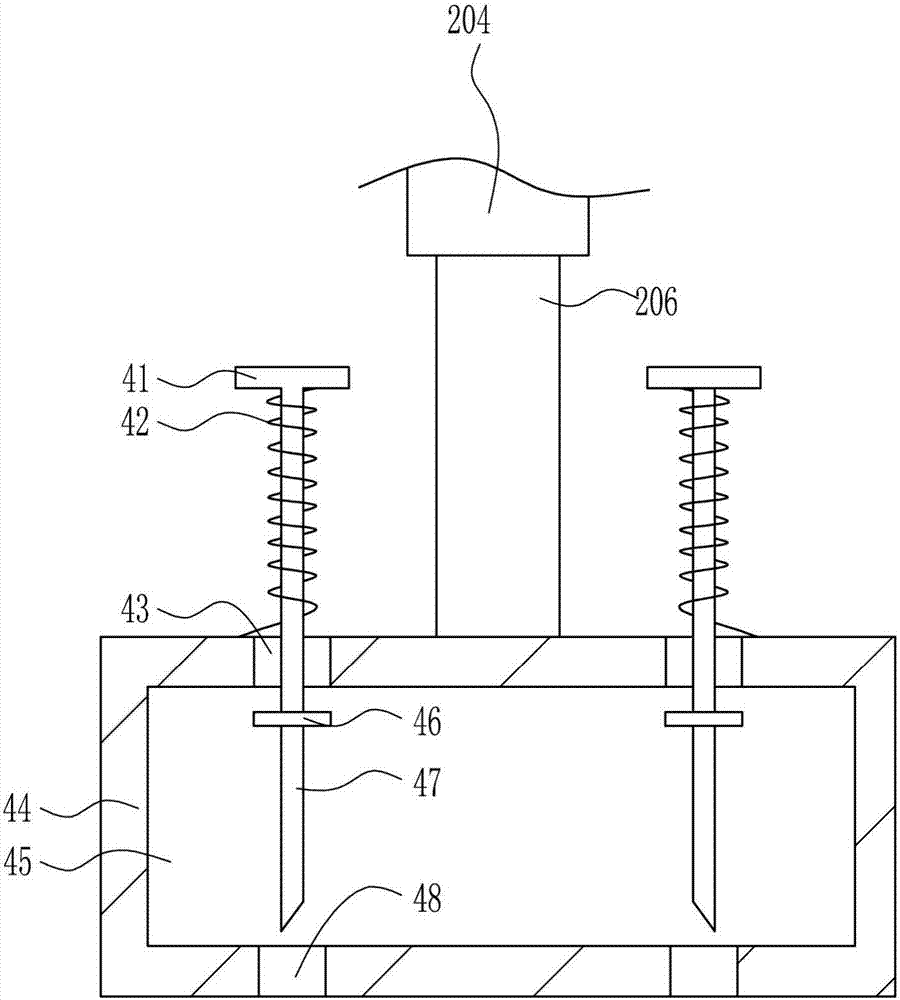

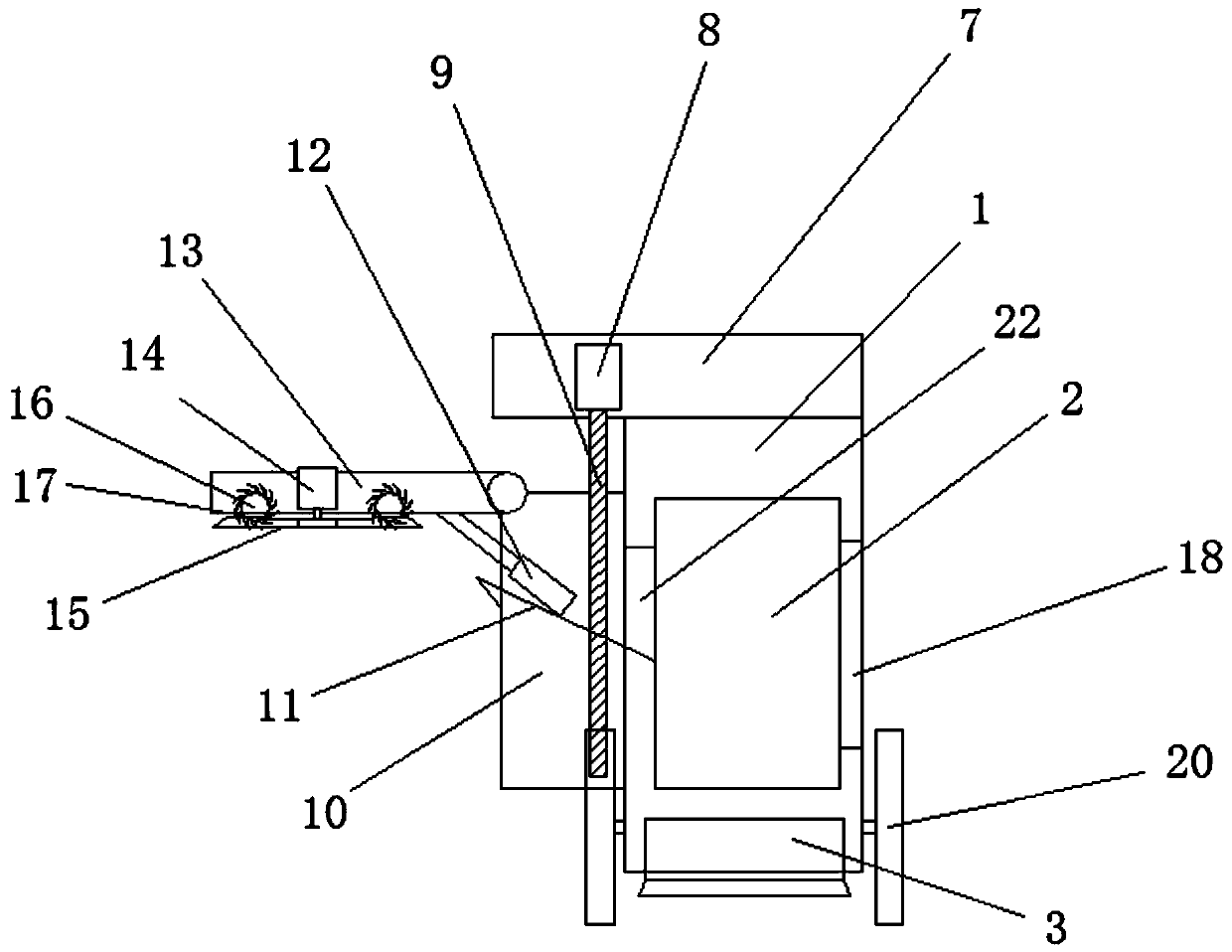

Leather shoe shell fabric tailoring equipment for leather shoe processing

The invention relates to tailoring equipment and in particular relates to leather shoe shell fabric tailoring equipment for leather shoe processing. The invention aims to provide the leather shoe shell fabric tailoring equipment for leather shoe processing, wherein the position of the leather shoe is easily fixed when the leather shoe is formed and the equipment is conveniently used by shoe-making personnel. In order to solve the technical problem, the invention provides the leather shoe shell fabric tailoring equipment for leather shoe processing. The leather shoe shell fabric tailoring equipment for leather shoe processing comprises a top plate, a tailoring device, a bottom plate, a placing table, a clamping device and the like, wherein the placing table is arranged on the top of the bottom plate, the top plate is arranged right above the bottom plate, the tailoring device is arranged on the bottom of the top plate, and the locking device is mounted on the bottom of the tailoring device. The equipment provided by the invention is simple to operate and convenient for the shoe-making personnel to use, and a new tailoring blade is conveniently replaced by the shoe-making personnel and the tailoring blade can be fixed well.

Owner:林安益

Woven fabric and process for producing same

ActiveCN104641029AReduce loose edgeExcellent uniform coatingLoomsPedestrian/occupant safety arrangementWoven fabricSynthetic fiber

Woven fabric most suitable as base fabric for airbags is provided in which selvage waving has been reduced by inhibiting the weaving sheds of the selvage edge parts from receding during high-density weaving and which is excellent in terms of smooth processability and even coatability in the steps of scouring, setting, and coating and is excellent also in terms of cuttability and sewability. Also provided is a process for producing the woven fabric. The woven fabric employs synthetic-fiber multifilament yarns as the ground yarns. This woven fabric includes in the selvage weave parts of the edge parts: a leno yarn constituted of a filament having a fineness of 33 dtex or less; an additional yarn constituted of a filament having a fineness of 33 dtex or less; and a selvage-tightening yarn constituted of a multifilament yarn having a total fineness that is 80% or more of the total fineness of the ground yarns. In a process for producing the woven fabric, filaments with a fineness of 33 dtex or less are used as a leno yarn and an additional yarn for forming selvage weave parts at edges parts of woven fabric to conduct weaving while a multifilament yarn having a total fineness that is 80% or more of the total fineness of the ground yarns is being inserted as a selvage-tightening yarn into each selvage weave part.

Owner:TORAY IND INC

Trimming cutter for textile fabric

The invention discloses an edge cutting machine for textile fabrics, which comprises a working platform and supporting feet, the supporting feet are arranged on four corners of the bottom surface of the working platform, support rods are symmetrically distributed on the working platform, and the top of the supporting rods is provided with a fixed Clamps, there is a drive cylinder between the fixed clamps, a platen assembly is provided between the support rods, the drive cylinder is connected to the platen assembly, elastic pressure seats are provided on both sides of the platen assembly, blades are provided at the bottom of the platen assembly, and the working platform There is a backing plate on the top, the backing plate is located below the blade, a wiper is slidably connected to the working platform, and a strip brush is arranged on the bottom surface of the wiper, and the strip brush is in contact with the backing plate, and U-shaped frames are symmetrically distributed on the bottom surface of the working platform , A collection frame is arranged on the U-shaped frame, and the collection frame is in the shape of an upper opening. The invention has the advantages of compact structure, flexible connection, high working efficiency, good cutting effect, convenient cleaning of waste materials, and effectively keeping the working environment clean.

Owner:嵊州市靖洁纺织机械有限公司

Cutting machine structure special for automotive trim gauze

InactiveCN106938798AAvoid offsetGuaranteed crop sizeSevering textilesArticle deliveryPunchingEngineering

The invention discloses a special cutting machine structure for automotive interior gauze. The limit device on the rear end frame, the guide wheel arranged on the rear end frame of the limit device, and the conveying device arranged on the rear end frame of the guide wheel, the conveying device includes: conveying rollers, conveyor belts, front The press-fit device and the rear press-fit device, the front press-fit device is slidably arranged on the slide rail through the slider, and the thread sleeve cooperating with the lead screw is fixedly arranged on the slide block, and the lead screw is connected with the motor. A punching and forming device is arranged on the frame at the rear end of the device. The structure of the punching and forming device includes: a punching machine base, a punching platform is arranged in the middle of the punching machine base, and a punching platform is arranged on the punching machine base. The upper end of the base is provided with a punching cylinder.

Owner:盐城市鑫富华机械有限公司

Textile fabric cutting device with accurate positioning function

PendingCN107724042AGuaranteed accuracyAvoid imprecisionSevering textilesStructural engineeringMechanical engineering

The invention discloses a textile fabric cutting device with an accurate positioning function. The textile fabric cutting device comprises a base. A first slide groove is formed in a side of the outerwall of the top of the base, a first slider is slidably connected with the inner wall of the first slide groove, a support rod which is vertically arranged is welded on the outer wall of the top of the first slider, a transverse beam which is horizontally arranged is welded on the top of the outer wall of a side of the support rod, an electric slide rail is fixed to the outer wall of the bottom of the transverse beam by the aid of screws, a second slider is slidably connected with the inner wall of the electric slide rail, a cylinder is fixed to the outer wall of the bottom of the second slider by the aid of screws, a connecting plate is welded at the bottom of the cylinder, a tailoring device is fixed to the outer wall of the bottom of the connecting plate by the aid of screws, clamp grooves are formed in four corners of the outer wall of the top of the base, and auxiliary magnets are clamped inside the clamp grooves. The textile fabric cutting device has the advantages that the textile fabric cutting device is simple in structure, the problem of inaccuracy due to manual operation cutting can be solved by the aid of the textile fabric cutting device in the integral design, the cutting accuracy can be guaranteed, and excellent cutting effects can be realized.

Owner:盐城融凡纺织制衣有限公司

Multifunctional vehicle trim gauze cutting machine

PendingCN106884307AAvoid offsetEliminate offsetSevering textilesElectric machineryStructural engineering

The invention discloses a multifunctional vehicle trim gauze cutting machine. The multifunctional vehicle trim gauze cutting machine comprises a machine frame, an unreeling device, an infrared ray optoelectronic switch, a limiting device, a guide wheel and a delivery device, wherein the unreeling device is arranged at the front-most end of the machine frame, the infrared ray optoelectronic switch is arranged at the position, at the rear end of the unreeling device, of the machine frame, the limiting device is arranged at the position, at the rear end of the optoelectronic switch, of the machine frame, the guide wheel is arranged at the position, at the rear end of the limiting device, of the machine frame, and the delivery device is arranged at the position, at the rear end of the guide wheel, of the machine frame; the delivery device comprises a deliver roller, a delivery belt, a front stitching device and a rear stitching device, the front stitching device is slidably arranged on a slide rail through a slide block, the slide block is fixedly provided with a screw cover which is matched with a led screw, the lead screw is connected to a motor, the position, at the rear end of the delivery device, of the machine frame device is provided with a punching forming device, and the structure of the punching forming device comprises a punching machine base, the middle portion of the punching machine is provided with a punching platform, and the upper end of the punching machine base is provided with a punching air cylinder.

Owner:盐城市鑫富华机械有限公司

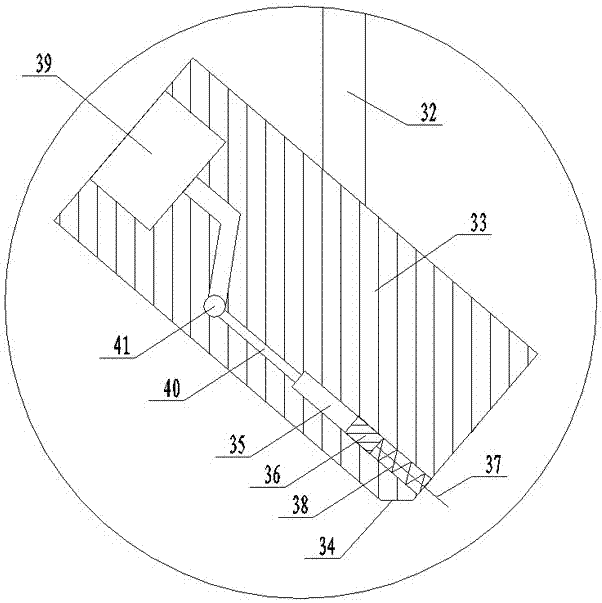

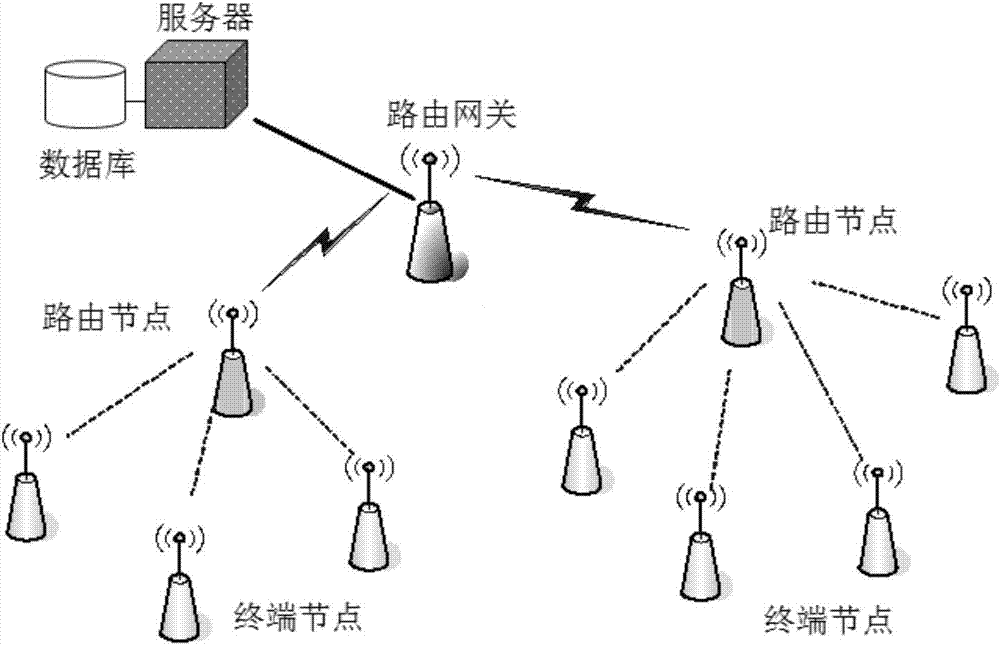

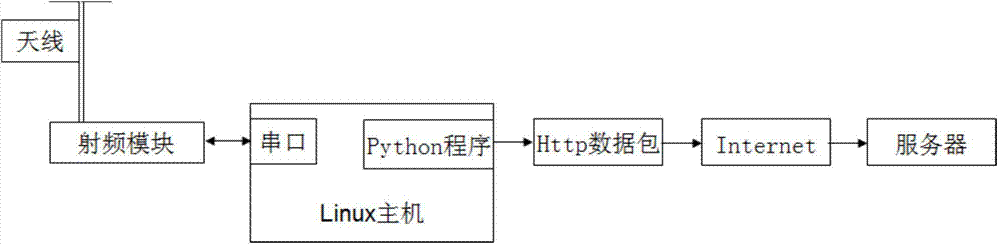

Arduino-based wireless sensor network island parameter monitoring system

InactiveCN104332042AGood cropping effectReduce casualtiesTransmission systemsNetwork topologiesMonitoring systemWireless sensor networking

The invention discloses an Arduino-based wireless sensor network island parameter monitoring system, comprising a plurality of terminal nodes, a plurality of routing nodes, a routing gateway and a data server, wherein the terminal nodes are used for measuring island parameters and transmitting data to the routing nodes which take charge of transferring; the routing nodes are used for monitoring the parameters which are the same as the terminal nodes, receiving data of the plurality of managed terminal nodes, and transferring the data and the data of the terminal nodes to the routing gateway; the routing gateway is used for collecting data of all terminal nodes and routing nodes and uploading the data to the data server through a network; and the data server is used for writing the data into a database after receiving the data, processing the data according to the requirements of users, and providing web access service. The system disclosed by the invention is low in cost, the cutting property of hardware is good, the hardware can be flexibly modified to support different sensors according to the requirements of measured parameters; the data which are monitored by the system in real time can be applied to advanced warning of disasters; and economic losses and casualties are reduced.

