Prism diffusion plate, prism diffusion plate preparation method and lamp

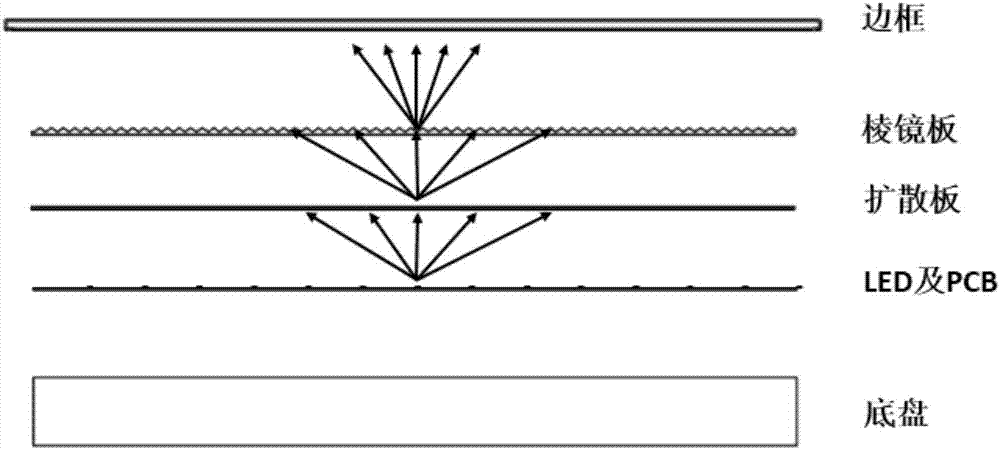

A diffuser and prism technology, applied in prisms, optics, instruments, etc., can solve the problems of increasing product cost, increasing assembly thickness, wasting resources, etc., and achieving the effect of light and thin lamps, good finished product effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

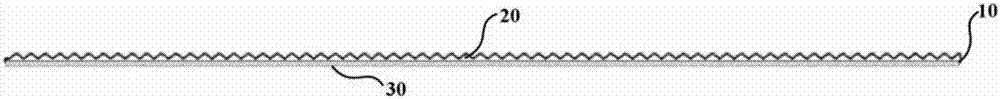

[0055] Figure 9 It is a method for preparing a prism diffuser plate according to an embodiment of the present invention, such as figure 1 As shown, the preparation method of a prism diffuser plate according to one embodiment of the present invention includes:

[0056] Step S902, integrally molding the microprism structure layer and the substrate by extrusion molding or injection molding process, wherein the microprism structure layer is formed on one surface of the substrate;

[0057] Step S904, coating the diffusion ink or paint on the other surface of the substrate by silk screen printing or spraying process, so as to form a diffusion layer.

[0058] According to the preparation method of the prism diffusion plate provided in this embodiment, firstly, an integrated substrate with a micro-prism structure layer can be directly prepared by extrusion molding or injection molding, and then the diffusion layer is prepared by silk screen printing or spraying, and the The prism d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com