Patents

Literature

30results about How to "Without spoiling the flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process fr processing mushroom instant food

InactiveCN1531869AWithout spoiling the flavorProtect NutrientsFood preservationFood preparationFlavorConvenience food

The production process of instant mushroom food includes washing fresh mushroom as material, sterilizing with ozone solution, pickling and hardening with low concentration sodium chloride and calcium chloride solution, seasoning and pickling, vacuum packing, microwave cooking and sterilizing. The production process has no damage to the flavor of mushroom food and most of the nutrient components maintained, and the product may be stored, transported and sold and has storage period up to 6 months.

Owner:福建超大现代农业集团有限公司

Production process for blueberry fruit wine

InactiveCN104893892ARich in nutrientsWithout spoiling the flavorAlcoholic beverage preparationFruit wineCold treatment

The invention discloses a production process for the blueberry fruit wine, and belongs to the manufacturing technical field of the blueberry fruit wine, which mainly comprises the steps of firstly, sorting and cleaning raw materials; secondly, crushing raw materials; thirdly, deploying components: dissolving white sugar and honey, and blending the white sugar and the honey in a blending pot; fourthly, conducting the primary fermentation: adding and inoculating the microzyme in the obtained blending slurry, stirring evenly the blueberry fruit pulp, and hermetically fermenting the pulp; fifthly, filtering; sixthly, conducting the secondary fermentation: fermenting the filtrated raw wine, obtained in the fifth step, for a second time; seventhly, ageing and clearing up the raw wine; eighthly, conducting the cold treatment in the directly freezing manner; ninthly, sterilizing and packaging. According to the invention, the production process for the blueberry fruit wine is realized through the fermentation treatment for two times, and the sterilization is conducted after the cold treatment. In this way, on the premise that the flavor and the nutritional substances of the blueberry fruit wine are prevented from being destroyed, the problem that the blueberry fruit wine easily gets turbid and tastes abnormal can be solved.

Owner:李辉

Process for producing mushroom concentrated juice

InactiveCN101991091AWithout spoiling the flavorReserve the tasteFood preparationShiitake mushroomsCentrifugal separation

The invention discloses a process for producing mushroom concentrated juice which has the advantages of convenience of production, no enzymic preparation addition, short production cycle, mushroom taste reservation and convenience of conservation. The process comprises the steps of: leaching mushroom handles or refuse parts, filtering, performing centrifugal separation, oscillation filtering and vacuum low-temperature instantaneous concentration, sterilizing the concentrated liquid, and filling, cooling and refrigerating.

Owner:FUJIAN CHANGLYU FOOD & BEVERAGE CO LTD

Preparation method of vitamin A microcapsule nutrition enhancer for beverage

ActiveCN102224934AImprove the ability to resist the external environmentImprove antioxidant capacityFood shapingFood preparationSolubilityFlavor

The invention relates to a preparation method of a vitamin A microcapsule nutrition enhancer for a beverage. The method comprises the following steps of: first, preparing vitamin A palmitate and an anti-oxidant into a vitamin A palmitate oil solution containing anti-oxidant in an anaerobic state; then adding sodium caseinate, maltodextrin and white sugar into purified water which has been deoxidized through a thermal spray deoxygenator, and dissolving by heating; mixing dissolved vitamin A palmitate oil and the sodium caseinate solution, emulsifying under an anaerobic condition, and homogenizing 3-5 times; carrying out hot air spray drying on the emulsion to obtain a vitamin A microcapsule. A product prepared by the invention can be used as a nutrition enhancer for a beverage. The product can not be destroyed during beverage processing and will not influence mouthfeel flavor of the beverage; besides the prepared product has good dissolvability and stable quality in beverage, and performance of the product will not change after one year storage.

Owner:泉州雷恩生化有限公司

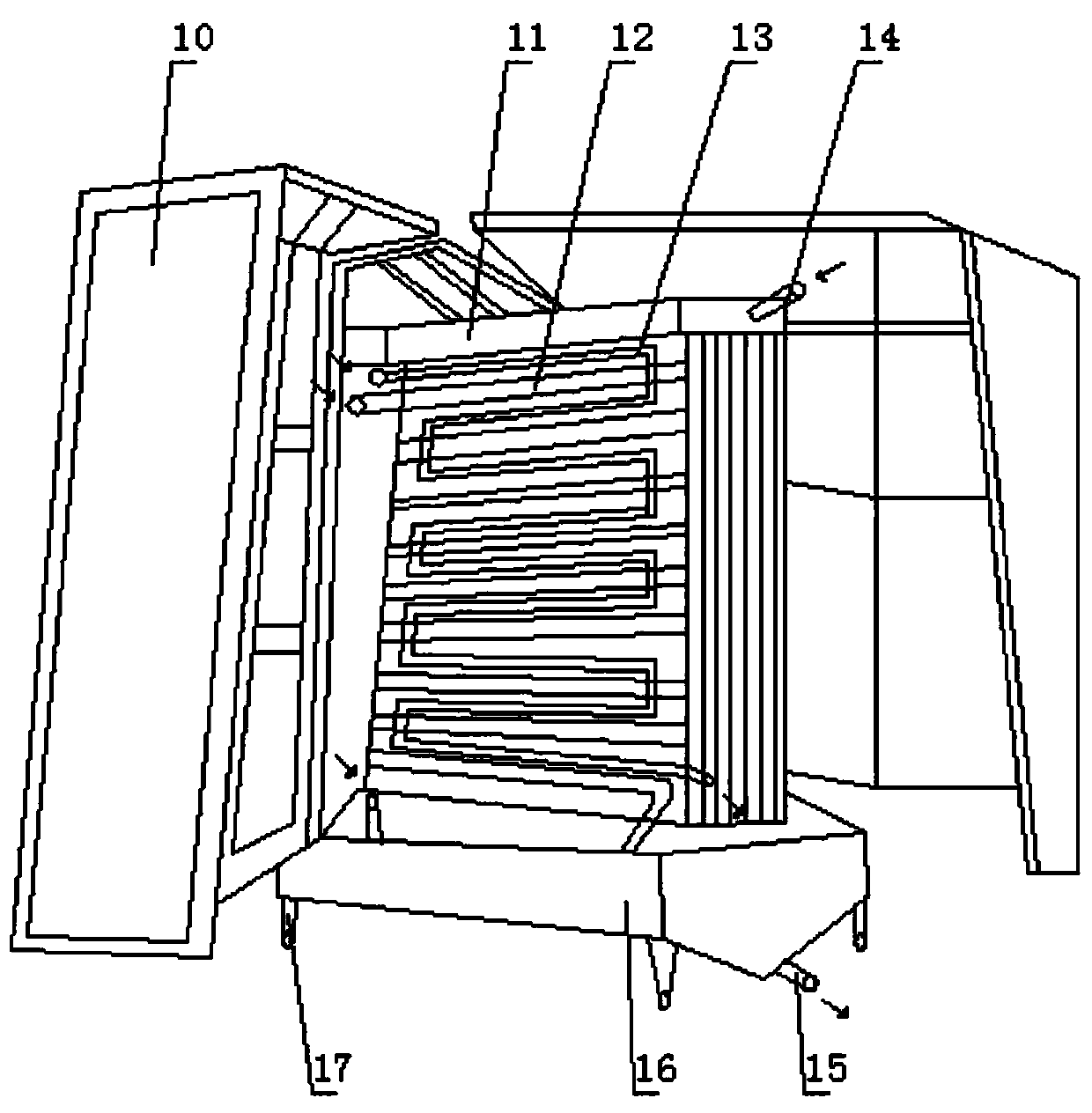

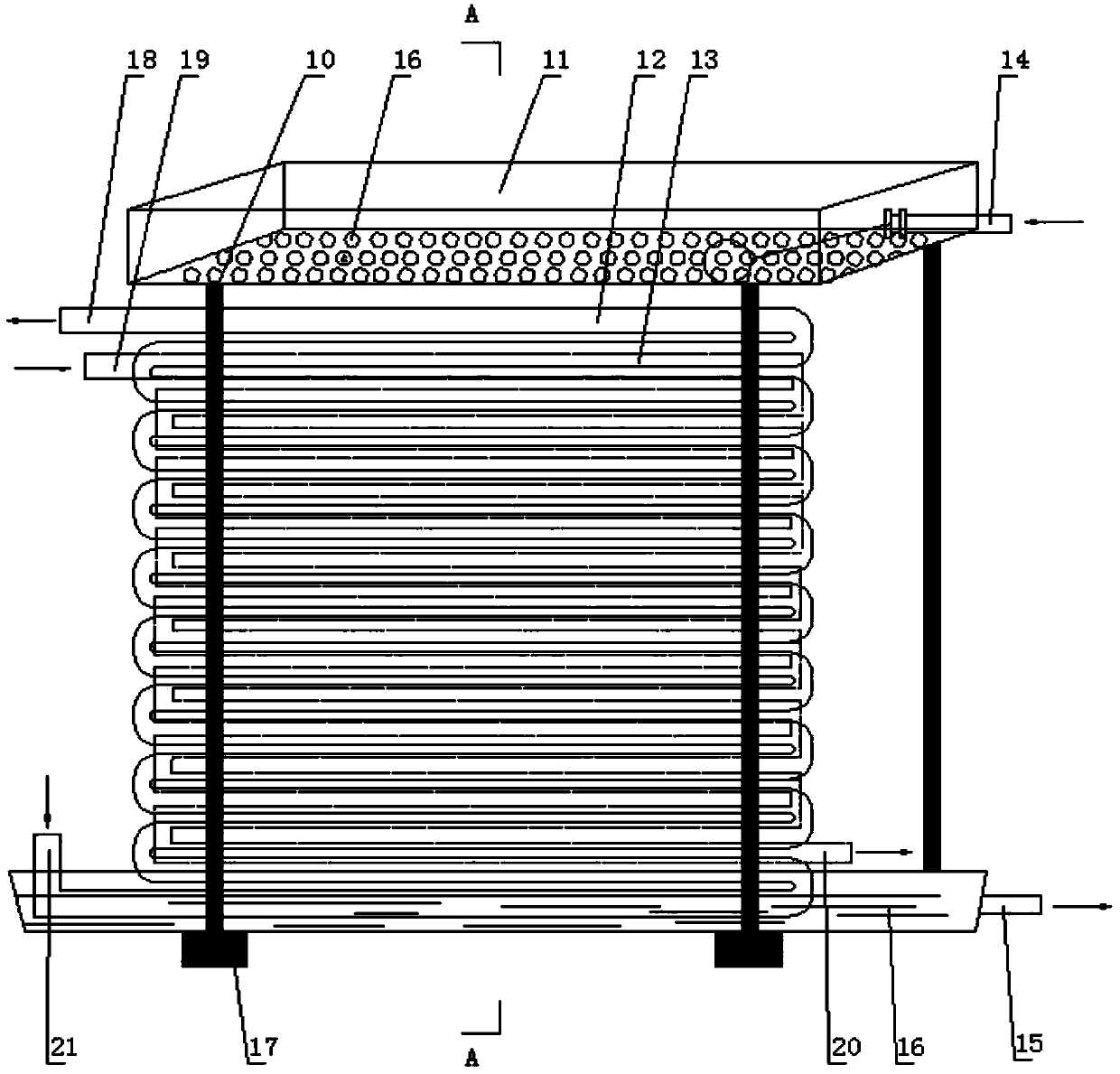

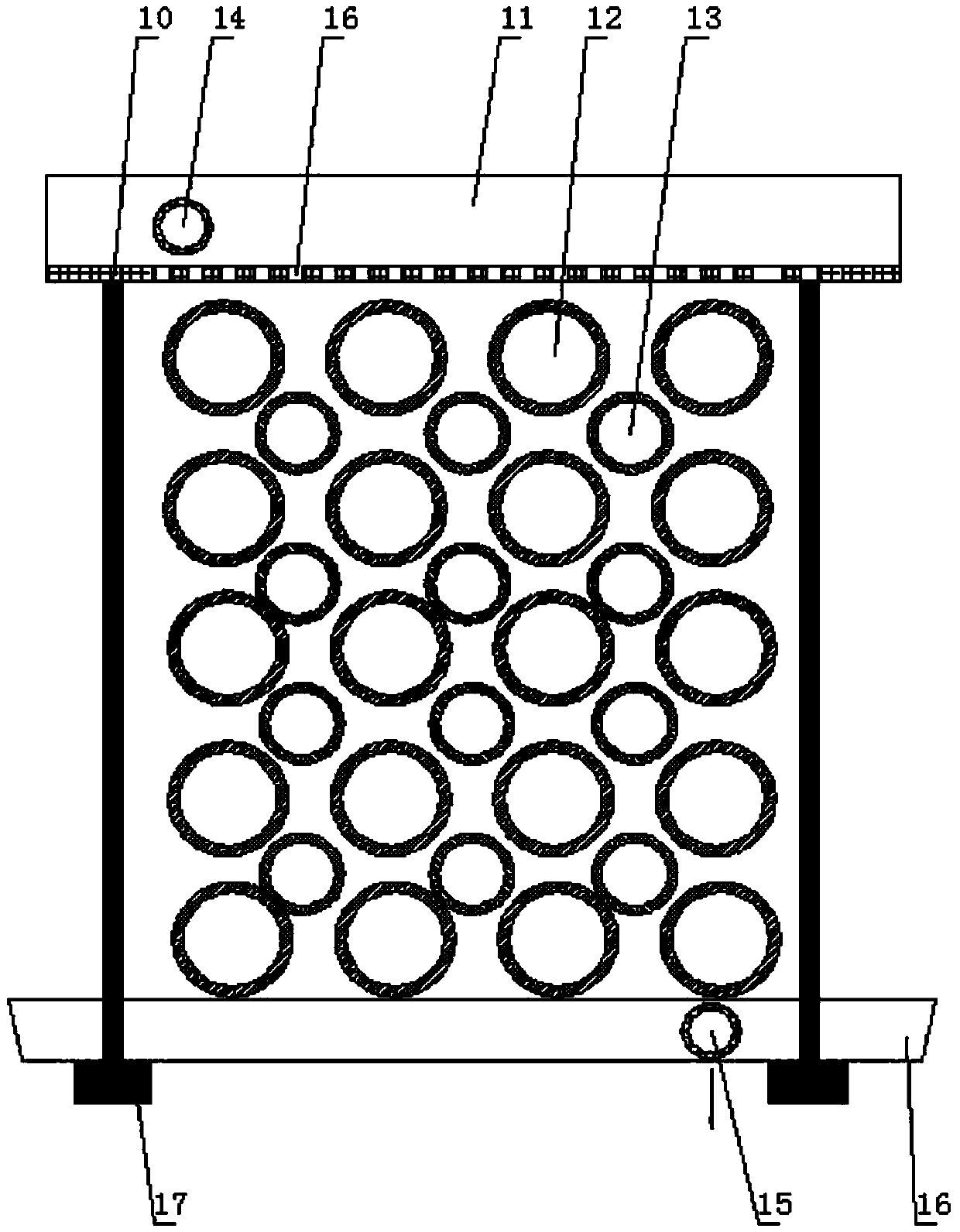

Processing method and equipment for performing safe fresh keeping on raw sliced fish and sliced meat