Owner:ZHEJIANG UNIV

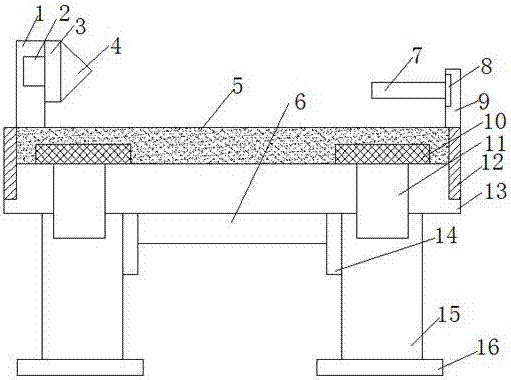

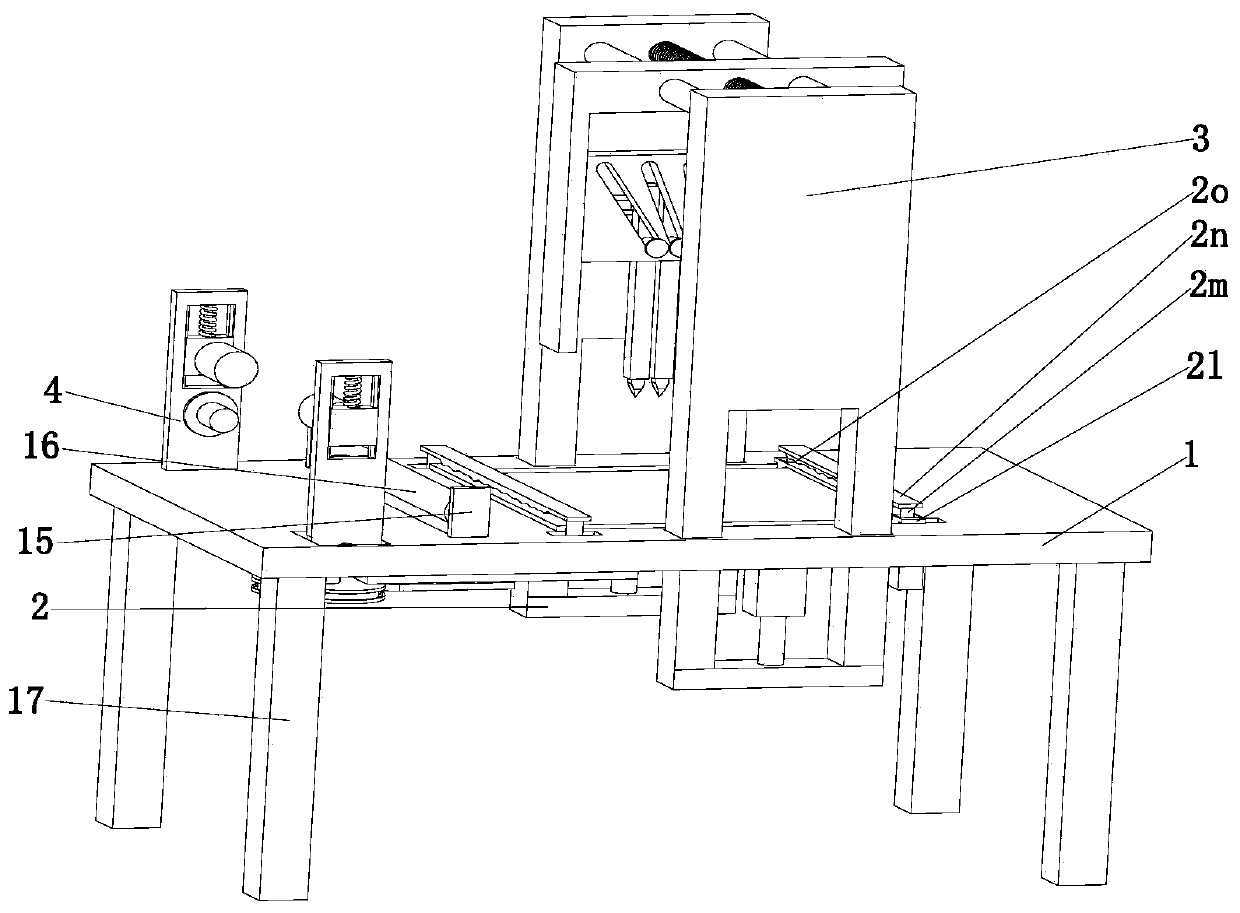

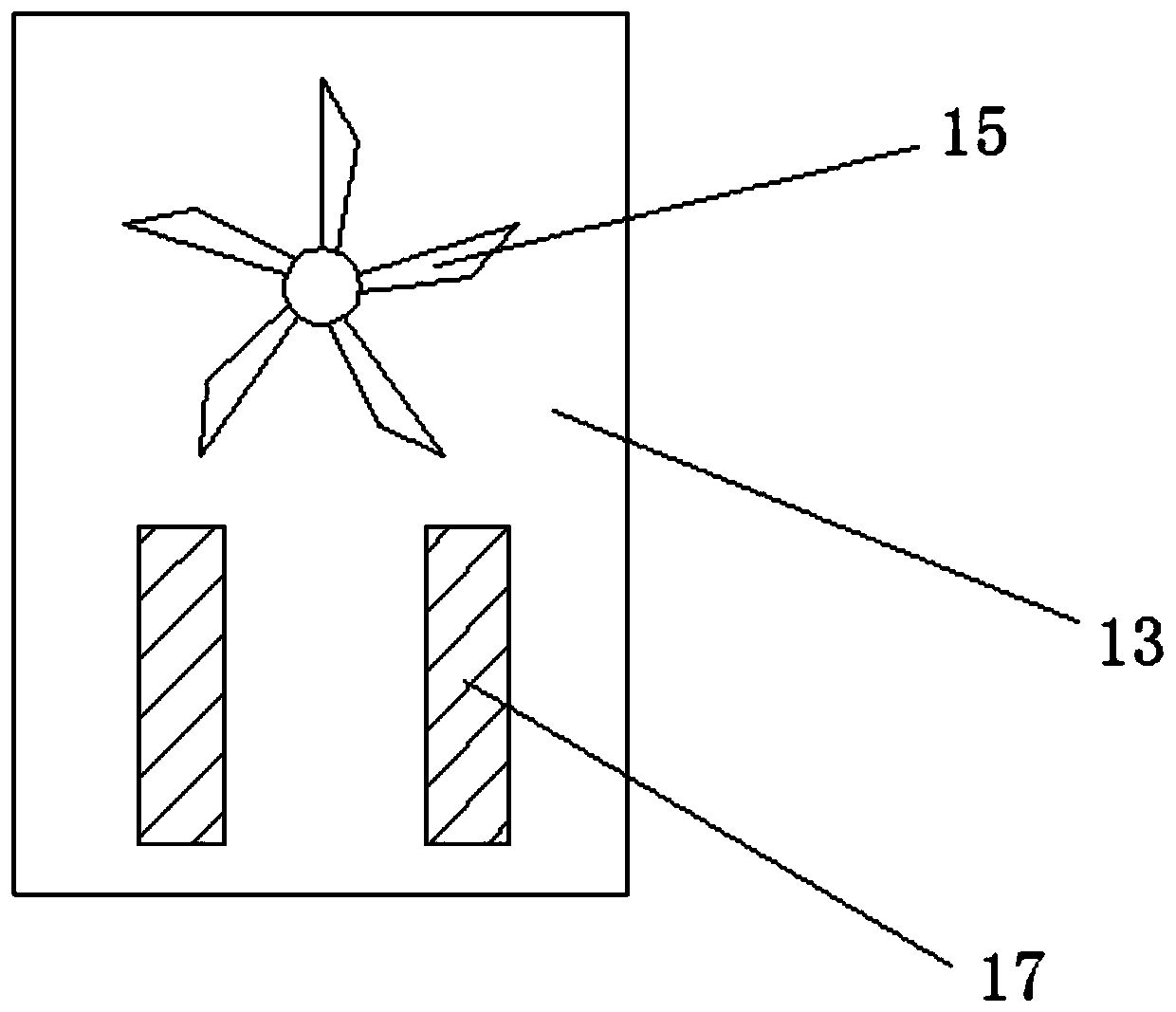

Cotton cloth cutting device

InactiveCN107099992AGood cropping effectEasy to useSevering textilesBiochemical engineeringCotton cloth

The invention discloses a cotton cloth cutting device. The device comprises a device body, the two sides of the lower end of the device body are both provided with supporting columns, the lower ends of the supporting columns are provided with a placing bottom plate, one end of each supporting column is provided with a fixing plate, a connecting rod is arranged between every two fixing plates, the upper end of the device body is provided with a placing table, an inner cavity of the placing table is provided with an adjusting plate, the lower end of the adjusting plate is provided with an extending strut, one end of the extending strut extends into the inner cavities of the supporting columns, the two ends of an inner cavity of the device body are both provided with mounting plates fixedly connected with the placing table, and one side of the upper end of the device body is provided with a connecting strut. The cotton cloth cutting device has a good cotton cutting effect, and has the advantages of being convenient to use, capable of bringing much convenience and saving lots of time and energy, and capable of ensuring the using effect of the device in the usage process at the same time.

Owner:YANCHENG XUER TEXTILE

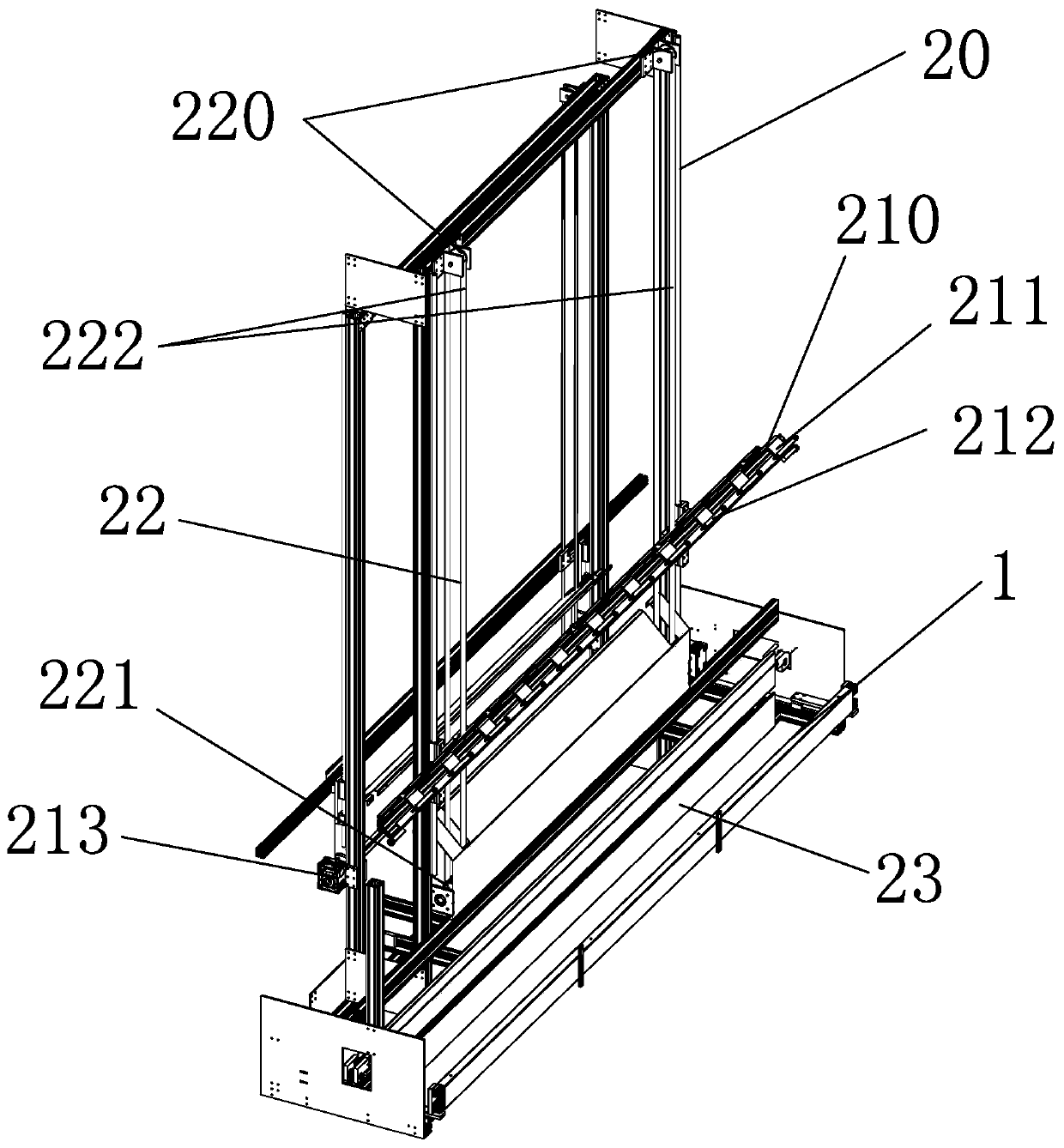

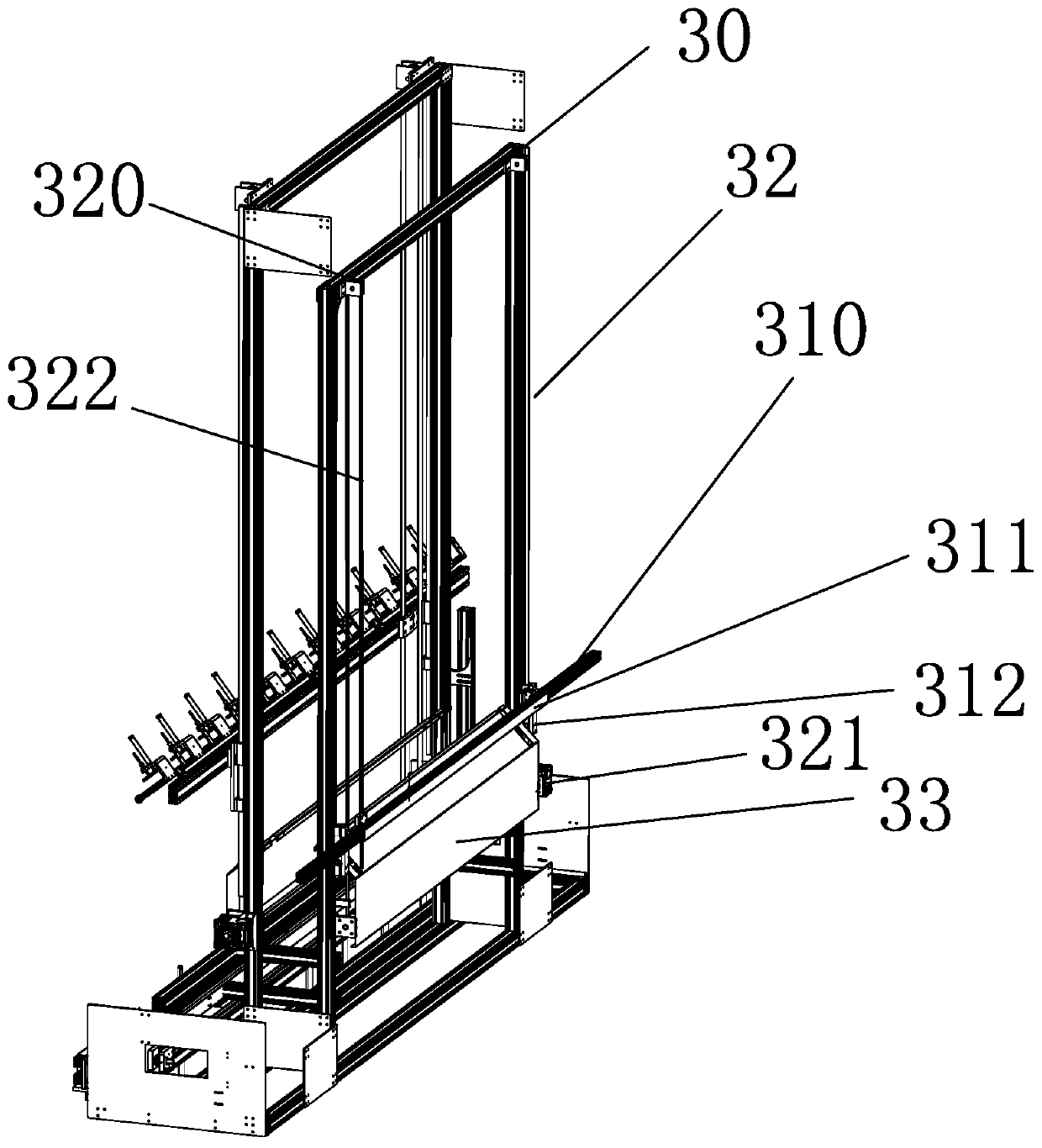

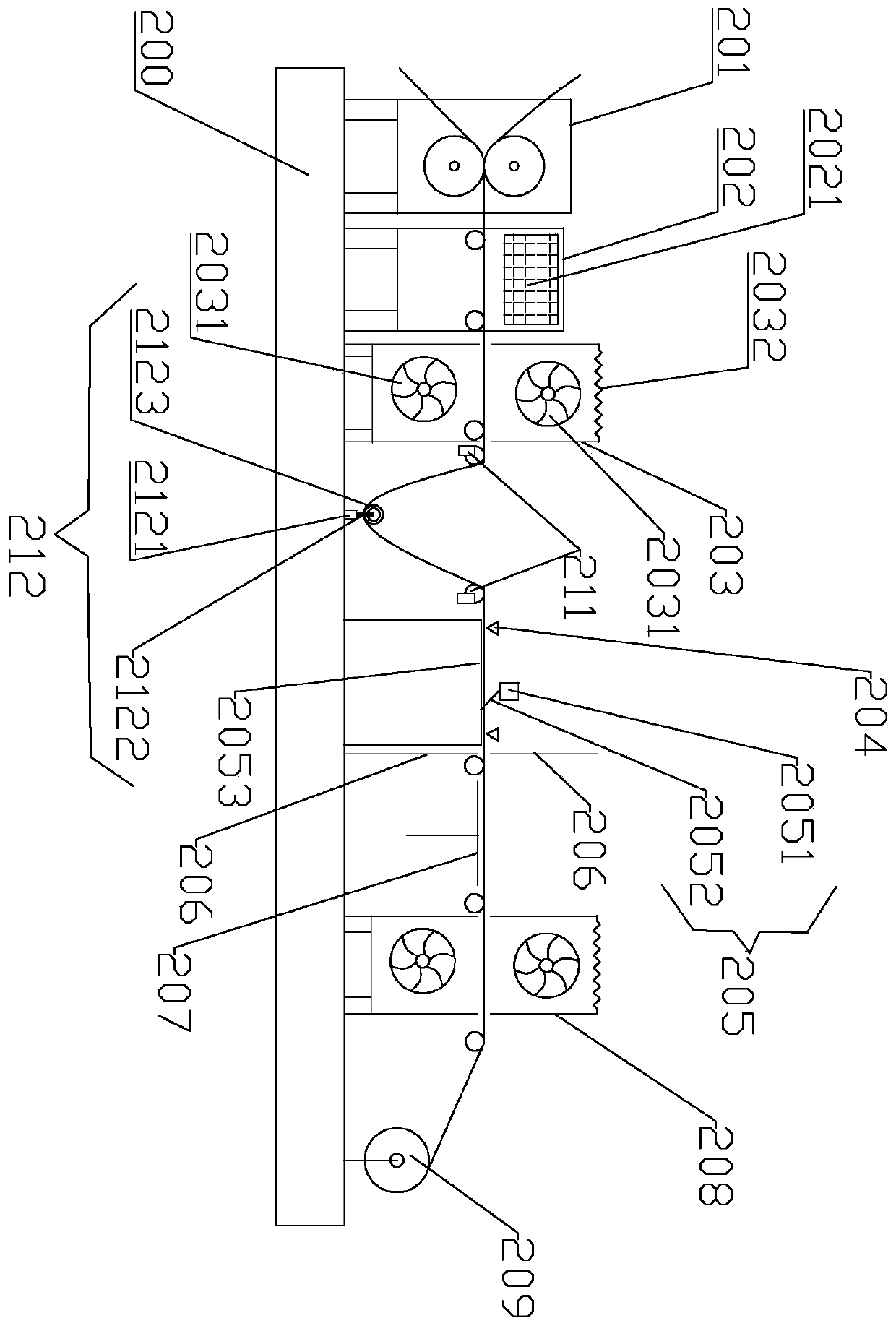

Multifunctional curtain cutting and inspection all-in-one machine and processing method thereof

PendingCN111379157AGood cropping effectImproved performance of the finished productInspecting textilesSevering textilesMachineIndustrial engineering

The invention discloses a multifunctional curtain cutting and inspection all-in-one machine and a processing method thereof, and aims to provide a multifunctional curtain cutting and inspection all-in-one machine which integrates cutting and inspection, and is simple in structure and high in practicability. According to the technical scheme, the multifunctional curtain cutting and inspection all-in-one machine is characterized in that a height fixing surface structure used for height fixing cutting is arranged on one side of a machine frame, and an inspection surface structure used for detecting the quality of a cut curtain is arranged on the other side of the machine frame. According to the multifunctional curtain cutting and inspection all-in-one machine and the processing method thereof, the height fixing surface structure and the inspection surface structure are combined, so that the height fixing cutting of the curtain and the detection of the quality of a finished product are facilitated, and the processing efficiency is improved; and the multifunctional curtain cutting and inspection all-in-one machine and the processing method thereof are suitable for the technical field ofcurtain processing equipment.

Owner:绍兴众杰屹自动化设备科技有限公司

Full-automatic rotating plate type ear wire electric welding machine for mask production

InactiveCN111497266ARealize no movementHigh degree of automationDomestic articlesEngineeringSpot welding

The invention relates to the technical field of mask production, and discloses a full-automatic rotating plate type ear wire electric welding machine for mask production. The full-automatic rotating plate type ear wire electric welding machine comprises an mask machine main body, fixed supports are fixedly installed at four corners of the bottom of the mask machine main body, a platform plate is fixedly installed at the top of the mask machine main body, a button induction switch is fixedly installed on the front face of the top of the platform plate, an ear strap straightening and length fixing device is fixedly installed on the back face of the platform plate, a supporting frame is fixedly installed on the back face of the top of the platform plate, three crosspieces are fixedly installed on the top of the supporting frame, and a tabletting air cylinder is fixedly installed at the bottoms of the crosspieces at the front end. According to the full-automatic rotating plate type ear wire electric welding machine for the mask production, the purpose of high ear wire electric welding automation degree is achieved by arranging two rotating air cylinders, the tabletting air cylinder, the crosspieces and the like, a mask sheet does not deviate in the rotating process through a first rotating air cylinder and a rotating plastic pressing plate on the upper part, and it is guaranteed that second-time spot welding succeeds.

Owner:俞建峰

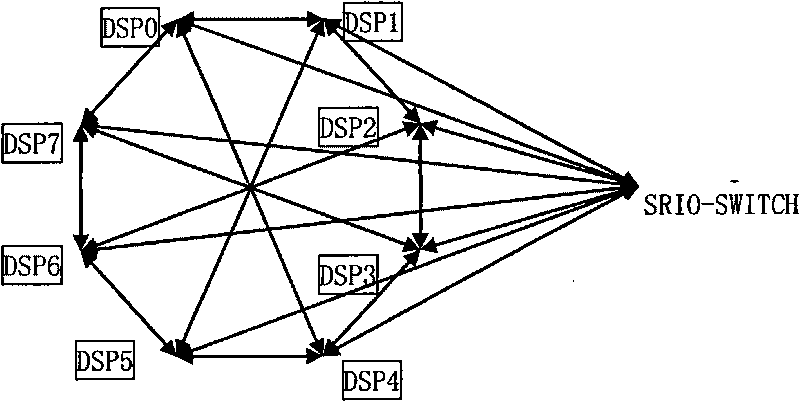

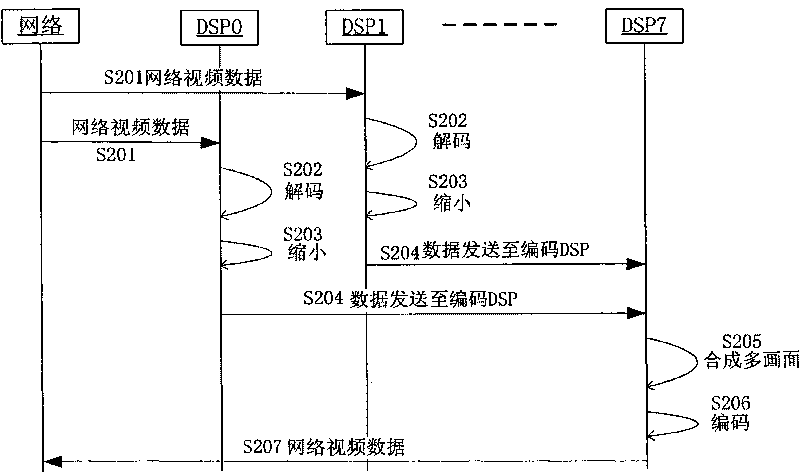

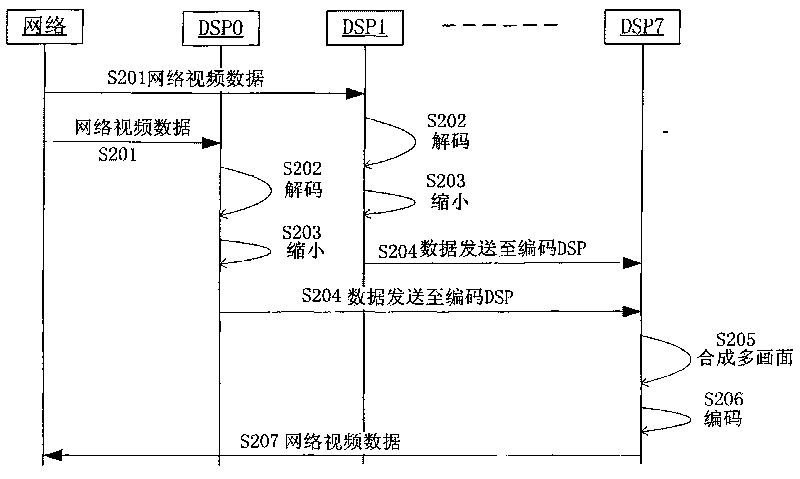

System and method for realizing multi-picture based on serial differential switch

ActiveCN101742220ASolve Video Bandwidth BottlenecksGood scalability and tailoringPulse modulation television signal transmissionTelevision conference systemsHigh definitionSignal processing

The invention discloses a system and a method for realizing multi-picture based on a serial differential switch. An image processing unit for implementing the method comprises a plurality of decoding modules and encoding modules which are connected with each other through serial differential interfaces. The method comprises the following steps: when each of the decoding modules is connected with the serial differential switch through the serial differential interfaces, zooming received image data to small picture image data in multi-picture image data by the decoding modules; transmitting the small picture image data to the encoding modules through the serial differential switch; and combining a plurality of small picture image data into multi-picture image data by the encoding modules. Because the transmission of image data is realized by the serial differential switch, a bottleneck problem of video bandwidth is solved so that a conference television user can receive high-definition multi-picture clearly; and simultaneously, the number of digital signal processors can be selected as required according to the maximum number of the multi-picture, which not only saves implementation cost for low-end users, but also meets the requirements of high-end users by increasing the number of the digital signal processors.

