Production process of mushroom concentrated powder

A production process and technology of concentrated powder, which is applied in the field of production process of mushroom concentrated powder, can solve the problems of low brix liquid unfavorable storage, flavor damage of mushrooms, long production cycle, etc., to shorten drying time, save heat energy, and prevent wall sticking and the effect of burnt powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: This embodiment discloses a production process of mushroom concentrated powder, and its production steps are as follows:

[0024] (1) Put the shiitake mushroom feet and water with a weight ratio of 1:13 into the extraction tank, continue to stir and heat the mixture (the solution of shiitake mushroom feet and water) to 90°C, stir at constant temperature for 1.5 hours, and then mix the mixture Heating to 95°C, the mixed liquid passes through the 60-mesh filter at the bottom of the extraction tank for initial filtration. At this time, because there are too many impurities on the 60-mesh filter, the filtration speed is slow, and the air is pressurized into the extraction tank to improve the filtration. Speed, the filtered liquid enters the fine filter; after the filtration is completed, the extraction tank is opened to remove the residue in the extraction tank for the next process production.

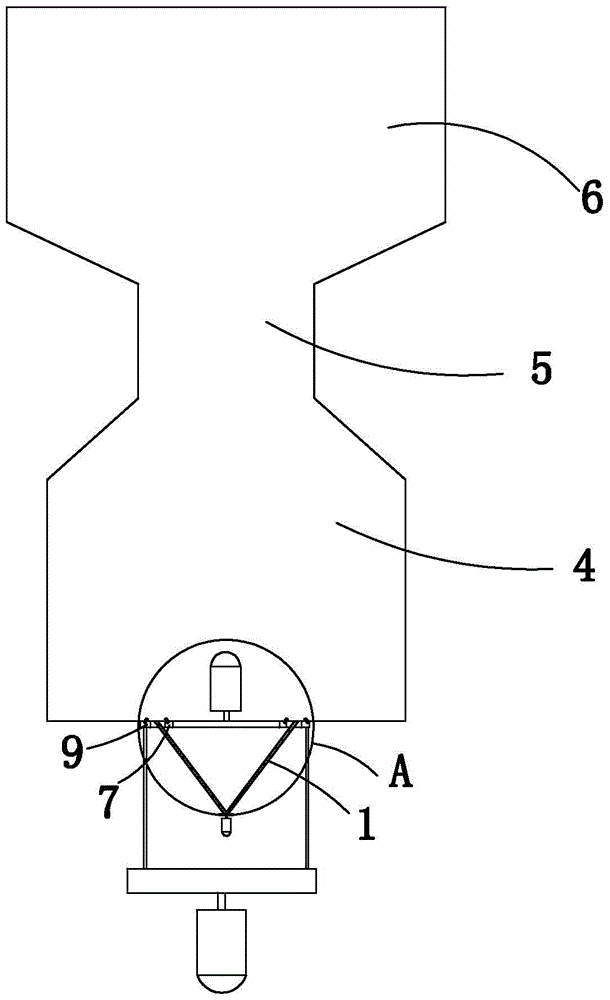

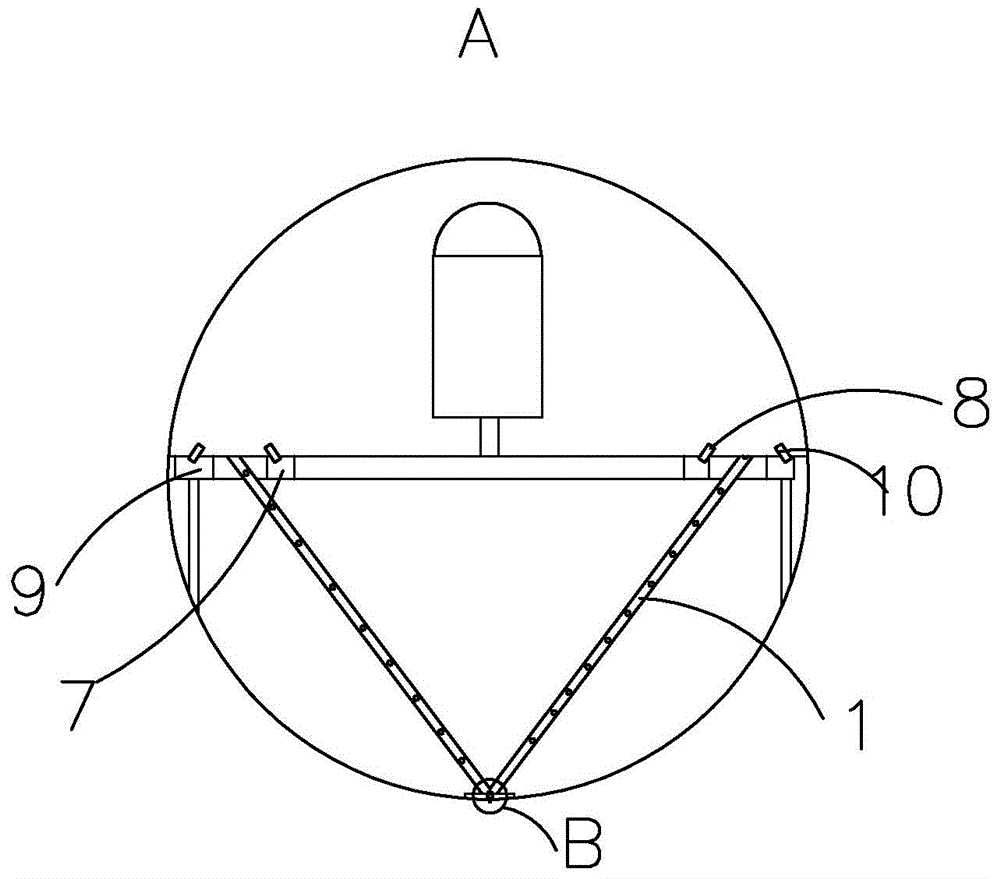

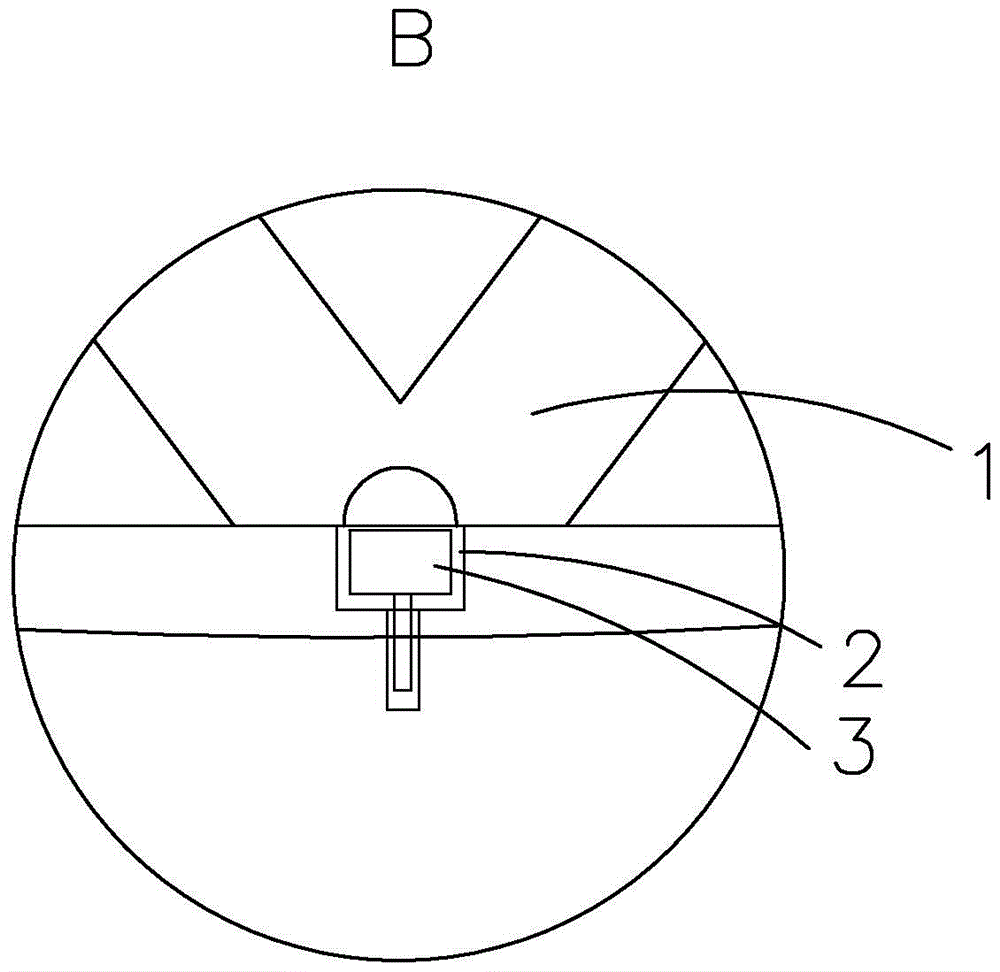

[0025] The structure of the extraction tank is a hollow structure...

Embodiment 2

[0041] Put the shiitake mushroom feet and water with a weight ratio of 1:20 into the extraction tank, continue to stir and heat the mixture to 90°C, and stir at a constant temperature for 3 hours, and the rest of the steps are the same as in Example 1.

[0042] In each of the above-mentioned production process steps, the weight ratio of the shiitake mushrooms to water is feasible in the ratio range of 1:10 to 1:20, and different ratios have the same effect on the invention; the heating temperature range in each process step , the number of meshes of the filter screen, and the sterilization time are all feasible within the scope limited by the corresponding steps, which can also achieve the purpose of the present invention, and will not cause obvious or obvious differences in the prepared concentrated solution due to different values. fundamental difference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com