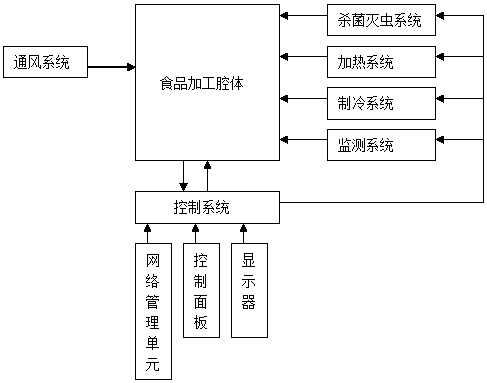

PendingCN108157482AThe condition is not damagedNot spoil the tasteFood thermal treatmentMeat/fish preservation by heatingFlavorControl system

The invention discloses a food processing method and equipment capable of performing safe fresh keeping on raw sliced fish and sliced meat and quickly killing pathogenic bacteria and parasites. The equipment mainly comprises a food processing cavity, a control system, a sterilizing and parasite killing system, a heating system, a refrigeration system, a monitoring system and a power system, is mainly applied to fresh food materials of the raw sliced fish, the sliced meat or fruits and vegetables and the like, and can quickly kill pathogenic bacteria and the parasite in the fresh food materials. While in use, foods to be processed are placed in the food processing cavity and are processed according to requirements; sterilizing and parasite killing are performed through corresponding operations; and the change of temperature of the foods is controlled and managed, so as to obtain better condition, better mouth feel and better flavor of foods. I In addition, the operating power and the operating manner of each system can be intelligently adjusted by the equipment disclosed by the invention through monitoring the change of the state in the course of processing the food materials, so that the effect of performing sterilizing and parasite killing on different bacterium species and different parasites of the different food materials is achieved; the equipment is safe and hygienic; andbesides, the purposes that the condition, the mouth feel and the flavor of the foods are maintained is achieved.

Owner:GUANGXI NQT ELECTRONICS TECH CO LTD

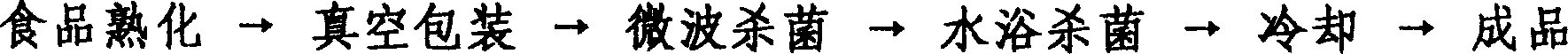

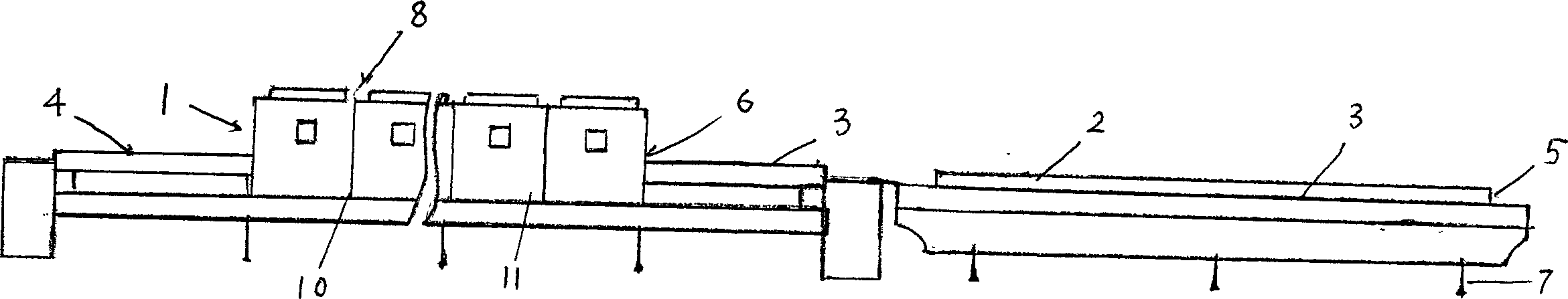

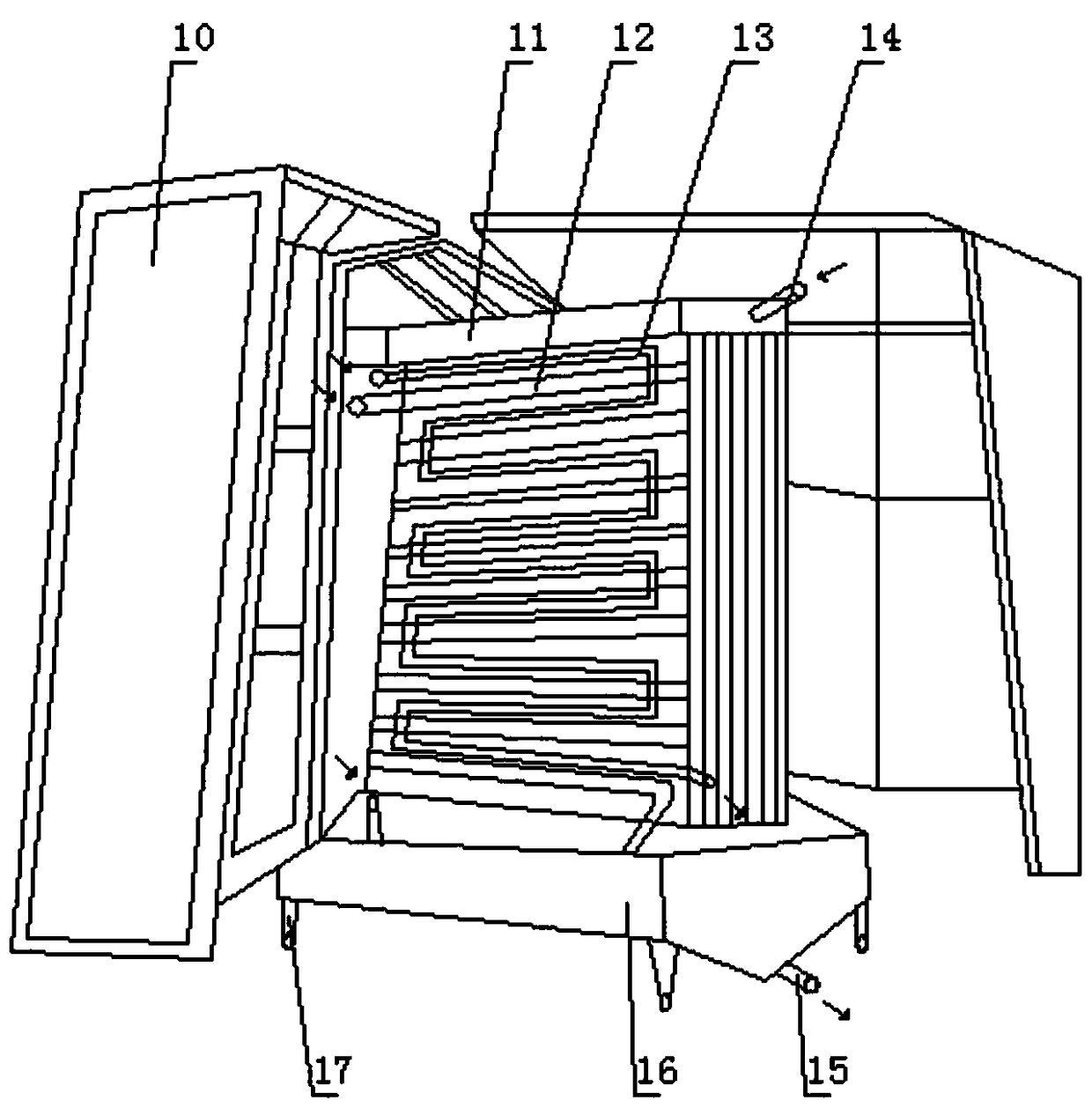

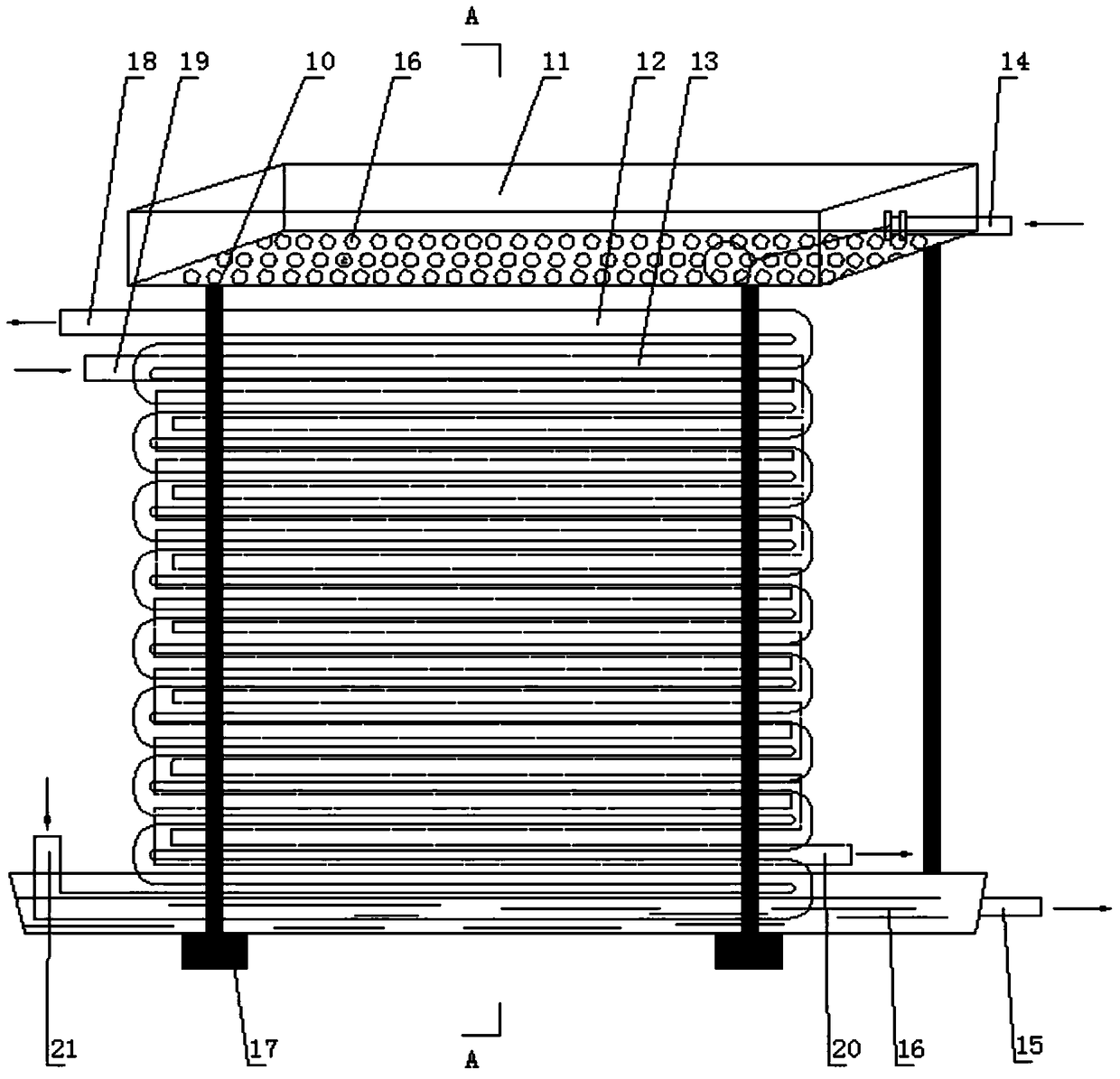

Non - high temperature method for sterilizing and preserving cooked product, and equipment

InactiveCN1871950AMeet the needs of production and operationWithout spoiling the flavorFood preservationWater bathsMicrowave

An sterilizing and antistaling method without high temp for the cooked food includes such steps as vacuum packing, microwaving sterilizing at 85-100 deg.C for 1-40 min, sterilizing by water bath at 85-100 deg.C for 1-40 min, and cooling. Its apparatus is composed of conveying belt, microwave unit, water bath unit, and automatic control system consisting of infrared probe, temp control meter and computer.