Owner:ZTE CORP

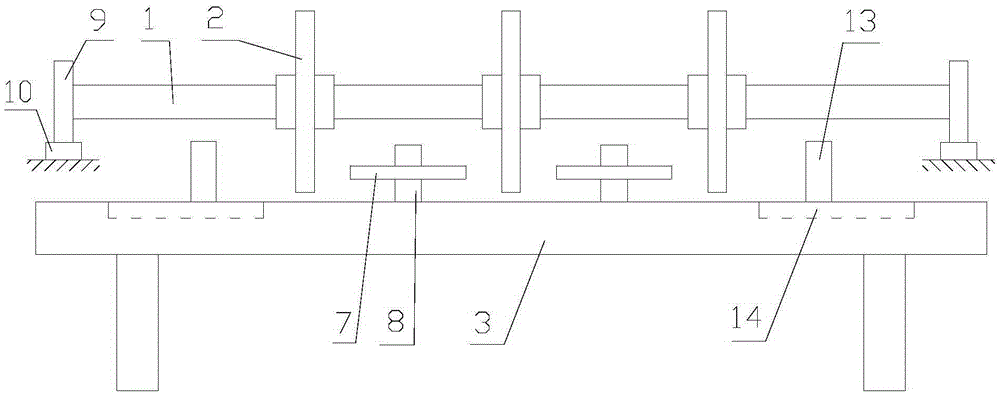

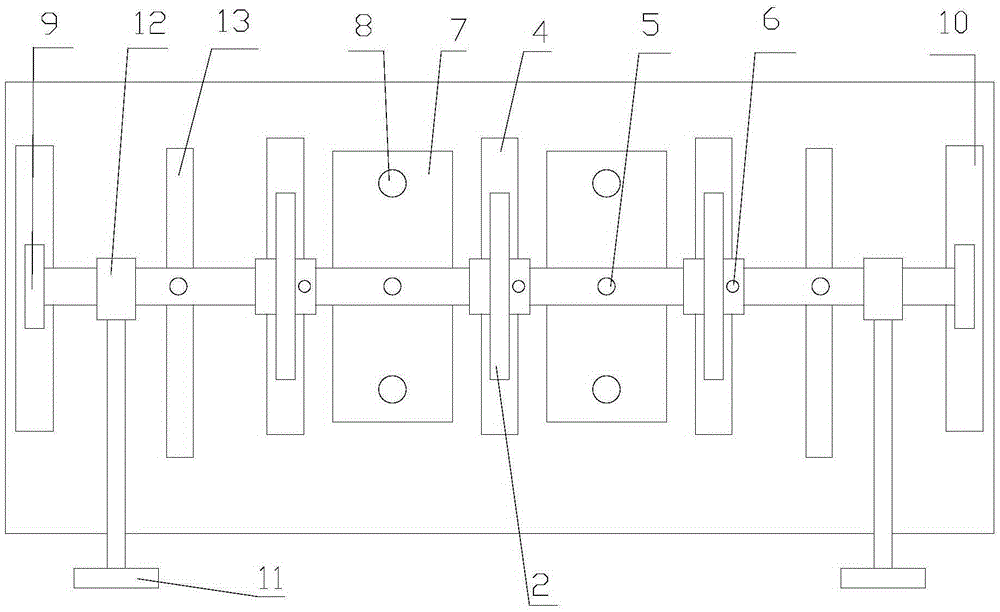

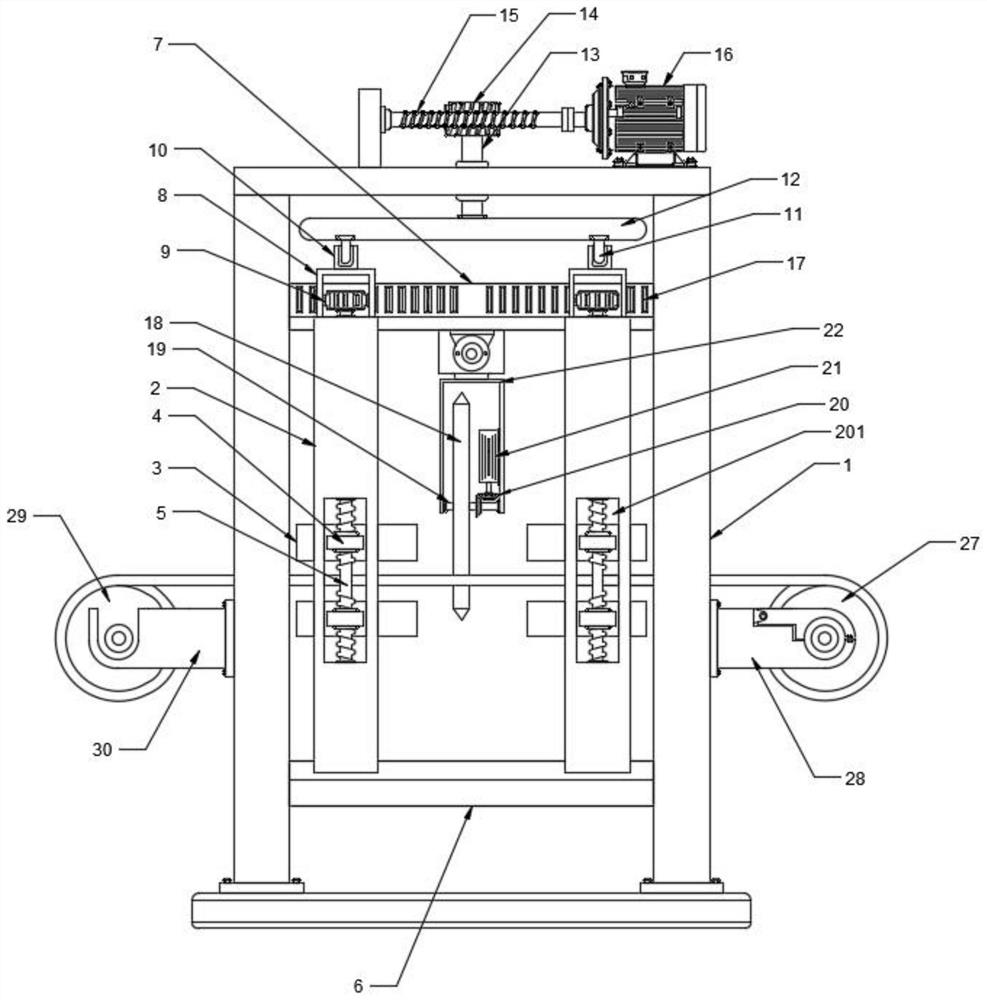

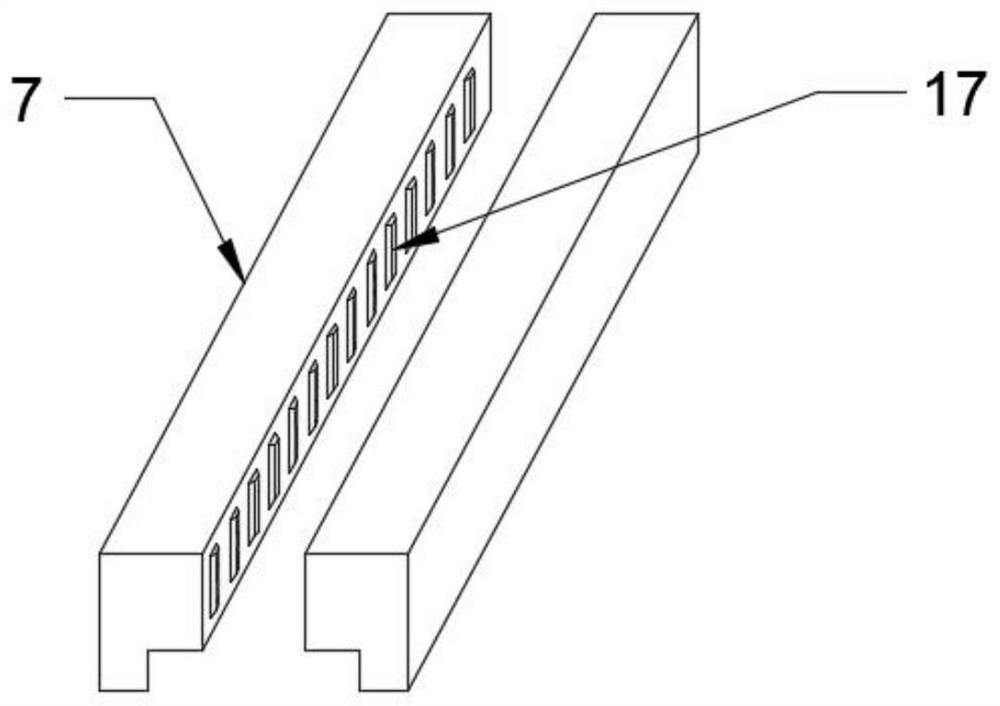

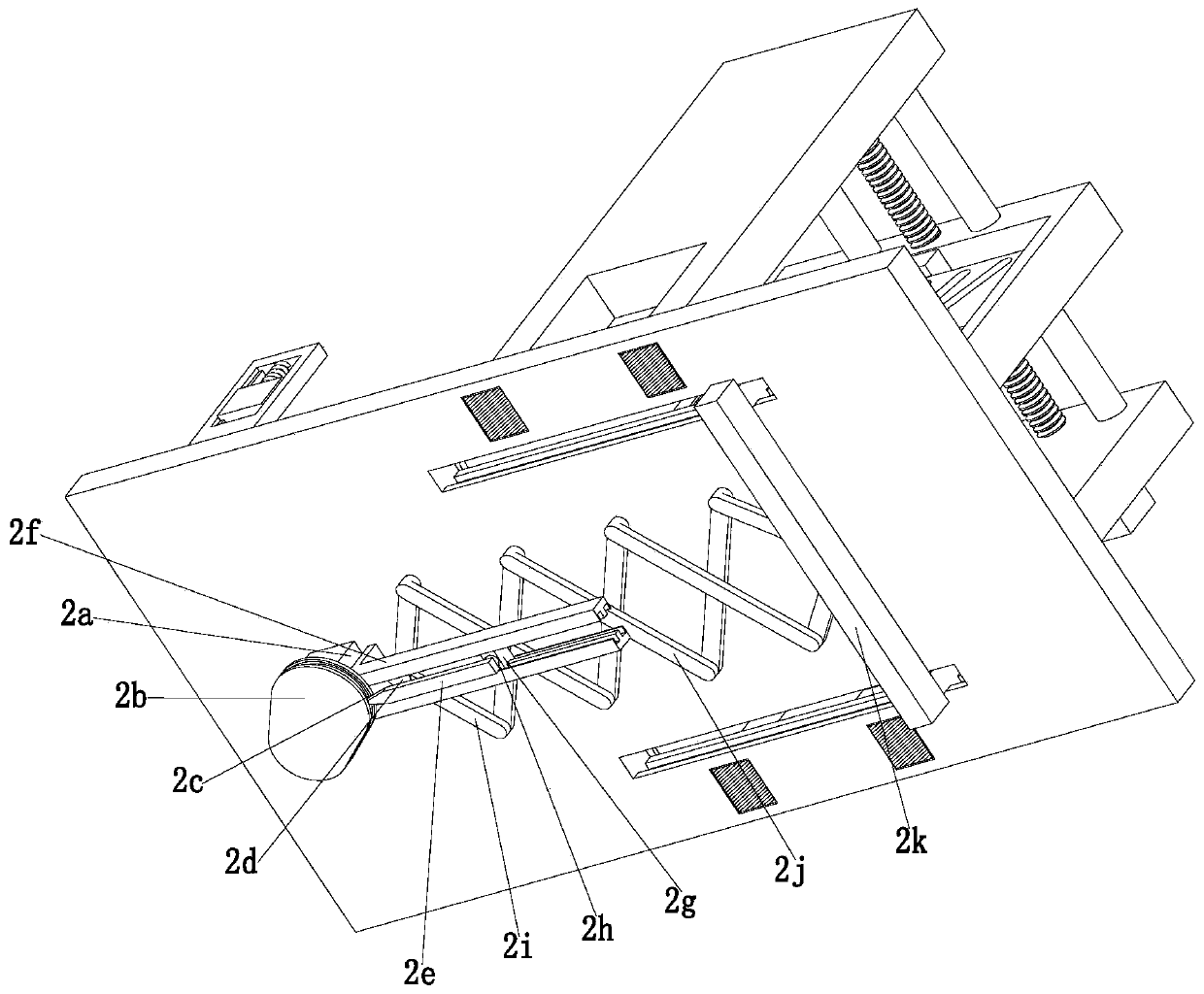

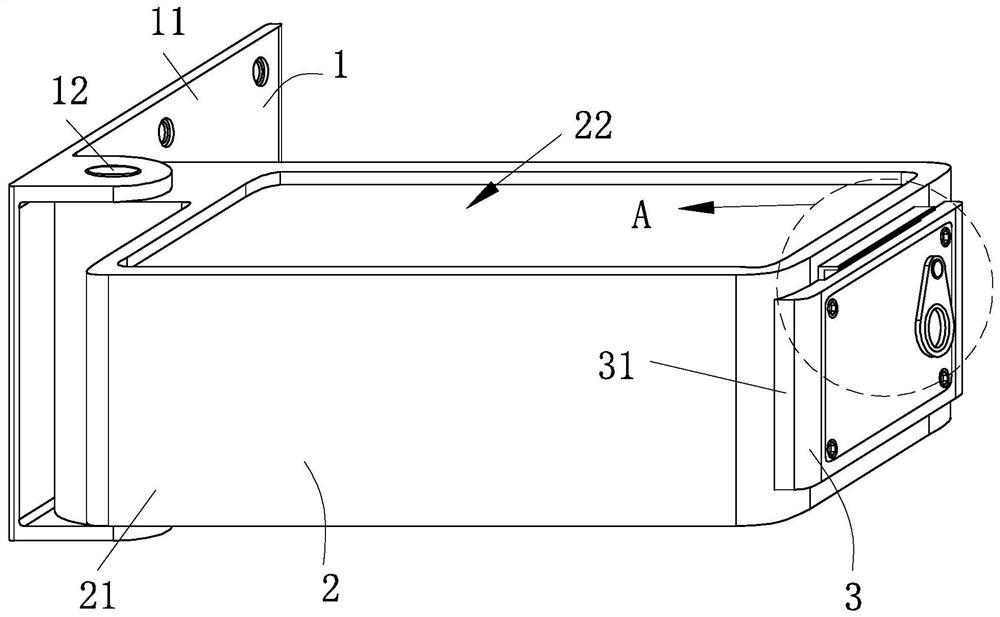

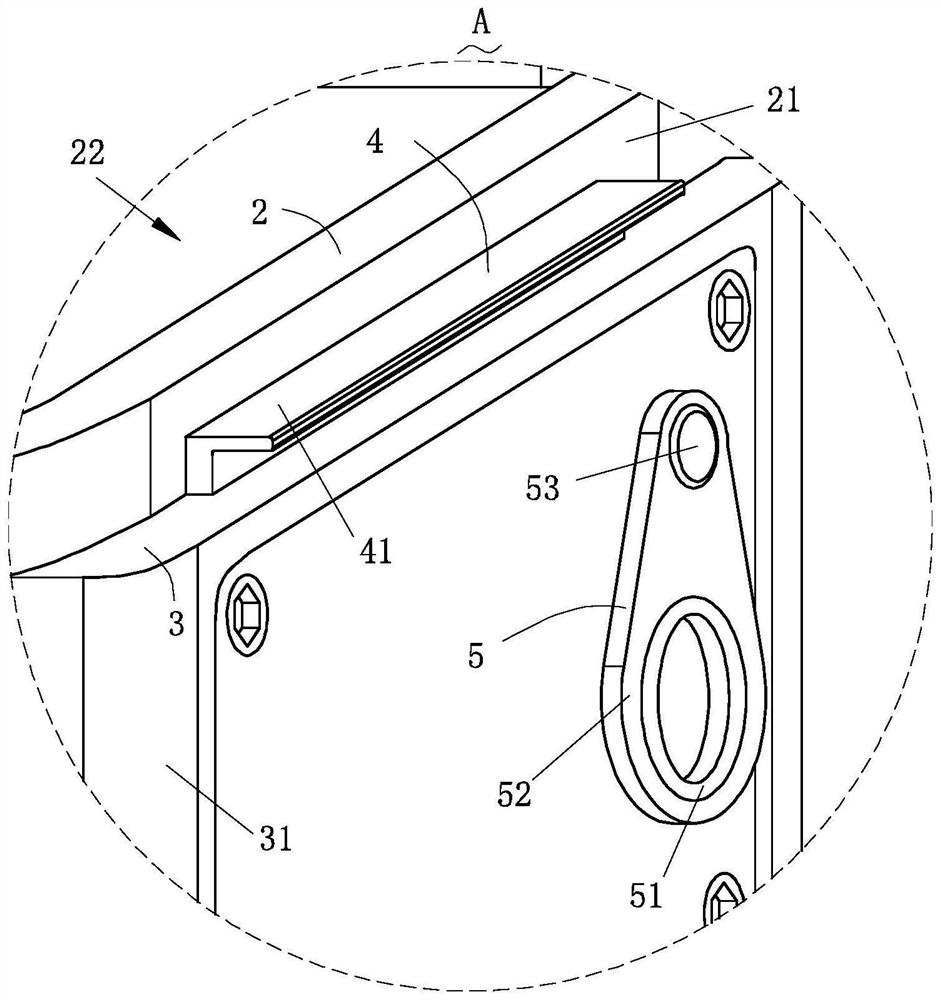

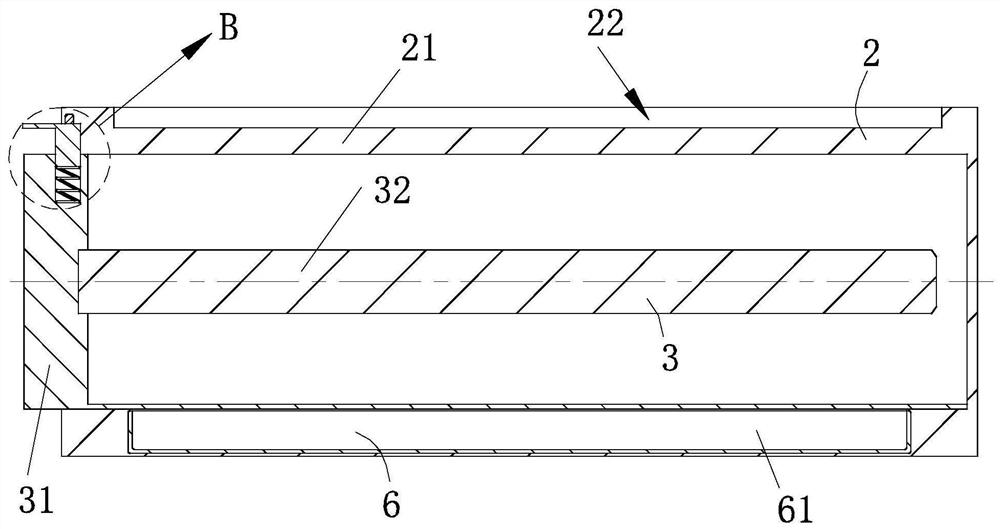

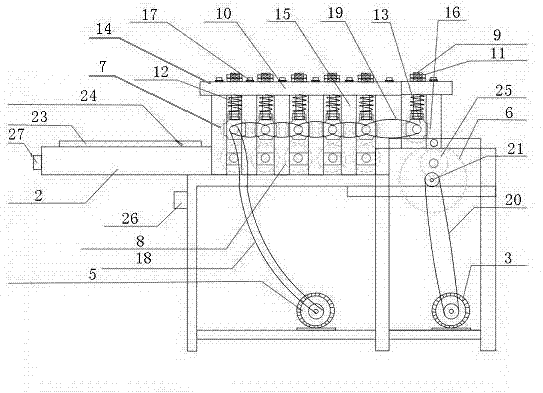

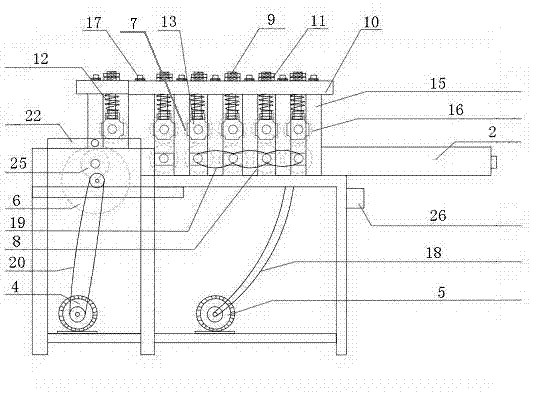

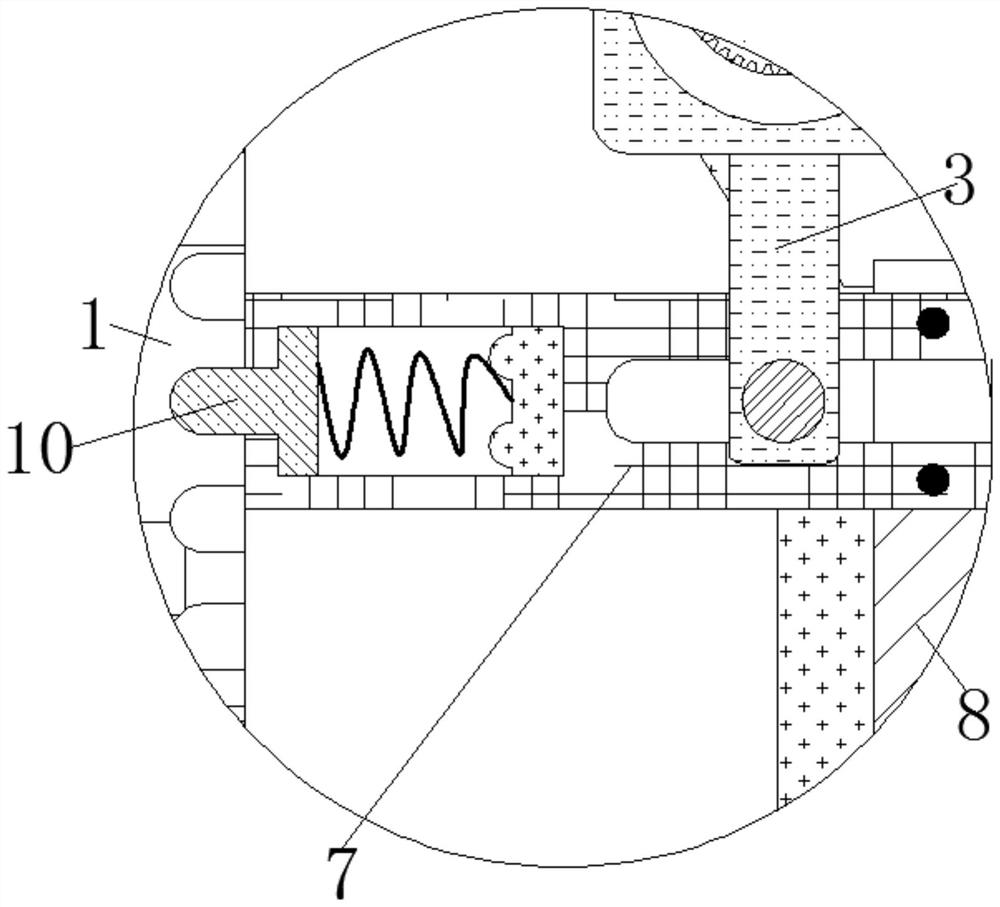

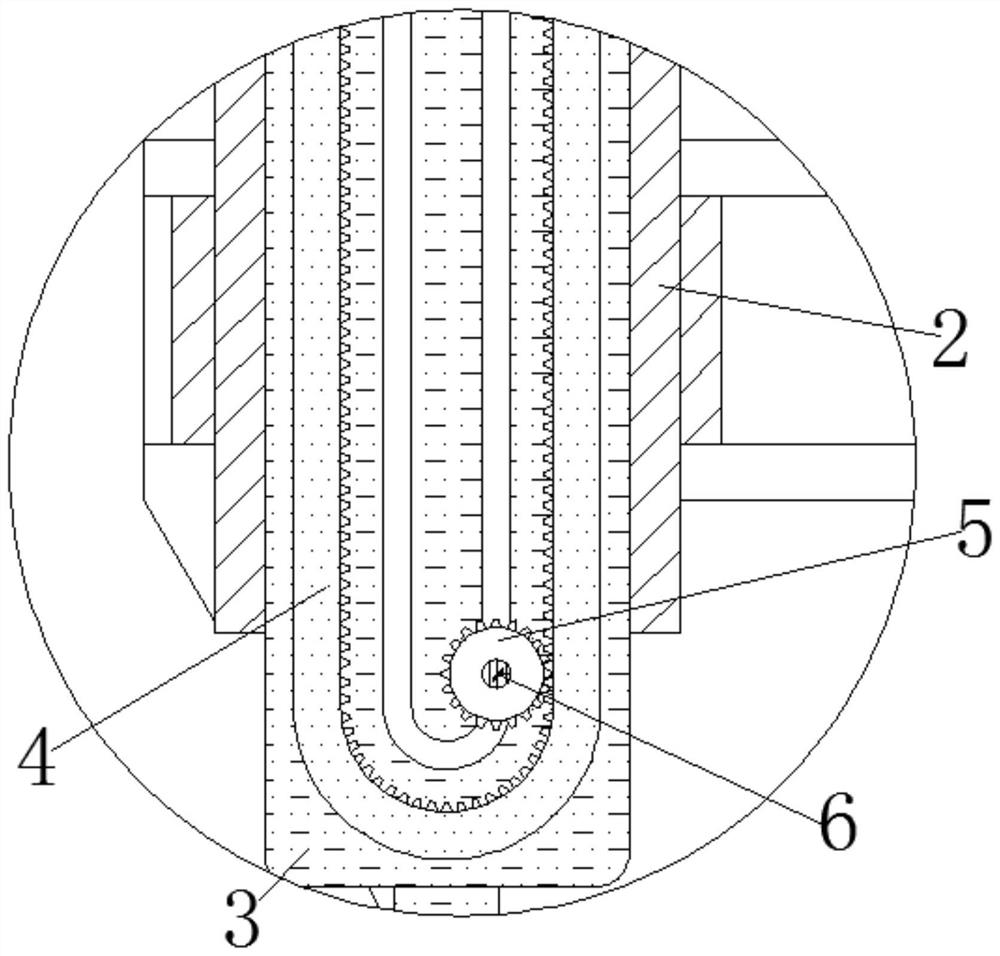

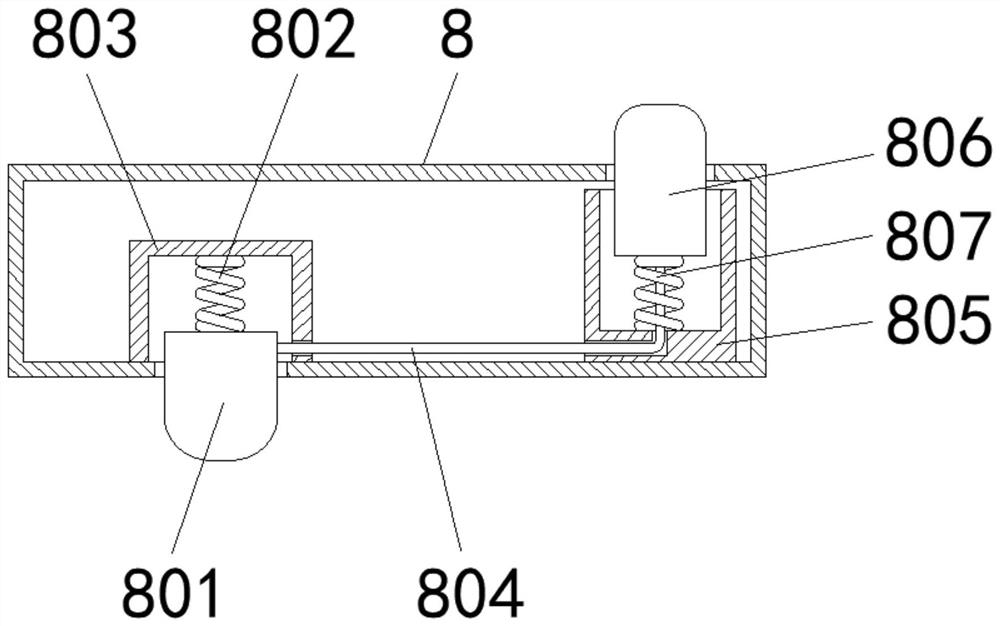

Moving and rotating mechanism and cloth cutting device for cotton textile production

InactiveCN112482004AEnable mobilityImprove cutting efficiencySevering textilesGear wheelTextile production

The invention relates to textile cloth cutting equipment, in particular to a moving and rotating mechanism and a cloth cutting device for cotton textile production. The moving and rotating mechanism comprises a mounting frame and two sets of clamping assemblies arranged on the inner side of the mounting frame; each clamping assembly comprises a set of moving plates which are symmetrically arrangedfront and back; and an upper guide rail is clamped in the upper end of each moving plate and is in sliding connection with the moving plate. By arranging the moving plates, clamping plates, first moving blocks, bidirectional lead screws, rolling gears, rack plates, moving frames, connecting frames, upper guide rails, longitudinal sliding groove plates, traction columns and eccentric discs, transverse movement and opposite movement of the clamping plates are achieved; by arranging the moving and rotating mechanism, a cutting mechanism and a winding mechanism, the operation of clamping and thencutting the textile fabric is achieved, it is guaranteed that the fabric is kept in a tensioned state during cutting, the cutting efficiency and the cutting flatness are improved, and the relativelygood cutting effect is achieved.

Owner:李照明

Adhesive composition, adhesive sheet, and touch panel

ActiveCN102906207AGood cropping effectEasy to operateAdhesive processesEster polymer adhesivesHeat resistanceFace sheet

The present invention relates to an adhesive composition, to an adhesive sheet, and to a touch panel. The present invention provides an adhesive composition, particularly an adhesive composition for a touch panel, which is prepared without using a low molecular weight polymer as an additive. The adhesive composition, the adhesive sheet, and the touch panel of the present invention exhibit superior heat resistance in a hardening process, a printed circuit board assembly process, or the like, and have superior physical properties such as optical characteristics, wettability, cuttability, workability, anti-curling properties, and durability.

Owner:LG CHEM LTD

Weaving fabric cutting device

InactiveCN108755089ASolve the problem of poor cropping effectGood cropping effectSevering textilesThreaded pipeMechanical engineering

