Automatic paper cutting drum type continuous rotary inkjet printer

An inkjet printer and paper cutting technology, applied in printing devices, printing, etc., can solve the problems of reduced printing efficiency and printing quality, and achieve good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

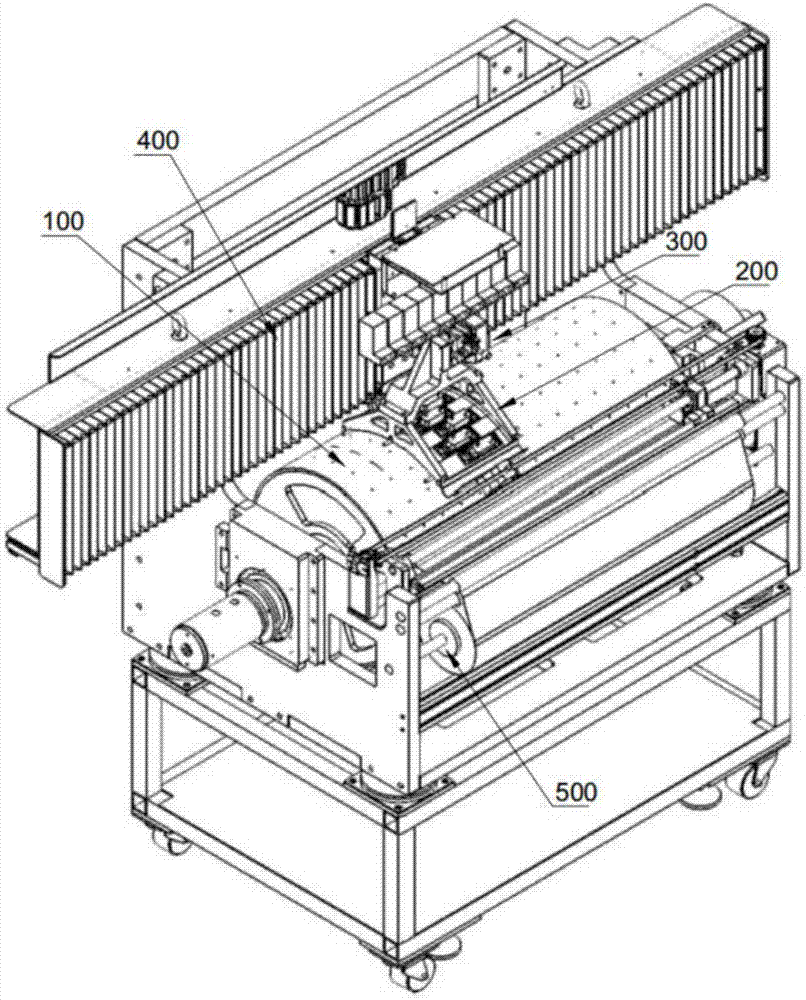

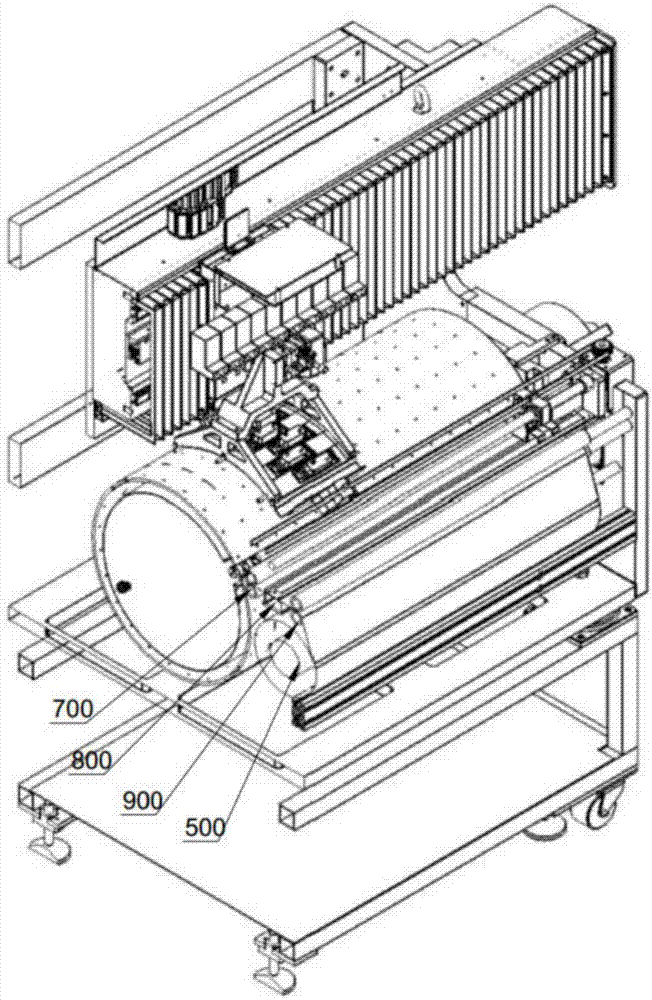

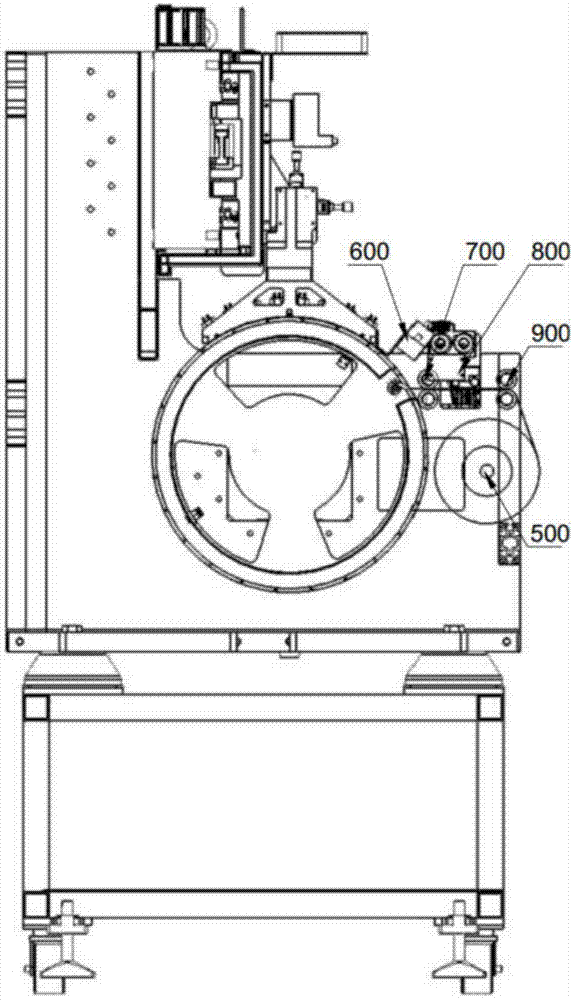

[0029] Such as Figure 1~5 As shown, an automatic paper-cutting drum type rotary inkjet printer includes a printing drum 100 and a paper feeder, and an inkjet trolley 200 is matched with the printing drum 100, and the position of the inkjet trolley 200 is adjusted by an adjustment mechanism 300. The motor 400 performs displacement. One side of the inkjet trolley 200 is fixed with a UVLED drying device 600 to quickly dry the printing paper; the cylindrical surface of the printing drum 100 is provided with a gap along the axial direction of the printing drum, and the gap is provided with a clamping device 120 The clamping device 120 is a paper gripping tooth rotatably arranged on the printing drum; the paper gripping tooth includes a rotating shaft 121 and a tooth piece 122 fixed on the rotating shaft 121, and one end of the rotating shaft 121 is connected with a rotating motor, Under the action of the rotating shaft, the tooth piece can press against the notch of the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com