High glow-wire and fiber halogen-free flame-retardant nylon 66 material and preparation method thereof

A technology of high glow wire and flame-retardant nylon, which is applied in the field of high-glow wire, high-performance fiber-added, halogen-free and environmentally friendly flame-retardant nylon 66 materials and its preparation, can solve the problems of high glow wire performance that cannot meet the requirements of halogen-free environmental protection at the same time, Achieve the effect of smooth production process, low cost and large market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

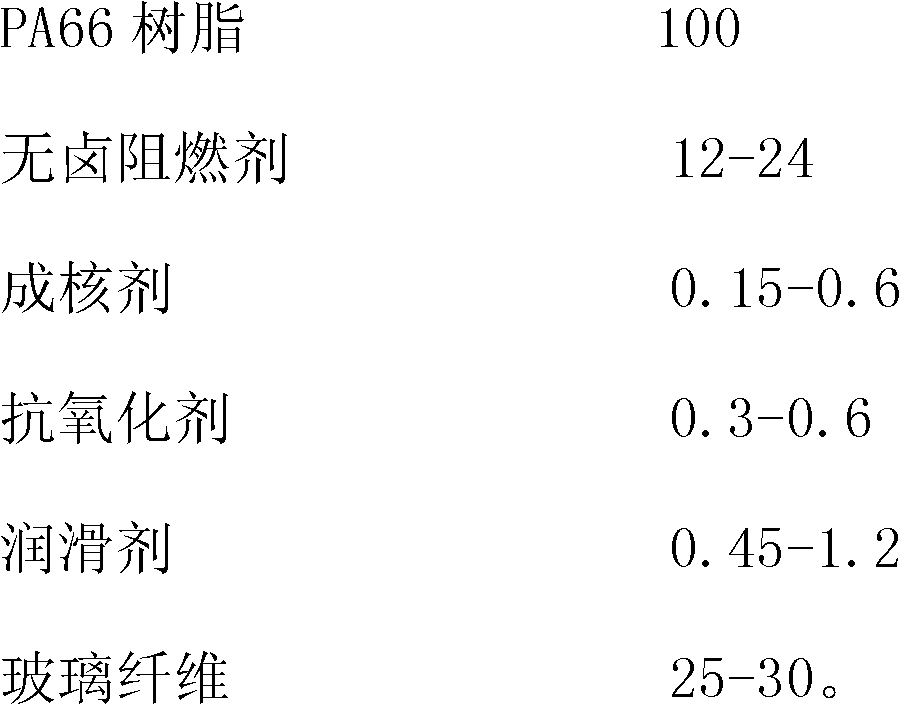

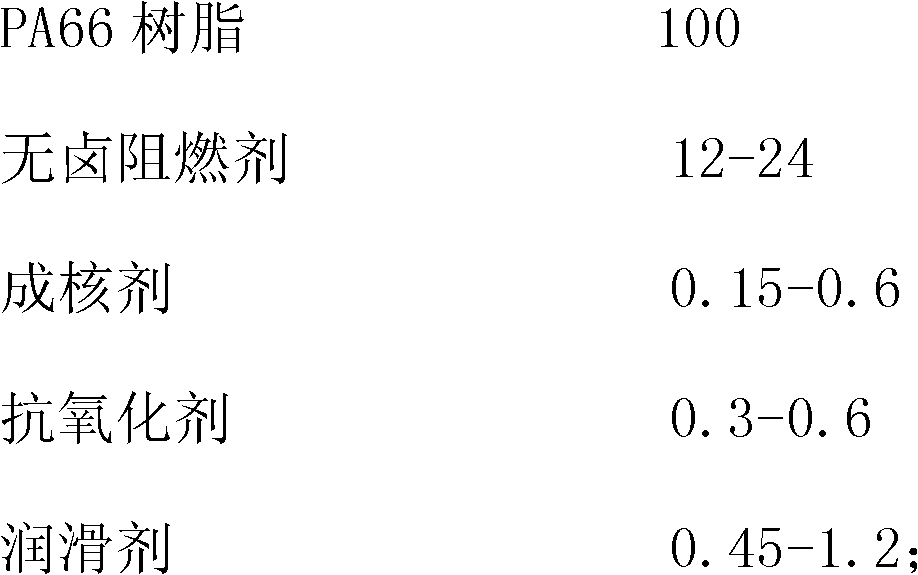

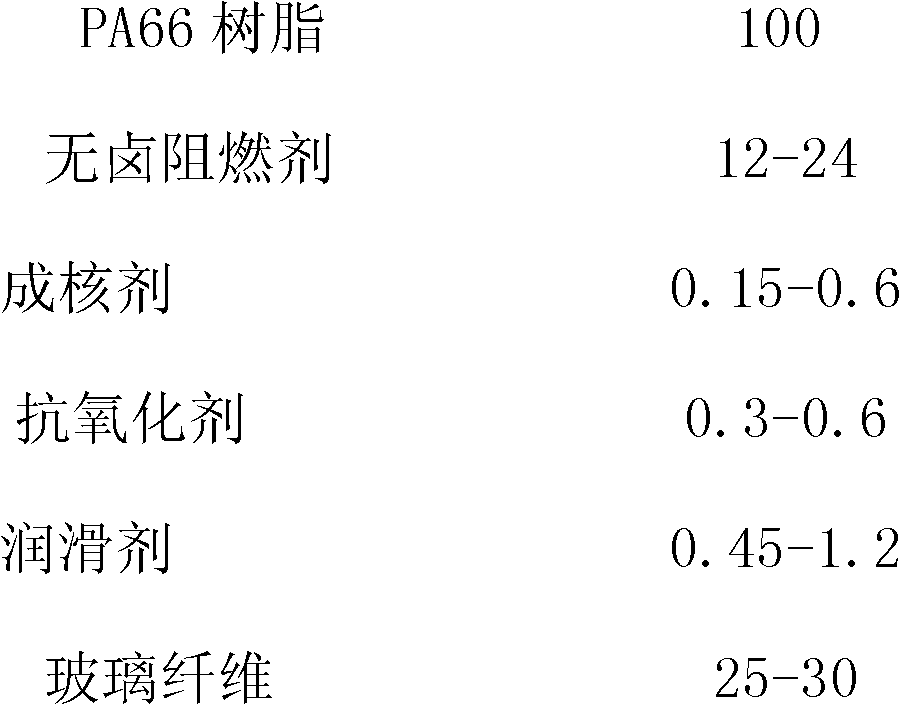

[0024] Dry the PA66 resin at 100°C for 2-3 hours, and dry the composite halogen-free flame retardant at 80°C for 2-3 hours, and control the moisture content below 0.02%. After drying, 100 parts of PA66 resin, 12 parts of halogen-free flame retardant, 0.15 parts of nucleating agent, 0.3 parts of antioxidant, and 0.45 parts of lubricant are placed in a mixing tank and stirred for 10 minutes, and then extruded through a twin-screw extruder For granulation, in the middle section of the extruder, 25 parts by weight of glass fibers are added. The processing temperature is 240-260℃ in the first zone, 240-270℃ in the second zone, 250-270℃ in the third zone, 250-275℃ in the fourth zone, 240-265℃ in the fifth zone, 240-260℃ in the sixth zone, and 250℃ in the seventh zone. -280°C; the extrusion treatment time is 1-3 minutes. The pellets were dried in a blast drying oven at 120°C for 3 hours, and then prepared into standard test specimens through an injection molding machine.

Embodiment 2

