Compound for improving heat resistance of amino-modified silicone oil carbon fiber oil formulation and preparation and application thereof

An amino-modified and aminopropyl-modified technology, applied in the direction of silicon organic compounds, carbon fibers, fiber processing, etc., can solve the problems of high-performance carbon fiber damage, broken wires, sticking rollers, etc., and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

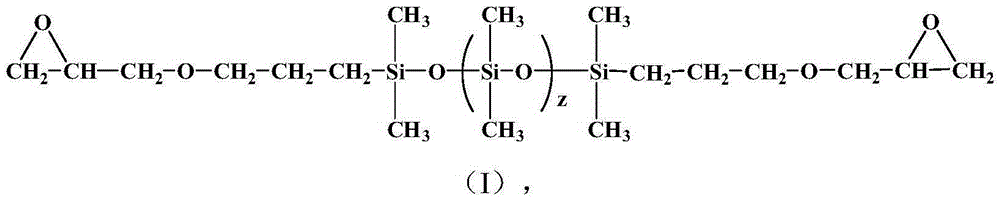

[0035] A compound A that improves the heat resistance of amino-modified silicone oil carbon fiber oil has a structure shown in formula (I):

[0036]

[0037] In formula (I), z=2-5.

[0038] Preparation method: Mix 88.8g of hexamethylcyclotrisiloxane and 160.8g of tetramethyldisiloxane, stir evenly, lower the temperature to 0°C, add 0.1g of catalyst trifluoromethanesulfonic acid, react for 0.5h, medium And to neutral, vacuum distillation, pressure 1.33kPa, take 115 ℃ ~ 120 ℃ fraction, obtain decamethyldihydropentasiloxane; 71.2g of the above-mentioned ultra-short chain hydrogen-containing silicone oil, 45.6g of allyl glycidol Ether was mixed with 0.08g of Carl's Platinum catalyst, heated to 85°C, reacted for 3h, and unreacted raw materials were removed by distillation under reduced pressure to obtain compound A (z=3).

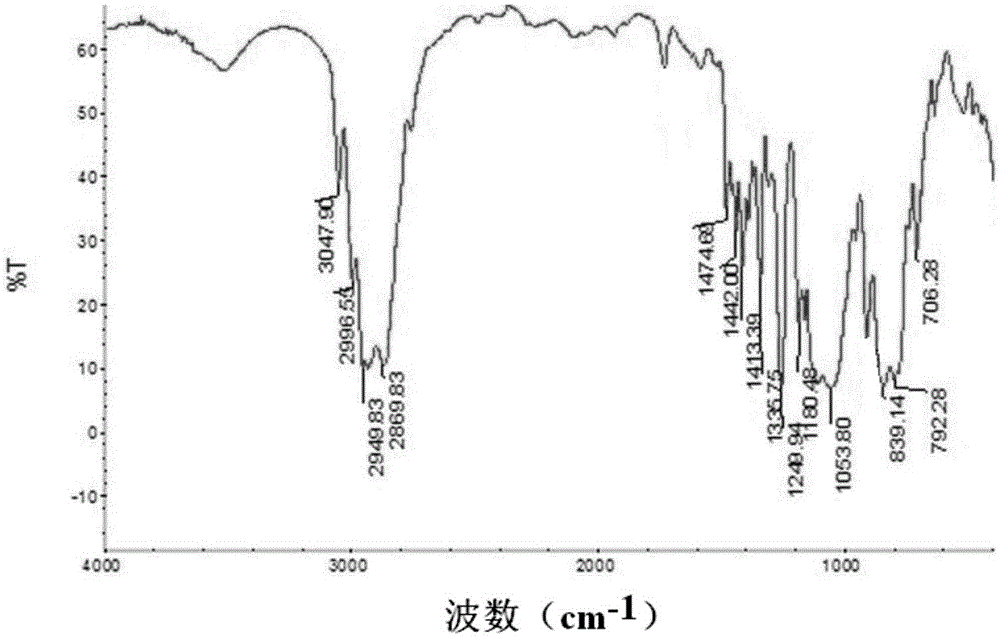

[0039] figure 1 For the infrared spectrogram of the compound A that this embodiment makes, wherein 792.28cm -1 , 839.14, 1249.94cm -1 for Si-CH 3 Absorp...

