Granular thickening agent and method for producing the same

A manufacturing method and particle technology, which is applied in the field of thickener particles and its manufacture, can solve the problems of easy caking, poor dispersibility, and effort, and achieve the effect of no agglomeration, rapid viscosity, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] [Manufacture of thickener granules]

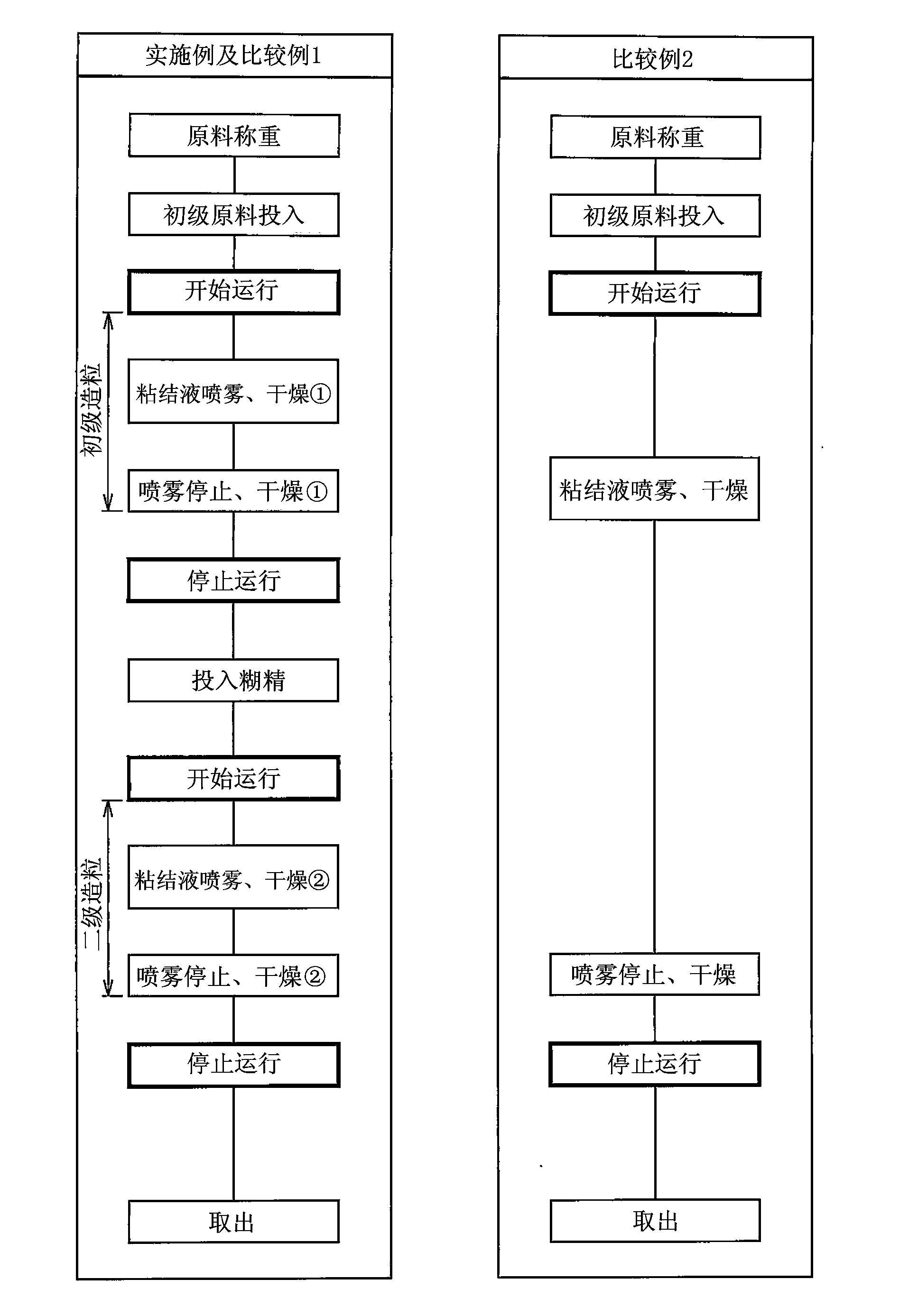

[0065] figure 1 It is a flow chart showing the outline of the production process of thickener granules in Examples and Comparative Examples.