The invention discloses a weaving fabric cutting device, which comprises a base, wherein a first casing is fixedly connected onto the top of the base; a first motor is fixedly connected onto the leftside of the bottom of an inner cavity of the first casing; a first belt wheel is sleeved on the output end of the first motor; a rotating rod is movably connected with an inner cavity of the first casing. Through the arrangement and the matched use of the base, the first casing, the first motor, the first belt wheel, the rotating rod, a second belt wheel, a threaded sleeve, a first belt, a fixingplate, a cutter blade, a first slide block, a first slide rod, an opening, a through opening, a roller, a fixing rod, a top plate, a second casing, a second motor, a third belt wheel, a threaded rod,a fourth belt wheel, a second belt, a threaded pipe, a press plate, a second slide rod, a second slide block and support legs, the problem of poor shearing effect of the existing weaving fabric shearing device is solved. The weaving fabric shearing device has the advantage of good shearing effect and is worthy of being popularized.

Owner:SUZHOU BAIBI TEXTILE TECH CO LTD

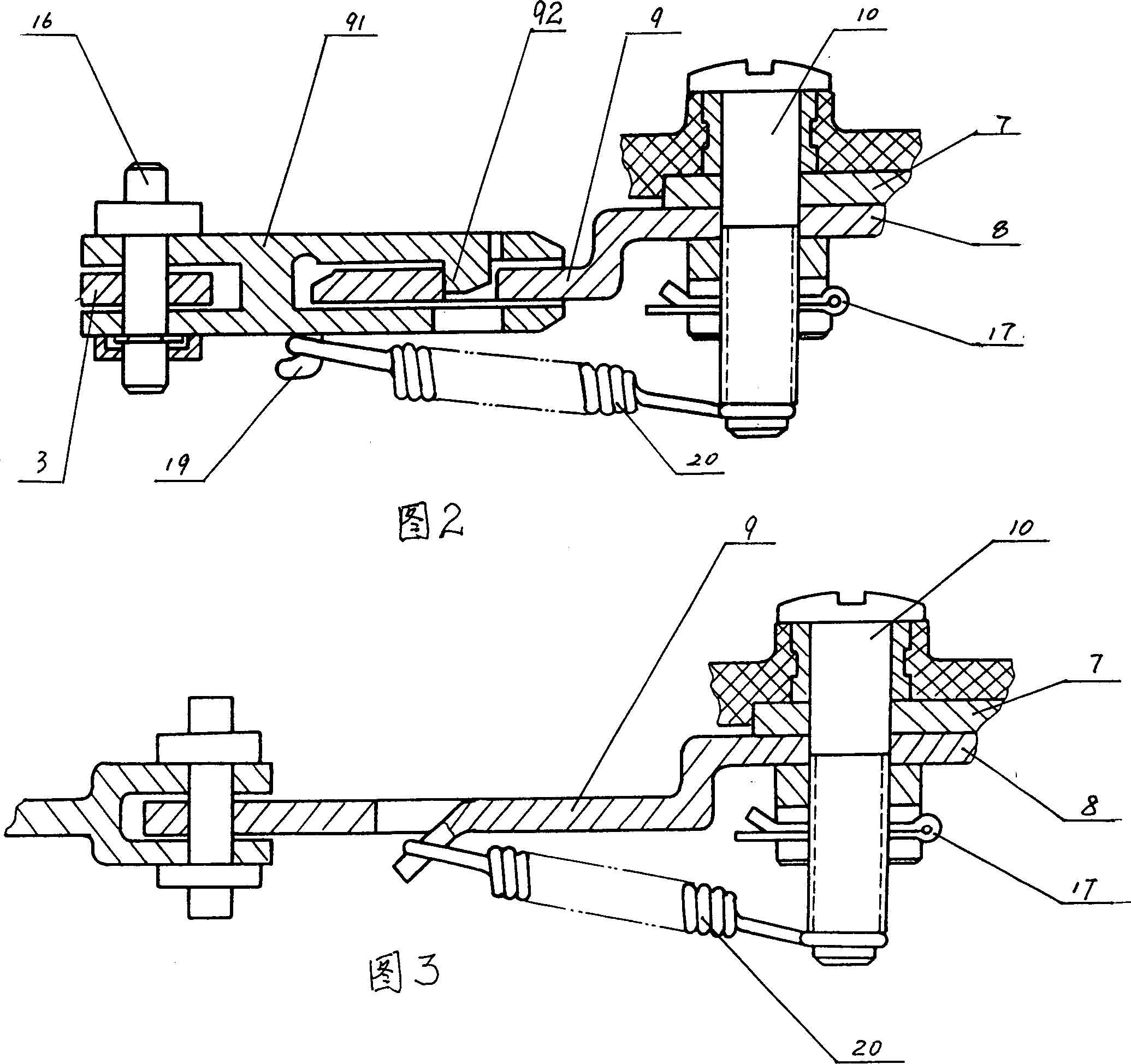

Safe electric scissors

InactiveCN1436641AStructural summaryReasonable arrangementMetal working apparatusGear wheelFront edge

The safe electric scissors is for shearing leather and other thick matter. Its transmission mechanism consists of eccentric wheel set on a gear and link rod outside the gear. The link rod has the other end hinged to the handle of the movable blade, the movable blade is hinged to the fixed blade and the feeding port is set outside the opening end on the wrapping casing. The eccentric wheel has small degree of eccentricity and the wrapping casing wraps all the parts except the front edge end. The present invention has simple and compact structure, reasonable configuration and excellent shearing performance.

Owner:苏和生

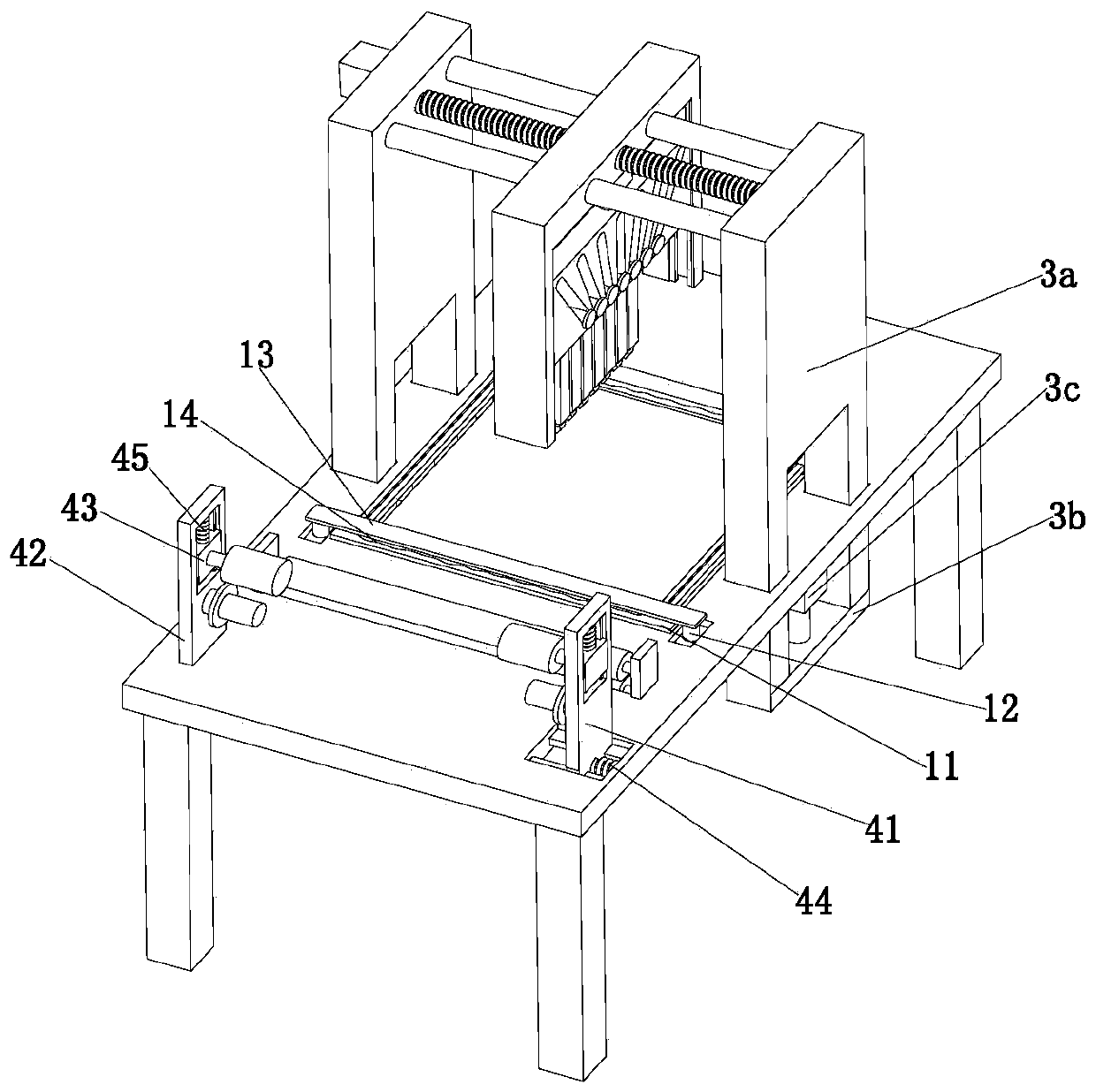

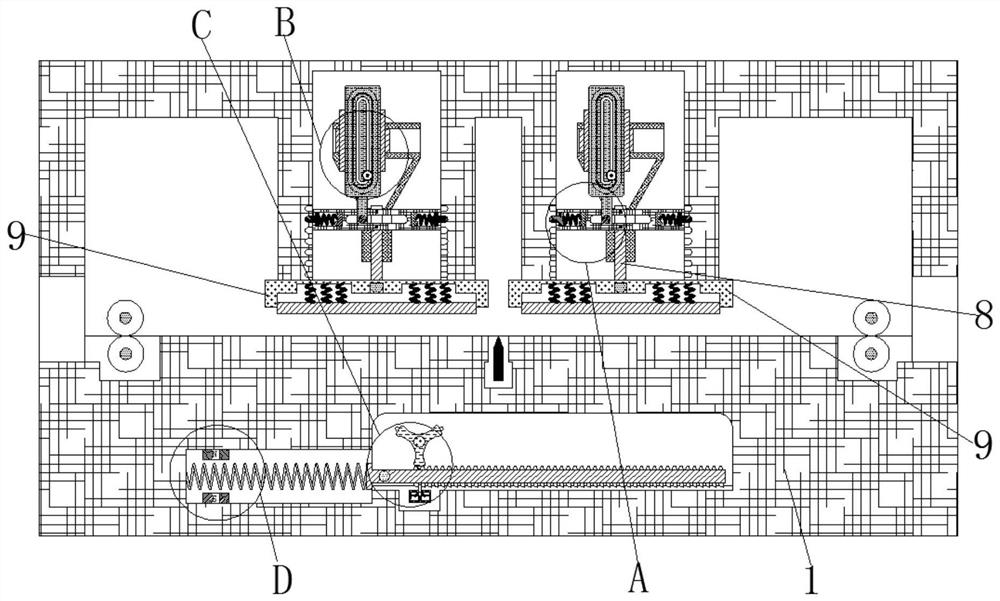

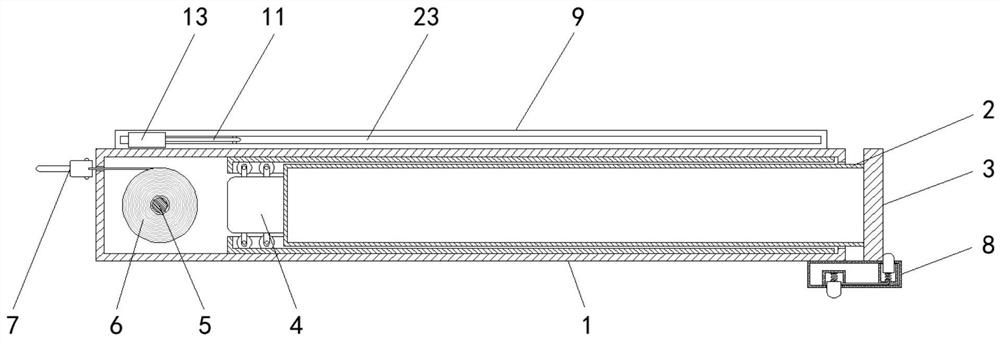

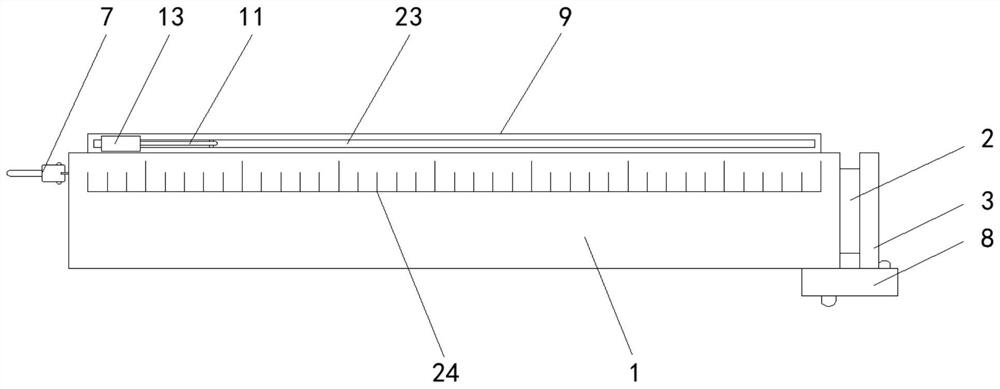

Precise cloth cutting device and method

ActiveCN111394981AImprove cutting efficiencyImprove croppingSevering textilesWebs handlingEngineeringMechanical engineering

The invention relates to a precise cloth cutting device. The precise cloth cutting device comprises a bottom plate, a stretching device, a cutting device and an unwinding device, wherein the stretching device is mounted at the lower end of the bottom plate; the cutting device is mounted at the middle end of the bottom plate; and the unwinding device is mounted at the left end of the bottom plate.The precise cloth cutting device can solve the following problems in an existing cloth cutting process: 1, when cloth is cut by manually holding scissors, the cutting precision is low, burrs are easily generated, the labor intensity is high, the cutting efficiency is low, and the cut cloth is difficult to reach the required size due to the fact that the factor of human errors is large, and the cutting precision is low; and 2, in the manual cutting process, the cloth is soft, so that the cloth is easily stressed and contracted during cutting, cutter relieving is caused, the cutting quality cannot be guaranteed, the cloth is cut in a manual tensioning mode, large-batch processing is not facilitated, sometimes, the width of the cloth is too large, the cloth is often cut to be uneven, the appearance is influenced, the cloth is wasted, and the cloth cutting efficiency and the cutting effect are greatly improved.