Owner:吴永年 +1

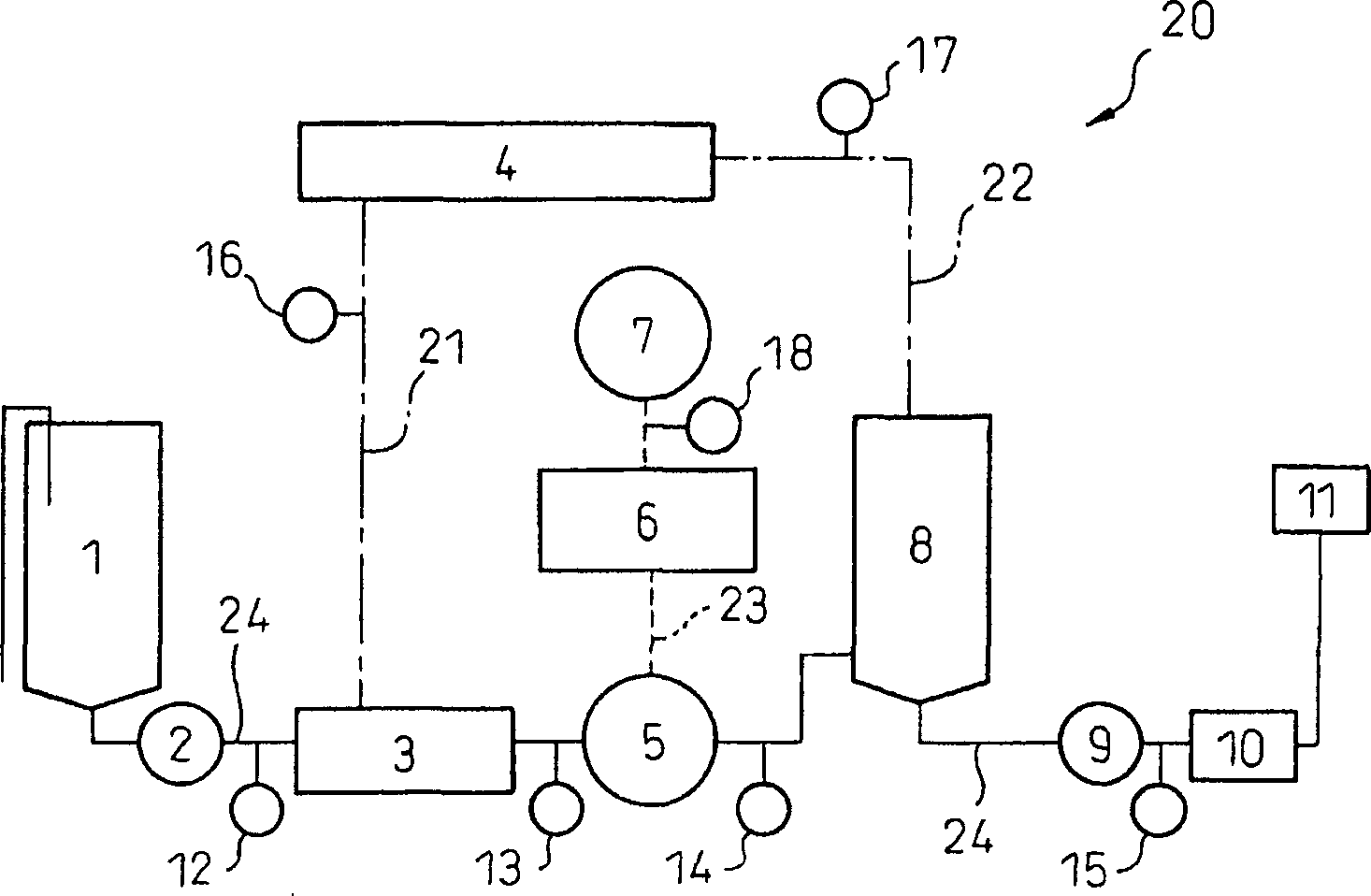

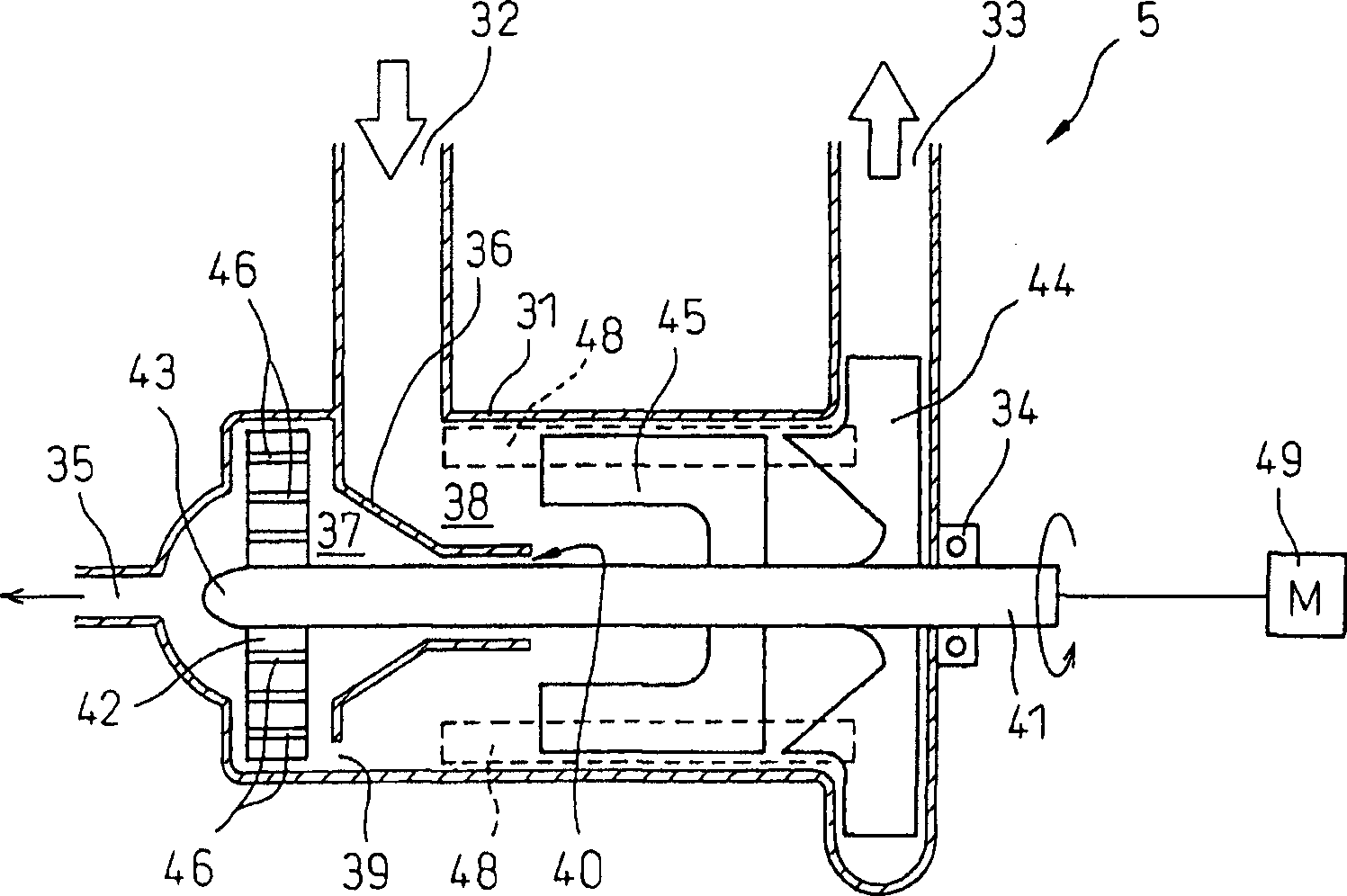

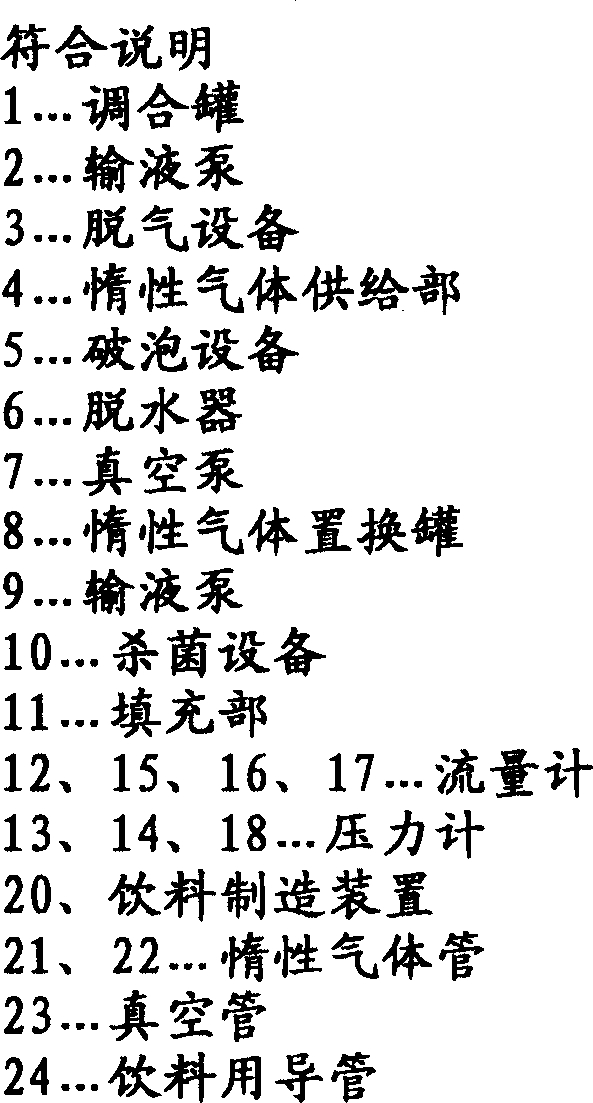

Method and apparatus for manufacturing beverage

InactiveCN1863465AReduce dissolved gasReduce dissolved oxygenLiquid degasification with auxillary substancesBeverage vesselsFlavorManufactured apparatus

A method and an apparatus for manufacturing a beverage capable of eliminating air bubbles formed in the beverage without impairing the flavor of the beverage. The beverage manufacturing apparatus (20) comprises a beverage deaerating means (3) and a bubble breaking means (5), and these manufacturing method uses the beverage manufacturing apparatus. The apparatus may comprise a beverage sterilizing means (10). The deaerating means may comprise at least one of a deaerator, an inert gas stripping part, and a static mixer, and the bubble breaking means may be a pump capable of breaking the film of air bubbles. In addition, the amount of dissolved oxygen in the beverage after air bubbles are broken is desirably 0.5 ppm or below.

Owner:SUNTORY HLDG LTD

Method for preparing grape wine rich in gamma-aminobutyric acid

InactiveCN101633874AWithout spoiling the flavorWith health functionMicroorganism based processesWine preparationFreeze-dryingGrape wine

The invention provides a method for preparing grape wine rich in gamma-aminobutyric acid. The invention belongs to the technical field of wine brewing, which in particular relates to a method for preparing health-care grape wine. On the basis of the traditional brewing technique of claret, an MRS culture medium, saccharification liquid and yeast slurry are utilized to culture and obtain lactobacillus brevis. Then, a lactobacillus brevis yeast starter obtained by centrifugation and freeze drying and active alcoholic wine cocci are added into the apple emulsion fermentation stage of the claret together. Gamma-aminobutyric acid fermentation 2d is carried out, malic acid-lactic acid fermentation 5d is carried out below 20 DEG C, and the gamma-aminobutyric acid fermentation 2d and the malic acid-lactic acid fermentation 5d are both carried out under a closed condition. The content of the gamma-aminobutyric acid of a finished product of the grape wine is 1g / L (the content of the gamma-aminobutyric acid in the existing finished product wine is 0.05-0.1g / L), the vinosity is delicate and mellow, the fragrance is elegant and noble, and the finished product of the grape wine is in a clear ruby-red color.

