Method for preserving raw milk by using nitrogen, and system thereof

A nitrogen and raw milk technology, applied in the field of food science, can solve the problems of prolonging the sterilization time, increasing the sterilization temperature, destroying nutrition, etc., and achieving the effect of prolonging the storage time, improving the production efficiency and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

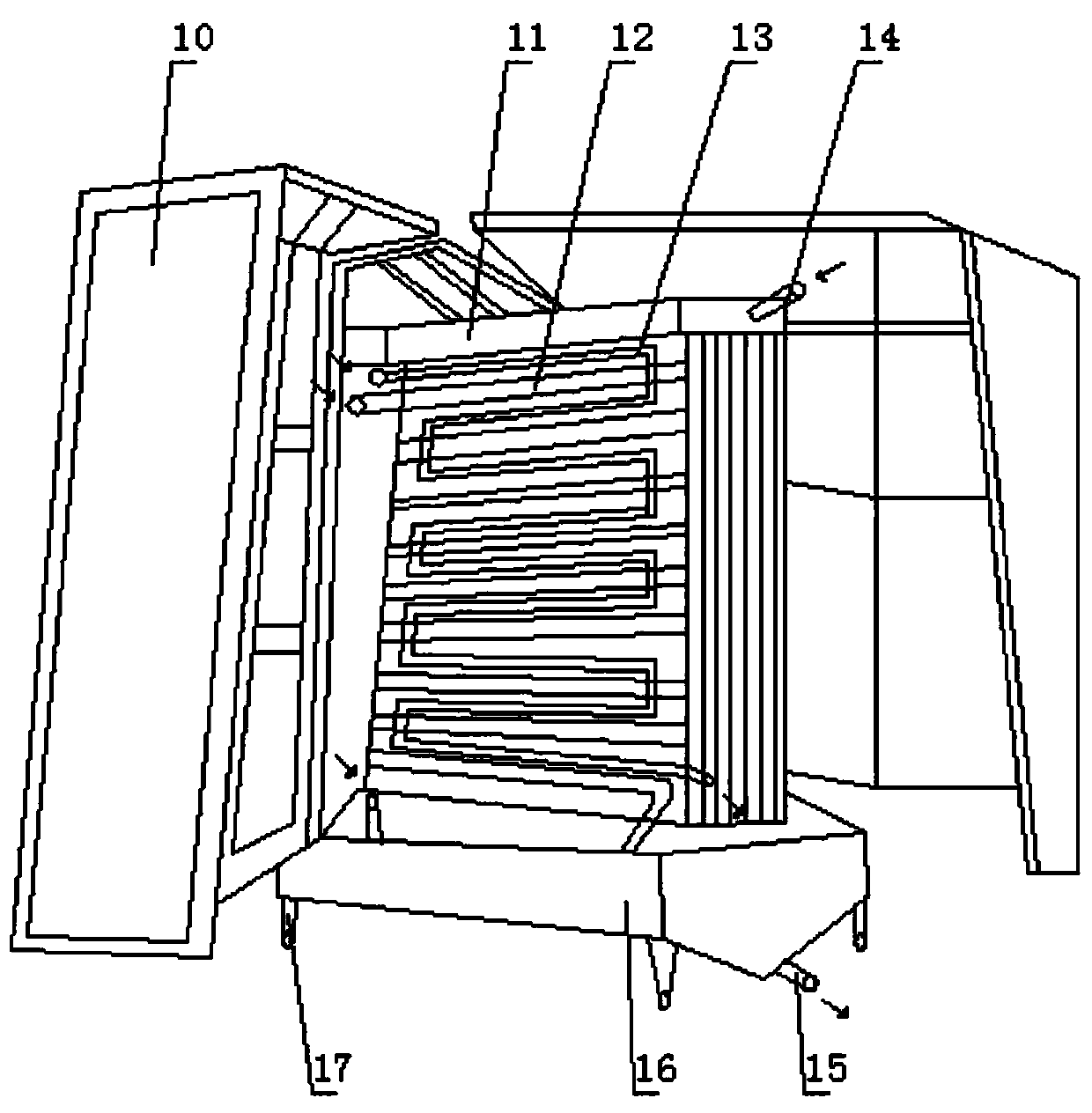

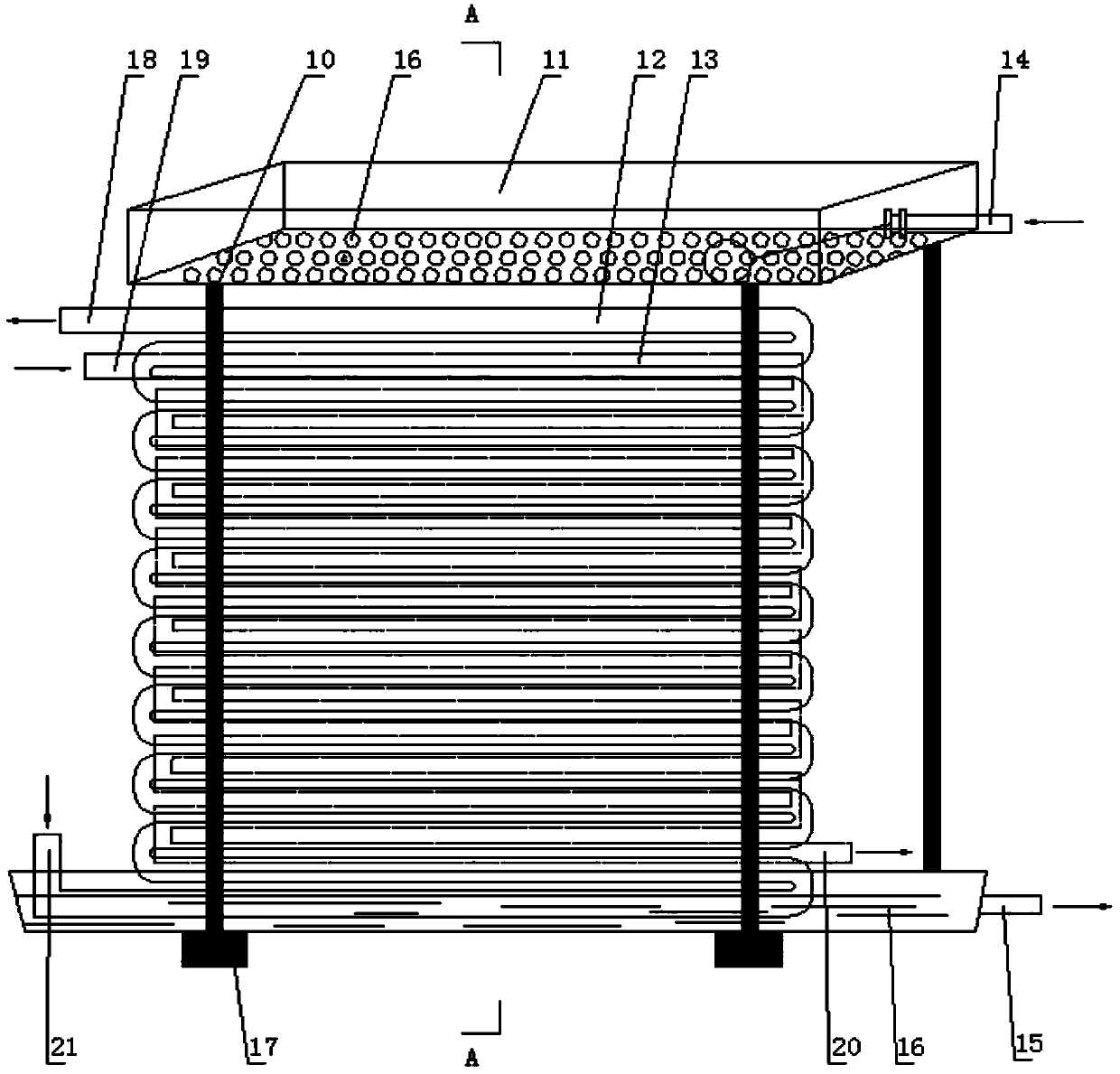

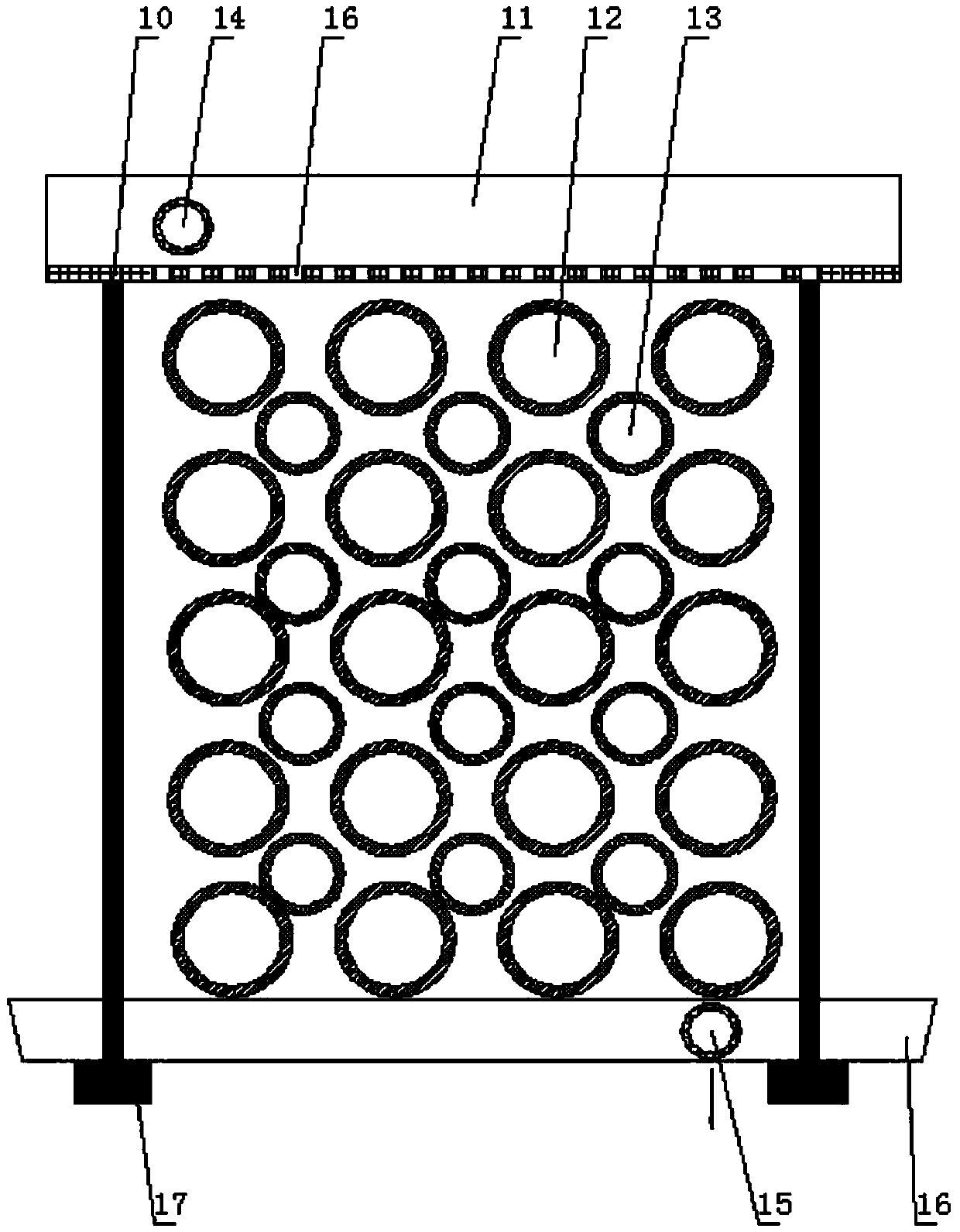

Method used

Image

Examples

Embodiment 1

[0033] A method for preserving raw milk by using nitrogen gas, the specific steps are as follows:

[0034] (1) Pre-treatment: Nitrogen production by pressure swing adsorption (PSA) is passed into JHa nitrogen purification equipment to complete the purification of nitrogen;

[0035] (2) Raw milk pretreatment: After collecting fresh raw milk, use a closed centrifugal milk cleaner to separate and purify the milk. The purification volume is 1000-3000L / hour, the rotation speed of the separation bowl is 6000 rpm, and pre-pasteurization (pasteurization) 63 ℃, 15 seconds processing;