Owner:北京东方蓝地服装股份有限公司

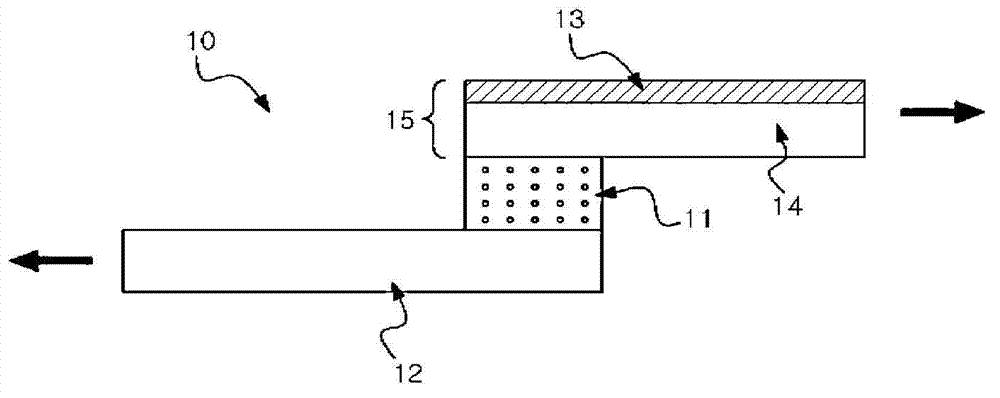

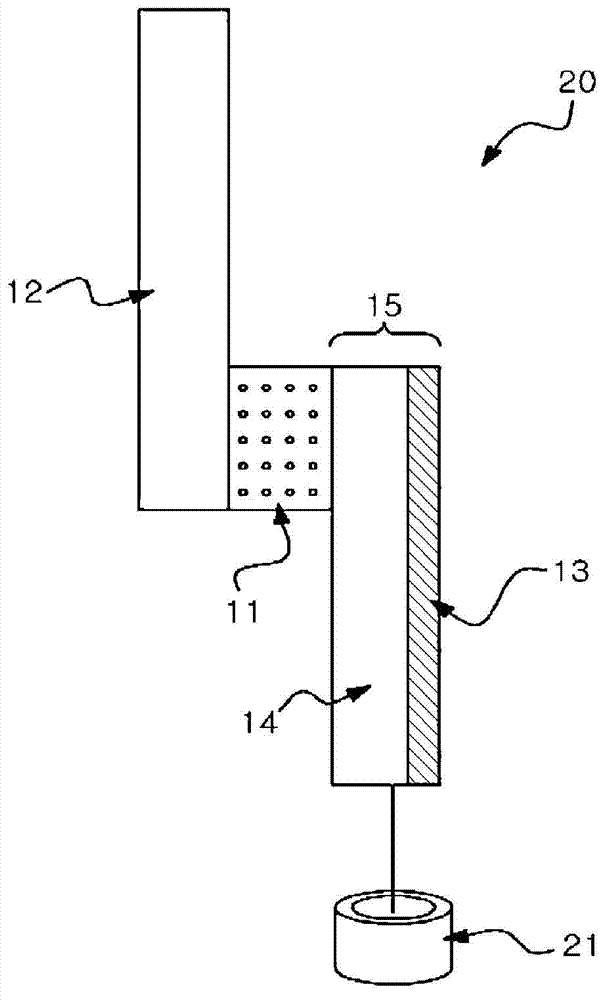

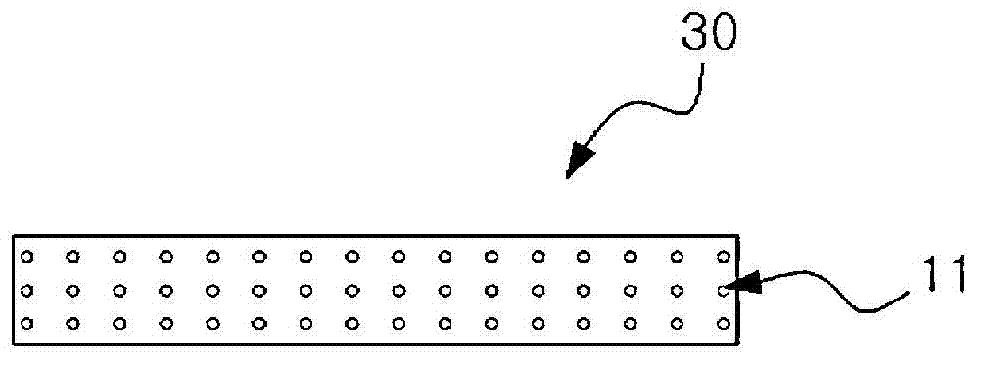

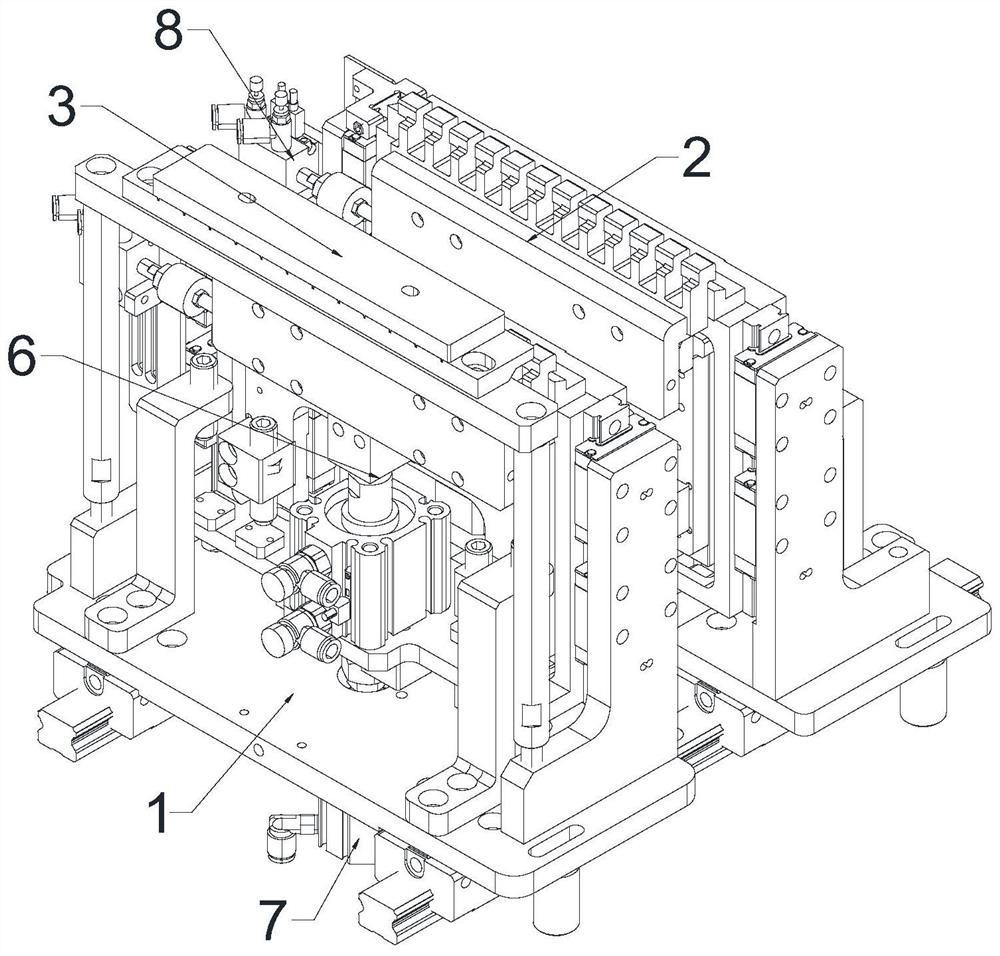

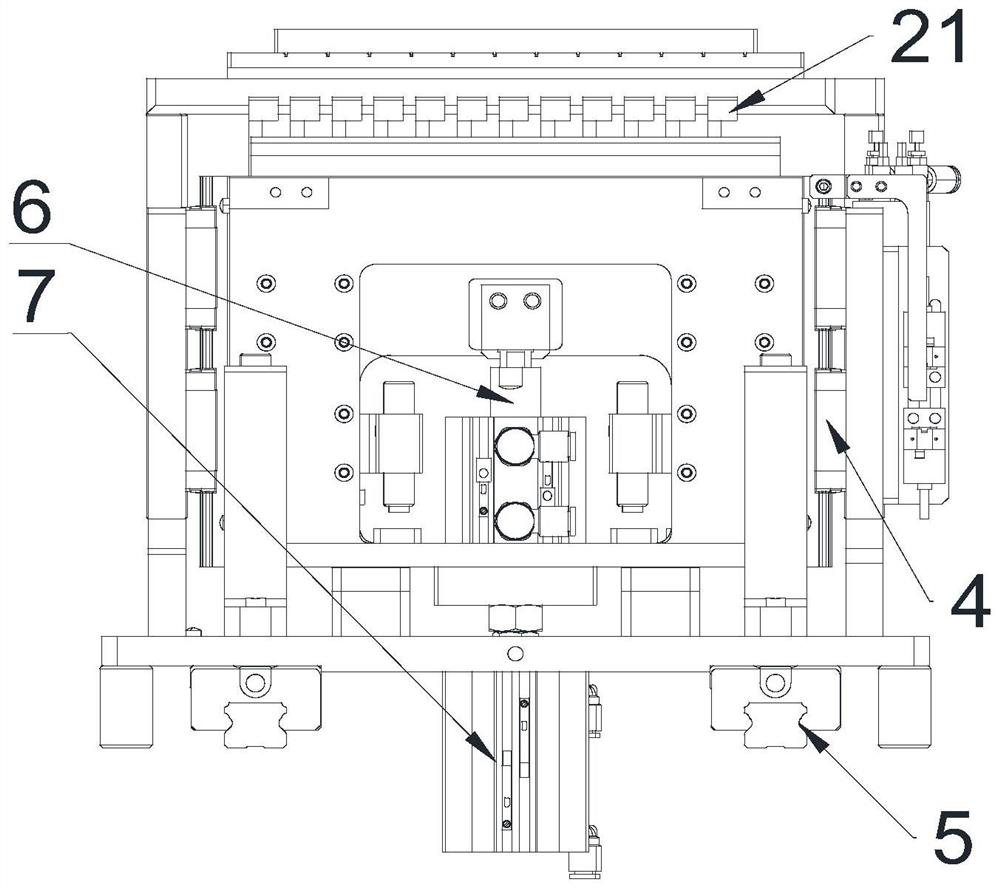

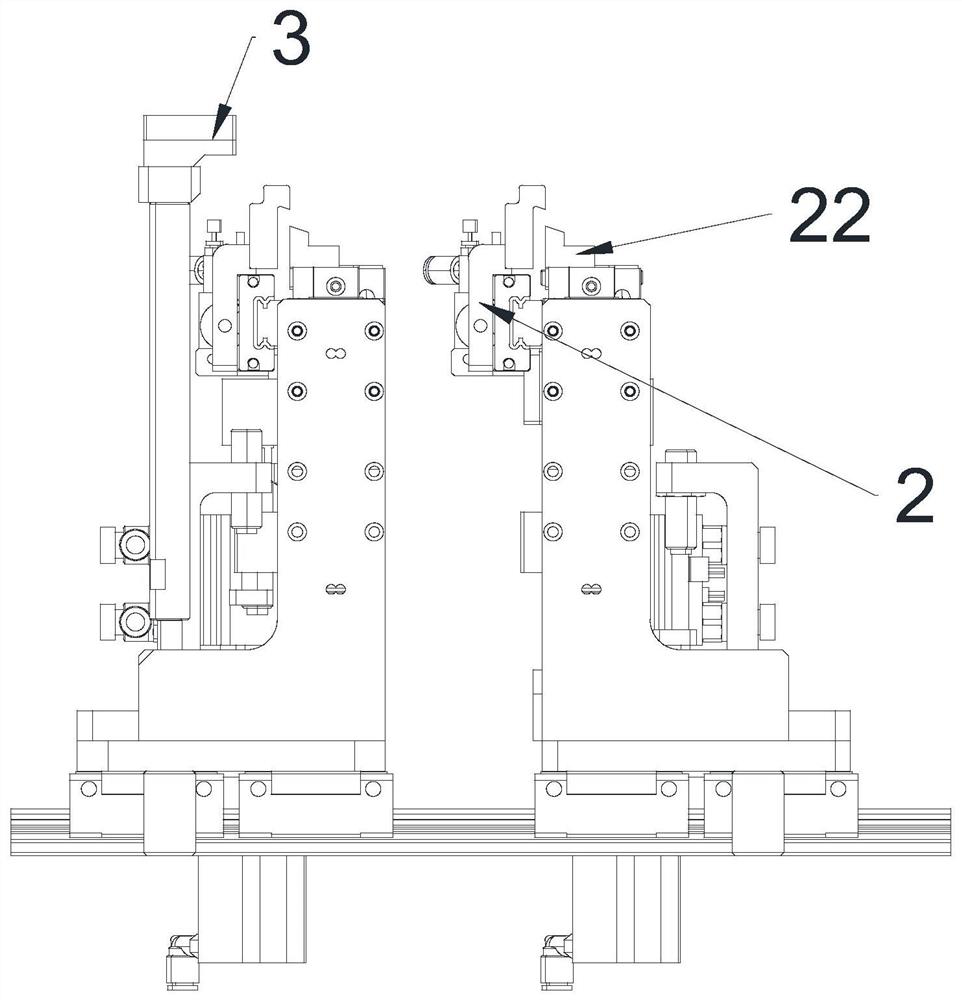

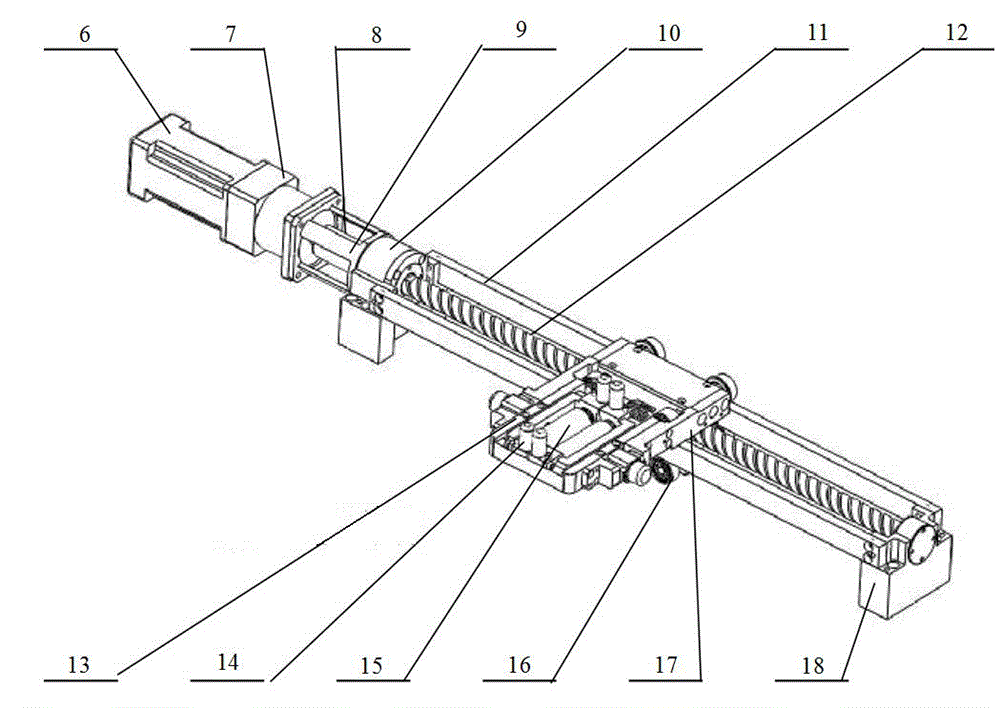

Three-axis welding strip cutter and implementation method thereof

ActiveCN113102815AImprove cutting efficiencyGood cropping effectShearing machinesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a three-axis welding strip cutter and an implementation method thereof, and relates to the technical field of welding strip cutting. The three-axis welding strip cutter comprises a base, a transverse moving cutter set, wire guiding mechanisms, a first guide rail, a second guide rail, a cutting air cylinder, a lifting air cylinder, a transverse moving air cylinder and a welding strip, the base is provided with a mounting block, the mounting block is fixedly connected with the transverse moving cutter set, multiple sets of wire guiding mechanisms, the first guide rail, the cutting air cylinder, the lifting air cylinder and the transverse moving air cylinder, the transverse moving cutter set comprises multiple sets of cutters, the transverse moving cutter set comprises a special-shaped cutter, the special-shaped cutter is connected to the cutting air cylinder and the transverse moving air cylinder, and the cutter point of the special-shaped cutter extends by a certain volume. The transverse moving cutter set and a lower cutter are both connected to the lifting air cylinder. The three-axis welding strip cutter and the implementation method thereof have the following advantages that (1) the welding strip cutting efficiency is improved; (2) the cutting effect of a welding strip is good; (3) welding strip cutting is facilitated; and (4) the cutters are in a low position when not working and are far away from an operator, so that the safety is high.