Owner:TIANJIN VOCATIONAL INST

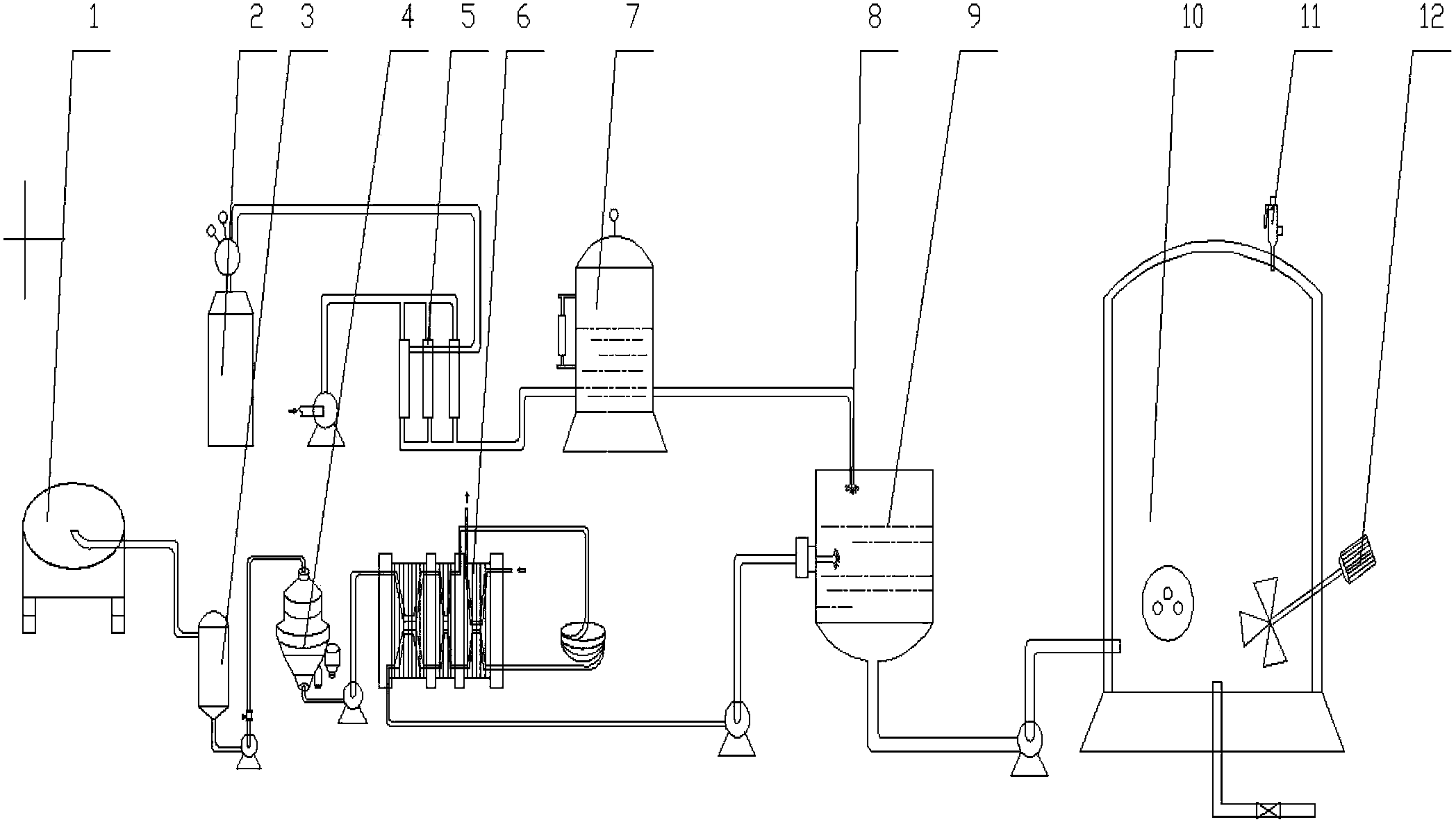

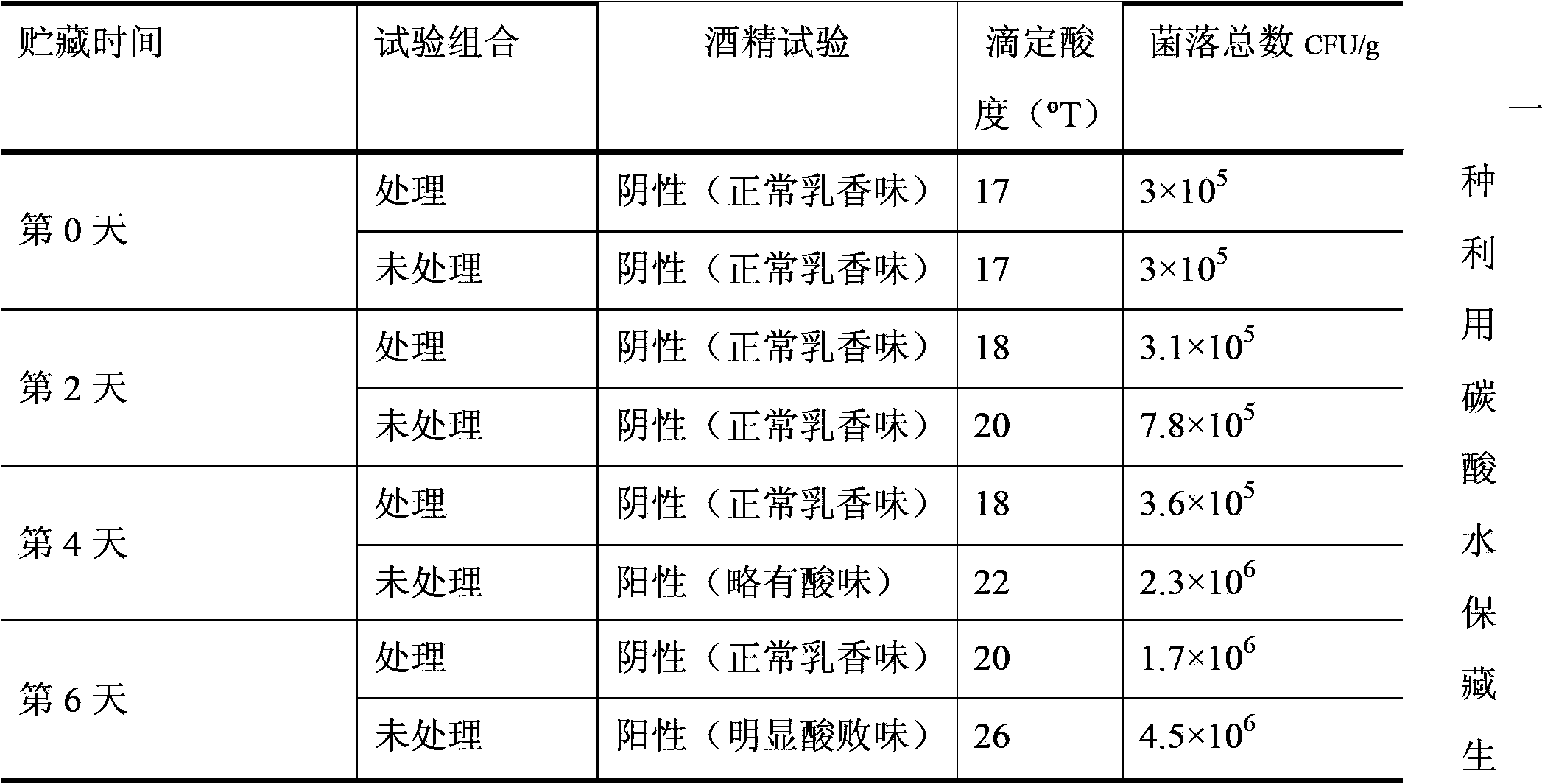

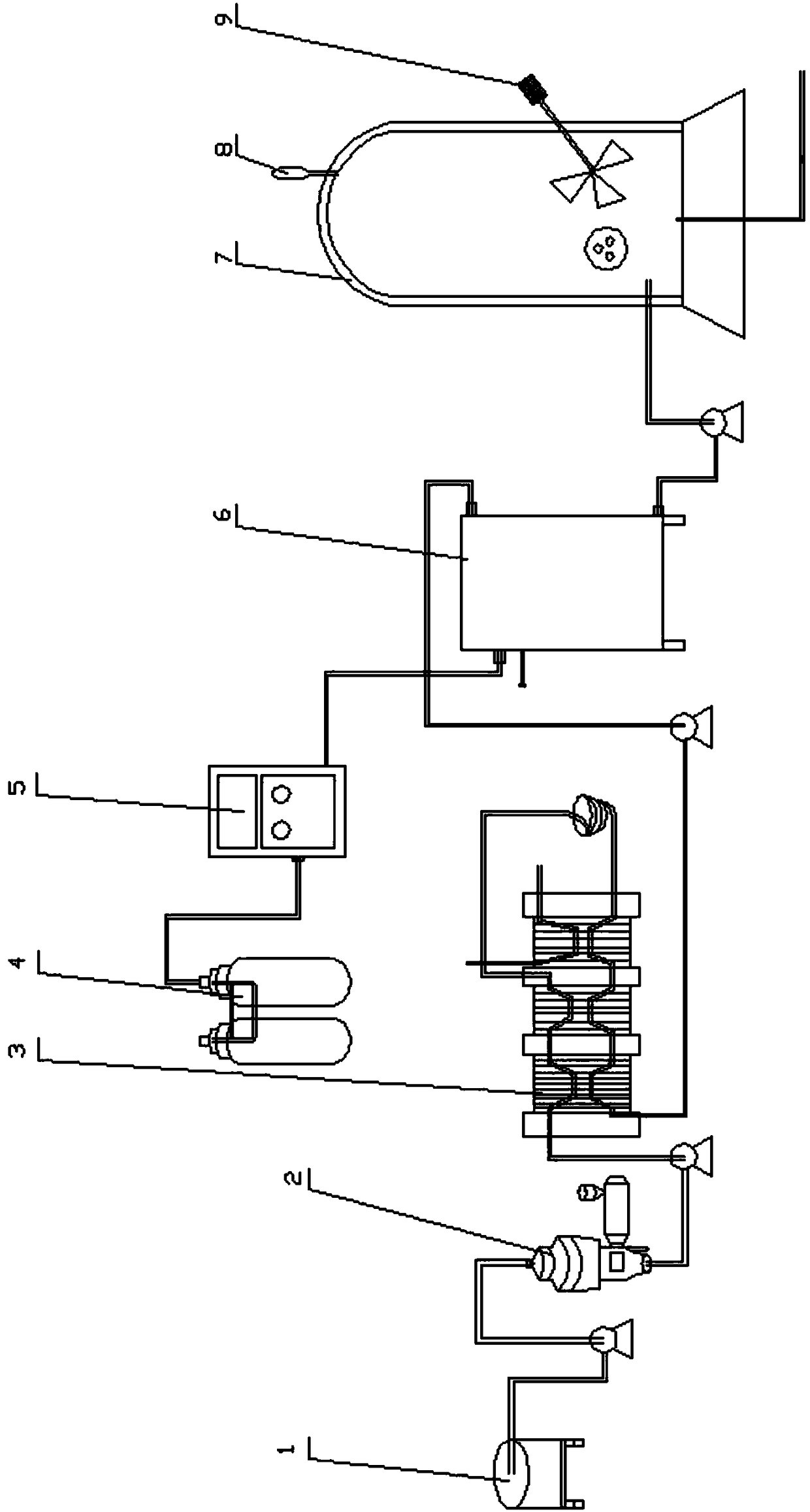

Method and system of using carbonated water for preserving raw milk

ActiveCN102907492ADo not destroy ingredientsWithout spoiling the flavorMilk preservationProduct gasPasteurization

The invention relates to a method of using carbonated water for preserving raw milk. The method is performed in a system and includes the specific steps of (1) carbonation of water by mixing CO2 gas subjected to purification treatment with water subjected to sterile cooling, so that carbonated water saturated solution is obtained; (2) raw milk pretreatment by means of raw milk degasification, centrifugal raw milk purification and pre-pasteurization; and (3) spraying of the carbonated water to raw milk by spraying the carbonated water in the step (1) into the raw milk in the step (2), and uniformly mixing so that the raw milk prepared by the carbonated water preserving method is obtained. By the method of using the carbonated water for preserving the raw milk, the used carbonated water which is liquid is extremely easily mixed with the raw milk and can be well and uniformly mixed with the raw milk, and the addition quantity of the carbonated water can be flexibly adjusted according to different processing products, so that waste caused by escape of the CO2 gas can be avoided. The method is simple and easy to operate, preserving and processing costs are saved, and production efficiency of enterprises is improved. Additionally, the method is not high in requirements on cooling pressurization and spraying equipment and suitable for popularization of large-scale production of the enterprises.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of pomegranate powder

InactiveCN103704621AImprove solubilityWithout spoiling the flavorFood shapingFood preparationMaterials preparationSpray dryer

The invention provides a preparation method of pomegranate powder. The method comprises: (1) a step of material preparation, wherein ripe pomegranate is used as a raw material, and a raw pomegranate juice is obtained by a technology of sorting, peeling, squeezing and filtering; and (2) a step of powder preparation, wherein auxiliary materials weight of which accounts for 5-20% of the weight of the obtained pomegranate juice is added into the pomegranate juice, the auxiliary materials and the pomegranate juice are mixed uniformly and subjected to spray drying, the air feeding temperature is controlled to be 100-170 DEG C, the wind discharging temperature is 60-100 DEG C, the negative pressure of the spray drying is controlled to be -5-10 Pa, and spray-dried objects, namely products of the pomegranate powder, are collected. According to the preparation method, the natural pomegranate is used as the main raw material to obtain the raw pomegranate juice, and the natural pomegranate powder is produced by utilization of a spray drying process. Wall hanging and retention of the pomegranate juice in the spray dryer are avoided by addition of the auxiliary materials, and therefore the production is guaranteed to be completed successfully.

Owner:上海多普富生物科技有限公司

Preparation method of vitamin A microcapsule nutrition enhancer for beverage

ActiveCN102224934BImprove the ability to resist the external environmentImprove antioxidant capacityFood shapingFood preparationSolubilityEmulsion

The invention relates to a preparation method of a vitamin A microcapsule nutrition enhancer for a beverage. The method comprises the following steps of: first, preparing vitamin A palmitate and an anti-oxidant into a vitamin A palmitate oil solution containing anti-oxidant in an anaerobic state; then adding sodium caseinate, maltodextrin and white sugar into purified water which has been deoxidized through a thermal spray deoxygenator, and dissolving by heating; mixing dissolved vitamin A palmitate oil and the sodium caseinate solution, emulsifying under an anaerobic condition, and homogenizing 3-5 times; carrying out hot air spray drying on the emulsion to obtain a vitamin A microcapsule. A product prepared by the invention can be used as a nutrition enhancer for a beverage. The product can not be destroyed during beverage processing and will not influence mouthfeel flavor of the beverage; besides the prepared product has good dissolvability and stable quality in beverage, and performance of the product will not change after one year storage.

Owner:泉州雷恩生化有限公司

Green environment-friendly modified starch and preparation method thereof

InactiveCN109770334ASimple reaction conditionsImprove reaction efficiencyFood scienceGreen environmentMonoglyceride

The invention discloses green environment-friendly modified starch and a preparation method thereof. The green environment-friendly modified starch comprises the following raw materials by mass percentage: 8-12% of original starch, 30-40% of esterified starch, 5-8% of goat milk protein, 3-6% of sucrose ester, 5-10% of monoglyceride, 2-4% of methyl benzoate, 5-8% of selenium-enriched yeast, 6-8% ofproanthocyanidins, and 4-6% of carrageenan. The modified starch prepared by the method of the invention has high viscosity and good elasticity of paste liquid, and can improve the health of the food.

Owner:GUANGXI GAOYUAN STARCH

Method for preserving raw milk by using nitrogen, and system thereof

ActiveCN103988901ADo not destroy ingredientsWithout spoiling the flavorMilk preservationCow milkingSingle substance

The invention relates to a method for preserving raw milk by introducing nitrogen to the raw milk. The method concretely comprises the following steps: preparing nitrogen by using air, and carrying out purifying treatment on the prepared nitrogen; carrying out centrifuge purifying treatment on the raw milk, and pre-pasteurizing; and introducing nitrogen to discharge oxygen dissolved in the raw cow milk in order to nitrogen filled cow milk. Nitrogen used in the preservation number of the raw milk accounts for 78% of the volume of air, exists in air in a single substance form, is inexhaustible, is a colorless, nontoxic and tasteless inert gas, is highly safe, and can be well and uniformly mixed with the raw milk, and the introduction amount of nitrogen can be flexibly adjusted according to the difference of processing products. The method has the advantages of simplicity, easy operation, preservation and processing cost saving, improvement of the production efficiency of an enterprises, and low requirements on equipment, and is suitable for the large scale production popularization of the enterprise.

