Friction material adding and reducing integrated device and machining method

A technology of adding and subtracting materials and equipment, applied in the field of additive manufacturing, can solve the problems of low mechanical properties of parts, poor compactness, and the geometric accuracy and surface quality of additive parts cannot meet the design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

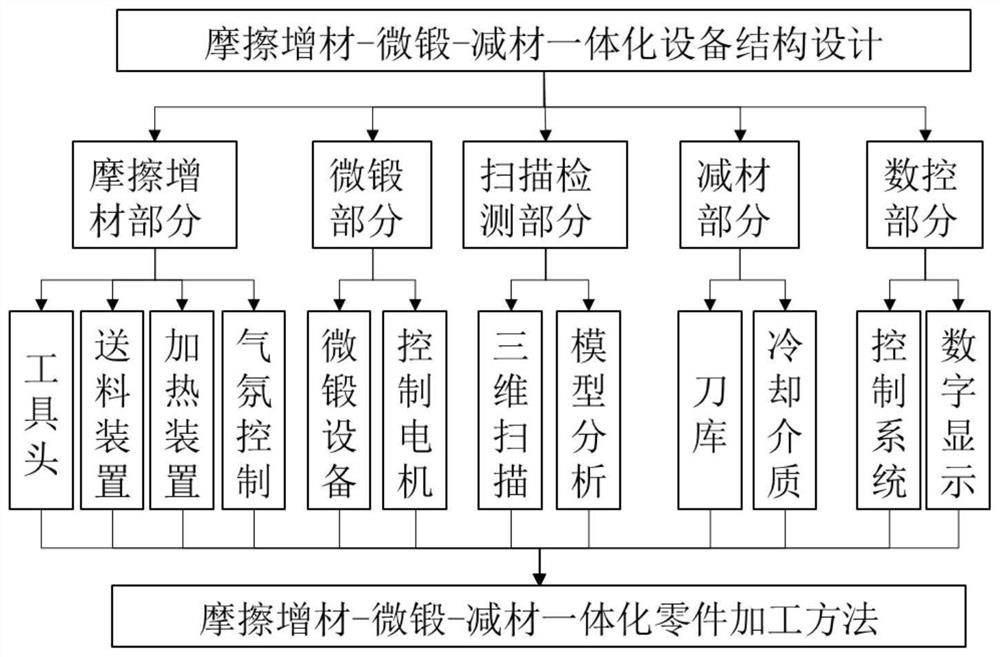

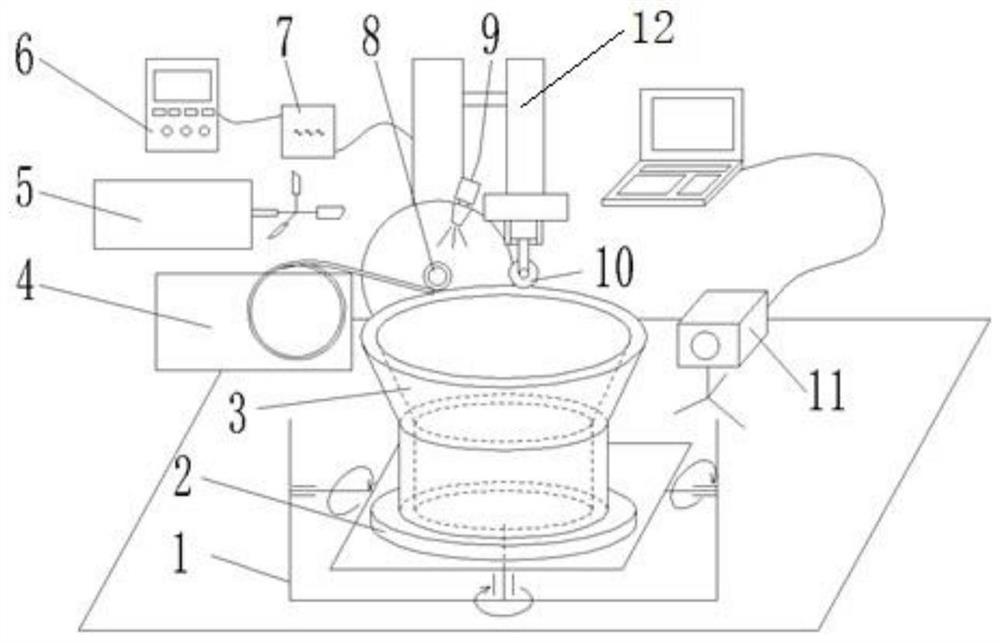

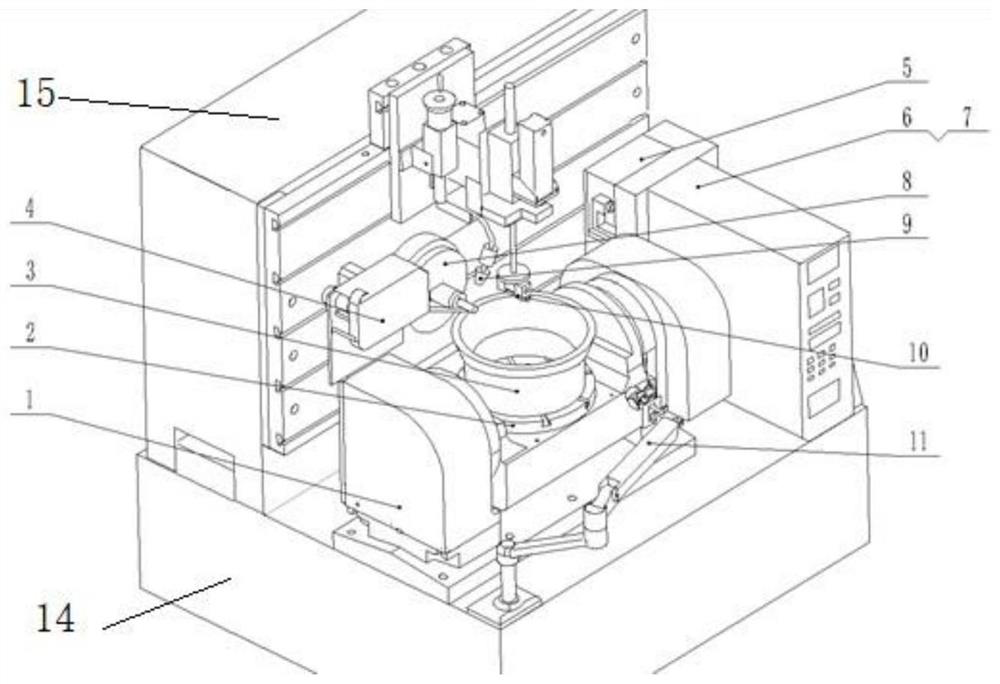

[0029] figure 1 This is the equipment module diagram of this embodiment. In order to achieve the goal of integrating friction addition-micro-forging-subtraction, the necessary structural design includes friction addition parts, micro-forging parts and material reduction parts. The additive manufacturing part includes a positioner (1), a rotary table (2), a rotary tool head (8), a feeding device (4), and an auxiliary heating device and an atmosphere control device are also provided for fixing parts. Phase additive manufacturing forming; the micro-forging part includes a forging hammer and a motor, which are used to increase the compactness of the formed part, reduce internal defects, and improve mechanical properties; the scanning inspection part includes a laser three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com