Owner:HANGZHOU JOY ENERGY TECH CO LTD

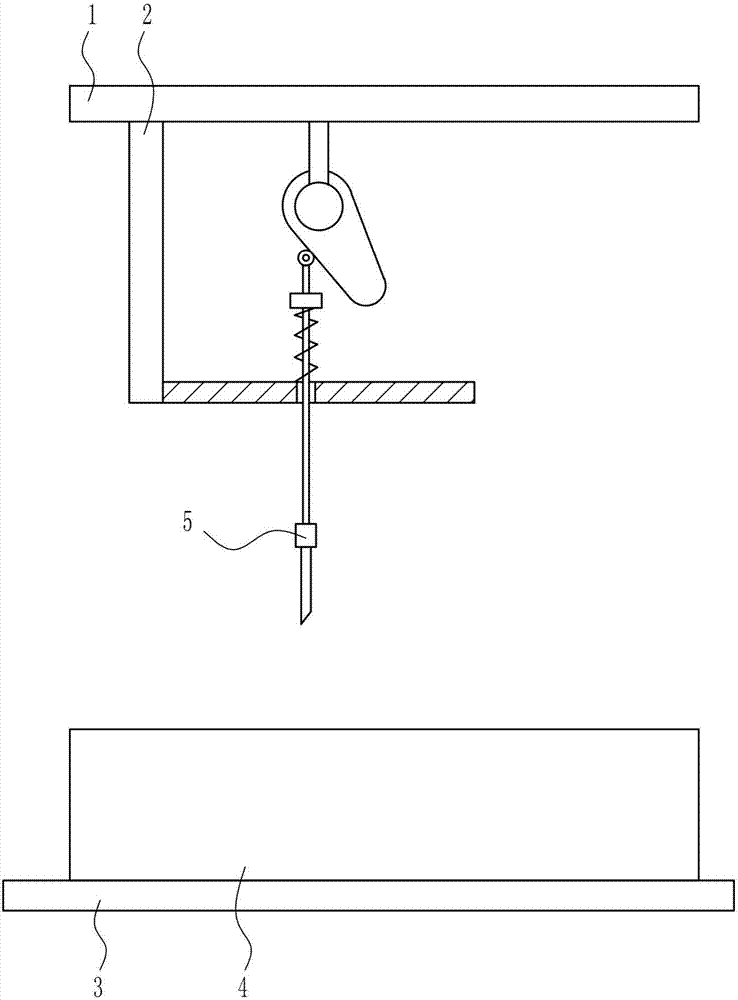

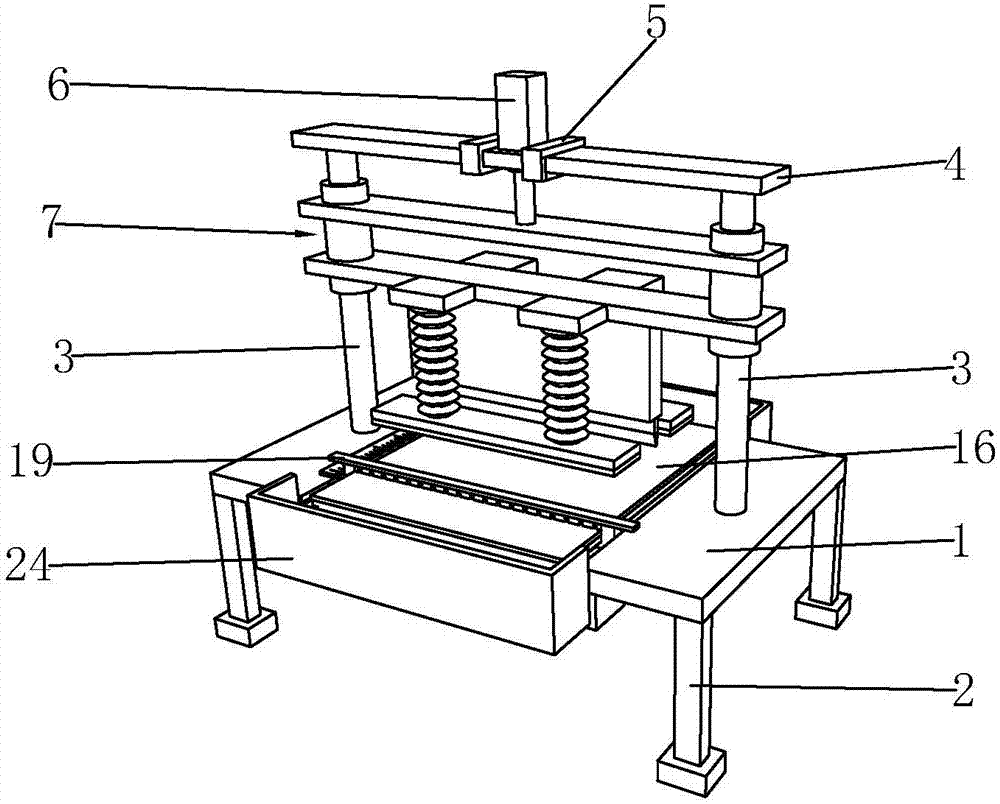

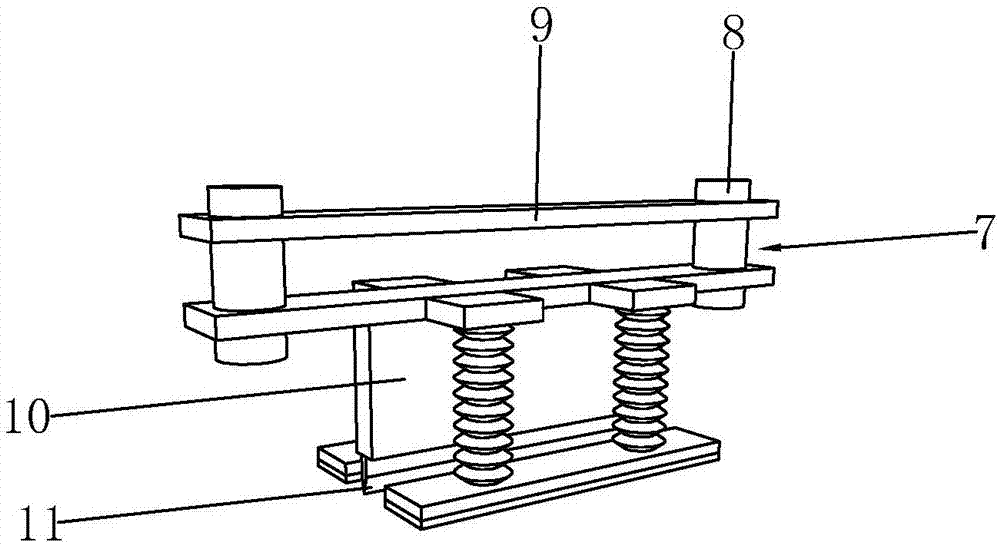

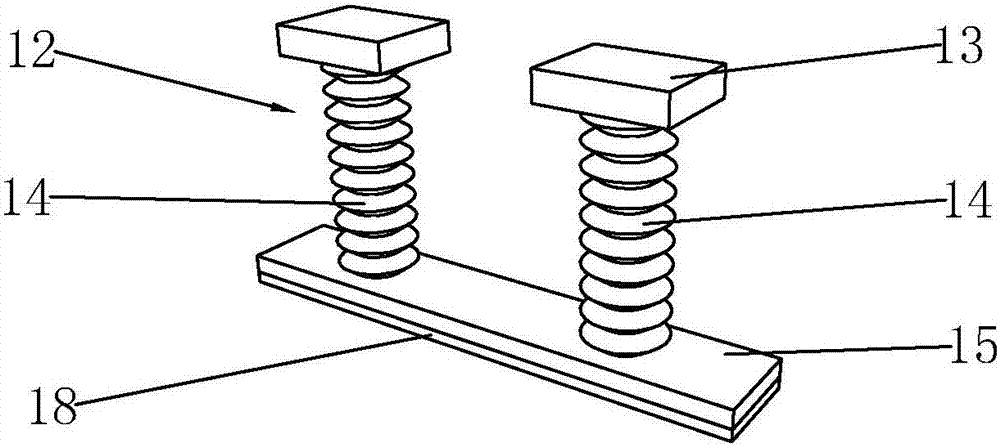

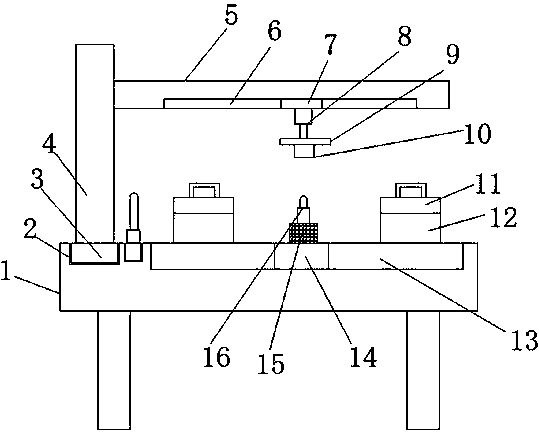

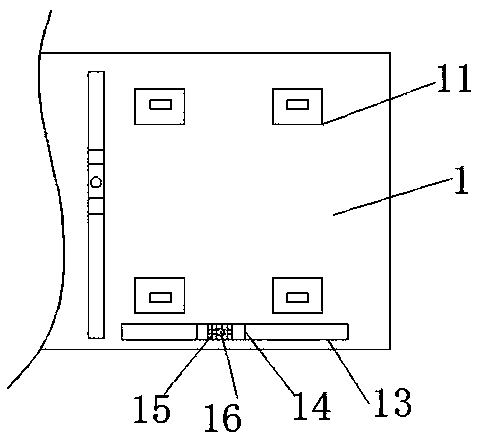

Fast leather shoe fabric cutting equipment for leather shoe processing

InactiveCN106889703ABenefit protectionAvoid hurtingShoemaking devicesHeelsMechanical engineeringEngineering

The invention relates to cutting equipment, in particular to fast leather shoe fabric cutting equipment for leather shoe processing. The fast leather shoe fabric cutting equipment comprises a top plate and the like and is characterized in that a placing plate is arranged at the top of a bottom plate, the top plate is arranged right above the bottom plate, a moving device is arranged at the bottom of the top plate, and a cutting device is arranged at the bottom of the moving device. The fast leather shoe fabric cutting equipment has the advantages that the equipment is simple to operate and convenient for a shoemaker to use, a leather shoe can be easily fixed during leather shoe shaping, and the shoemaker can constantly downwardly press a first pressing rod so as to well cut leather shoe fabric.

Owner:林安益

Shearing machine

InactiveCN110846874AGuaranteed smoothThere will be no unevennessSevering textilesHeating/cooling textile fabricsTool bitEngineering

The invention discloses a shearing machine. The shearing machine comprises a shearing machine supporting table as well as a lining sticking device, a heating and shaping device, a first cooling box, acutting device, a steam ironing device, a second cooling box and a winding roller which are sequentially arranged on the shearing machine supporting table; two supporting blocks are arranged betweenthe first cooling box and the cutting device, and a tensioning device is arranged between the supporting blocks; the cutting device comprises a knife rest and a knife head which are symmetrically arranged on the front side and the rear side, and a cutting table is arranged below the cutting device; a pressing block is arranged above the cutting table and on the left side and the right side of thecutting device; and a partition plate is arranged between the pressing block and the steam ironing device. By adoption of the shearing machine, the circumstance that the shaped fabric is not tidy enough due to shrinkage of the fabric can be avoided, especially for some high-end fabrics, the quality of the whole clothes is improved, and the rejection rate of the fabrics is effectively reduced.

Owner:JIAXING BIANKA BAG & CASE

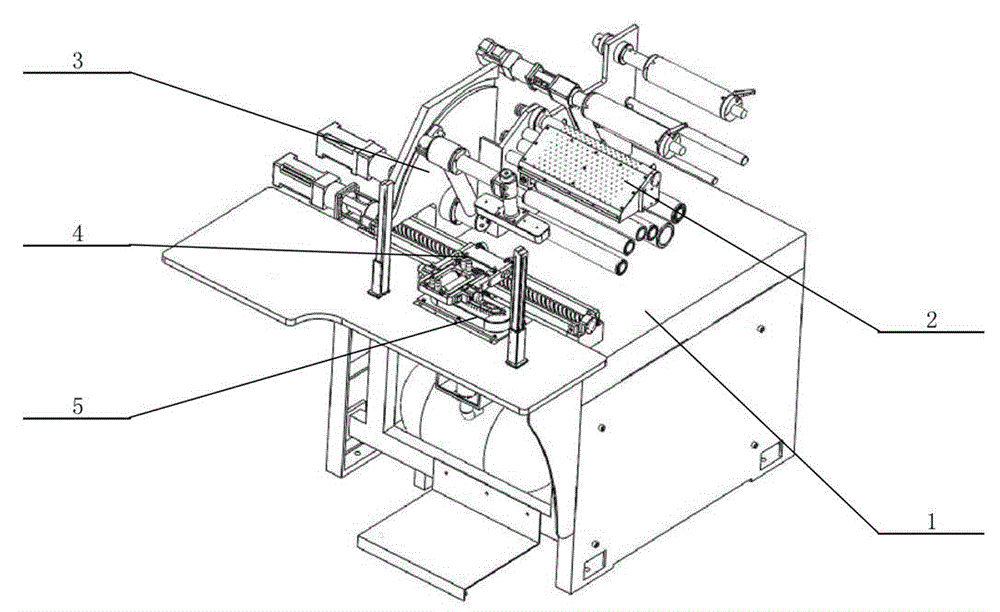

Automatic paper cutting drum type continuous rotary inkjet printer

InactiveCN107962881AEffective attachmentTrim parts neatlyOther printing apparatusBlade plateReciprocating motion

The invention relates to the field of printers, in particular to an automatic paper cutting drum type continuous rotary inkjet printer. The automatic paper cutting drum type continuous rotary inkjet printer comprises a printed drum and a paper feeder; the printed drum is provided with a clamping device for clamping papers; the paper feeder comprises a paper winding roller, and at least two pairs of paper feeding rollers for conveying the papers on the paper winding roller; one pair of the paper feeding rollers can be opposite to the clamping device on the printed drum; and a tailoring device capable of tailoring the papers is arranged between the two pairs of paper feeding rollers. The tailoring device comprises a blade mechanism, a driving mechanism for driving the blade mechanism to perform a reciprocating motion, and a cutter board mechanism for cooperating with the blade mechanism; the blade mechanism comprises a cutter; the cutter board mechanism is provided with a paper inlet anda paper outlet; and the cutter leans against the paper outlet of the cutter board mechanism to realize tailoring of the papers. The automatic paper cutting drum type continuous rotary inkjet printeris provided with the tailoring device in the paper feeder for tailoring the papers with proper sizes according to actual demands.