Owner:天津海河乳品有限公司

Method and system of using carbonated water for preserving raw milk

ActiveCN102907492BDo not destroy ingredientsWithout spoiling the flavorMilk preservationProcess engineeringEnvironmental engineering

The invention relates to a method of using carbonated water for preserving raw milk. The method is performed in a system and includes the specific steps of (1) carbonation of water by mixing CO2 gas subjected to purification treatment with water subjected to sterile cooling, so that carbonated water saturated solution is obtained; (2) raw milk pretreatment by means of raw milk degasification, centrifugal raw milk purification and pre-pasteurization; and (3) spraying of the carbonated water to raw milk by spraying the carbonated water in the step (1) into the raw milk in the step (2), and uniformly mixing so that the raw milk prepared by the carbonated water preserving method is obtained. By the method of using the carbonated water for preserving the raw milk, the used carbonated water which is liquid is extremely easily mixed with the raw milk and can be well and uniformly mixed with the raw milk, and the addition quantity of the carbonated water can be flexibly adjusted according to different processing products, so that waste caused by escape of the CO2 gas can be avoided. The method is simple and easy to operate, preserving and processing costs are saved, and production efficiency of enterprises is improved. Additionally, the method is not high in requirements on cooling pressurization and spraying equipment and suitable for popularization of large-scale production of the enterprises.

Owner:山东百慧乳业股份有限公司

Braised bone-in pork capable of being stored and transported in refrigeration and ready to eat by microwaving and preparation method of braised bone-in pork

InactiveCN105661339AWithout spoiling the flavorExtended shelf lifeFood scienceReady to eatAdditive ingredient

The invention discloses braised bone-in pork capable of being stored and transported in refrigeration and ready to eat by microwaving and a preparation technology of the braised bone-in pork.The braised bone-in pork is prepared from a main ingredient and minor ingredients, wherein bone-in streaky pork with the skin is used as the main ingredient.The braised bone-in pork is characterized in that taking the total mass of the main ingredient as a base, the minor ingredients include, by mass, 80%-90% of pure water, 73%-85% of yellow rice, 2.5%-5.0% of fresh ginger, 4.0%-8.0% of fresh shallot, 7.5%-9.0% of white sugar, 0.20%-0.5% of star anise, 1.0%-2.0% of tomato sauce, 12%-25% of soybean sauce, 0.2%-1.5% of oyster sauce, 3.5-7.0% of edible oil and 0.2%-2.2% of chicken essence.The braised bone-in pork has the advantages that through lean mixing of the formula, color, aroma, taste and shape of the Chinese traditional classical dish are guaranteed; through a set of innovative technological process and method, flavor of the braised bone-in pork is not destroyed, and shelf life of the braised bone-in pork can be prolonged to two years and even longer.

Owner:王溢炯 +1

Method for removing peculiar smell of pork intestines

InactiveCN108925818ASimple and efficient operationImprove efficiencyAnimal intestine cleaningChemistryFlavor

The invention relates to the technical field of food, and in particular, relates to a method for removing peculiar smell of pork intestines. The method is characterized by comprising the steps: bean dregs as a main component cooperate with various auxiliary components and are mixed and kneaded with the pork intestines, then the pork intestines are washed with water, and thus the peculiar smell ofthe pork intestines can be effectively removed and the unique flavor of the pork intestines is maintained. The strong adsorption capacity of bean dregs fibers is fully utilized to adsorb food residuesand peculiar smell substances of inner walls of the pig intestines, and the pork intestines are allowed to be clean and white. The method has simple operation, does not destroy the flavor of the porkintestines, can be used in mechanized production, and greatly improves the efficiency of removing the peculiar smell of the pork intestines.

Owner:HUBEI UNIV OF ARTS & SCI

A kind of method that hydrogen peroxide and ethanol remove rice blastin in rice protein under neutral conditions

ActiveCN105104920BWithout compromising qualityPromote decompositionFood ingredientsAlcoholRice protein

The invention discloses a method for desorbing isoprothiolane in rice protein through hydrogen peroxide and ethyl alcohol under a neutrality condition. The method comprises the following steps that firstly, treatment through hydrogen peroxide is carried out, wherein the rice protein with the isoprothiolane exceeding the standard and hydrogen peroxide with the mass concentration of 0.5-5% are mixed according to the weight ratio of 1:4-7, the pH is regulated to be 6.5-7.5, stirring treatment is carried out for 1-2 h, filtering is carried out, and filtering residues are obtained; secondly, treatment through ethyl alcohol is carried out, wherein the filtering residues obtained in the first step and an ethyl alcohol solution with the mass concentration higher than 60% are mixed according to the mass ratio of 1:4-7, stirring treatment is carried out for 1.5-2 h at the temperature of 35 DEG C-75 DEG C, filtering is carried out until the moisture is lower than 55%, and filtering residues are obtained; thirdly, post-treatment is carried out, wherein the filtering residues obtained in the second step are washed with water, dried and sterilized, the sterilized materials are smashed, and the rice protein with the isoprothiolane content lower than 10 ppb is obtained. By means of the method, the isoprothiolane desorbing rate can reach higher than 90%, the technology is simple, operation is convenient, and the method is suitable for mass production.

Owner:义乌市海之纳生物工程有限公司

Process for producing mushroom concentrated juice

InactiveCN101991091BWithout spoiling the flavorReserve the tasteFood preparationMushroomCentrifugal separation

