Non - high temperature method for sterilizing and preserving cooked product, and equipment

A high-temperature sterilization and preservation method technology, which is applied in food preservation, food science, application, etc., can solve the problems of destroying product flavor and nutritional content, difficult to control the uniformity of sterilization, and unstable product quality. The effect of high sterilization efficiency and convenient use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method of the present invention refers to a non-high-temperature sterilization and fresh-keeping method for packaged products such as cooked meat, poultry, eggs, beans, and fish: first vacuum-pack the food, sterilize it through microwaves, and then sterilize it in a water bath. 100°C, then cooled. The holding time is 1-40 minutes, especially 3-35 minutes, and then it can be cooled.

[0017] Through the above, the method of the present invention can prolong the fresh-keeping time of food, reaching six months or longer at normal temperature.

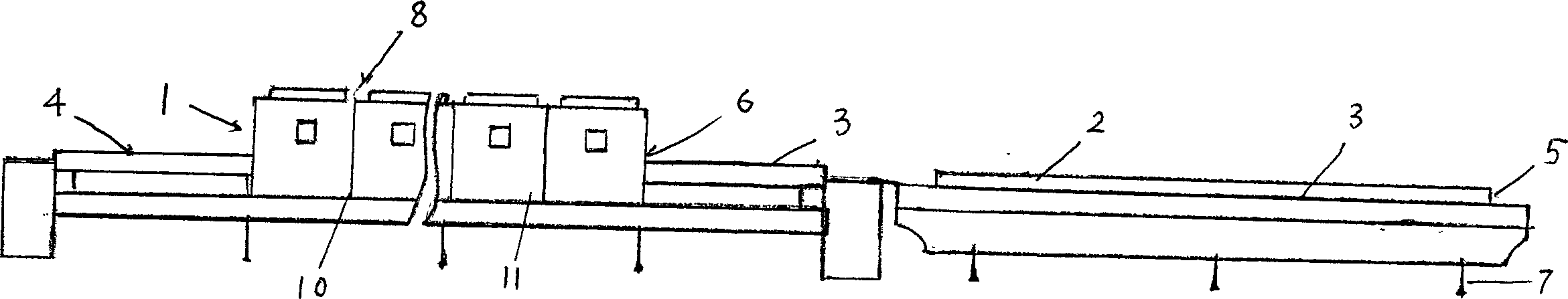

[0018] Equipment covered by non-high-temperature sterilization methods for cooked meat, poultry, eggs, beans, fish and other products:

[0019] 1. The whole machine of non-high temperature food joint sterilization equipment: the front section is the microwave sterilization part, and the rear section is the water bath sterilization part. Enter from the entrance and exit from the exit to complete the entire sterilization process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com