[0026] Dry the PA66 resin at 100°C for 2-3 hours, and dry the composite halogen-free flame retardant at 80°C for 2-3 hours, and control the moisture content below 0.02%. After drying, 100 parts of PA66 resin, 15 parts of halogen-free flame retardant, 0.3 part of nucleating agent, 0.4 part of antioxidant, and 0.6 part of lubricant are placed in a mixing bucket and stirred for 10 minutes, and then extruded through a twin-screw extruder For granulation, in the middle section of the extruder, 26 parts by weight of glass fibers are added. The processing temperature is 240-260℃ in the first zone, 240-270℃ in the second zone, 250-270℃ in the third zone, 250-275℃ in the fourth zone, 240-265℃ in the fifth zone, 240-260℃ in the sixth zone, and 250℃ in the seventh zone. -280°C; the extrusion treatment time is 1-3 minutes. The pellets were dried in a blast drying oven at 120°C for 3 hours, and then prepared into standard test specimens through an injection molding machine.

Embodiment 3

[0028] Dry the PA66 resin at 100°C for 2-3 hours, and dry the composite halogen-free flame retardant at 80°C for 2-3 hours, and control the moisture content below 0.02%. After drying, 100 parts of PA66 resin, 18 parts of halogen-free flame retardant, 0.4 part of nucleating agent, 0.5 part of antioxidant, and 0.75 part of lubricant are placed in a mixing tank and stirred for 10 minutes, and then extruded through a twin-screw extruder For granulation, in the middle section of the extruder, 27 parts by weight of glass fibers are added. The processing temperature is 240-260℃ in the first zone, 240-270℃ in the second zone, 250-270℃ in the third zone, 250-275℃ in the fourth zone, 240-265℃ in the fifth zone, 240-260℃ in the sixth zone, and 250℃ in the seventh zone. -280°C; the extrusion treatment time is 1-3 minutes. The pellets were dried in a blast drying oven at 120°C for 3 hours, and then prepared into standard test specimens through an injection molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com