Process method for producing nitro fulvic acid compound fertilizer by virtue of high tower and compound fertilizer

A technology of nitrofulvic acid and production process, which is applied in ammonium nitrate fertilizer, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, etc. Nitro compound fertilizer and other problems, to achieve the effect of smooth process, simplified production process and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

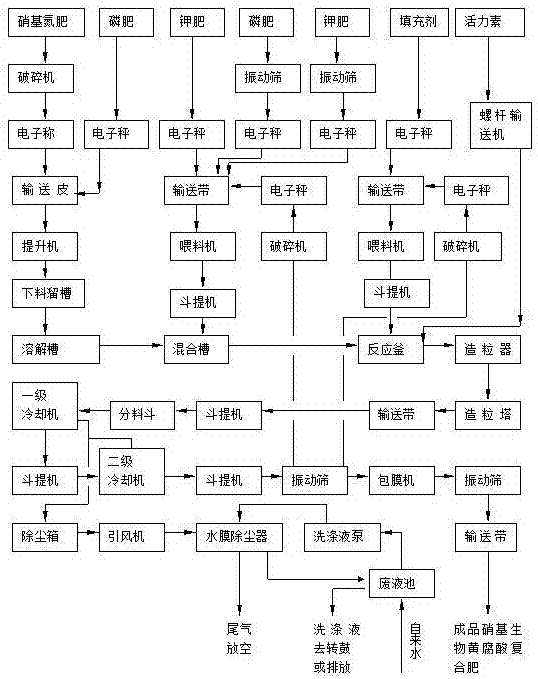

Image

Examples

Embodiment 1

[0036] 1) Dissolution: Weigh 745 parts of potassium ammonium nitrate and put it into a crusher to crush to obtain granular potassium ammonium nitrate, then add it and 100 parts of monoammonium phosphate into the dissolving tank, stir evenly, and the temperature of the dissolving tank is 160°C , the dissolving time is 30min, and the particle diameter of the granular potassium ammonium nitrate is 2cm;

[0037] 2) Mixing: transfer the mixed solution prepared in step 1) into a mixing tank, add 35 parts of potassium sulfate, stir evenly, the temperature of the mixing tank is 148°C, and the mixing time is 30 minutes;

[0038] 3) Reaction: transfer the mixed solution prepared in step 2) into the reactor, add 120 parts of activin, stir evenly, the temperature of the reactor is 135°C, and the reaction time is 5 minutes;

[0039] 4) Granulation: input the slurry prepared in step 3) to the granulation tower through the granulator for high-tower granulation;

[0040] 5) Cooling: Cool the...

Embodiment 2

[0043] 1) Dissolution: Weigh 440 parts of potassium ammonium nitrate and put it into a crusher to crush to obtain granular potassium ammonium nitrate, then add it and 90 parts of monoammonium phosphate into the dissolving tank, stir evenly, and the temperature of the dissolving tank is 158°C , the dissolution time is 40min, and the particle diameter of the granular potassium ammonium nitrate is 5cm;

[0044] 2) Mixing: transfer the mixed solution prepared in step 1) into a mixing tank, add 290 parts of potassium sulfate, stir evenly, the temperature of the mixing tank is 145°C, and the mixing time is 25 minutes;

[0045] 3) Reaction: transfer the mixed solution prepared in step 2) into the reactor, add 180 parts of activin, stir evenly, the temperature of the reactor is 135°C, and the reaction time is 15 minutes;

[0046] 4) Granulation: input the slurry prepared in step 3) to the granulation tower through the granulator for high-tower granulation;

[0047] 5) Cooling: Cool t...

Embodiment 3

[0050] 1) Dissolution: Weigh 450 parts of potassium ammonium nitrate and put it into a crusher to crush to obtain granular potassium ammonium nitrate, then add it and 150 parts of monoammonium phosphate into the dissolving tank, stir evenly, and the temperature of the dissolving tank is 155°C , the dissolving time is 45min, and the particle diameter of the granular potassium ammonium nitrate is 3cm;

[0051] 2) Mixing: Transfer the mixed solution prepared in step 1) into a mixing tank, add 90 parts of potassium sulfate and 210 parts of monoammonium phosphate, and stir evenly. The temperature of the mixing tank is 140°C, and the mixing time is 10 minutes;

[0052] 3) Reaction: transfer the mixed solution prepared in step 2) into the reactor, add 100 parts of activin, stir evenly, the temperature of the reactor is 130°C, and the reaction time is 10 minutes;

[0053] 4) Granulation: input the slurry prepared in step 3) to the granulation tower through the granulator for high-towe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com