Leather shoe shell fabric tailoring equipment for leather shoe processing

A technology for leather shoes and fabrics, which is applied in the field of leather shoe fabric cutting equipment for leather shoe processing, can solve the problems of inconvenience for shoemakers, difficulty in controlling the position of cutting blades, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

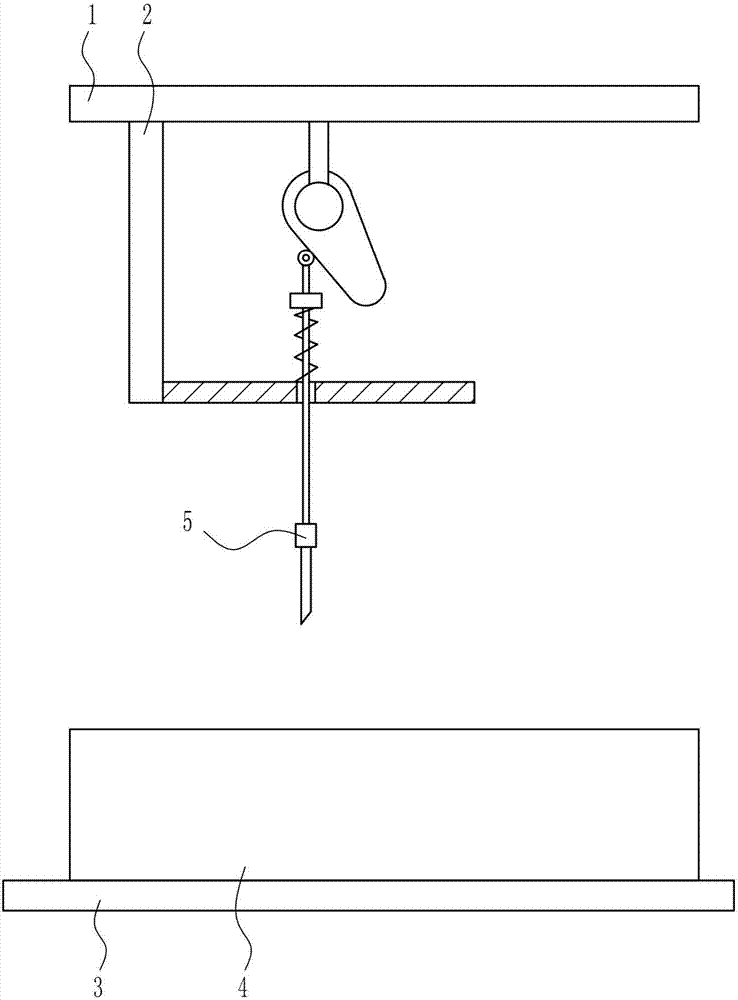

[0042] A kind of leather shoe fabric cutting equipment for leather shoe processing, such as Figure 1-7 As shown, it includes a top plate 1, a cutting device 2, a bottom plate 3, a placing table 4 and a clamping device 5, the top of the bottom plate 3 is provided with a placing table 4, the top plate 1 is provided directly above the bottom plate 3, and the bottom of the top plate 1 is provided with a cutting device 2 , The clamping device 5 is installed at the bottom of the cutting device 2 .

