Paper mold forming system

A paper mold and transfer system technology, which is applied in papermaking, paper recycling, textiles and papermaking, etc., can solve the problems of small scale and no assembly line, and achieve the effect of good broomization, easy mold release and high drying degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

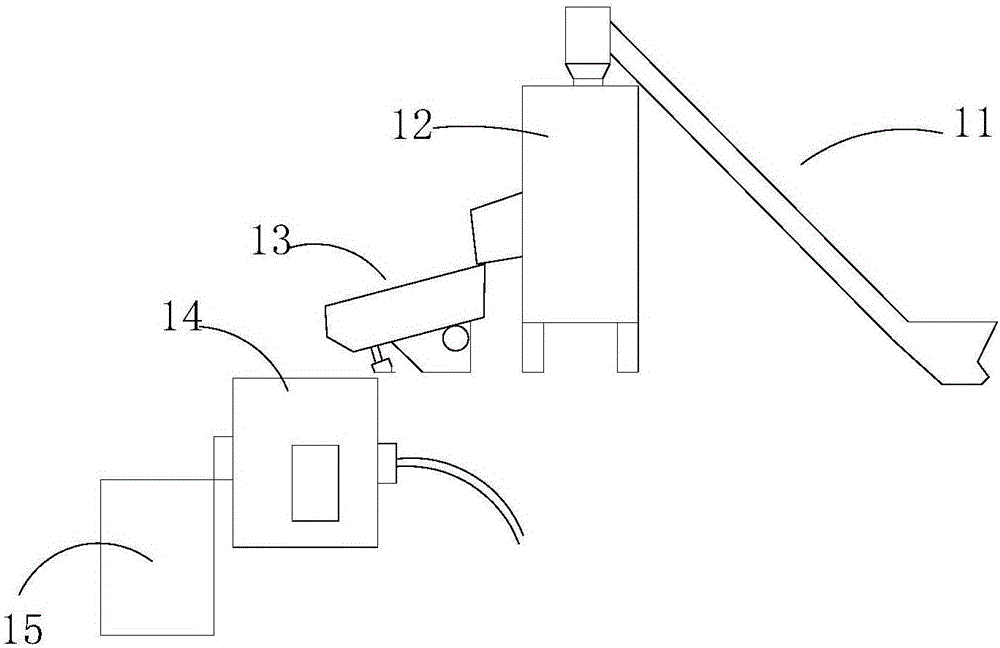

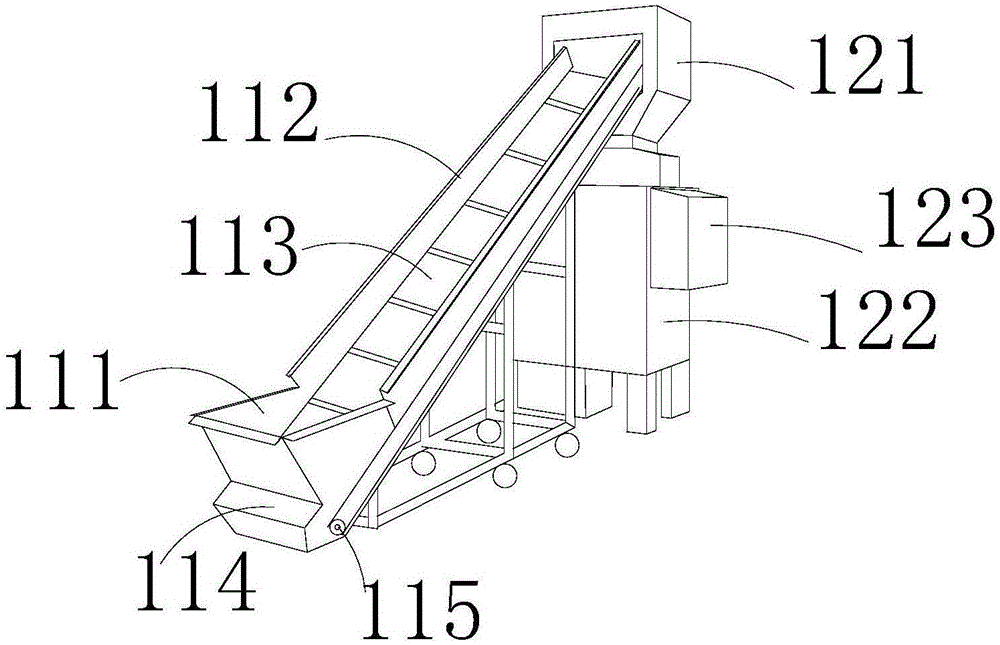

[0035] like figure 2 The beating system shown includes a conveyor 11, a paper shredder 12, a vibrating feeder 13, a soaking tank 14 and a beating machine 15. The conveyor 11 is an inclined conveying form from bottom to top, and its upper part is connected to the feeder of the paper shredder. Material box 121, the discharge port of the shredder is connected to the vibrating feeder 13, the outlet end of the vibrating feeder 13 is connected to the material inlet of the soaking tank 14, and the discharge end of the vibrating feeder 13 corresponds to the upper opening of the soaking tank 14 , the outlet 143 of the soaking pool is connected to the beating inlet 153 of the beater 15; the raw paper is passed to the feed box 121 of the shredder 12 by a conveyor and then enters the box 122 for shredding, and is shredded by the shredder 12 The outlet end falls into the upper part of the vibrating feeder 13, and falls into the immersion tank after vibration for immersion. There is a spir...

Embodiment 2

[0050] like Figure 7 As shown, the wet billet forming transfer system includes a second control box 21, a wet billet forming system and a transfer system. The wet billet forming system includes a pulp tank 24 equipped with pulp, and a forming device 22 is located inside the pulp tank 24; The system includes a first transfer device 23 and a second transfer device 25. The first transfer device includes a first rotating panel 234 that can be rotated by a hinge mechanism, and the second transfer device 25 includes a reciprocating or rotating panel that can be driven by a hinge mechanism. The second suction device 255, the first suction device 235 is fixed below the first rotating panel 234. Under normal conditions, the first suction device 235 is arranged directly above the forming device 22, and the forming device 22 makes a wet billet and rises. The device 235 picks up the wet billet and rotates to the second transfer device 25 at an angle of 90 degrees, and is inserted into th...

Embodiment 3

[0062] Embodiment 3, as the forming system in embodiment 2, the upper surface of the first lifting table 222, the edge of the wet blank mold is provided with a flat groove, and a silk screen is laid in the flat groove to produce a wet blank with an outer eaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com