[0036] ⑶Preparation of nitrogen-filled raw milk: Use the nitrogen in step ⑴ to remove the dissolved oxygen in the raw milk in step ⑵ and fill it with nitrogen to obtain nitrogen-filled milk with a longer shelf life. The nitrogen flow rate is about 10mL / 100mL of milk, and the nitrogen gas is kept during mixing The pressure is 0.03-0.06MPa, the temperature is 6-8°C, and the nitrogen-filled milk prepared b...

Embodiment 2

[0039] A method for preserving raw milk by using nitrogen gas, the specific steps are as follows:

[0040] (1) Pre-treatment: Nitrogen production by pressure swing adsorption (PSA) is passed into JHa nitrogen purification equipment to complete the purification of nitrogen;

[0041] (2) Raw milk pretreatment: After collecting fresh raw milk, use a closed centrifugal milk cleaner to separate and purify the milk. The purification volume is 1000-3000L / hour, the rotation speed of the separation bowl is 6000 rpm, and pre-pasteurization (pasteurization) 63 ℃, 15 seconds processing;

[0042] ⑶Preparation of nitrogen-filled raw milk: Use the nitrogen in step ⑴ to remove the dissolved oxygen in the raw milk in step ⑵ and fill it with nitrogen to obtain nitrogen-filled milk with a longer shelf life. The nitrogen flow rate is about 10mL / 100mL of milk, and the nitrogen gas is kept during mixing The pressure is 0.03-0.06MPa, the temperature is 6-8°C, and the nitrogen-filled milk prepared b...

Embodiment 3

[0045] A method for preserving raw milk by using nitrogen gas, the specific steps are as follows:

[0046] (1) Pre-treatment: Nitrogen production by pressure swing adsorption (PSA) is passed into JHa nitrogen purification equipment to complete the purification of nitrogen;

[0047] (2) Raw milk pretreatment: After collecting fresh raw milk, use a closed centrifugal milk cleaner to separate and purify the milk. The purification volume is 1000-3000L / hour, the rotation speed of the separation bowl is 6000 rpm, and pre-pasteurization (pasteurization) 63 ℃, 15 seconds processing;

[0048] ⑶Preparation of nitrogen-filled raw milk: Use the nitrogen in step ⑴ to remove the dissolved oxygen in the raw milk in step ⑵ and fill it with nitrogen to obtain nitrogen-filled milk with a longer shelf life. The nitrogen flow rate is about 10mL / 100mL of milk, and the nitrogen gas is kept during mixing The pressure is 0.03-0.06MPa, the temperature is 6-8°C, and the nitrogen-filled raw milk prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com