Embodiment 2

[0041] Mix 88.8g of hexamethylcyclotrisiloxane and 107.2g of tetramethyldisiloxane, stir evenly, lower the temperature to 10°C, add 0.1g of catalyst trifluoromethanesulfonic acid, react for 2h, neutralize to neutral, Vacuum distillation, pressure 1.33kPa, take 105 ℃ ~ 135 ℃ fraction to obtain ultra-short-chain hydrogen-containing silicone oil; mix 89g of the above-mentioned ultra-short-chain hydrogen-containing silicone oil, 45.6g allyl glycidyl ether and 0.08g platinum catalyst, and heat up to 85°C, react for 3 hours, and distill off unreacted raw materials under reduced pressure to obtain A, which is a mixture of z=2~5.

Embodiment 3

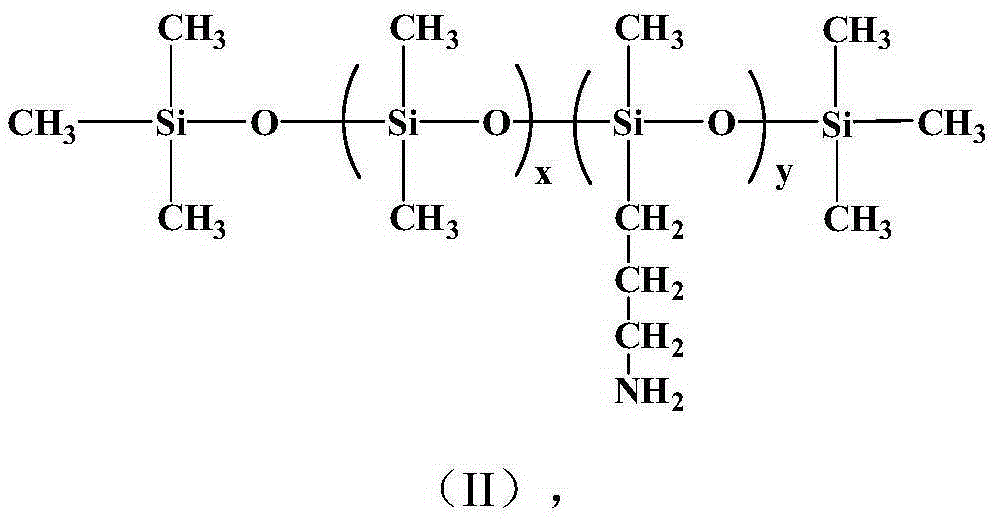

[0043] Side chain aminopropyl modified silicone oil has the structure shown in formula (II):

[0044]

[0045] (II), x=80~160, y=1~3.

[0046] Preparation method: 890g octamethylcyclotetrasiloxane, 24.9g aminopropylmethyldiethoxysilane, 4.9g deionized water, 16.2g hexamethyldisiloxane and 0.09g tetramethylhydroxide Ammonium is added to the reactor, and N 2 , stir, heat up to 80°C to 90°C for 2 hours, then reduce the pressure to 66.7kPa, raise the temperature to 100°C to 110°C for 4 hours, return to normal pressure, raise the temperature to 170°C for 1 hour to decompose the catalyst, and finally reduce the pressure to 133Pa Raise the temperature to 175°C to 180°C to remove small molecular substances, and obtain a side chain aminopropyl modified silicone oil with a kinematic viscosity of 200cp, an ammonia value of 0.16mmol / g, and a volatile component of 3.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com