Owner:GUANGDONG IMETTO DIGITAL IMAGING TECH

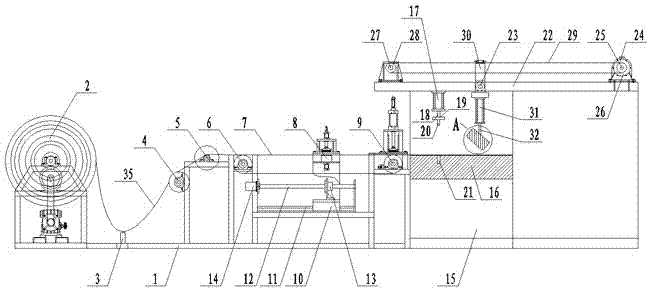

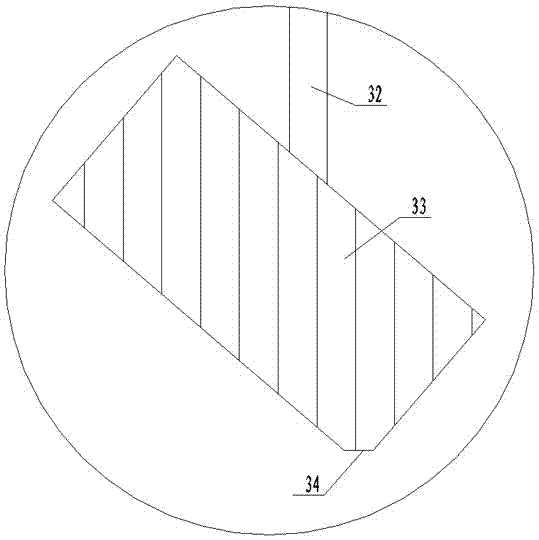

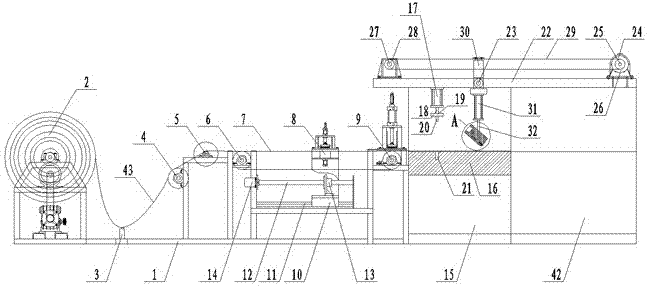

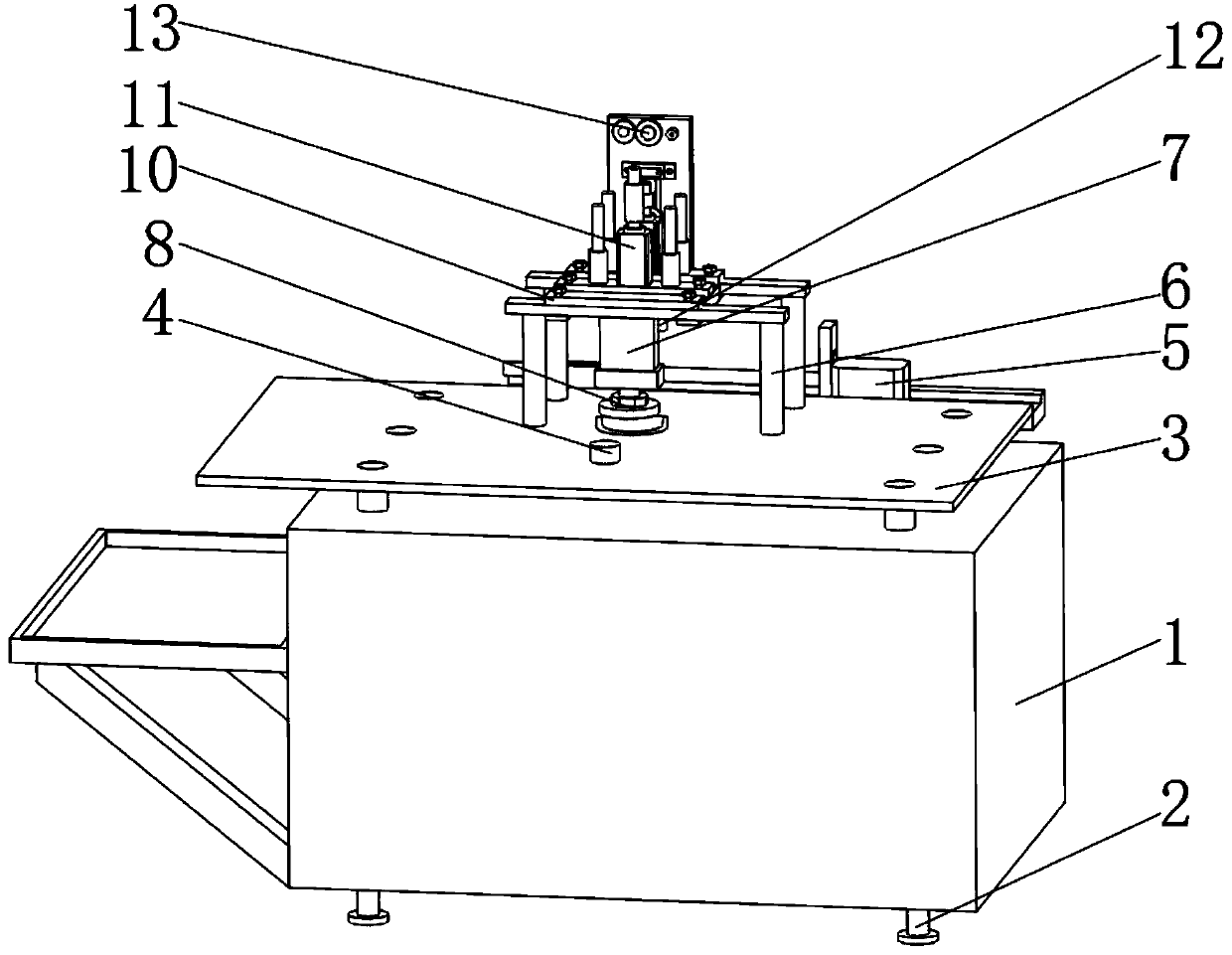

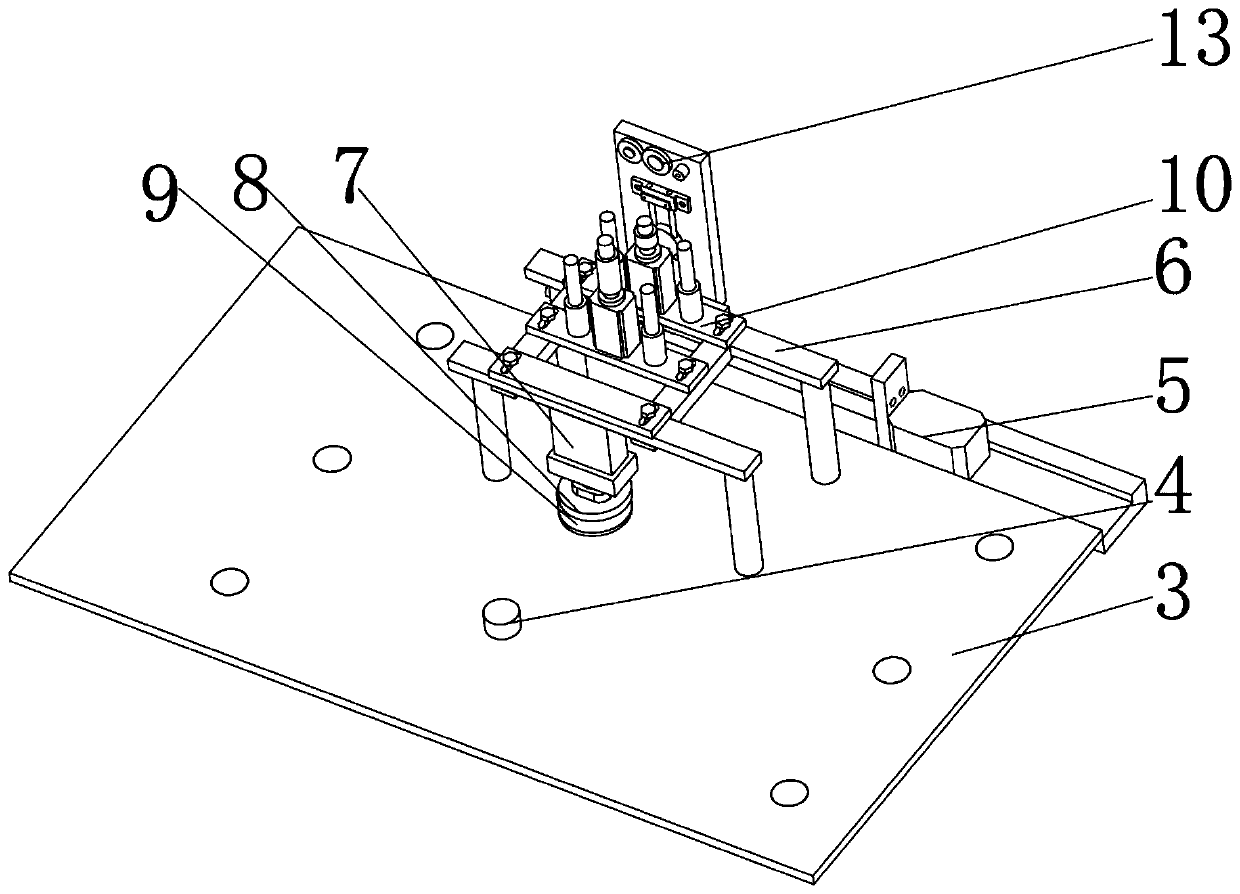

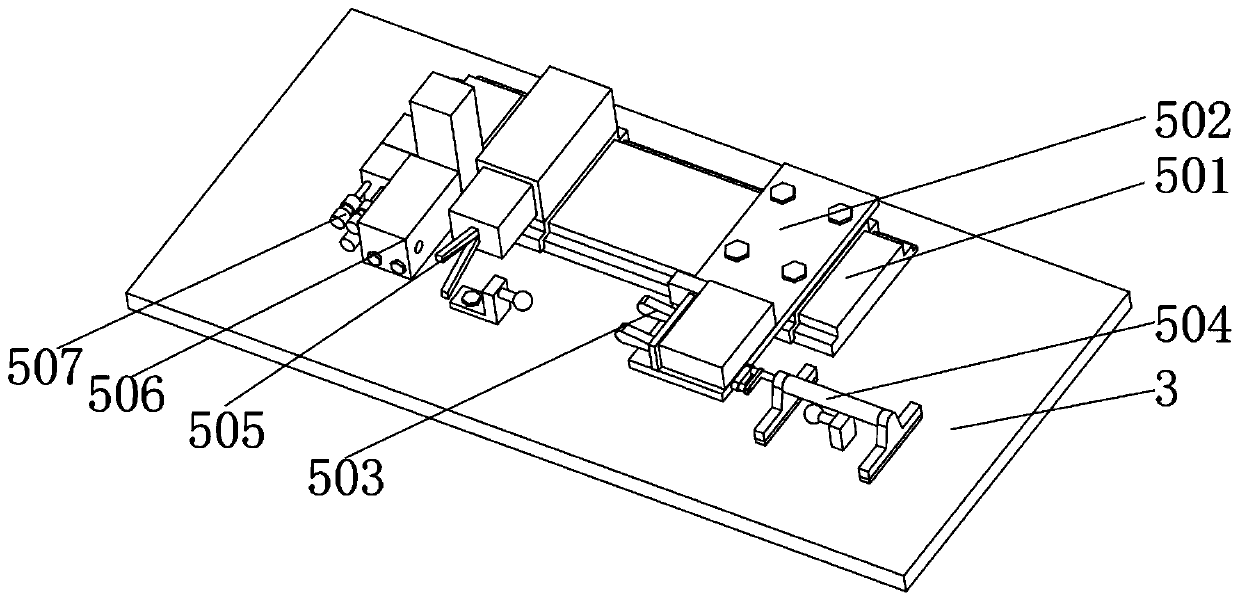

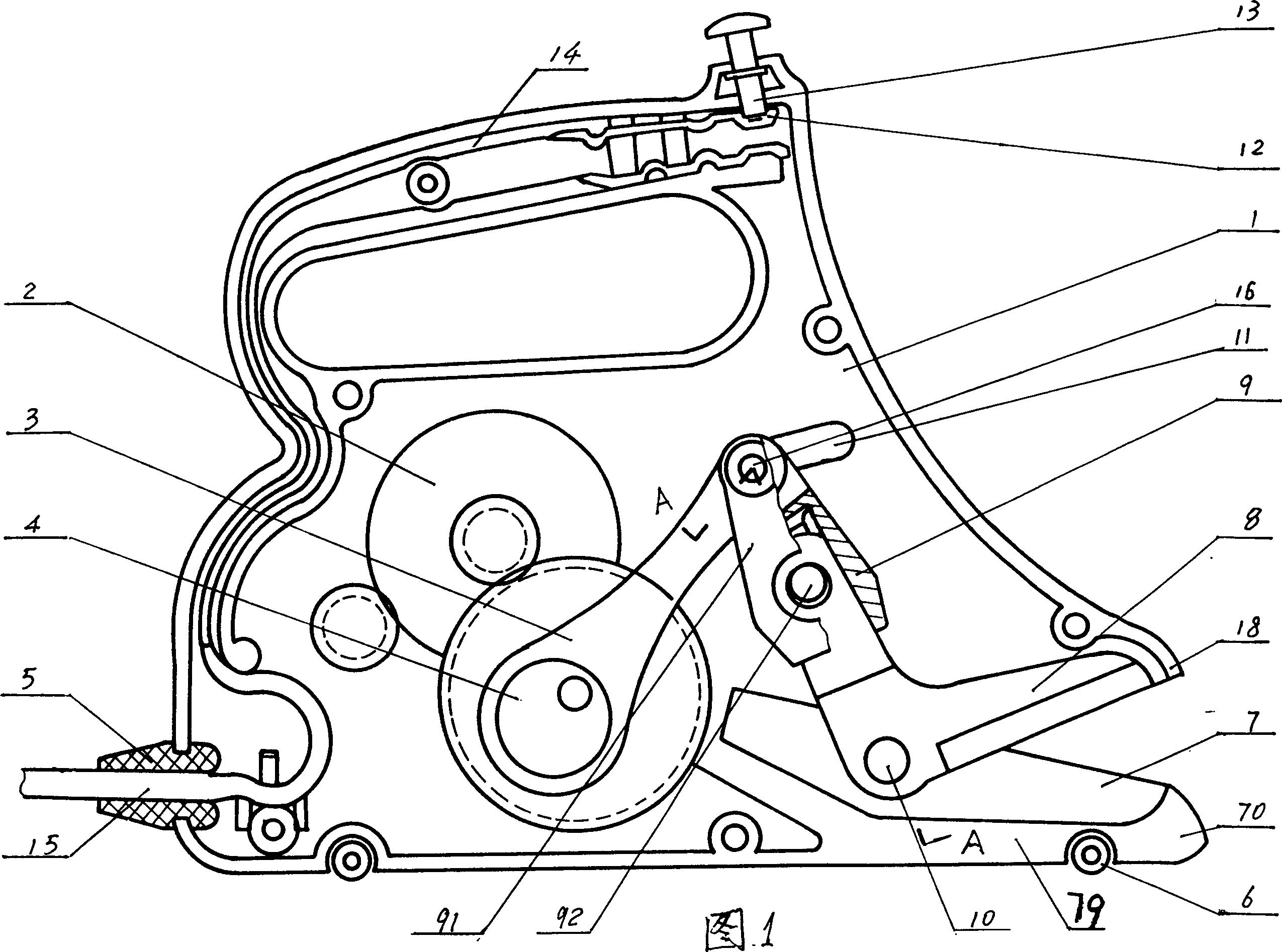

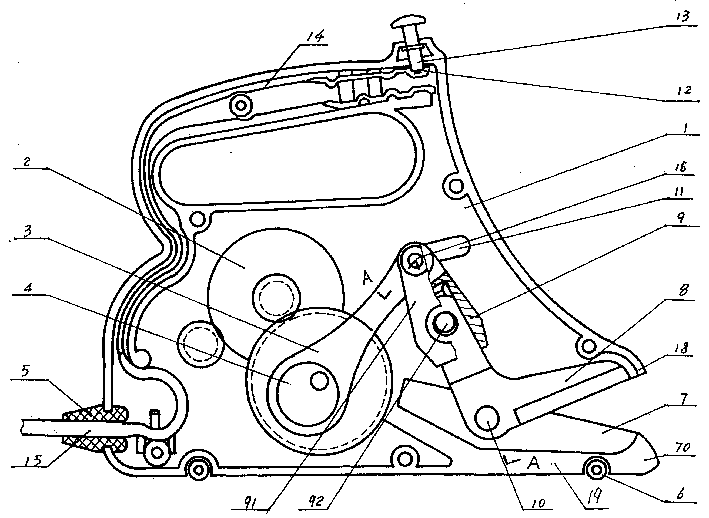

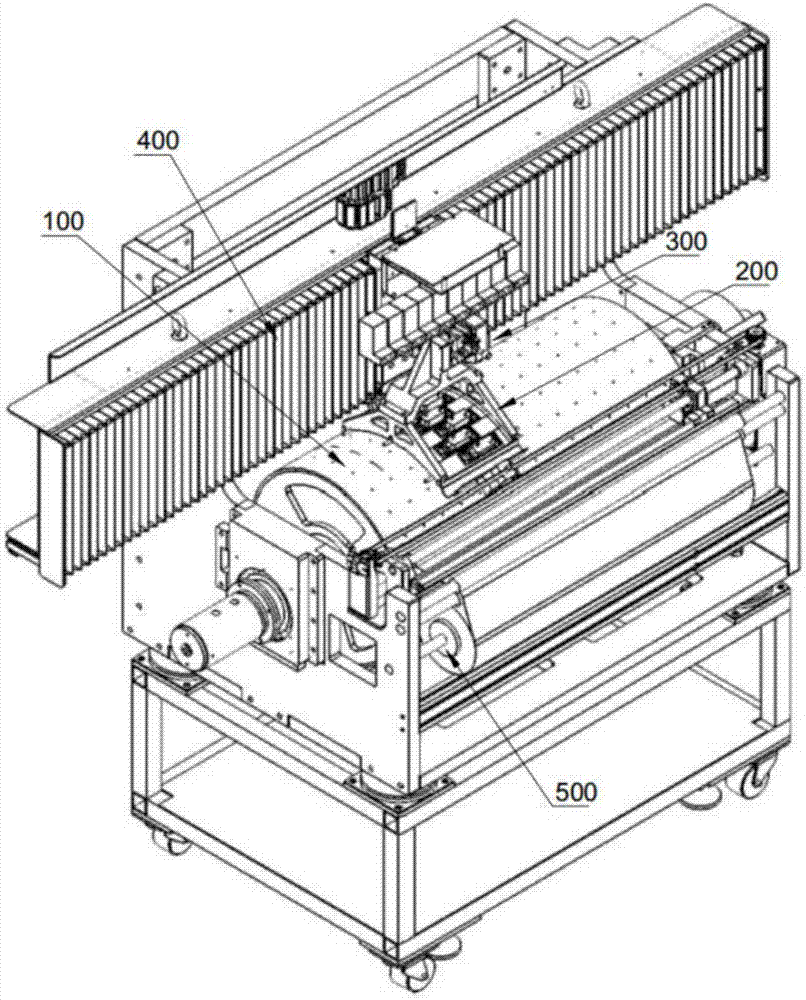

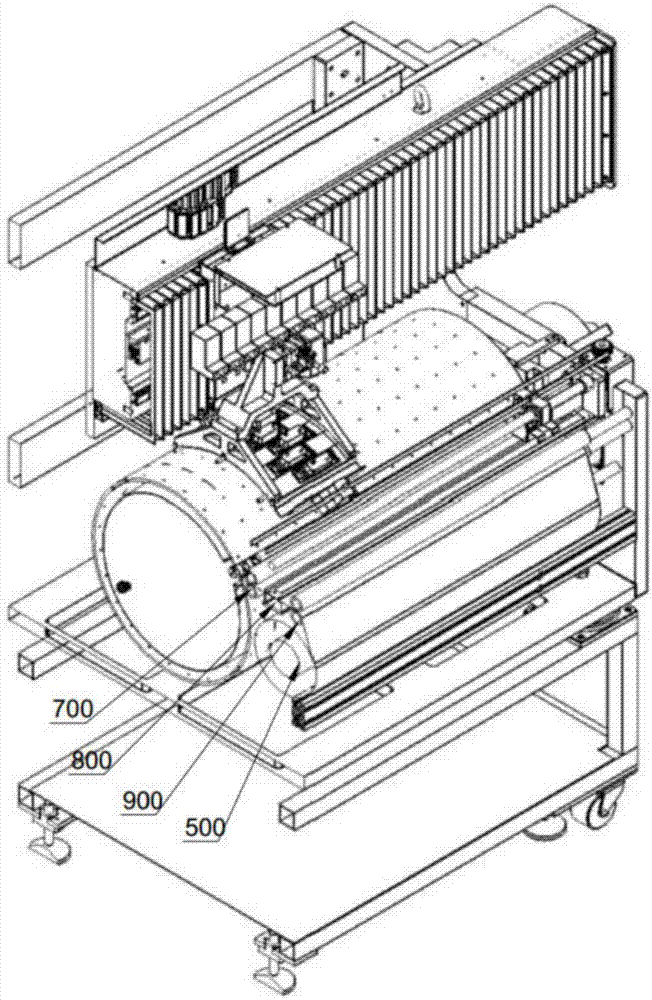

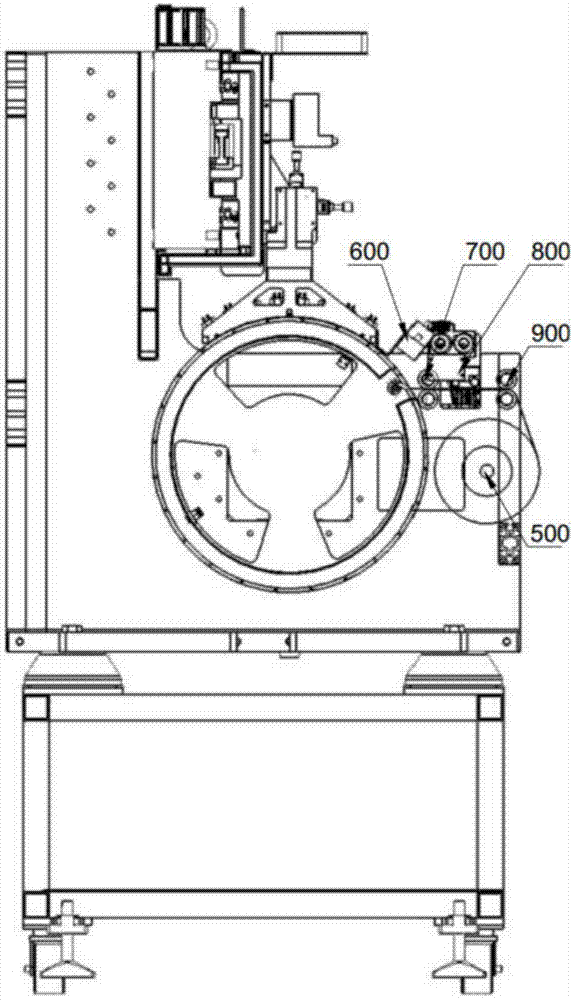

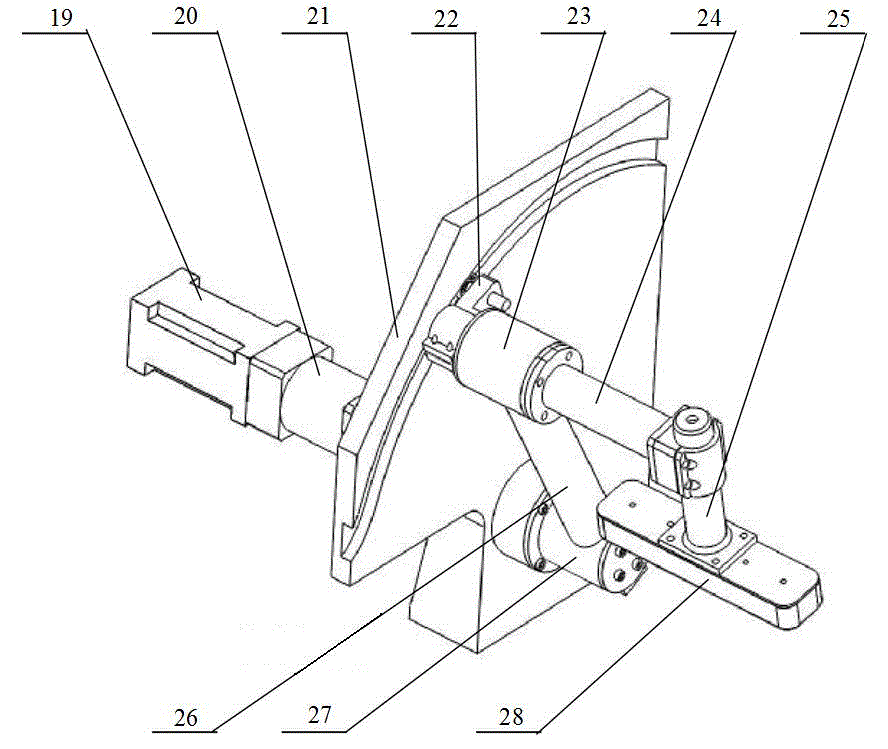

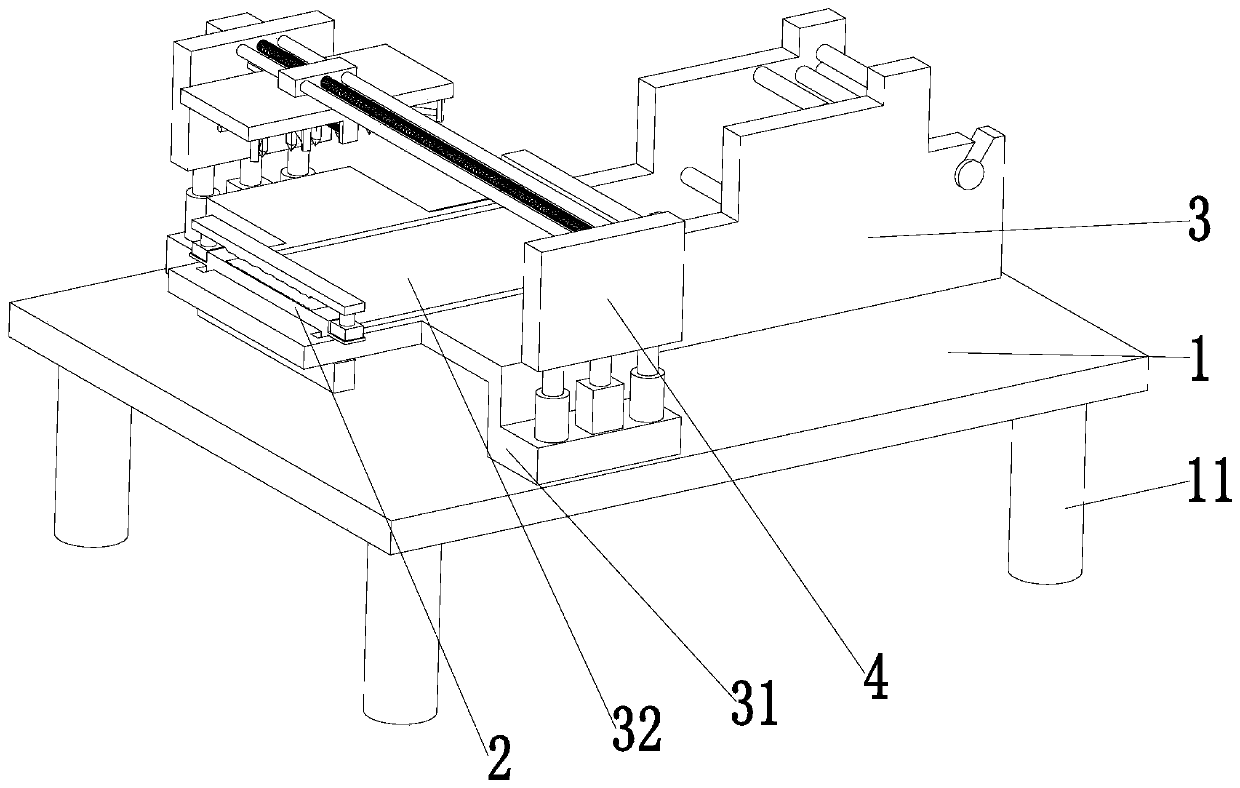

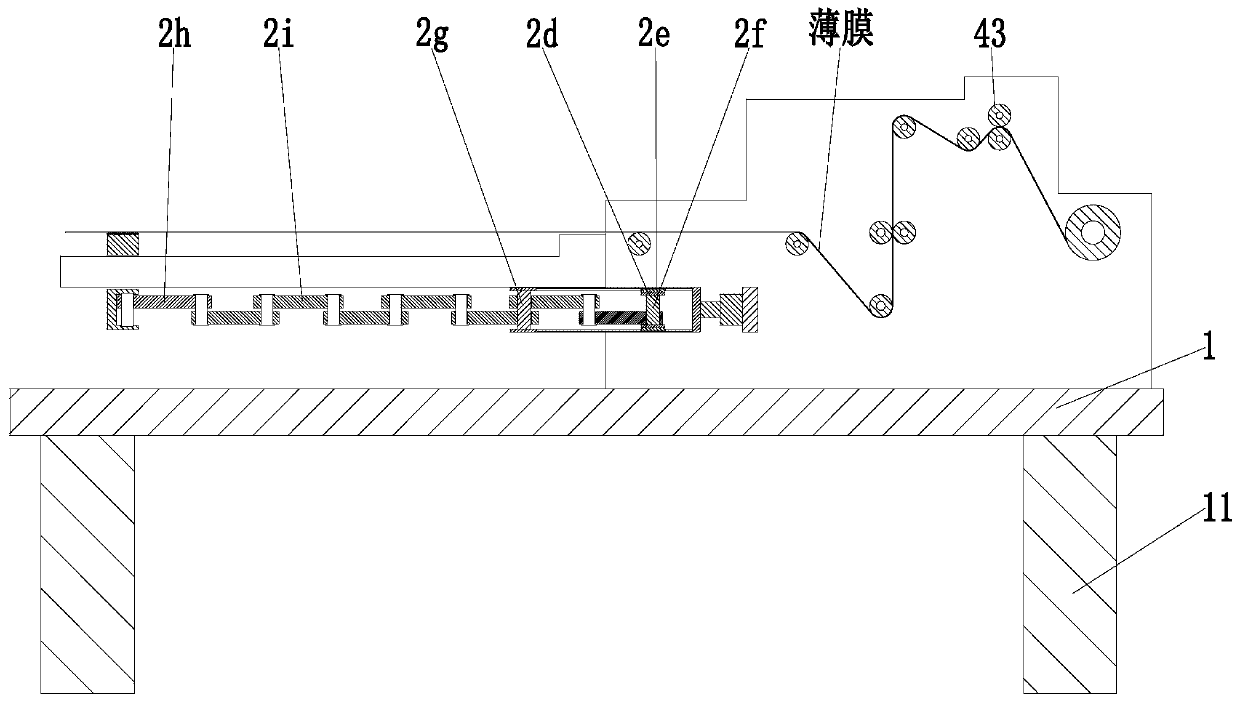

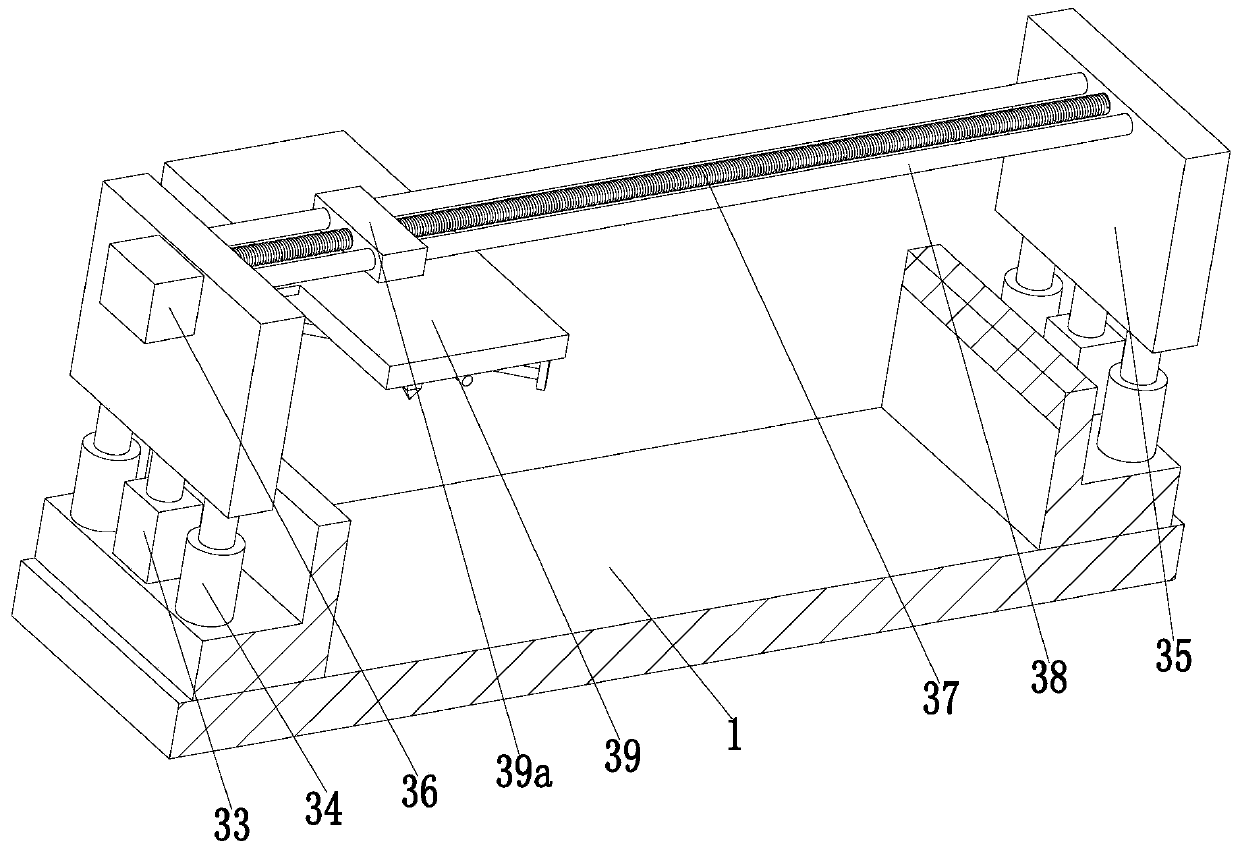

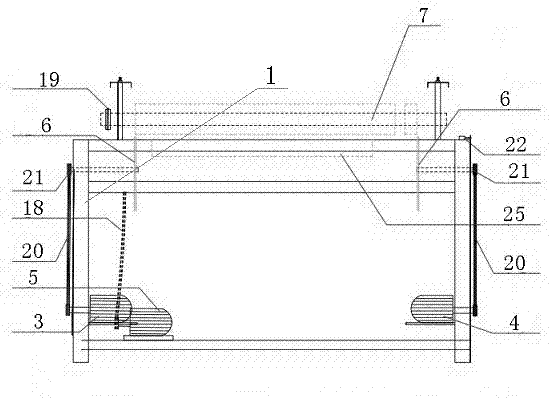

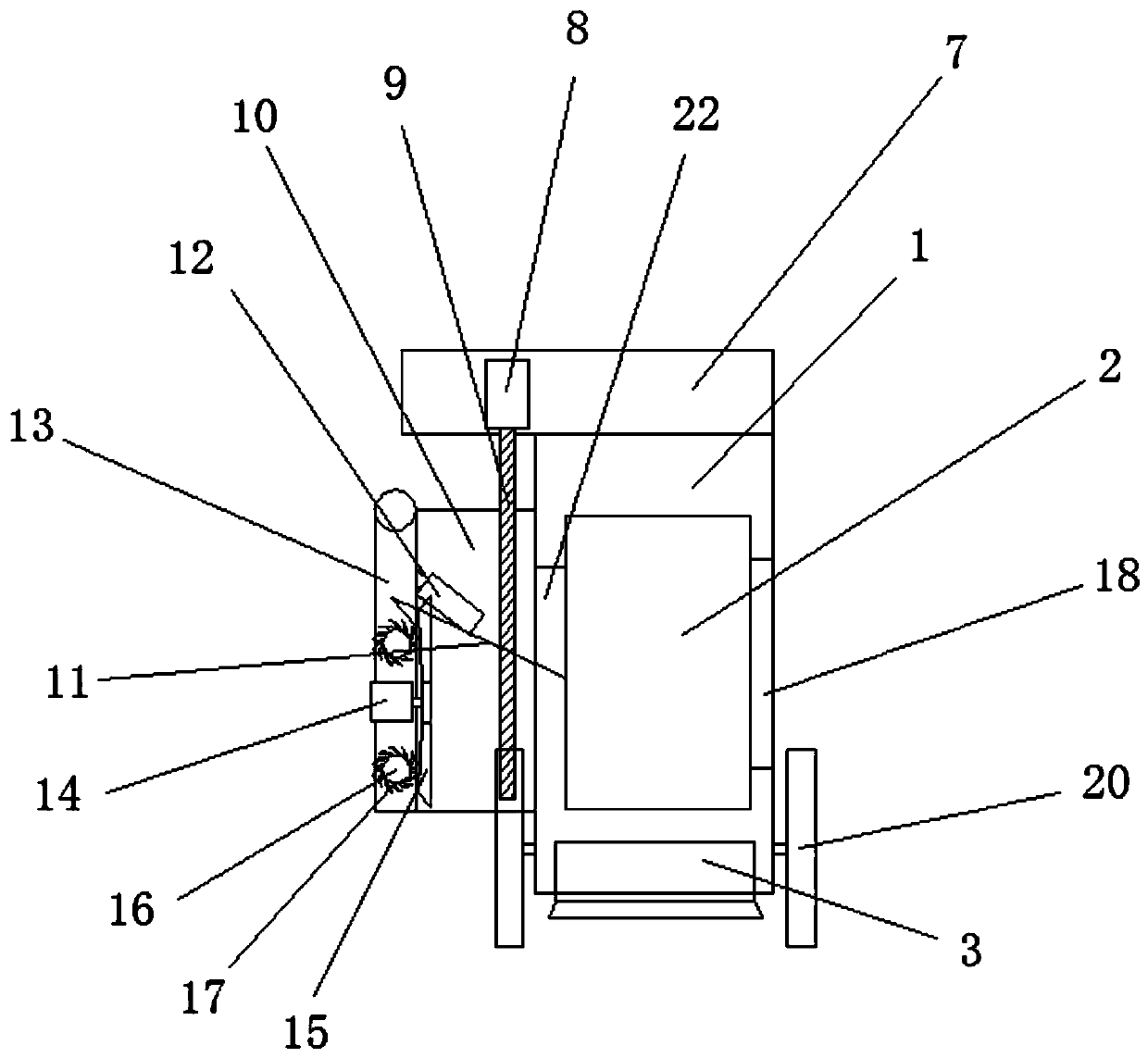

Cigar coat forming machine

The invention discloses a cigar coat forming machine, which is characterized in that a rolling mechanism (4), a sheet moving mechanism (3), a take-up mechanism (2) and a cutting mold mechanism (5) are mounted on a base (1), wherein the rolling mechanism (4) is mounted above the cutting mold mechanism (5); the sheet moving mechanism (3) is mounted behind the cutting mold mechanism (5); the take-up mechanism (2) is mounted behind the sheet moving mechanism (3); and the cutting mold mechanism (5), the rolling mechanism (4), the sheet moving mechanism (3) and the take-up mechanism (2) are connected with a control mechanism to constitute the cigar coat forming machine. The cigar coat forming machine is reasonable in structure, flexible in operation and reliable in running; and the cutting speed is high, the cutting is in good trim, the form of cut cigar coats is uniform, the control precision is high, automatic manufacture of the cigar coats is achieved, and the work efficiency is high.

Owner:徐彬

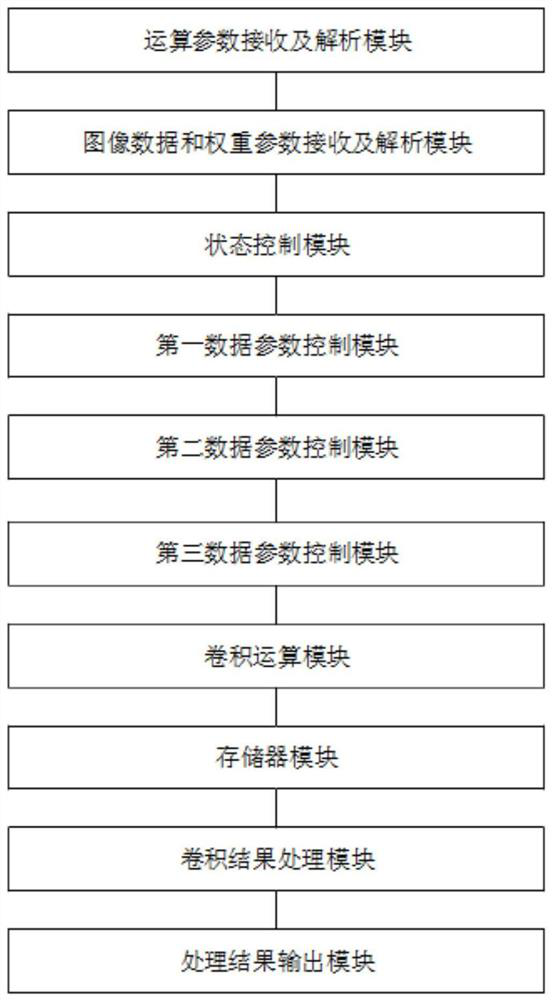

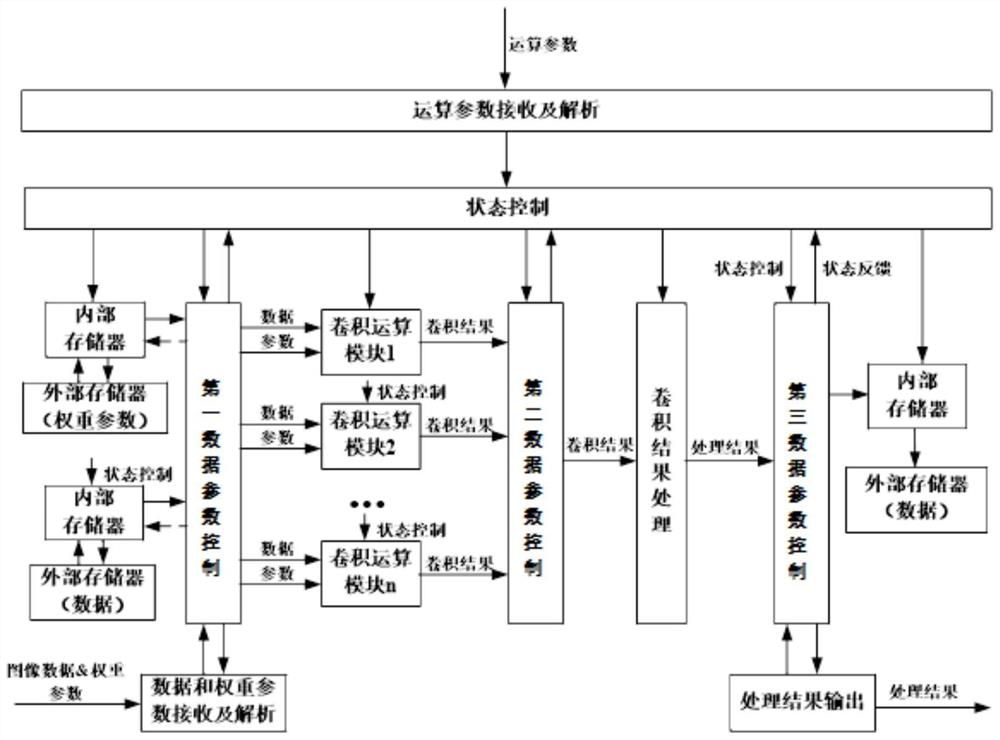

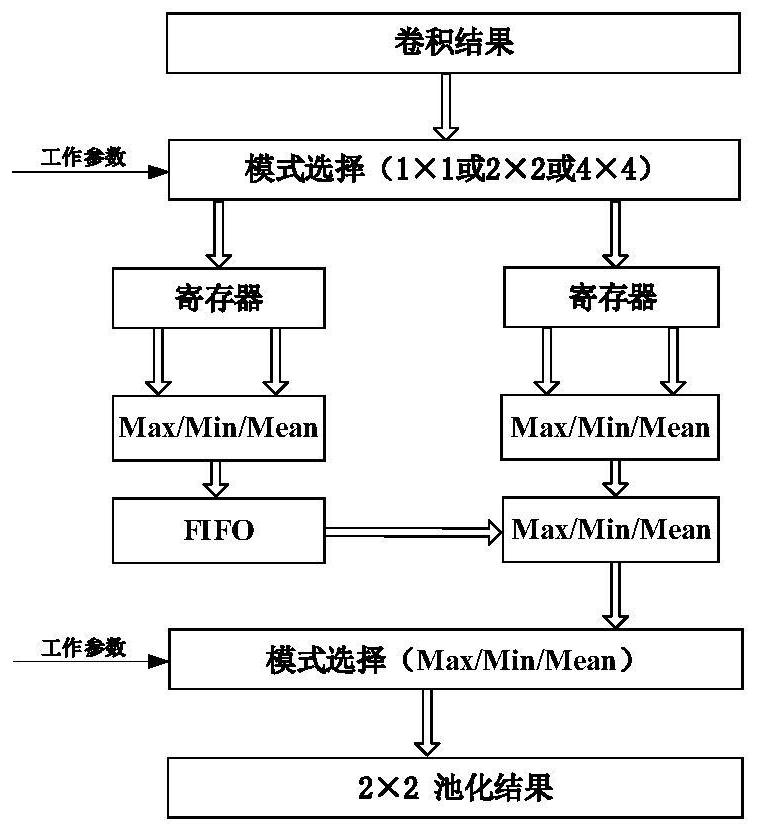

Universal convolution operation device

PendingCN114707649ASimplify Computing ArchitectureImprove computational efficiency and design efficiencyNeural architecturesInference methodsParallel pipelineProcess module

The invention discloses a universal convolution operation device. Comprising an operation parameter receiving and analyzing module, an image data and weight parameter receiving and analyzing module, a state control module, a first data parameter control module, a second data parameter control module, a third data parameter control module, a convolution operation module, a memory module, a convolution result processing module and a processing result output module. All the modules are designed by adopting a full parallel pipeline processing architecture, and the working process control of the convolution operation module is realized through working parameters such as the number of convolution layers, the convolution operation precision, the convolution operation mode, the number of convolution operations and a feature map data processing method, so that the convolution operation requirements of the current mainstream convolution neural network are met; according to the method, the calculation framework is simplified, the calculation efficiency and the design efficiency are improved, the generalization degree is high, the flexibility is good, the energy efficiency ratio is high, multiple convolution operations of various convolution kernel sizes can be completed in parallel, and good expansibility and tailorability are achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Paper-based degradable plastic bag molding and processing system and molding and processing technology

InactiveCN111483177AImprove efficiencyImprove croppingBag making operationsPaper-makingManufactured materialIndustrial engineering

The invention relates to a paper-based degradable plastic bag molding and processing system and molding and processing technology. The paper-based degradable plastic bag molding and processing systemcomprises a bottom plate, a stretching device, a cutting device and an unwinding device, wherein the unwinding device is arranged at the left end of the bottom plate, the cutting device is arranged atthe right end of the unwinding device, and the stretching device is arranged at the lower end of the cutting device. The paper-based degradable plastic bag molding and processing system and the molding and processing technology can solve the following problems existing in the cutting of an existing rolled film that when the traditional rolled film is cut, when the film needs to be cut by hand with a cutting knife, due to the large factor of human error, the film is easy to shrink under fore during cutting, the cutting quality cannot ensured, the cutting efficiency is low, and the cut film isdifficult to reach the required size; when the traditional film cutting machine cuts the film, the film can only be cut on one side and cannot be cut at equal interval at the same time; moreover, as the film is soft, the film is often cut unevenly, and thus the appearance is affected and raw materials are wasted.

Owner:罗嘉宇

Bathroom roll paper tube plastic shell

The invention relates to the field of roll paper tube plastic shells, in particular to a bathroom roll paper tube plastic shell which comprises a rotating structure, a containing structure, a windingstructure, a limiting structure, an adjusting structure, a storage structure and a cutting structure. The winding structure is provided with the adjusting structure used for fixing roll paper and controlling the pulling length, the containing structure is provided with the storage structure used for storing a mobile phone, the storage structure is in sliding connection with the containing structure, then the pulling length of the roll paper on the winding structure can be conveniently controlled through the adjusting structure, roll paper waste is effectively prevented, meanwhile, the roll paper can be cut off more conveniently and quickly, small objects such as a mobile phone can be stored temporarily and conveniently through the storage structure, and the objects are effectively prevented from being lost and damaged during defecation; the cutting structure for cutting the roll paper is arranged on the winding structure; due to the arrangement of the cutting structure, the roll papercan be cut off more conveniently and quickly, and meanwhile, excessive roll paper is effectively prevented from being pulled by matching with the adjusting structure.

