Low molecular weight polyethylene with dual-peak distribution of molecular weight and its preparing process and application

A molecular weight distribution, low molecular weight technology, applied in the field of low molecular weight ethylene polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 (1) Preparation of catalyst: the titanium-containing active component is prepared according to the method and conditions disclosed in Example 1 in the specification of Chinese Patent 85100997.2 to obtain a solid catalyst wherein the titanium content is 2.62%, the magnesium content is 17.01%, and the chlorine content is 55.88%, ester content 14.36%. (2) Ethylene polymerization: In a two-liter high-pressure stainless steel polymerization kettle equipped with a stirring and temperature-regulating device, fully replace with hydrogen, add one liter of heptane, 63.8 mg of the above-mentioned solid catalyst, and 10 ml of triethylaluminum, and start to heat up. At 70°C, the partial pressure of heptane is 0.04MPa, add hydrogen to 1.49Mpa (the amount of hydrogen added is 11.6 standard liters), then feed ethylene until the total pressure is 1.6Mpa, continue to heat up to 86°C, and maintain this temperature for two After one hour, the discharge obtained white polyethyl...

Embodiment 2

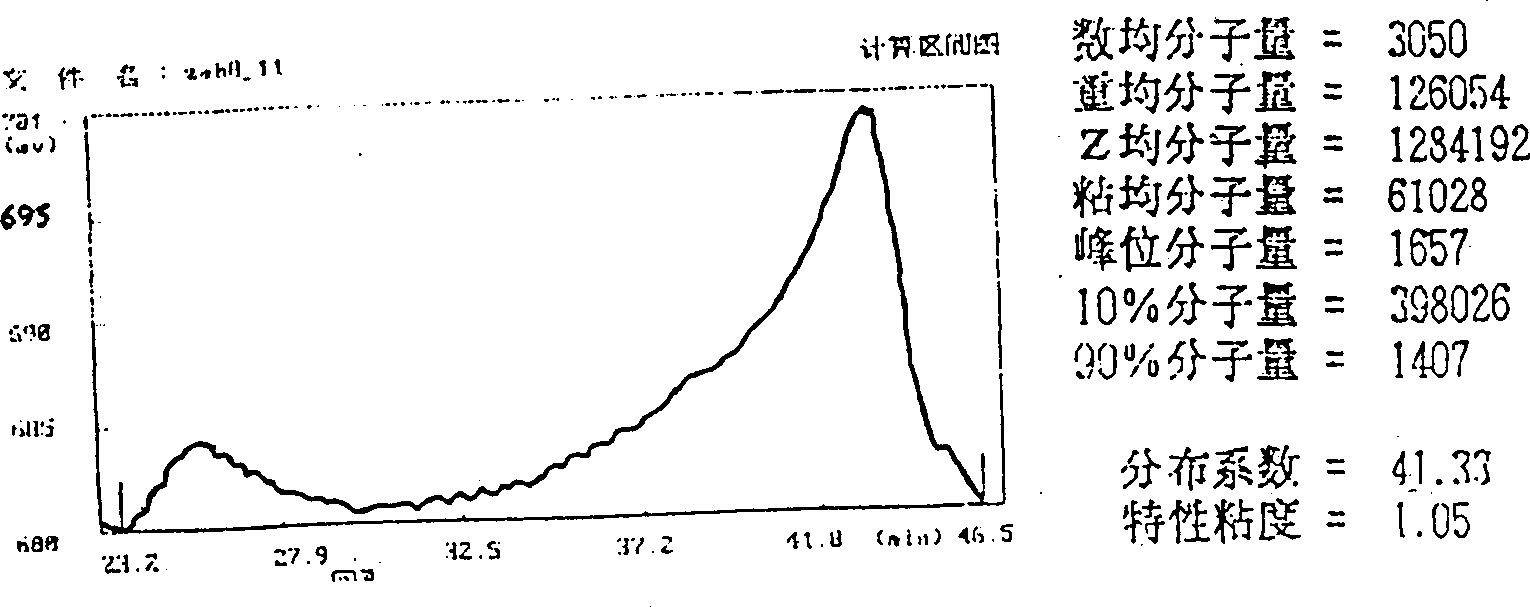

[0025] Embodiment 2 (1) Catalyst selection: Same as Example 1 (2) Ethylene polymerization: In a two-liter high-pressure stainless steel polymerization kettle equipped with stirring and temperature adjustment devices, fully replace with hydrogen, add one liter of heptane, the above-mentioned 42mg of solid catalyst, 10ml of triethylaluminum, start to heat up, when it reaches 70°C, the partial pressure of heptane is 0.04MPa, add hydrogen to 0.84Mpa (the amount of hydrogen added is 6.4 standard liters), then feed ethylene until the total pressure is 1.0Mpa, continue to heat up to 86°C, maintain this temperature for two hours, and then discharge to obtain white polyethylene powder (results are shown in Table 1). (3) Test polymer: polymer apparent density BD is 0.30g / cm 3, catalyst efficiency is 140kg polymkeric substance / g titanium, with the Waters150C instrument of U.S. production, tested the molecular weight and molecular weight distribution of product, the number average molecul...