Owner:FUJIAN CHANGLYU FOOD & BEVERAGE CO LTD

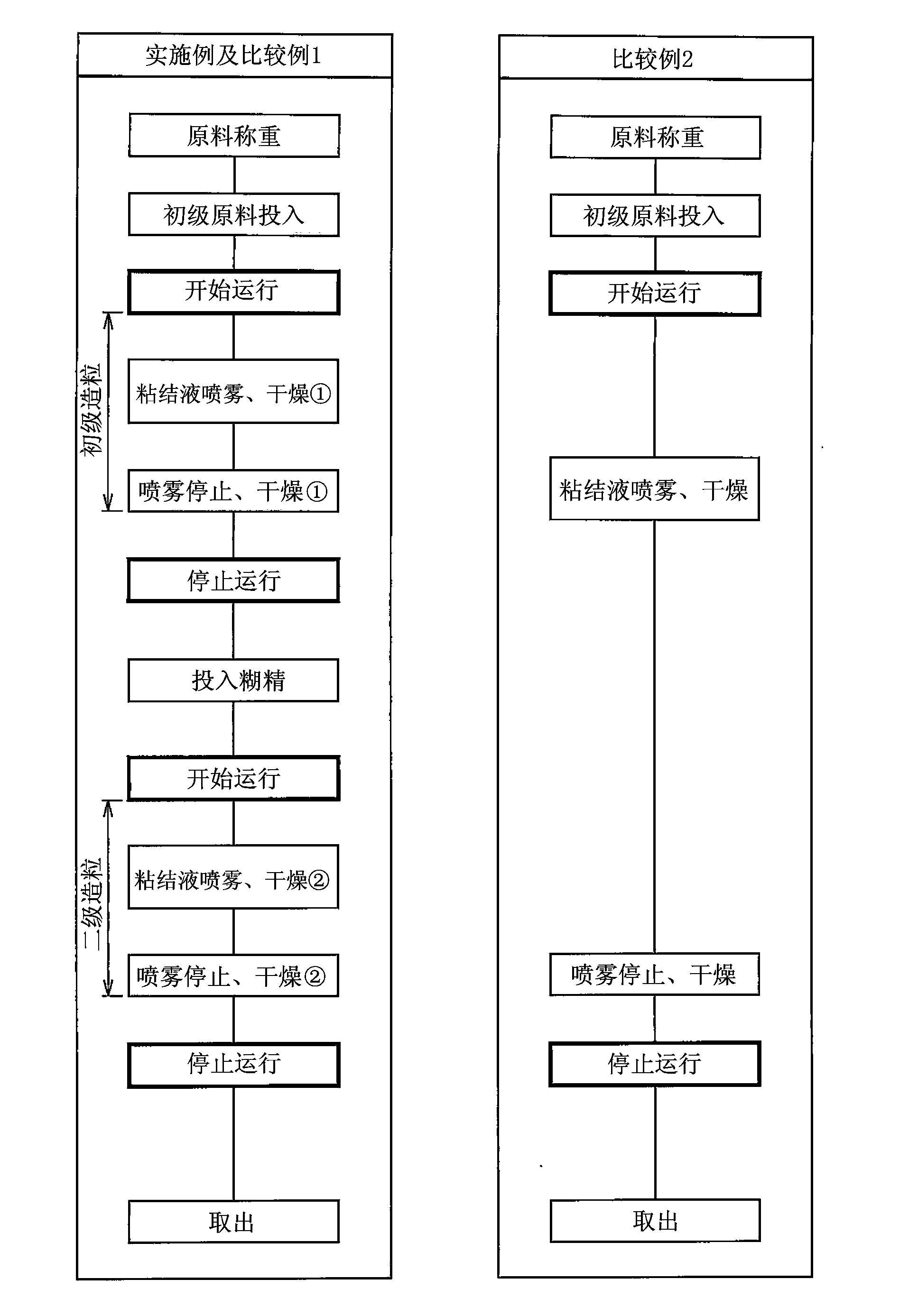

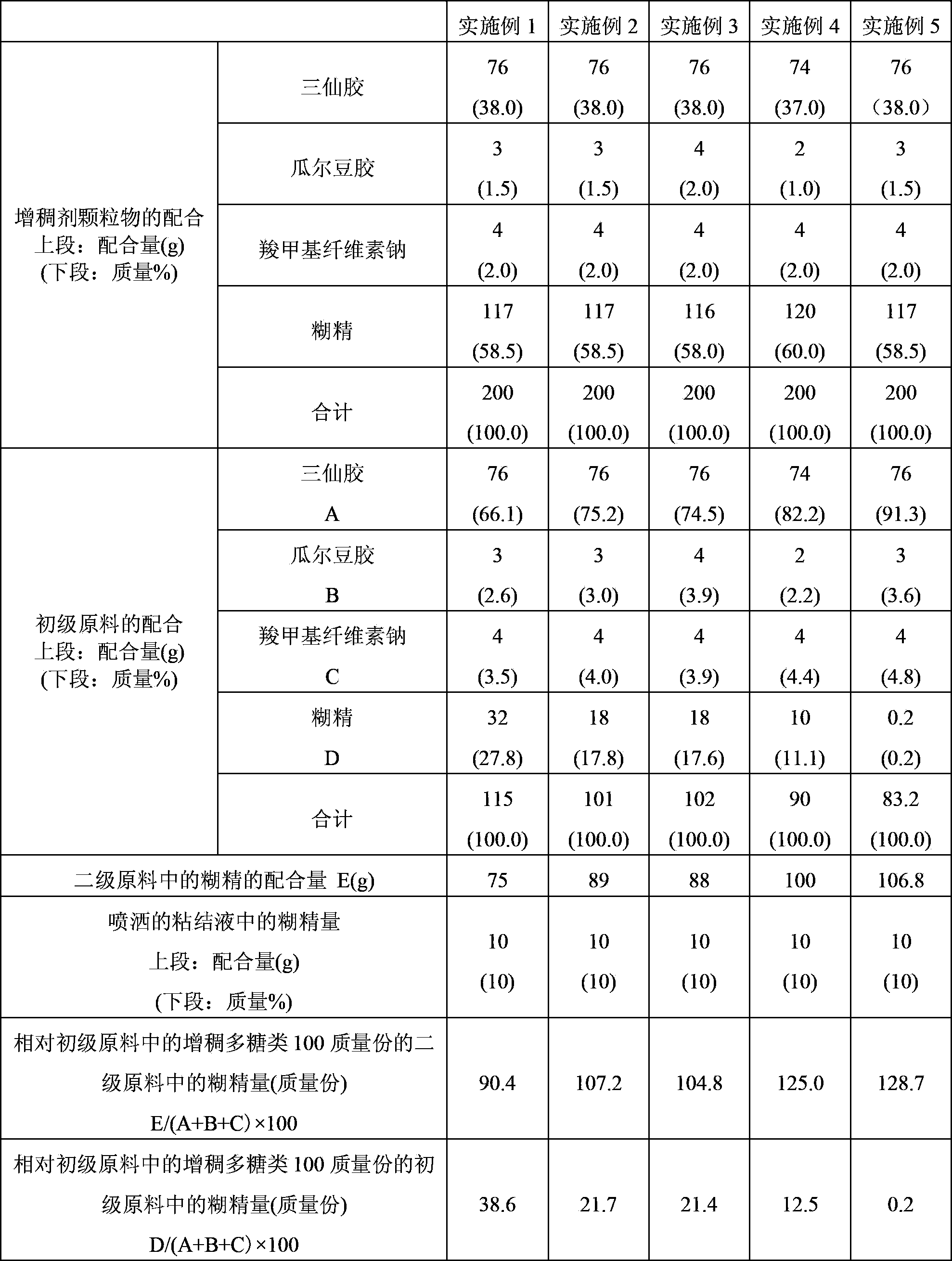

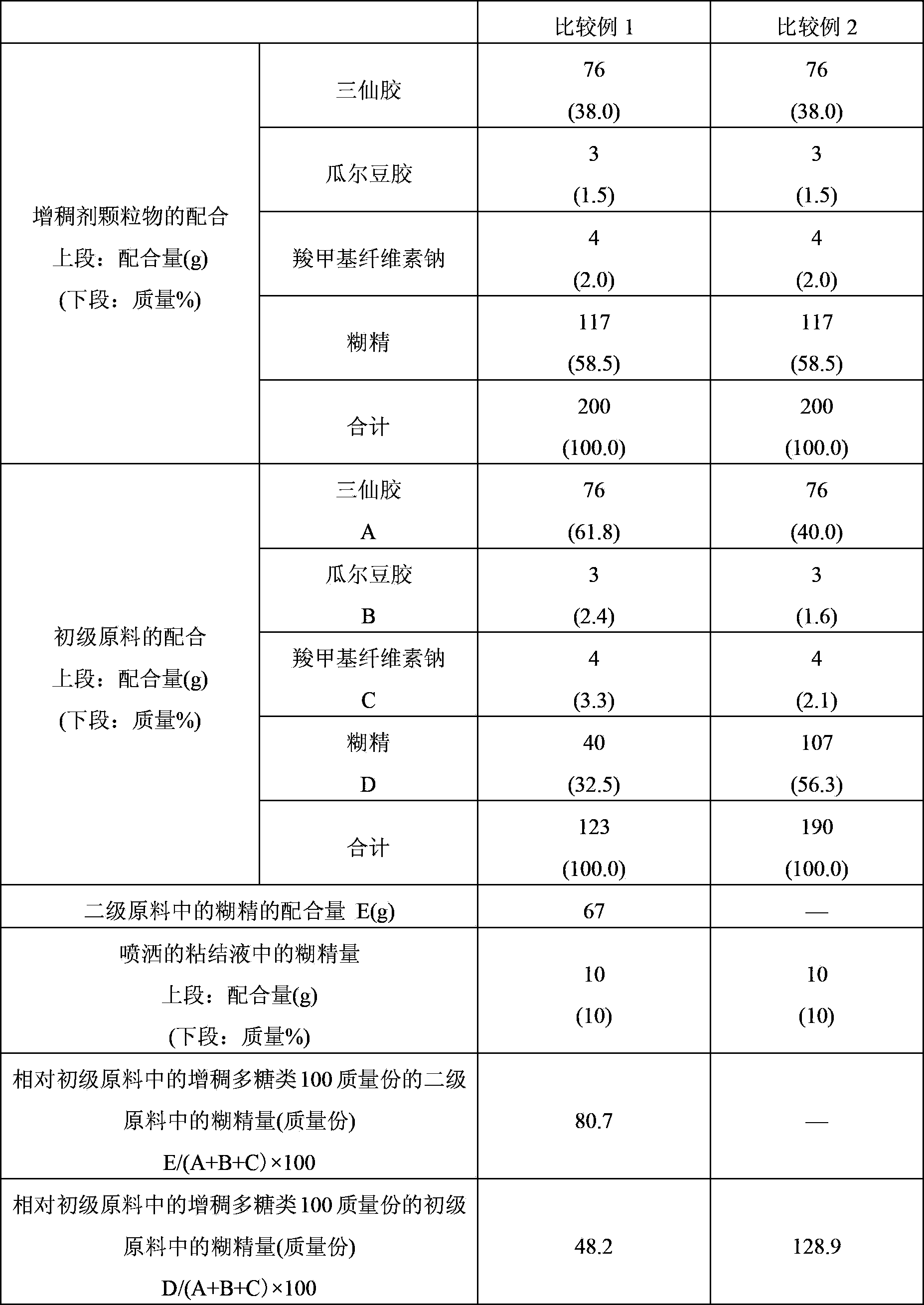

Granular thickening agent and method for producing the same

ActiveCN102883625BWithout spoiling the flavorGood dispersionFood coatingFood preparationParticulatesFlavor

Provided is a granular thickening agent with which dispersibility in water is good, aggregation does not occur, viscosity quickly rises, equilibrium viscosity is high, and the flavor of a food or beverage product is not compromised. Also provided are a method for producing the granular thickening agent, and a food or beverage for persons having difficulty chewing and swallowing that uses the granular thickening agent. The method for producing the granular thickening agent comprises: a step for spraying a binder liquid onto a primary starting material, which contains a thickening polysaccharide, to obtain primary granules; and a step for coating the primary granules with at least 85 parts by mass of dextrin per 100 parts by mass of the thickening polysaccharide.

Owner:THE NISSHIN OILLIO GRP LTD

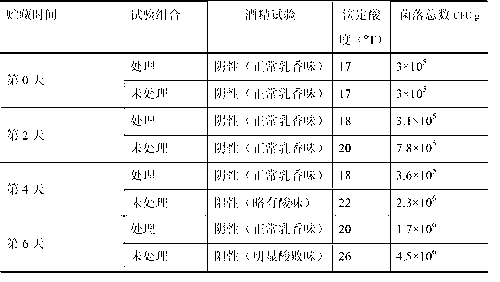

Compound biological preservative of food and preparation method thereof

InactiveCN101589839BAdd flavorFlavor not destroyedClimate change adaptationFood preservationMicroorganism preservationFlavor

The invention provides a compound biological preservative of food and a preparation method thereof, and relates to food preservation by microorganism. The biological preservative consists of nisin, wood vinegar and distilled water; and each 100 mL of the compound biological preservative of the food comprises 350 to 400 mg of the nisin, 15 to 25 mL of the wood vinegar, and the balance of the distilled water. The preparation method for the compound biological preservative comprises the following steps: mixing 350 to 400 mg of the nisin and 15 to 25 mL of the wood vinegar, and fixing the volume of the mixture to 100 mL by using the distilled water. The compound biological preservative of the food and the preparation method thereof comprehensively utilize the advantages and the characteristics of the nisin and the wood vinegar, and the nisin and the wood vinegar are compounded into the compound biological preservative of the food with oxidation resistance; and the compound biological preservative of the food has synergism, broad-spectrum preservation and the oxidation resistance; therefore, the compound biological preservative overcomes the defect that the prior food compound preservative is added with chemical agents and does not meet the requirement of the biological preservative basically, keeps the roast smoking flavor of the wood vinegar, and does not destroy the prior flavorof the food.

Owner:天津康益生物工程有限公司

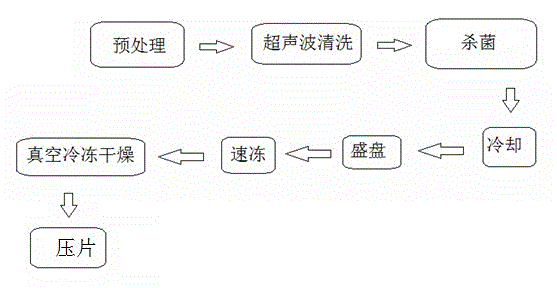

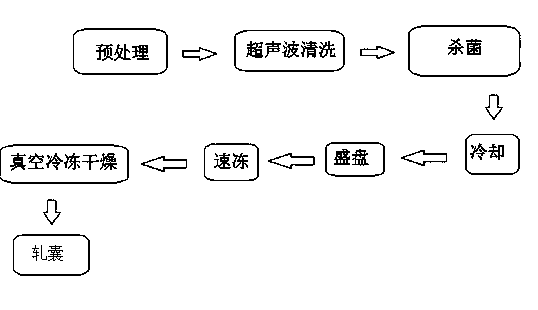

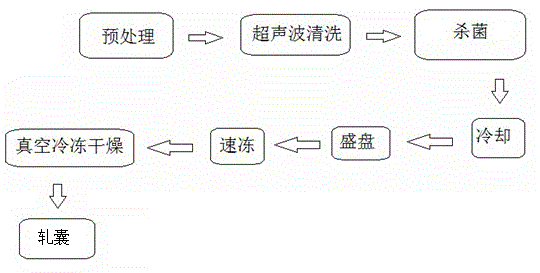

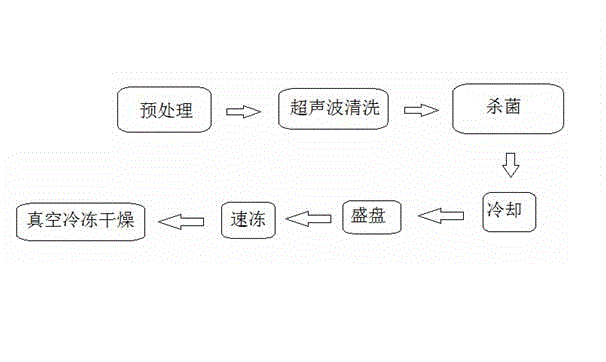

A kind of preparation method of freeze-dried bamboo weevil buccal tablet

InactiveCN104012993BEasy to cleanFull of nutritionFood freezingAnthropod material medical ingredientsBiotechnologyMicroorganism

The invention relates to a preparation method for freeze-dried bamboo weevil buccal tablets. The preparation method is characterized by successively comprising the following steps of preprocessing, ultrasonic washing, sterilizing, cooling, traying, quick-freezing, vacuum freeze-drying and tabletting. Through the preparation method provided by the invention, bamboo weevils can be better washed, and at the same time, the preparation method also has a sterilization function; microorganisms contained on limbs of the bamboo weevils can be killed; under the condition that the special flavor of original products is not destroyed, the fresh degree of the freeze-dried bamboo weevil buccal tablets is increased; the quality guarantee period of products is greatly prolonged; the prepared freeze-dried bamboo weevil buccal tablets are rich in nutrition and high in market values, so that the freeze-dried bamboo weevil buccal tablets are especially suitable for people with rheumatic arthralgia.

Owner:成都英泊科技有限公司

Production process of mushroom concentrated powder

InactiveCN105310063BWithout spoiling the flavorReserve the tasteFood shapingFiltrationCentrifugation

The invention discloses a process for producing concentrated mushroom powder with simple production, high fragrance, purity and fineness, high production efficiency and low cost. Extraction, filtration, centrifugal separation, vibration filtration, dextrin mixing and vacuum low-temperature instantaneous concentration, and then the concentrated liquid is spray-dried, solid-vapor separation, and the separated shiitake mushroom powder is dried and cooled before packaging.

Owner:FUJIAN CHANGLYU FOOD & BEVERAGE CO LTD

Method for processing hand-tearing bamboo shoot

InactiveCN101347214BDoes not destroy nutritionWithout spoiling the flavorFood preparationFlavorReady to eat

The invention relates to a hand-shredded bamboo shoot processing method which belongs to the technical field of fast food processing. The processing method comprises the steps of selecting, cleaning, rejecting, oil frying, oil dropping, soaking in a flavoring liquid, packing, etc. By adopting the characteristics that the processing of dried bamboo shoot is not affected by seasons, and the processed method can meet the ready-to-eat requirement of the modern people in the fast-paced life, the nutrients and the original flavor of the dried bamboo shoot are not damaged, and the dried bamboo shootis added with good flavor and taste, which is convenient for storage. The processing method of the invention solves the problems that processing of the dried bamboo shoot in the prior art is troublesome before eating, and is hard to meet the ready-to-eat requirement of the modern people in the fast-paced life, and the existing method for producing the ready-to-eat dried bamboo shoot damages the nutrients and the original flavor of the dried bamboo shoot.

Owner:郑国海

Fermented mushroom micro powder and preparation technology thereof

InactiveCN108236109AWithout spoiling the flavorReserve the tasteFood thermal treatmentFood ingredientsFlavorFiltration

The invention relates to fermented mushroom micro powder and a preparation technology thereof. Fresh mushroom stems or leftovers are fermented and extracted, mushroom juice is extracted with hot water, extract liquor is subjected to multi-layer filtration by virtue of a primary filter, a fine filtering machine, a centrifugal machine, a duplex filter and a vibrating screen and then enters a concentrating tower, and low temperature vacuum instant concentration is carried out in the concentrating tower, so as to guarantee that flavor of mushroom is not destroyed, and taste of the mushroom juice is reserved to the utmost extent; and sterilizing concentrated liquid, adding dextrin, enabling the concentrated liquid to enter a drying tower and carrying out spray drying. Aroma, purity and finenessof the mushroom powder are relatively high, and active ingredients are preserved completely.

Owner:西峡县锦澎食品有限公司

Preparation method for freeze-dried bamboo weevil health care products

InactiveCN104012965AExtended shelf lifeHigh market valueFood shapingFood ingredient functionsBiotechnologyFreeze-drying

The present invention relates to a preparation method for freeze-dried bamboo weevil health care products, the preparation method is characterized in comprising the following steps in sequence: pretreating, ultrasonic cleaning, sterilizing, cooling, dishing up, quick freezing, vacuum freeze-drying and rolling capsule. The present invention can freshen the freeze-dried bamboo weevil without destroying the flavor of the original products, and greatly prolongs the shelf life of the freeze-dried bamboo weevil health care products. The produced freeze-dried bamboo weevil capsules containing spiral algae are rich in nutrients, has high market value and are especially suitable for people suffering from rheumatic arthralgia syndrome.

Owner:成都英泊科技有限公司

A method and system for preserving raw milk using nitrogen gas

ActiveCN103988901BDo not destroy ingredientsWithout spoiling the flavorMilk preservationNitrogenOxygen

The invention relates to a method for feeding raw milk with nitrogen to preserve raw milk. The specific steps are as follows: using air to prepare nitrogen and purifying the prepared nitrogen for pretreatment; centrifuging raw milk for milk cleaning and pre-pasteurization; using nitrogen to discharge Nitrogen gas is injected into raw milk while oxygen dissolved in raw milk is removed to obtain nitrogen-filled milk. The method for preserving raw milk of the present invention uses nitrogen, which accounts for 78% of the volume of the air, exists in the air in the form of simple substances, is inexhaustible, is a colorless, non-toxic, and tasteless inert gas, and has It is very safe and can be well mixed with raw milk. It can also flexibly adjust the input amount according to different processed products. The method is simple, easy to operate, saves storage and processing costs, and improves the production efficiency of enterprises; In addition, the present invention has low requirements on equipment and is suitable for the promotion of large-scale production in enterprises.

