A Calculation Method of Process Parameters of Compression and Stretching of Propellant

A calculation method and technology of process parameters, applied in the field of calculation of propellant compression and stretching process parameters, can solve problems such as increased outlet pressure, inability to give a more suitable new formula, and large difference in results, so as to reduce material waste, shorten The effect of development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

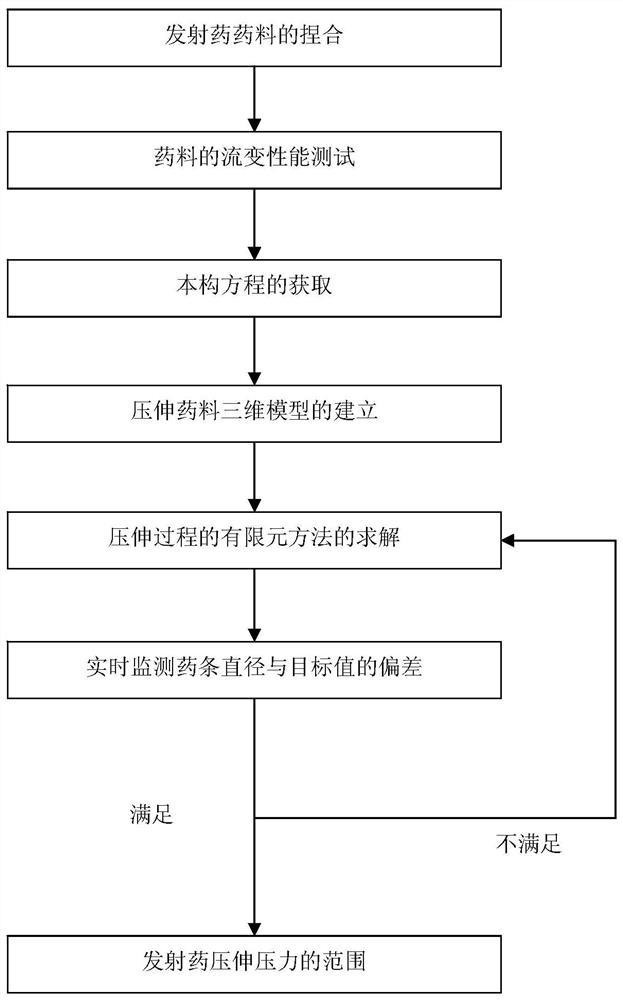

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] according to figure 1 , taking Sanji propellant as an example, the nitrogen content of nitrocellulose is 12.8%, the RDX is class 5, and the solvent ratio is 0.27. The calculation steps of the compression and stretching process parameters of the propellant are as follows.

[0022] (1) After weighing the required raw materials, the kneaded medicine is ready for use;

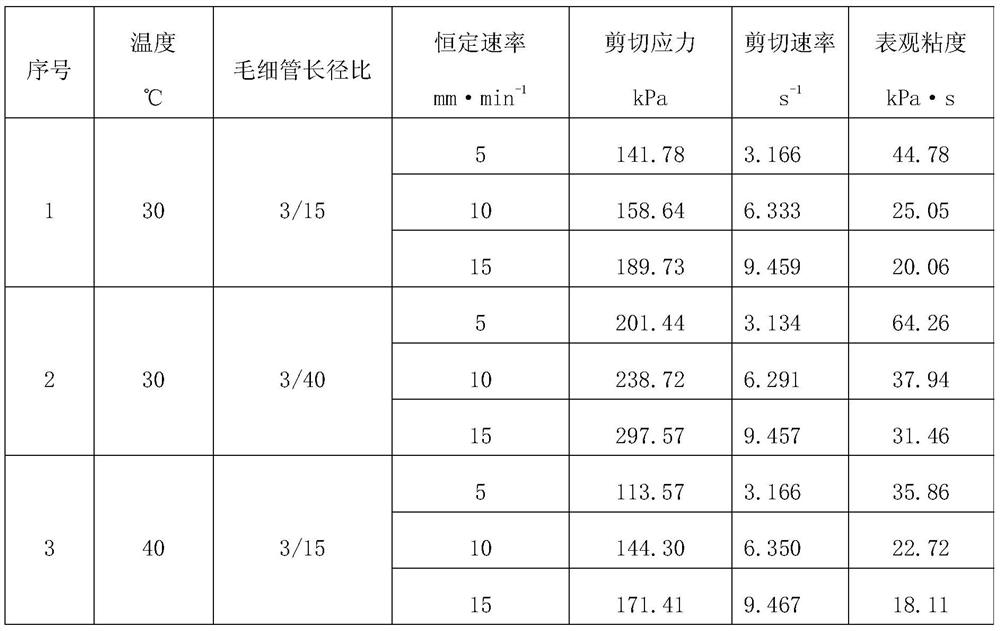

[0023] (2) Take a small amount of medicinal material by using a heat preservation device, and use a capillary rheometer to test the rheological properties of the medicinal material. The data are as follows:

[0024]

[0025] (3) Using modified Bingham model and Power model for fitting, modified Bingham model (fitting degree is 0.98), Power model (fitting degree is above 0.99);

[0026] (4) Select the constitutive equation with a higher degree of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com