Shearing machine

A shearing machine and cutting table technology, which is applied in the direction of fabric surface trimming, textile material cutting, heating/cooling fabric, etc., can solve the problems of uneven cooling, increase of scrap fabrics, curling, etc., to achieve good cooling effect, cutting Good effect, the effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

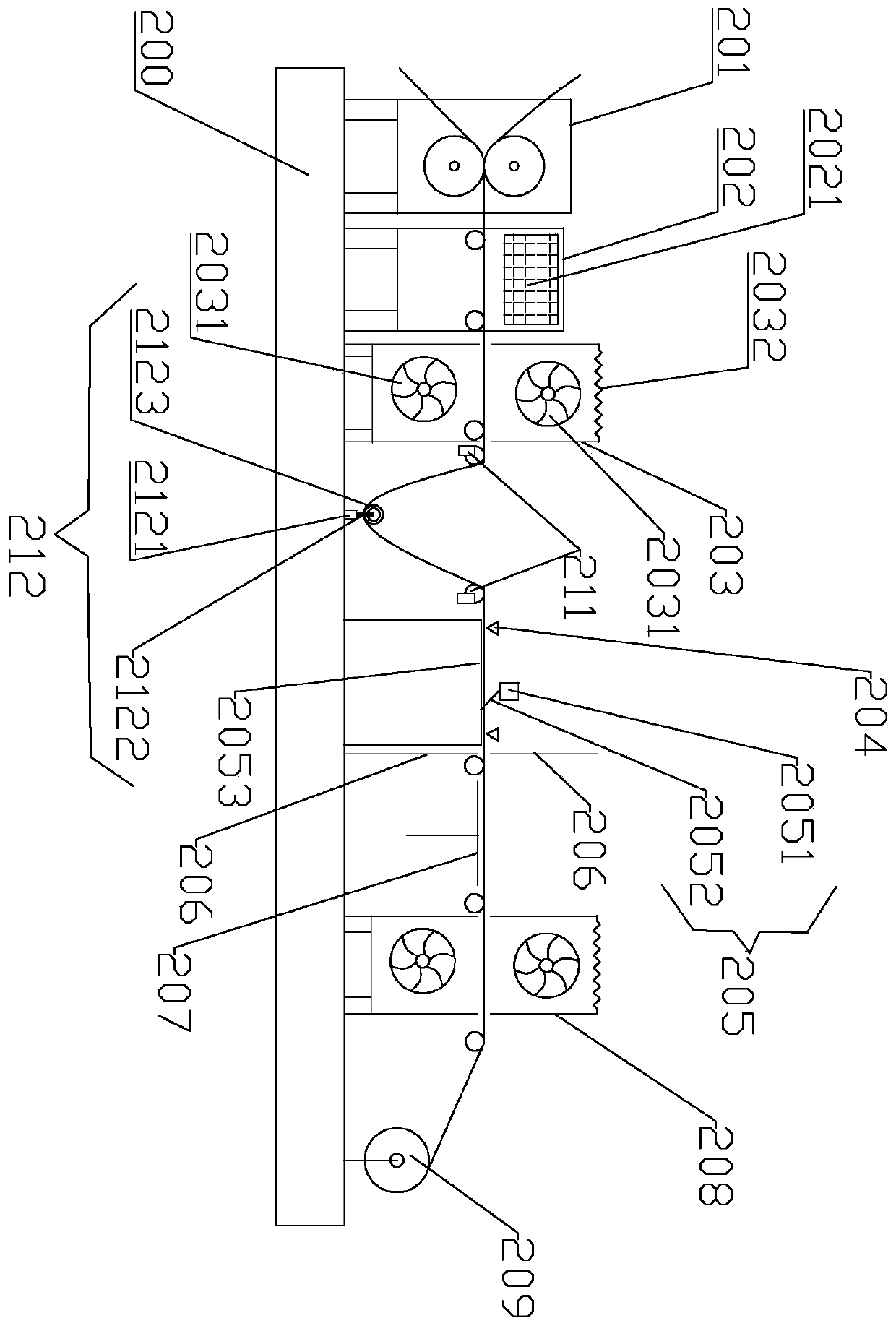

[0025] Such as figure 1 As shown, a shearing machine includes a shearing machine support table 200 and a lining device 201, a heating and setting device 202, a first cooling box 203, a cutting device 205, The steam ironing device 207, the second cooling box 208, and the winding roller 209; two support blocks 211 are arranged between the first cooling box 203 and the cutting device 205, and tensioning blocks 211 are provided between the support blocks 211 device 212; the tensioning device 212 includes a mounting base 2121, a floating link 2122 and a lightweight roller 2123; the cutting device 205 includes a knife rest 2051 and a cutter head 2052 that are symmetrically arranged on the front and rear sides, and the cutting device 205 A cutting table 2053 is provided below the cutting table 2053; above the cutting table 2053, and on the left and right sides of the cutting device 205, a pressing block 204 is arranged; between the pressing block 204 and the steam ironing device 207 ...

Embodiment 2

[0027] Such as figure 1 As shown, a shearing machine includes a shearing machine support table 200 and a lining device 201, a heating and setting device 202, a first cooling box 203, a cutting device 205, The steam ironing device 207, the second cooling box 208, and the winding roller 209; two support blocks 211 are arranged between the first cooling box 203 and the cutting device 205, and tensioning blocks 211 are provided between the support blocks 211 device 212; the tensioning device 212 includes a mounting base 2121, a floating link 2122 and a lightweight roller 2123; the cutting device 205 includes a knife rest 2051 and a cutter head 2052 that are symmetrically arranged on the front and rear sides, and the cutting device 205 A cutting table 2053 is provided below the cutting table 2053; above the cutting table 2053, and on the left and right sides of the cutting device 205, a pressing block 204 is arranged; between the pressing block 204 and the steam ironing device 207 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com