Owner:天津海河乳品有限公司

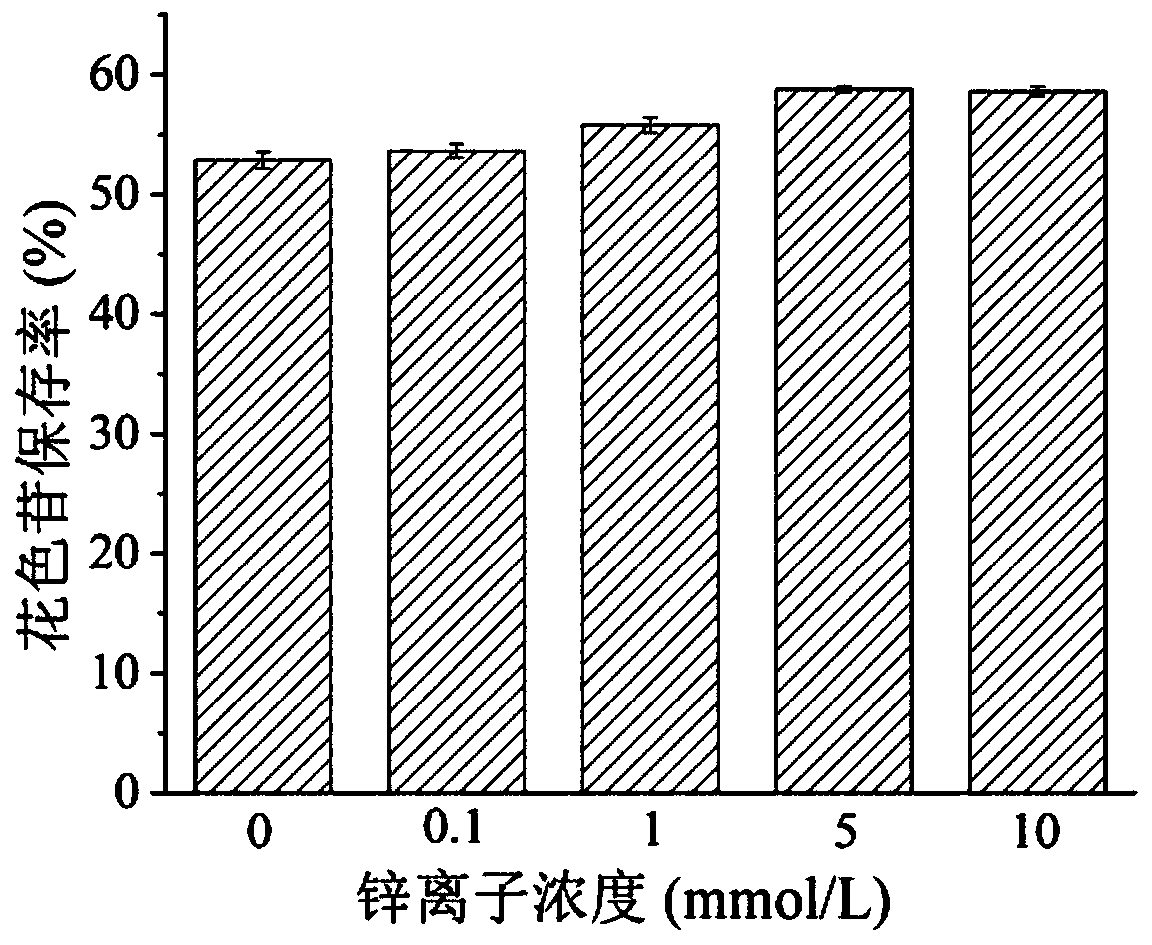

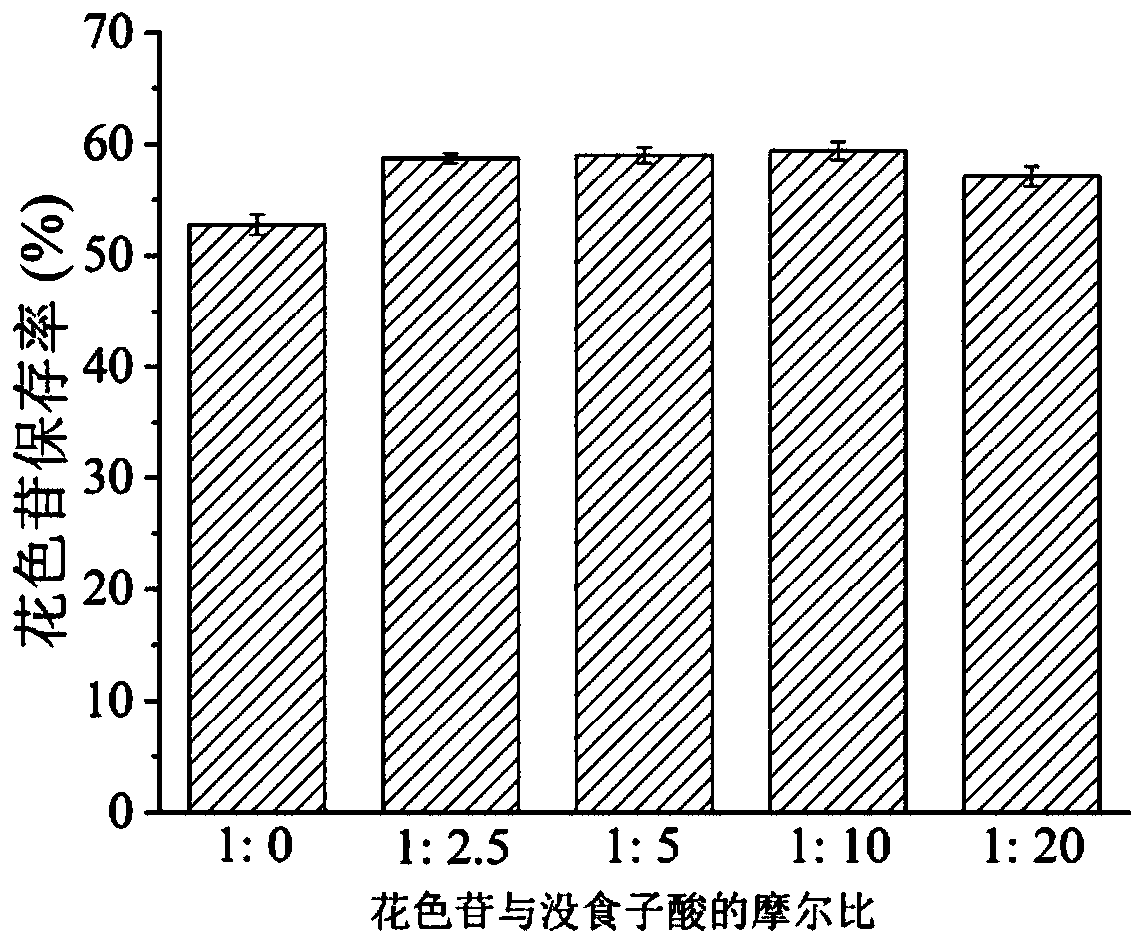

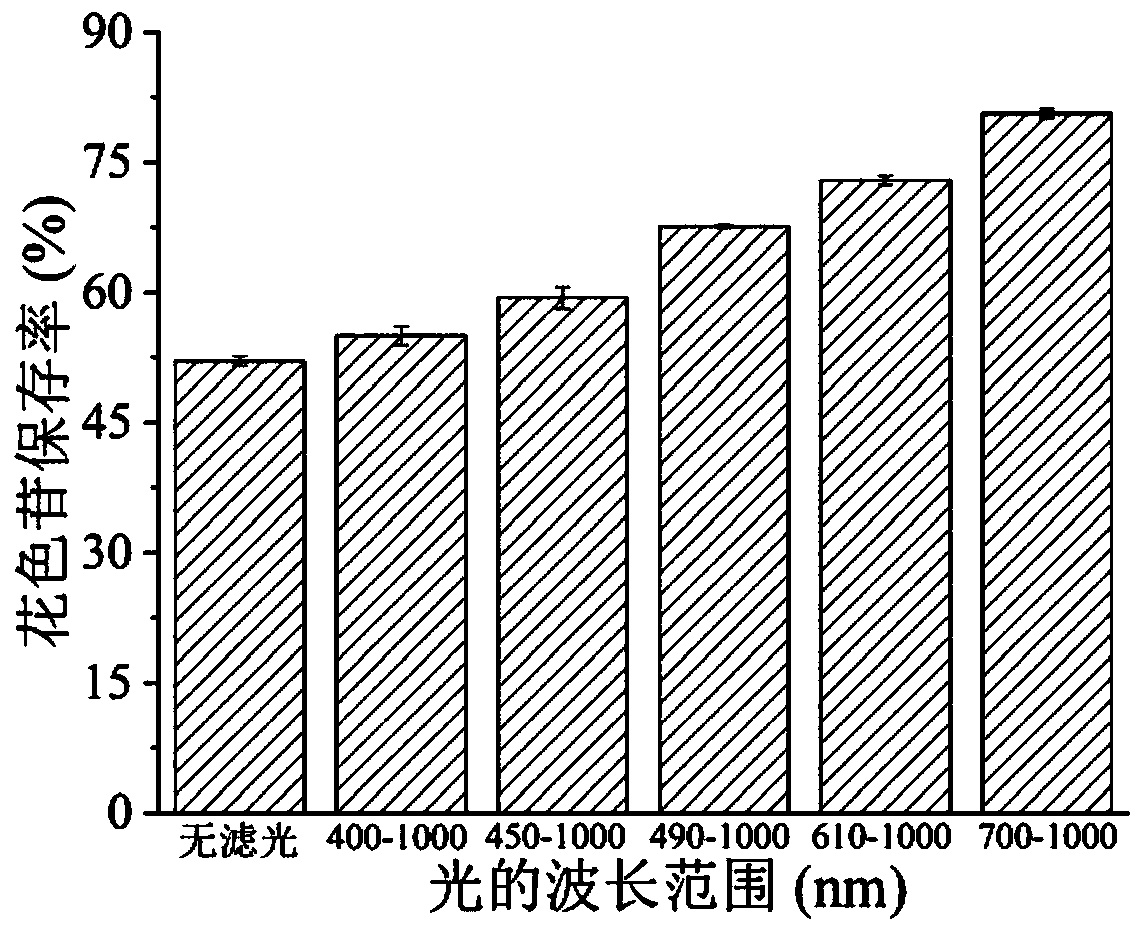

Color protection method of anthocyanin-rich purple rice wine

ActiveCN110747096AImproved color stabilityImprove stabilityAlcoholic beverage preparationBiotechnologySulfate zinc

The invention discloses a color protection method of anthocyanin-rich purple rice wine. The color protection method of the anthocyanin-rich purple rice wine includes the following steps that zinc sulfate is added into fermented purple rice wine, then accessory pigment gallic acid is added into the purple rice wine, a translucent packaging material controlling the wavelength range of incident lightis used for light-resistant packaging treatment, and finally, the purple rice wine is deoxidized. According to the color protection method, photodamage effect to the purple rice wine is reduced, theoxygen content in a system is decreased, the accessory pigment small molecule zinc sulfate and the gallic acid are added to improve the stability of anthocyanins in purple rice, and meanwhile the advantages of maintaining the perspectivity of the packaging material and not destroying the original flavor are achieved; and the obtained retention rate of the anthocyanins in the purple rice reaches 74.75-91.12%, the color protection method is safe, easy to operate, wide in raw material source and low in cost, and has good application prospects in the anthocyanin-rich purple rice wine.

Owner:SOUTH CHINA AGRI UNIV +1

Preparation method for freeze-dried bamboo weevil health care products

InactiveCN104012965BExtended shelf lifeHigh market valueFood shapingFood ingredient functionsBiotechnologyFreeze-drying

The present invention relates to a preparation method for freeze-dried bamboo weevil health care products, the preparation method is characterized in comprising the following steps in sequence: pretreating, ultrasonic cleaning, sterilizing, cooling, dishing up, quick freezing, vacuum freeze-drying and rolling capsule. The present invention can freshen the freeze-dried bamboo weevil without destroying the flavor of the original products, and greatly prolongs the shelf life of the freeze-dried bamboo weevil health care products. The produced freeze-dried bamboo weevil capsules containing spiral algae are rich in nutrients, has high market value and are especially suitable for people suffering from rheumatic arthralgia syndrome.

Owner:成都英泊科技有限公司

Preparation method of freeze-dried bamboo weevils

InactiveCN104012994BEasy to cleanFit for consumptionAnthropod material medical ingredientsFood ingredient functionsMicroorganismFreeze-drying

A preparation method of freeze-dried bamboo weevils is characterized by comprising the following steps in sequence: pre-treatment, ultrasonic cleaning, sterilizing, cooling, laying of the bamboo weevils on disks, quick freezing, and vacuum freeze-drying. The bamboo weevils are washed clean, and microorganisms on the limbs of the bamboo weevils can be killed through the sterilizing process. In the premise of not destroying the original product flavor, the freshness of the freeze-dried bamboo weevils is enhanced; the shelf life of the products is greatly prolonged; and the prepared freeze-dried bamboo weevils can be well restored, so that the freeze-dried bamboo weevils are especially suitable for patients suffering from wind-damp arthralgia syndromes.

