An energy-saving system and method for preparing phenylchlorosilane monomer

A technology of phenylchlorosilane and energy-saving system, which is applied in the direction of chemical instruments and methods, sustainable manufacturing/processing, and compounds of group 4/14 elements of the periodic table, etc. Utilization of low efficiency and other issues to achieve the effect of avoiding pipeline blockage, high energy utilization, and clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

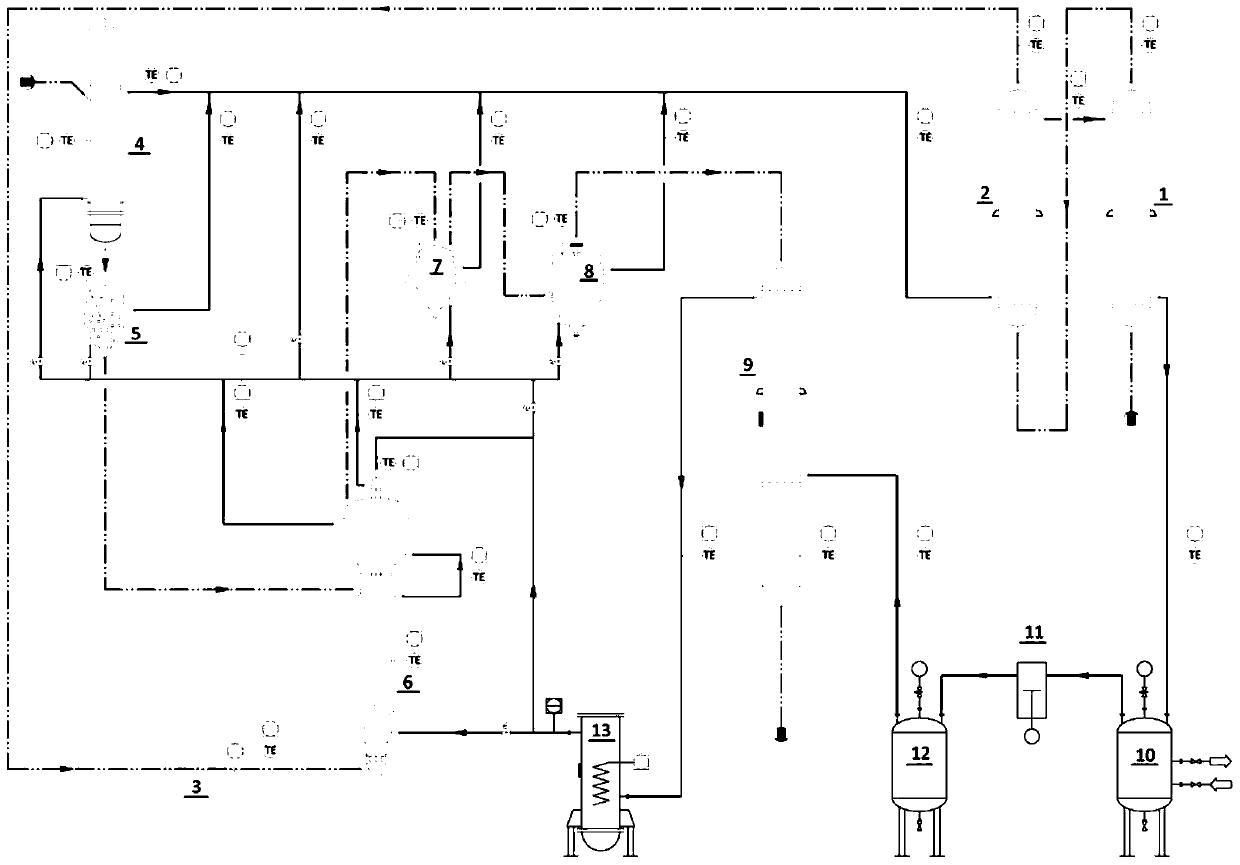

[0031] This example provides an energy-saving system for the preparation of phenylchlorosilane monomers, partly referred to figure 1 Shown, comprise the raw material path that is connected in sequence, reactor 6 and product path, and carry out the nitrogen circulation path of heat exchange with described raw material path, reactor or / and product path; Said raw material path includes respectively with described reactor Connected gas feed passage and solid feed passage;

[0032] The gas raw material passage includes a raw material liquid preheater 1, a raw material liquid vaporizer 2, and a raw gas electric heater 3 connected in sequence; the raw gas electric heater 3 is connected to the gas raw material inlet of the reactor 6;

[0033] The solid raw material path includes a silicon / copper powder drier 4 and a silicon / copper powder intermediate tank 5 connected in sequence; the silicon / copper powder intermediate tank 5 is connected to the solid raw material inlet of the reactor ...

Embodiment 2

[0037] In order to improve the safety and efficiency of the system, this embodiment further adds a temperature transmitter, a pressure transmitter and a regulating valve on the basis of Embodiment 1, such as figure 1 As shown, specifically:

[0038] In this embodiment, temperature transmitters are installed on the reactor, silicon-copper powder dryer, silicon-copper powder intermediate tank, dust collector, dust remover, and product heat exchanger, and the nitrogen gas main pipe of the nitrogen gas delivery pipeline is connected to each main body device Temperature transmitters are installed on the hot nitrogen inlet pipe and hot nitrogen bypass pipe, and temperature transmitters are installed on the output pipes of the preheater, vaporizer and raw gas electric heater;

[0039] Install a pressure transmitter on the nitrogen main pipe of the nitrogen delivery pipeline;

[0040] Hot nitrogen inlet pipe for reactor, hot nitrogen inlet pipe for silicon copper powder dryer, hot ni...

Embodiment 3

[0042] This example provides a method for preparing phenylchlorosilane monomer using the device described in Example 1 or Example 2. The method uses a direct method, using benzene chloride and silicon as raw materials, under the action of a copper catalyst After the reaction, the obtained phenylchlorosilane monomer product is mainly diphenyldichlorosilane, followed by monophenyltrichlorosilane, and a very small amount of triphenylchlorosilane.

[0043] The above method has many advantages such as high energy utilization rate, cleanness and no pollution, high process system safety, and high degree of automation.

[0044] Among them, using the production system provided in Example 2 that includes a temperature transmitter, a pressure transmitter, and a regulating valve can achieve a more excellent effect of energy saving and emission reduction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com