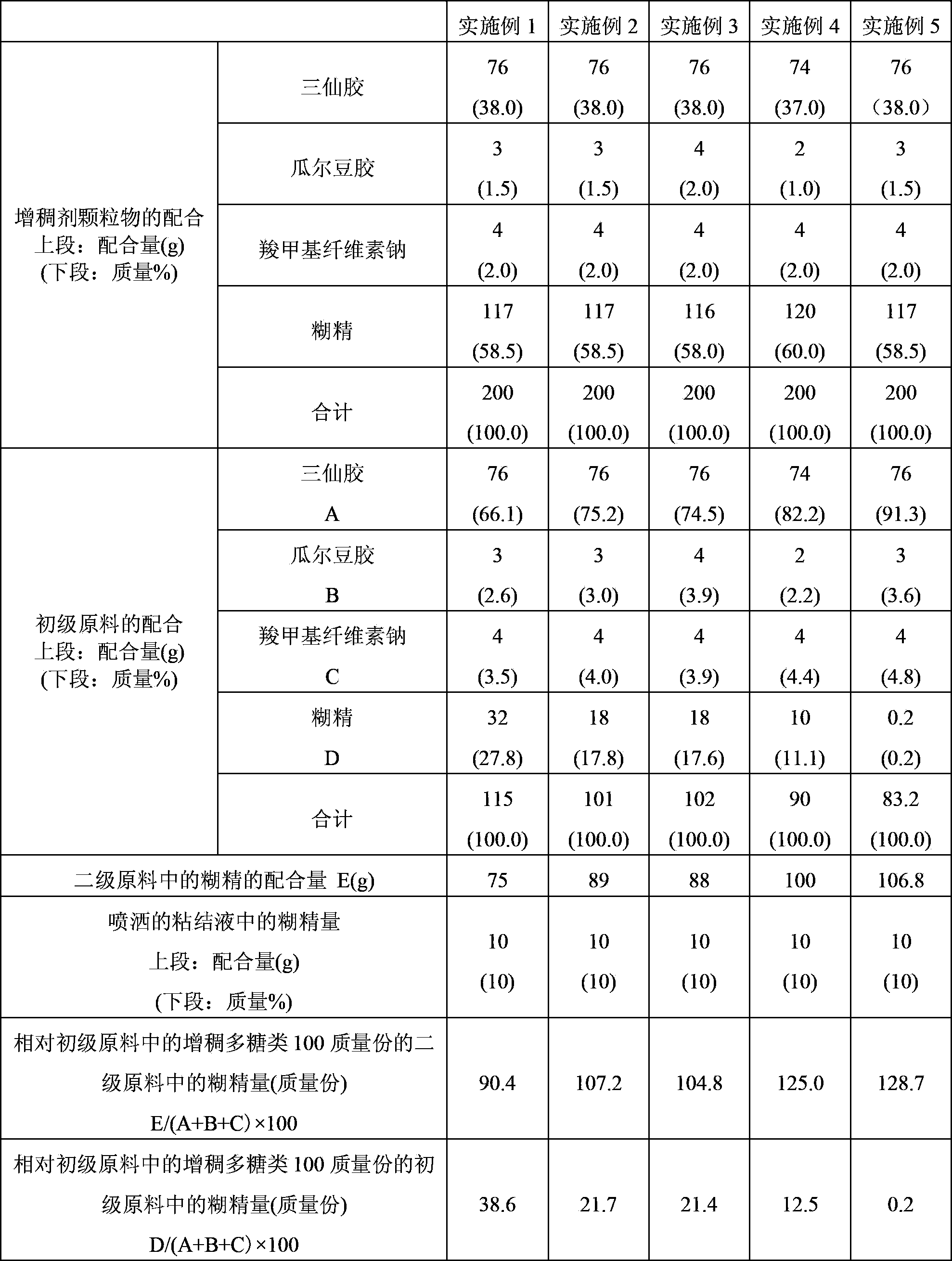

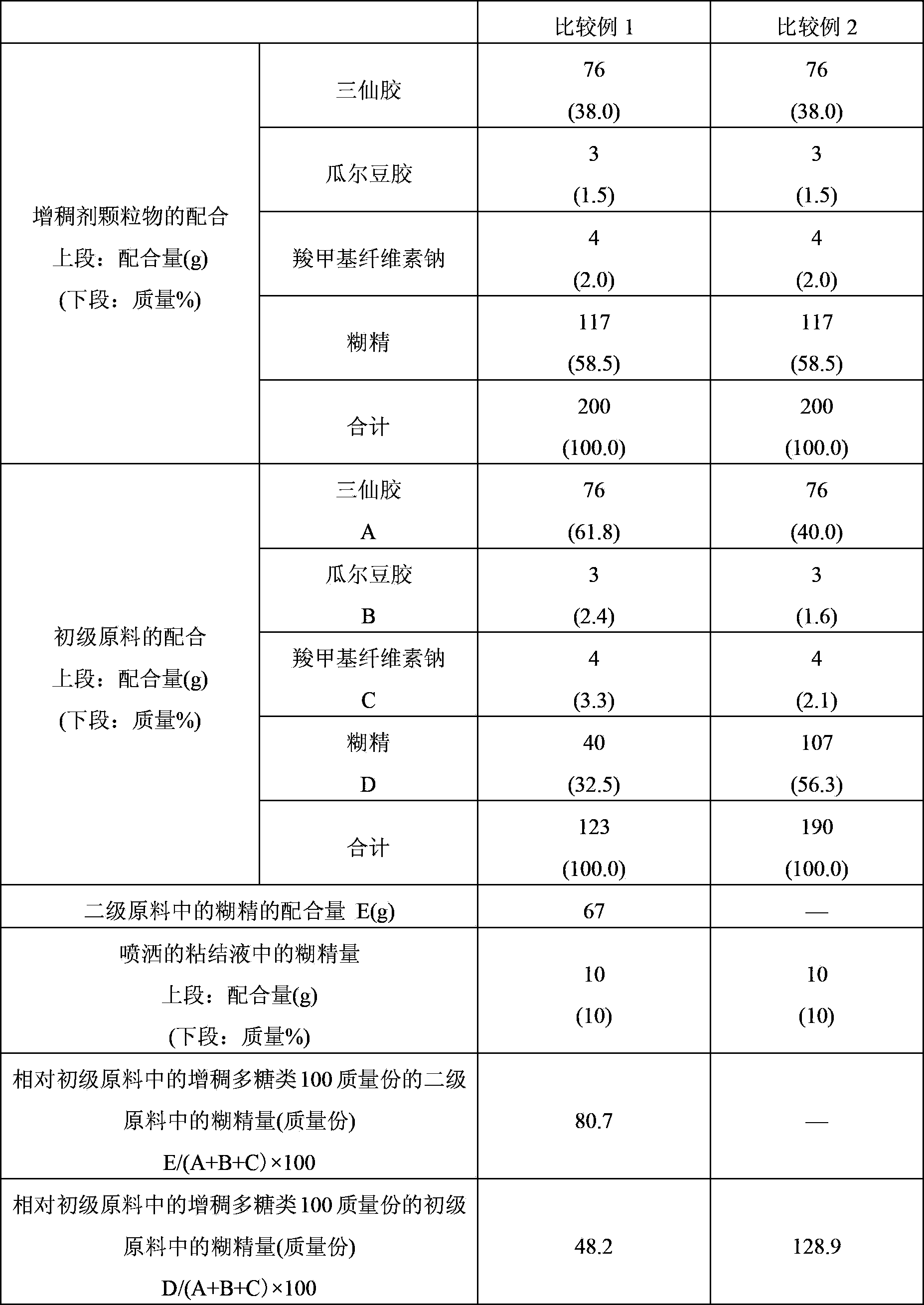

[0066] The thickener granules of Examples 1 to 5 and Comparative Example 1 were produced by the fluidized bed granulation method according to the compounding described in Tables 1 to 2 in the following procedure.

[0067] After each raw material is weighed at first, prepare primary raw material and bonding liquid (100g of 10 mass % dextrin aqueous solution) respectively, put primary raw material into fluidized bed granulation method coating device (trade name: SFC-LABO, フロイント Industrial Co., Ltd. Co., Ltd.), and hot air heated to 75° C. was blown from the bottom of the device to flow and mix the powder. Next, from the spray nozzle on the upper part of the device, the binding liquid was sprayed to the primary raw material at 5 mL / min and the air pressure was 0.8 MPa to form granules, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com