Embodiment 2

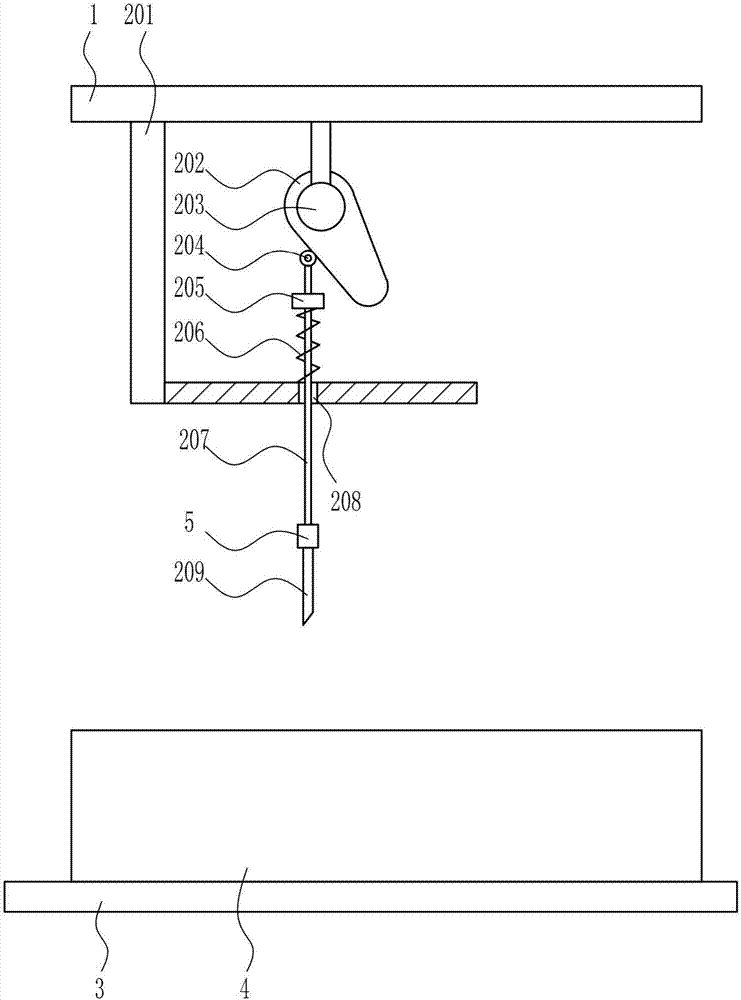

[0044] A kind of leather shoe fabric cutting equipment for leather shoe processing, such as Figure 1-7 As shown, it includes a top plate 1, a cutting device 2, a bottom plate 3, a placing table 4 and a clamping device 5, the top of the bottom plate 3 is provided with a placing table 4, the top plate 1 is provided directly above the bottom plate 3, and the bottom of the top plate 1 is provided with a cutting device 2 , The clamping device 5 is installed at the bottom of the cutting device 2 .

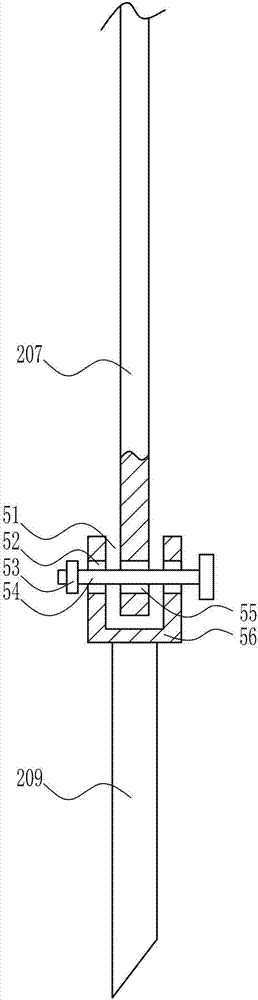

[0045] Cutting device 2 comprises first guide plate 201, cam 202, first motor 203, first contact roller 204, first baffle plate 205, first spring 206, elevating bar 207 and cutting blade 209, top plate 1 bottom is provided with the first A guide plate 201 and a first motor 203, the first guide plate 201 is located on the left side of the first motor 203, the first guide plate 201 is provided with a first guide hole 208, and the top of the first guide plate 201 is provided with a first s...

Embodiment 3

[0047] A kind of leather shoe fabric cutting equipment for leather shoe processing, such as Figure 1-7 As shown, it includes a top plate 1, a cutting device 2, a bottom plate 3, a placing table 4 and a clamping device 5, the top of the bottom plate 3 is provided with a placing table 4, the top plate 1 is provided directly above the bottom plate 3, and the bottom of the top plate 1 is provided with a cutting device 2 , The clamping device 5 is installed at the bottom of the cutting device 2 .

[0048] Cutting device 2 comprises first guide plate 201, cam 202, first motor 203, first contact roller 204, first baffle plate 205, first spring 206, elevating bar 207 and cutting blade 209, top plate 1 bottom is provided with the first A guide plate 201 and a first motor 203, the first guide plate 201 is located on the left side of the first motor 203, the first guide plate 201 is provided with a first guide hole 208, and the top of the first guide plate 201 is provided with a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com