Ultrasonic atomization concentration device

A technology of concentration device and ultrasonic wave, which is applied in the direction of combination device, spray evaporation, chemical instrument and method, etc., can solve the problems of poor reverse osmosis concentration processing effect, low penetration efficiency, time-consuming and labor-intensive, etc., and achieves ingenious design and high concentration efficiency. , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

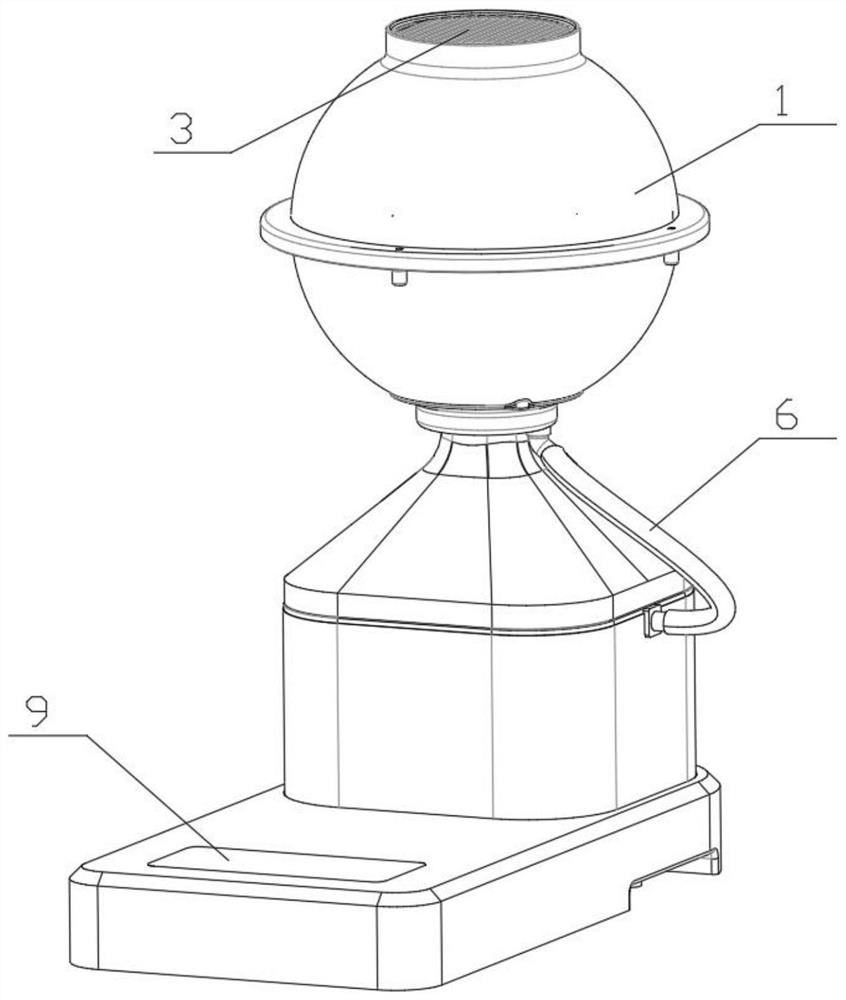

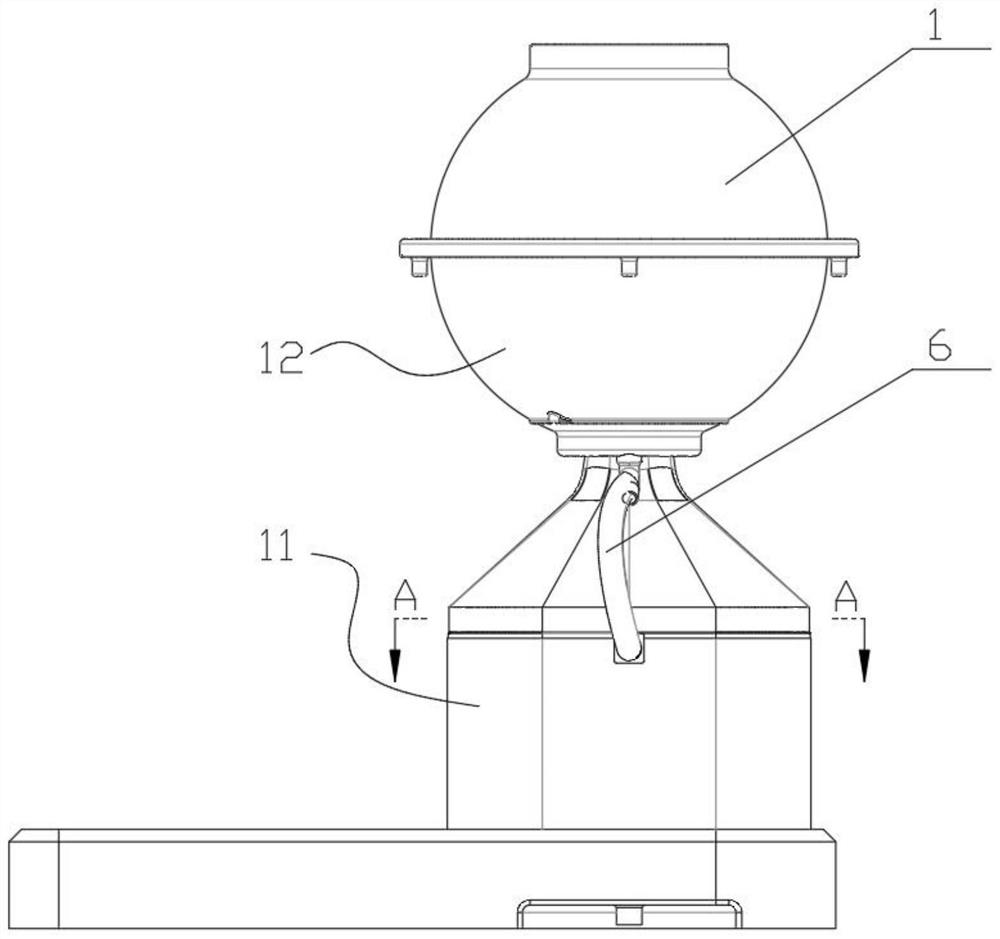

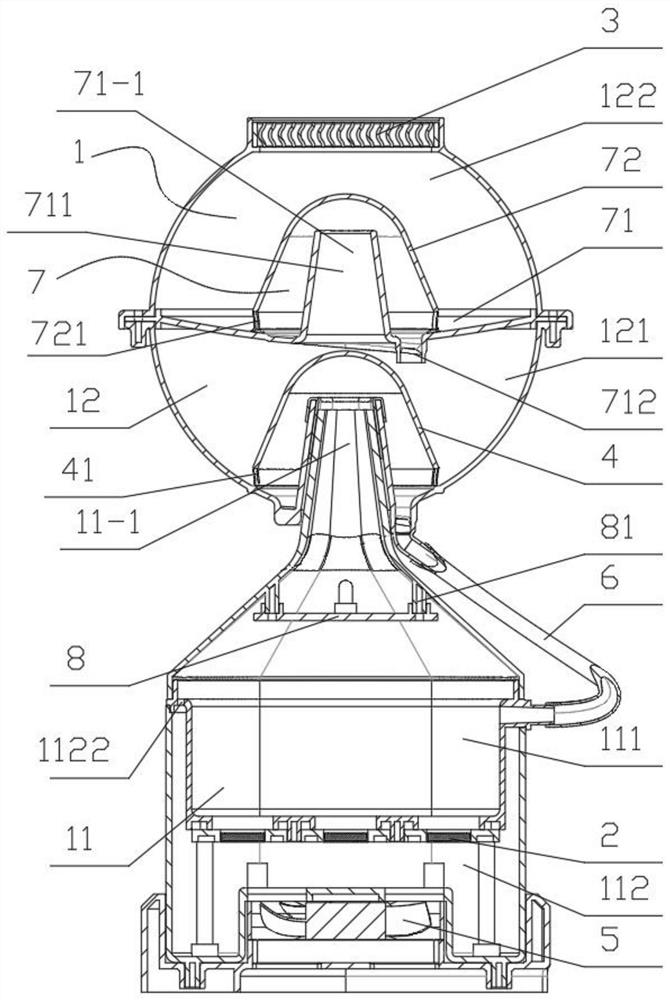

[0043] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, a kind of ultrasonic atomization concentrating device of this embodiment, comprise outer casing 1, ultrasonic atomization piece 2, defogger 3 and primary separation cover 4, inside outer casing 1 are separation cavity 12 and upper and lower respectively. The atomization chamber 11, the atomization chamber 11 and the separation chamber 12 are connected through the primary separation cover 4, the bottom of the separation chamber 12 is connected with the atomization chamber 11, the atomization chamber 11 is provided with an ultrasonic atomizing sheet 2, and the top of the separation chamber 12 is provided with There is a demister 3, and the liquid to be concentrated is placed in the atomization chamber 11.

[0044] The liquid to be concentrated is atomized into water mist by the ultrasonic atomizing sheet 2 and enters the separation chamber 12, wherein the small molecule water mist in th...

specific Embodiment approach 2

[0055] Specific implementation mode two: combination figure 1 , 2 , 5, 6, and 7 illustrate this embodiment, an ultrasonic atomization concentration device of this embodiment, including an outer casing 1, an ultrasonic atomization sheet 2, a demister 3 and a primary separation cover 4, and the upper and lower sides of the outer casing 1 They are the separation chamber 12 and the atomization chamber 11 respectively. The atomization chamber 11 and the separation chamber 12 are connected through the primary separation cover 4, the bottom of the separation chamber 12 is connected with the atomization chamber 11, and the atomization chamber 11 is provided with an ultrasonic atomizing sheet 2 , The top of the separation chamber 12 is provided with a demister 3, the liquid to be concentrated is placed in the atomization chamber 11, the outer shell 1 is made of corrosion-resistant smooth surface materials such as stainless steel, plastic, acrylic, etc., the condensed water has low adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com