Embodiment 3

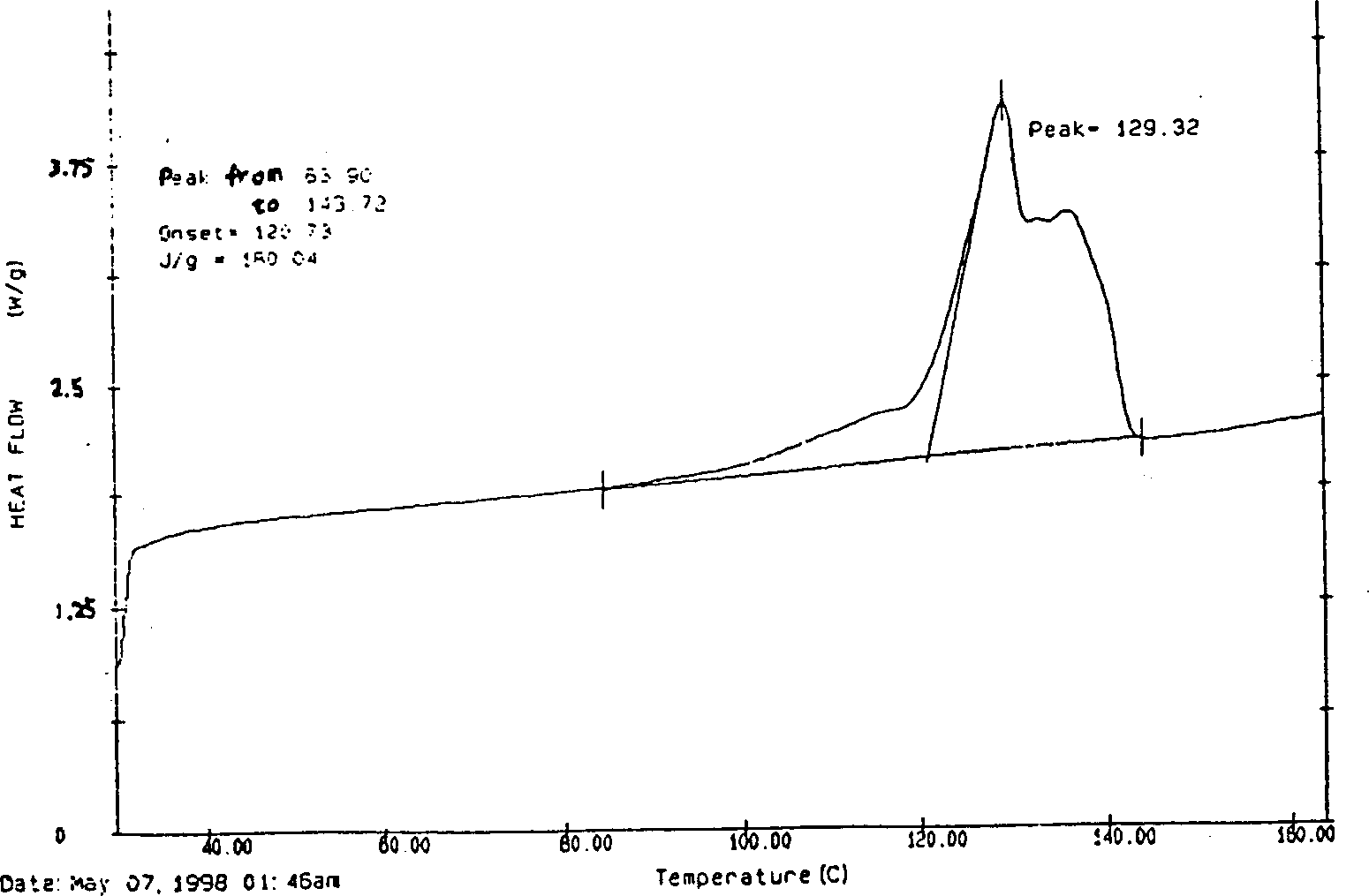

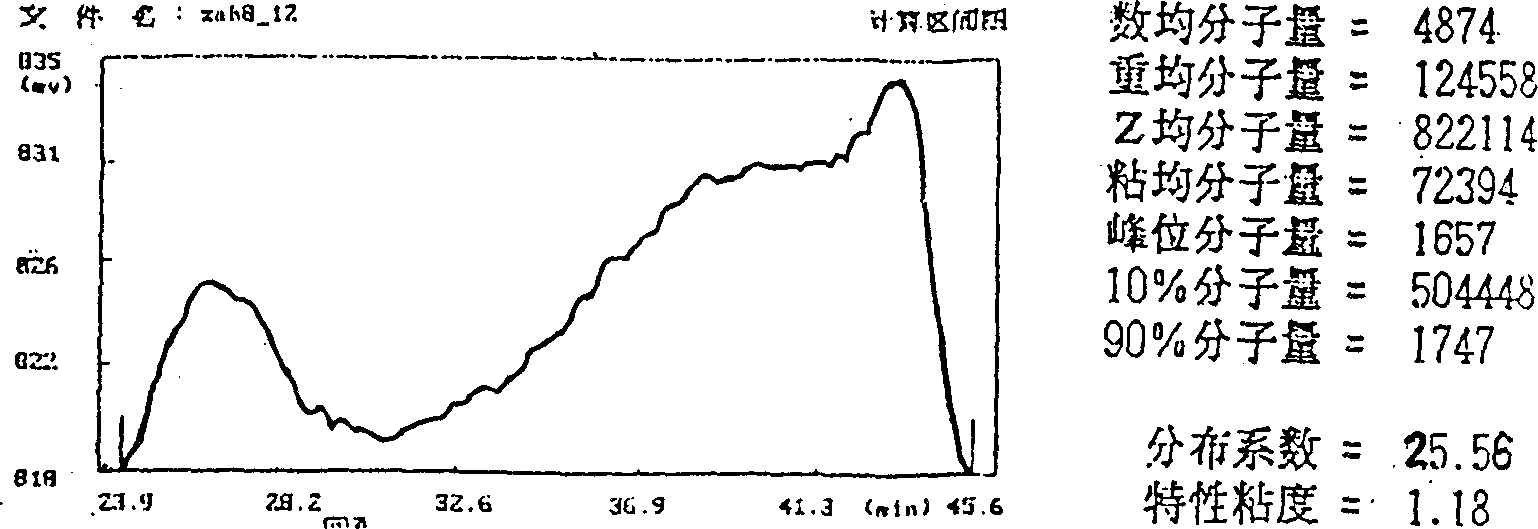

[0026] Embodiment 3 (1) Selection of the catalyst system: the titanium-containing active component is prepared according to the method and conditions disclosed in Example 7 in the specification of Chinese Patent 85100997.2 to obtain a solid catalyst wherein the titanium content is 2.20%, and the magnesium content is 17.86%. The chlorine content is 59.34%, and the ester content is 5.9%. (2) Ethylene polymerization: Carry out ethylene polymerization in the same way as in Example 2, and the results are listed in Table 1. (3) Polymer test: polymer apparent density BD is 0.30g / cm 3 , the catalyst efficiency is 100kg polymer / g titanium. On the Waters150C instrument made in the United States, the molecular weight and molecular weight distribution of the product are tested. The number average molecular weight of the polymer is 2980, and the product is bimodal. In addition, the PERKIN-ELMER differential thermal scanning A scan was made on the calorimeter DSC7, and the melting points w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com