Multifunctional vehicle trim gauze cutting machine

An automotive interior, multi-functional technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of inability to realize automatic feeding, feeding, inaccurate cutting size of gauze, inability to meet production requirements, etc., to ensure gauze Crop size, reduce scrap rate, good crop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

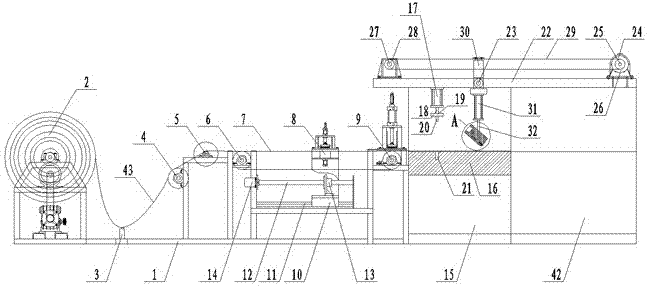

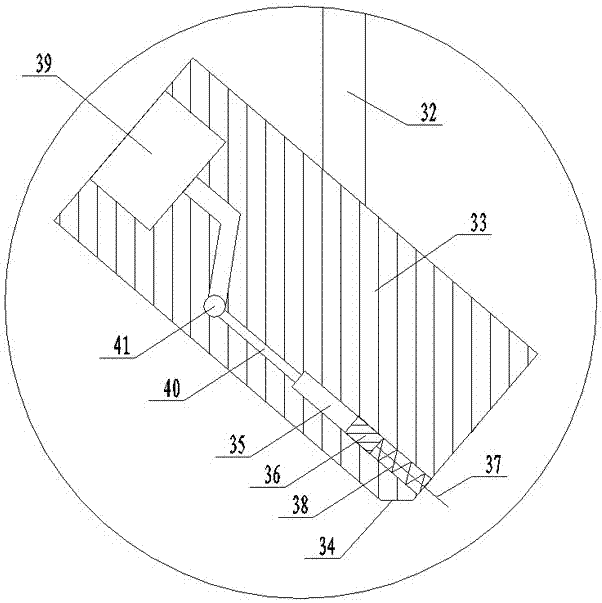

[0010] Such as figure 1 , figure 2 As shown, the multifunctional automotive interior gauze cutting machine includes: a frame 1, an unwinding device 2 arranged at the front end of the frame 1, an infrared photoelectric switch 3 arranged on the rear end frame 1 of the unwinding device 2, and a set The limit device 4 on the photoelectric switch 3 rear end frame 1, the guide wheel 5 that is arranged on the limit device 4 rear end frame 1, the delivery device that is arranged on the guide wheel 5 rear end frame 1, the described The conveying device comprises: a conveying roller 6, a conveyor belt 7, a front pressing device 8 and a rear pressing device 9, the front pressing device 8 is slidably arranged on the slide rail 11 through the slide block 10, and the slide block 10 is fixedly provided with a The screw sleeve 13 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com