A special formaldehyde-free sizing agent for mineral wool and its test method

A sizing agent and mineral wool technology, applied in the direction of acidic copolymer adhesives, measuring devices, adhesive types, etc., can solve the problems of sticking rollers, low initial tack, high initial tack, etc., and achieve simple test methods and test high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

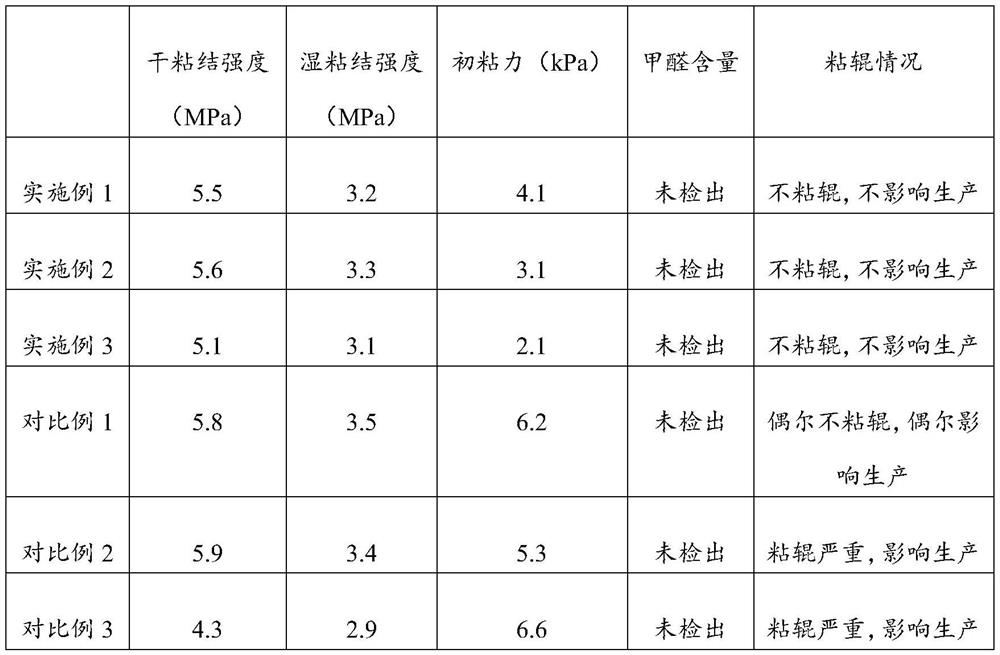

Embodiment 1

[0040] Embodiment 1 sizing agent is used for the test experiment of glass wool

[0041] Calculated according to the solid content of 100, take 80 parts of polyacrylic acid polymer with a number average molecular weight of 2500, 20 parts of glycerin, and 0.2 parts of glycerol polyether-12, and mix them with an appropriate amount of water to test the initial tack and dry- wet bond strength.

[0042] Use the setting agent ratio of the above example 1, add an appropriate amount of coupling agent, dustproof oil, water repellent and add an appropriate amount of water according to the process needs, mix evenly and spray the glue evenly on the centrifugal fiber, collect the cotton and solidify Forming to obtain glass wool, and test the performance of glass wool according to GB / T 13350-2017 "Glass Wool for Thermal Insulation and Its Products".

Embodiment 2

[0043] Embodiment 2 setting agent is used for the test experiment of rock wool

[0044] Based on the solid content of 100, take 90 parts of polyacrylic acid-methyl acrylate polymer with number average molecular weight of 1000 (acrylic acid:methyl acrylate monomer component ratio is 60:40), 1,4-butanediol 10 part, 0.1 part of coconut oil fatty acid diethanolamide, mixed evenly with an appropriate amount of water, and tested the initial tack and dry-wet bond strength of the sizing agent respectively.

[0045] Use the setting agent ratio of the above-mentioned Example 1, add an appropriate amount of coupling agent, dustproof oil, water repellent and add an appropriate amount of water according to the needs of the process, mix evenly and spray the glue evenly on the centrifugal basalt fiber, collect cotton After solidification and molding, rock wool is obtained, and the performance of rock wool is tested according to GB / T 19686-2015 "Rock Wool Thermal Insulation Products for Build...

Embodiment 3

[0046] Embodiment 3 sizing agent is used for the test test of mineral wool

[0047] Calculated according to the solid content of 100, take 60 parts of polyacrylic acid-maleic anhydride polymer with a number average molecular weight of 5000 (the monomer component ratio of acrylic acid: maleic anhydride is 55:45), 40 parts of trimethylolpropane, Mix 0.5 part of alkoxylated polyethyleneimine with an appropriate amount of water, and test the initial tack and dry-wet bond strength of the sizing agent respectively.

[0048] Use the sizing agent proportioning of above-mentioned embodiment 1, add appropriate coupling agent, anti-dust oil again, water-repellent and add appropriate amount of water according to process needs, mix evenly and glue is evenly sprayed in centrifugal slag cotton fiber, collect The cotton is solidified and formed to obtain slag wool, and the performance of the slag wool is tested according to GB / T 11835-2016 "Rock wool, slag wool and their products for thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com