Owner:鋐隆塑胶电子(深圳)有限公司

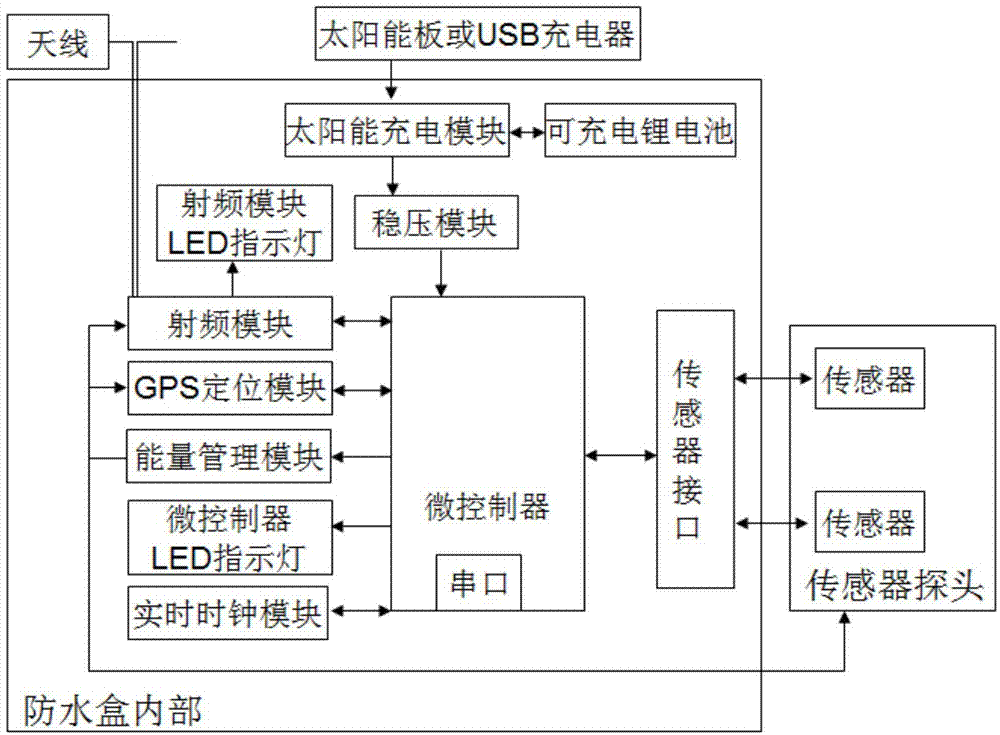

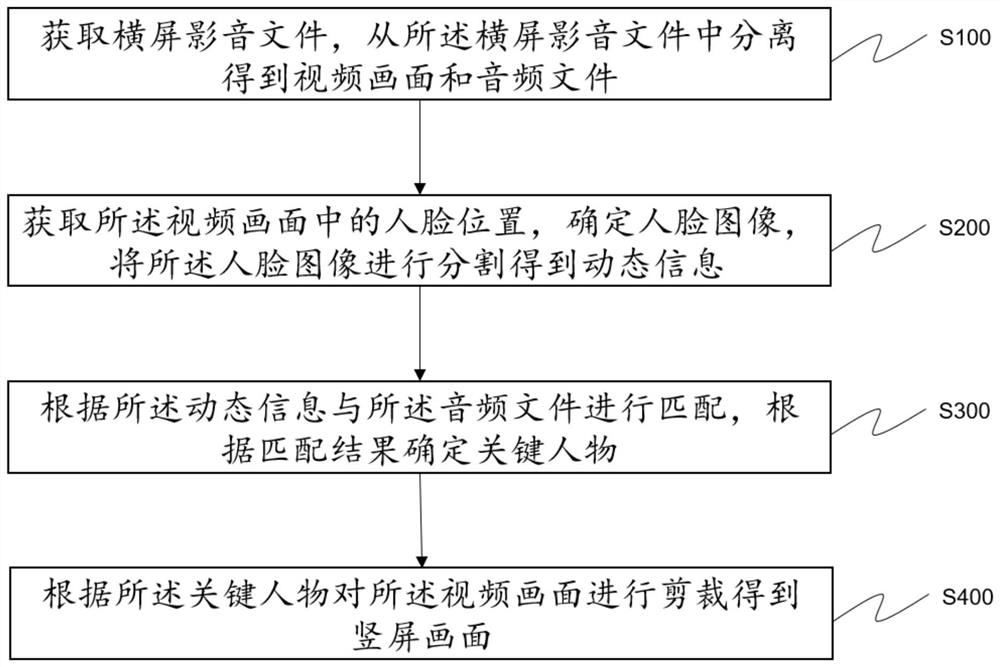

Clipping method, system and device for transverse and vertical screen conversion picture and medium

ActiveCN113077470AGood cropping effectImage enhancementImage analysisComputer graphics (images)Video processing

The invention provides a clipping method, system and device for a transverse and vertical screen conversion picture and a storage medium, and the method comprises the following steps: obtaining a transverse screen audio and video file, and separating the transverse screen audio and video file to obtain a video picture and an audio file; obtaining a face position in the video picture, determining a face image, and segmenting the face image to obtain dynamic information; and matching with the audio file according to the dynamic information, and determining a key character according to a matching result. According to the method, a video picture and an audio file are separated, dynamic information of a human face is segmented in the video picture, feature matching is carried out on the dynamic information obtained through segmentation and the audio file so as to locate speakers in the video, key figures and non-key figures are distinguished on a section of video containing a multi-person picture, therefore, the image of the key figure can be reserved as much as possible while the image of the non-key figure can be clipped to obtain a better clipping effect, and the method can be widely applied to the technical field of video processing.

Owner:天翼爱音乐文化科技有限公司

Edge cutting machine special for wood veneer

InactiveCN103612285APrecise control of cutting volumeSecondary flashCircular sawsWood veneerWood processor

The invention relates to a wood processing machine, in particular to an edge cutting machine special for wood veneer. The edge cutting machine special for the wood veneer comprises a machine frame. A wood veneer inlet operating platform is arranged on the rear portion of the machine frame, a left high-speed motor and a right high-speed motor are arranged on the two sides of the front end of the machine frame respectively, and an adjustable-speed motor is arranged on the lower portion of the machine frame. The edge cutting machine special for the wood veneer is characterized in that the left high-speed motor and the right high-speed motor are respectively connected with a saw blade, the adjustable-speed motor is connected with a plurality of adjustable compression rollers, compression rollers are arranged below the adjustable compression rollers, the adjustable compression rollers are fixed with a fixing bar assembly through fixing bars, high-low adjusting screws are arranged on the tops of the fixing bars, and the fixing bars are sleeved with pressure springs. The edge cutting machine special for the wood veneer has the advantages of being high in production efficiency, precise in cutting amount control, convenient to operate, high in product quality, capable of enabling the wood veneer to be completely unfolded for edge cutting in a grinding mode, good in cutting effect, and capable of avoiding secondary rough edges in the cutting process of the wood veneer.

Owner:李杰

Adjustable shrub pruning device

The invention discloses an adjustable shrub pruning device and relates to the field of environment friendliness. The adjustable shrub pruning device comprises a vehicle body; four groups of wheels arefixedly mounted at the bottom of the vehicle body; an inner cavity of the vehicle body is provided with a storage cavity; the top of the vehicle body is fixedly connected with an upper frame; the left side of the upper frame is movably connected with a lifting frame; the top of the left side of the lifting frame is rotatably connected with a roll-over stand; the bottom side of the roll-over standis fixedly provided with a pruning blade and a rotating roller; the outer wall of the rotating roller is fixedly connected with a plurality of scrabbling claws; the rear side of the bottom of the vehicle body is fixedly provided with a leaf suction cabin; an inner cavity of the leaf suction cabin is fixedly provided with a negative-pressure fan; the top of the negative-pressure fan is fixedly connected with a leaf suction hole; and a communication pipe is fixedly connected between the leaf suction hole and the storage cavity. The adjustable shrub pruning device is easy to operate, capable ofsaving time and manpower, good in pruning effect, capable of realizing adjustment according to the height of a shrub and recovering and centrally treating pruned branches and easy to popularize and apply.

Owner:陈思晟

Cutting device provided with good cutting effect and used for producing adhesive stickers

InactiveCN113478553AGood cropping effectAvoid situations with poor final croppingMetal working apparatusGear wheelSlide plate

Owner:吴顺权

Measurable-cutting auxiliary tool for sewing clothes

InactiveCN111719307AGood cropping effectEasy to measureSevering textilesClothes making applicancesClockworkKnife blades

The invention provides a measurable-cutting auxiliary tool for sewing clothes. The measurable-cutting auxiliary tool comprises a body, an extending and retracting caliper is installed in the body, a limiting baffle is fixedly installed at the right end of the extending and retracting caliper, a fixed block is fixedly installed at the left end of the extending and retracting caliper, and a clockwork spring mechanism is fixedly installed on the inner wall of the body. According to the measurable-cutting auxiliary tool for sewing the clothes, when the clothes are required to be cut, a positioningplate is pressed, a connecting piece is used for pressing a cutting blade to move downwards, so that the cutting blade is directly in touch with the clothes, the cutting blades moves downwards, and meanwhile, a first installation piece and a second installation piece compress a reset spring to a tightening state; and the positioning plate is pushed, an installation block slides in a sliding chuteby using a pulley, the cutting blade is driven to move to the right to effectively cut the clothes, the positioning plate is loosened after cutting, the reset spring pushes the cutting blade to an initial position through compression force, and thus the good cutting effect of the equipment is achieved.

Owner:徐献美

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com