Surface treatment method and device for metal sheets

A surface treatment device and surface treatment technology, applied in metal processing equipment, grinding/polishing safety devices, parts of grinding machine tools, etc., can solve the problem that the metal sheet cannot be used normally, the thermal transfer layer or the coating layer falls off , the surface effect cannot be satisfied, etc., to achieve the effect of saving equipment cost and maintenance cost, fast grinding speed and good finished product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

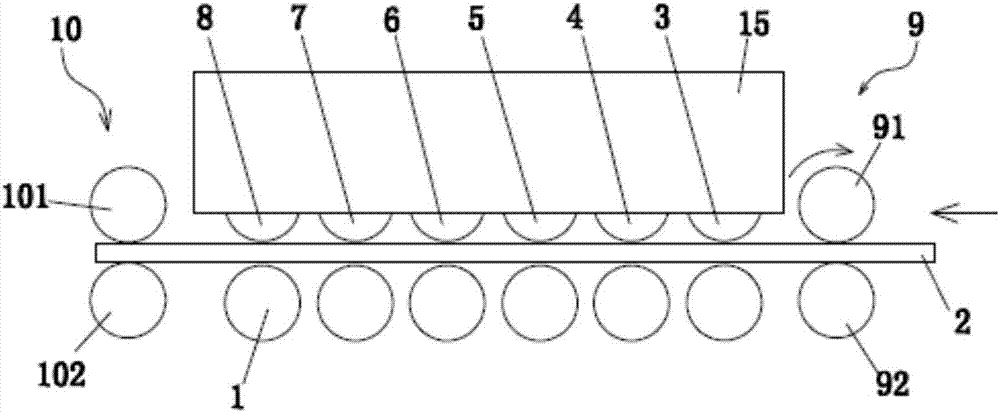

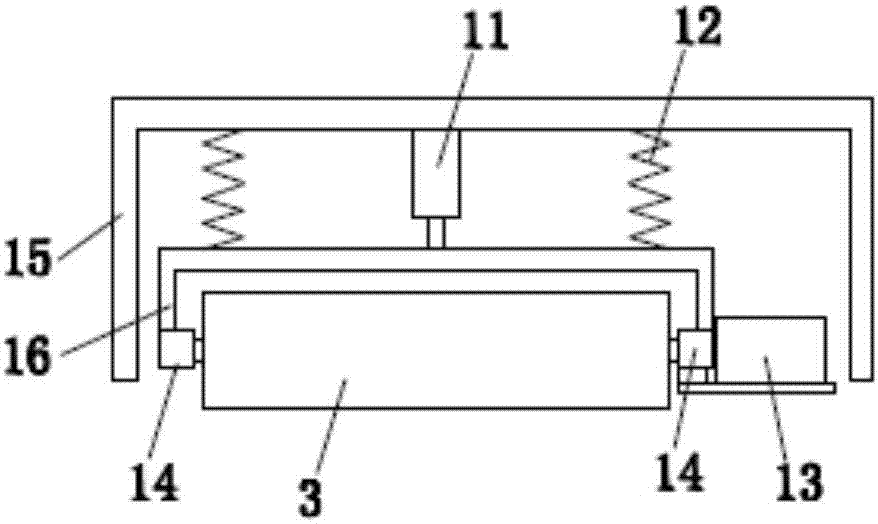

[0031] The specific embodiment of the present invention is as figure 1 and figure 2 As shown, a metal sheet surface treatment device includes a traction device for conveying the metal sheet, and also includes at least one set of grinding wheels, and the grinding wheel set includes a The grinding wheel and the support wheel 1 located on the other side of the metal sheet, the grinding wheel and the support wheel 1 are arranged oppositely.

[0032] In this embodiment, the metal sheet 2 is an aluminum sheet, and may also be an aluminum coil.

[0033] In this embodiment, the surfaces on both sides of the metal sheet 2 face vertically upward and vertically downward respectively, and the metal sheet 2 moves along the horizontal direction under the action of the traction device.

[0034] In this embodiment, the traction device is a first supporting wheel set 9 and a second supporting wheel set 10 . The first supporting wheel set 9 , the grinding wheel set and the second supporting...

Embodiment 2

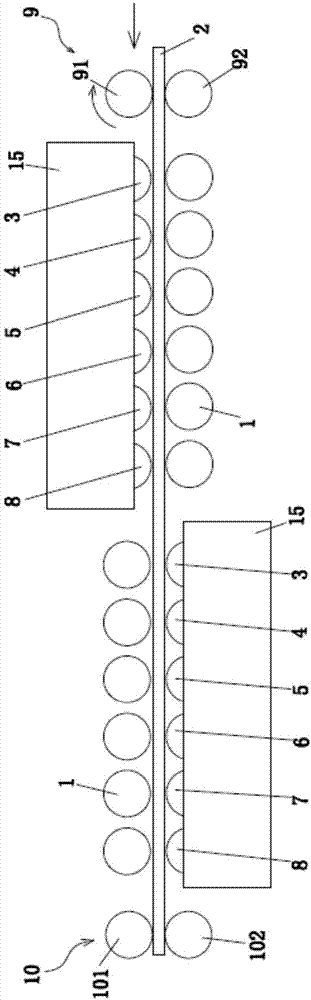

[0050] Such as image 3 As shown, the difference from Example 1 is that the upper and lower surfaces of the metal sheet 2 are respectively polished sequentially by 3-8 sets of grinding wheels. In this embodiment, specifically, the upper and lower surfaces of the metal sheet 2 are polished by 6 sets of grinding wheels, of which 6 sets of grinding wheels are located above the metal sheet 2, and the other 6 sets of grinding wheels are located on the metal sheet. Sheet 2 below. The grinding wheels on the upper surface and the lower surface of the metal sheet 2 are the first grinding wheel 3, the second grinding wheel 4, the third grinding wheel 5, the fourth grinding wheel 6, the fifth grinding wheel 7 and the sixth grinding wheel 8 . The method of grinding on both sides is suitable for metal sheets coated on both sides, or metal sheets coated on one side and thermally transferred on the other side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com