Owner:成都英泊科技有限公司

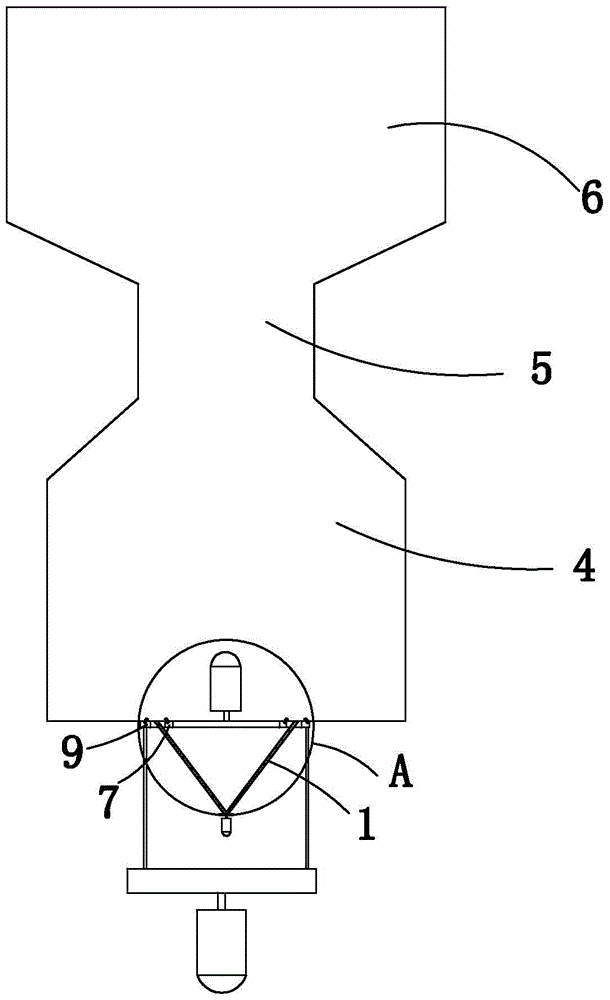

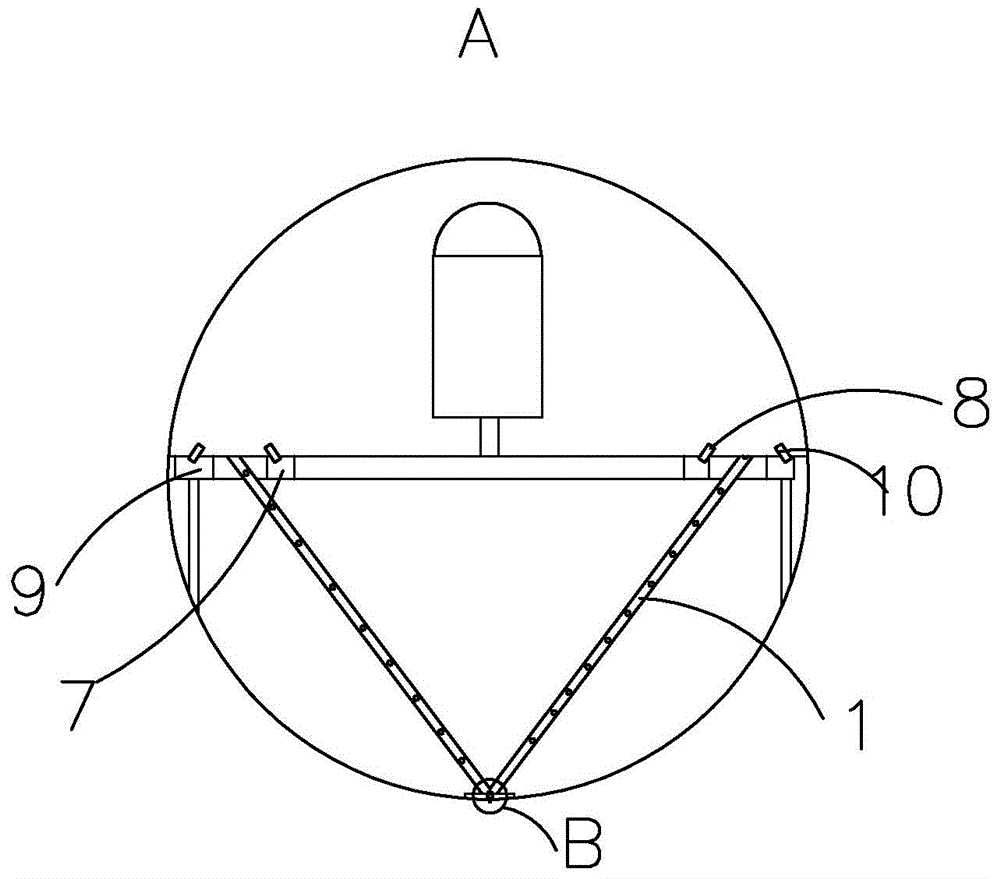

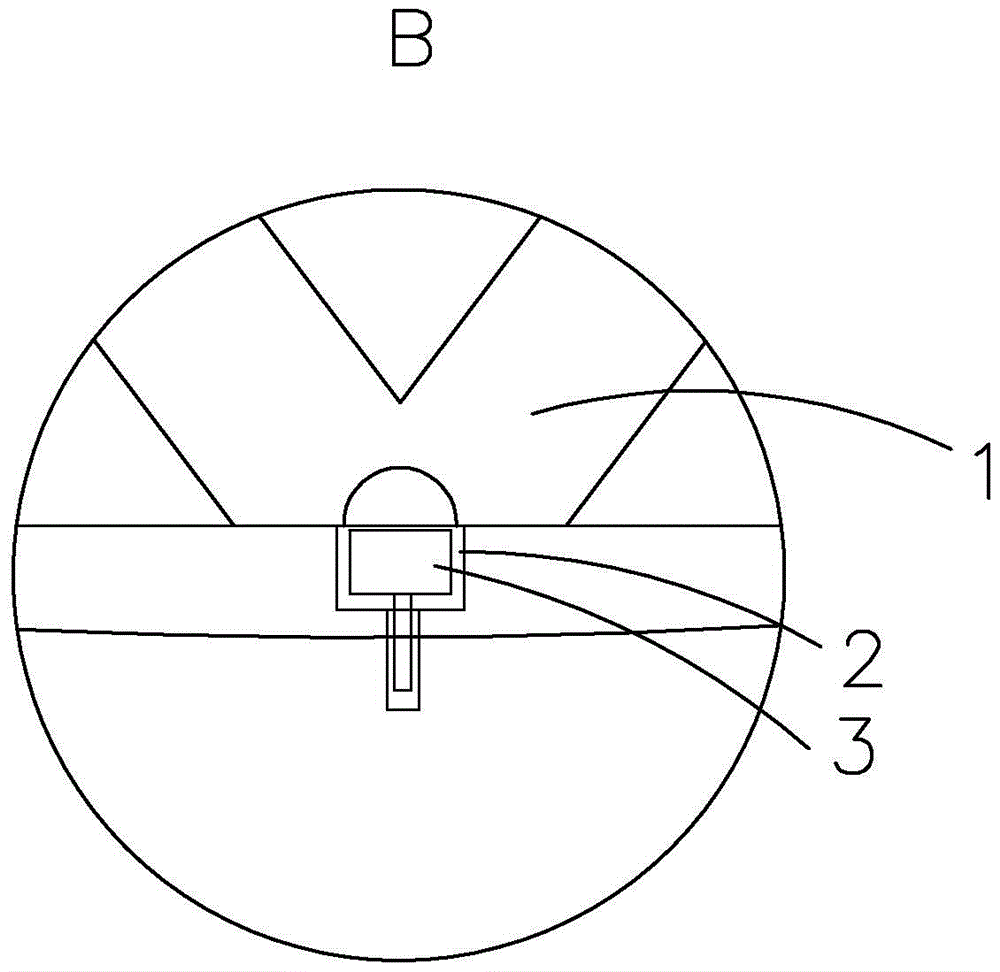

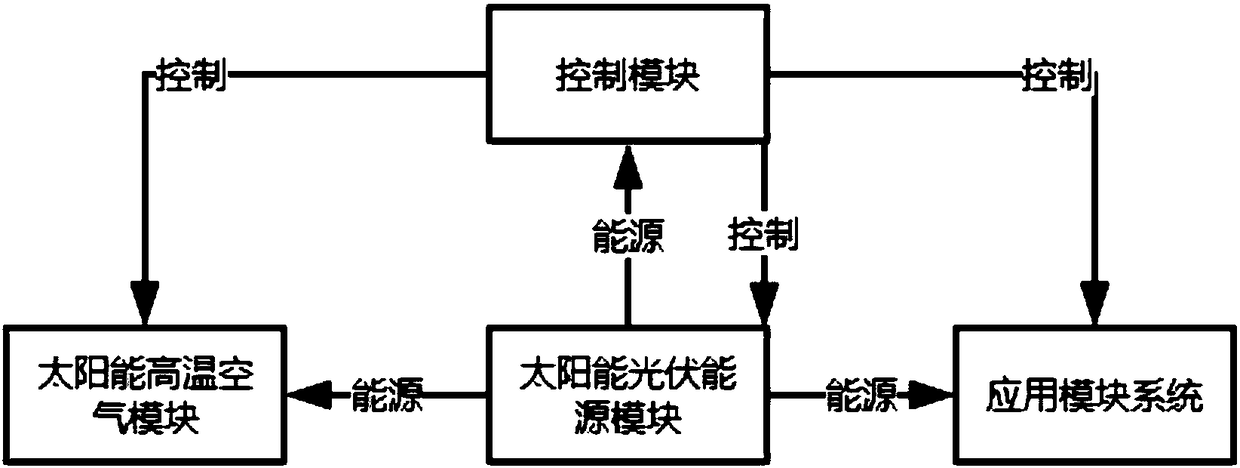

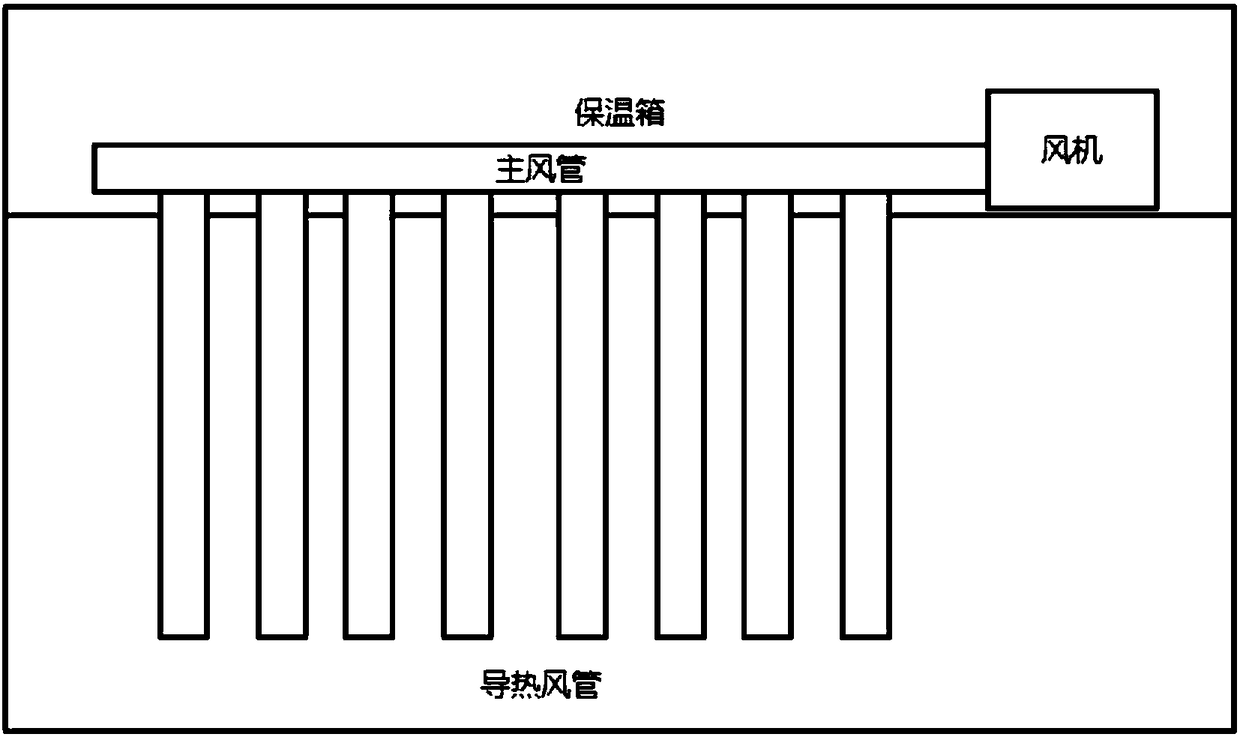

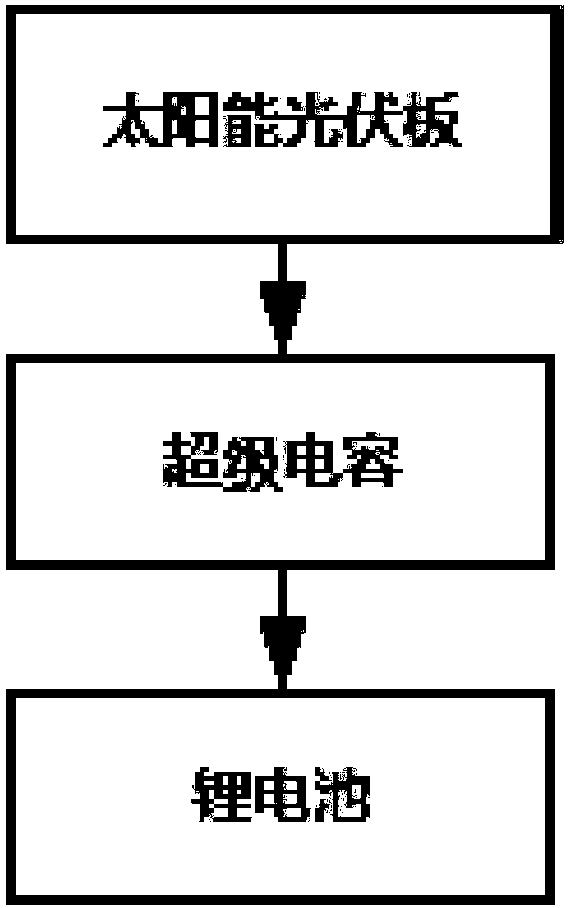

Solar-based multifunctional food cooking system

InactiveCN108552938AReduce the risk of fireCooked to achieveSolar heating energyBatteries circuit arrangementsThermal energyFood material

The invention discloses a solar-based multifunctional food cooking system, comprising: a solar high-temperature air module, a solar photovoltaic energy module, application modules and a control module. The solar high-temperature air module is used for converting solar energy into heat energy to cook food materials; the solar photovoltaic energy module is used for converting solar energy into electric energy that is stored to power the other modules; the application modules include various domestic appliances; the control module is used for controlling operation of the solar high-temperature air module, the solar photovoltaic energy module, and the application modules. The solar-based multifunctional food cooking system is suitable for cooking food in plateau regions, providing heat and electricity on plateau, and is energy efficient and environmentally friendly.

Owner:XICHANG COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com